Machine tool device

A machine tool and machine tool control technology, applied in the field of CNC machine tools, can solve the problems of long training cycle, high cost, lack of CNC programming system and high-skilled personnel training of fault diagnosis and maintenance experimental devices, etc., and achieve network transmission and monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

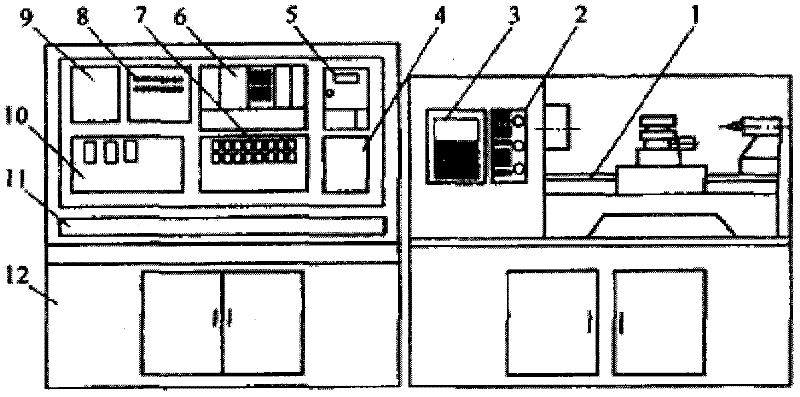

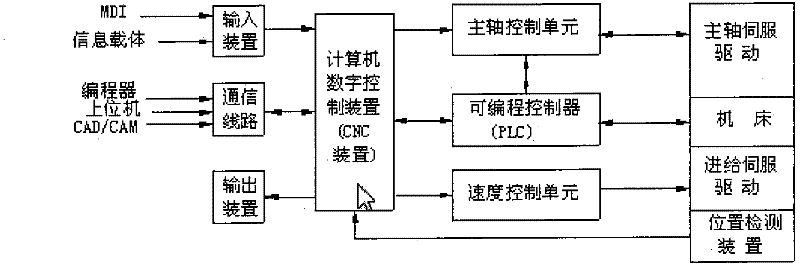

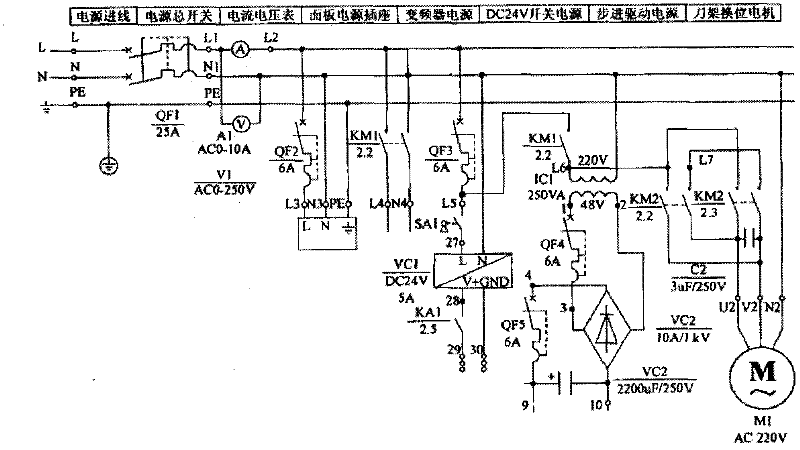

[0013] See Figure 1 to Figure 2 The present invention has a CNC lathe 1, a machine control panel 2 and a system operation panel 3; it also includes a servo simulation unit 4, a spindle frequency conversion unit 5, a numerical control unit 6, an input / output unit 7, a display control unit 8, a power input unit 9, Step drive unit 10 , power output unit 11 and pad box 12 . The above-mentioned numerical control unit is a CNC integrated system, including a computer numerical control device, a programmable controller, a spindle control unit, a speed control unit, an input / output device, and a communication line.

[0014] The above-mentioned input / output devices are respectively electrically connected to the computer numerical control device, the main shaft control unit and the speed control unit are respectively electrically connected to the computer numerical control device, the programmable controller is electrically connected to the main shaft control unit and the computer numer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com