Integrated experimental device for controlling dynamic process of flow industry

A process industry and dynamic process technology, applied in the field of experimental equipment, can solve the problems of large occupied area and crowded, and achieve the effects of small occupied area, improved practical quality and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the embodiments shown in the drawings.

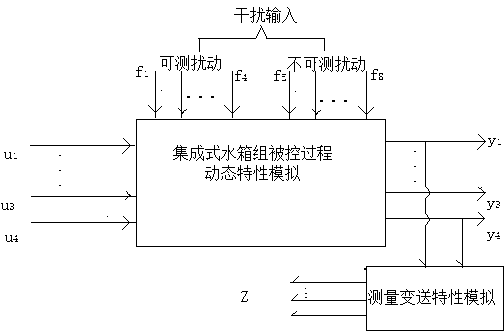

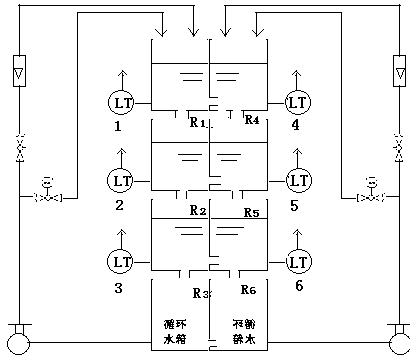

[0020] This process control experimental device is an integrated type, using a transparent water tank as the basic unit to simulate the dynamic characteristics of the controlled object and the measuring transmitter. There are no pipes and valves between the water tanks. The simulation principle is the same as the computer digital simulation mechanism, but it is a physical simulation method realized by fluid based on a mathematical model. The liquid resistance and liquid capacity of each tank constitute a first-order resistance-capacitance link, the flow resistance can be changed as needed, and the capacity coefficient can be adjusted. Multi-level system transfer functions are used to simulate multiple tanks, and the integration level ranges from two to many. The system time constant ranges from a few tenths of a second to several minutes or tens of minutes, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com