Single-tube air cannon capable of achieving continuous launching

A launch tube and air cannon technology, applied in compressed air guns, weapons without explosives, testing of machine/structural components, etc., can solve problems such as high cost, complex structure, and inability to guarantee the accuracy of projectile impact positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

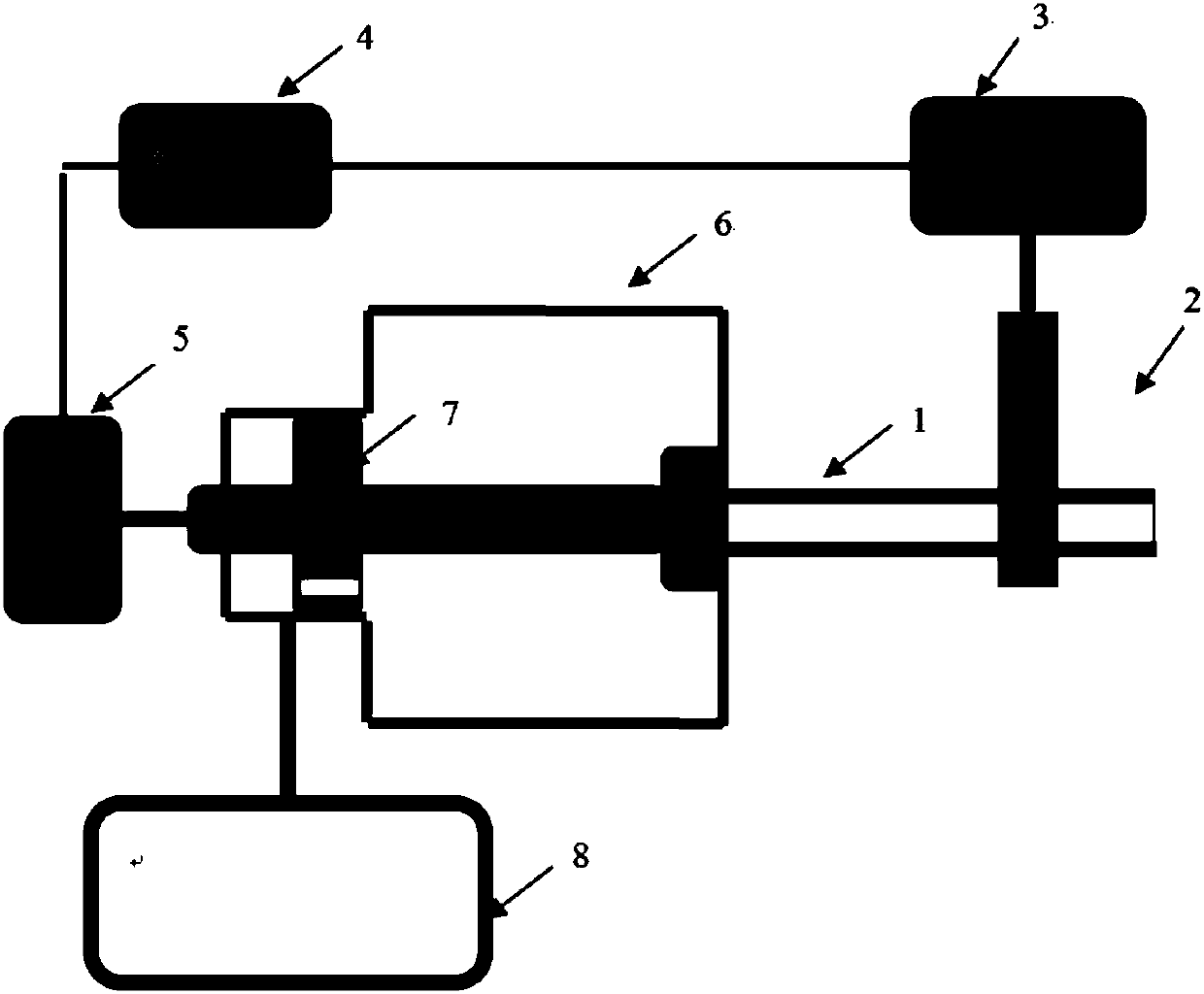

[0022] The following describes the implementation of the technical solution of the present invention in detail in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the device of the present invention is composed of a launching air chamber, a gun barrel, an air supply chamber, an air source, a combined valve body, a loading device, an electric servo actuator for launching / supplementing air, an electric servo actuator for loading bullets, and a control valve. The system consists of compressed air as the working medium. The loading device and tooling are equipped with multiple projectiles, which are connected with the barrel through a high-precision chute. One projectile is fired at a time, and the next projectile is pushed into the waiting area according to the control command under the action of the servo actuator for loading. launch location.

[0024] The launch chamber and the gun barrel are sealed by the cone of the combined valve body, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com