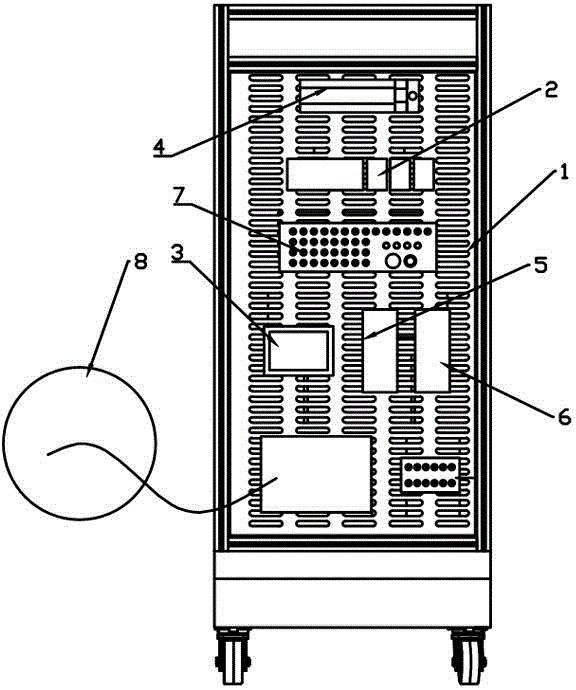

Automatic comprehensive practical training system

An experimental and integrated technology, applied in the direction of instruments, simulators, space navigation equipment, etc., can solve problems such as increasing students' learning experience, and achieve the effect of comprehensiveness and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

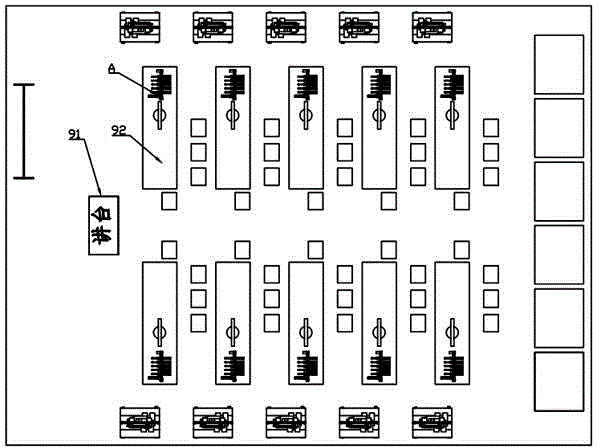

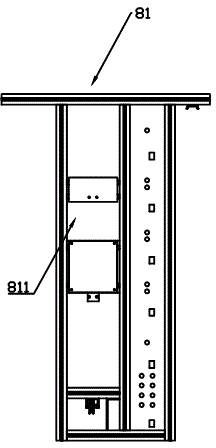

[0037] Example 1: Elevator control simulation:

[0038] In this embodiment, such as image 3 As shown, the experimental control object is an elevator control unit 81 composed of an aluminum profile platform, a linear motion mechanism, a car, an inductive sensor, an encoder, a three-phase asynchronous motor, and a terminal box. The linear motion mechanism is fixed on the aluminum profile platform And the car, inductance sensor, encoder, three-phase asynchronous motor and its own gear box are assembled in the linear motion mechanism 811, and all electrical components are connected to the modular replaceable PLC unit through the terminal box. During the training and teaching, the students’ hands-on ability can be cultivated. According to the design of the elevator structure and the power part, they can be assembled and connected based on the mesh plate base frame; then they can practice elevator control, sensor application and other technologies through programming teaching; During ...

Embodiment 2

[0039] Example 2: Simulation of automatic dispensing according to formula:

[0040] In this embodiment, the experimental control object is an automatic dispensing unit 82 composed of an aluminum profile platform, a conveying mechanism, a medicine pushing mechanism, a rotary encoder, an AC motor, a contactor, an automatic feeding cart, an electronic scale, and a terminal box. The mechanism is equipped with a DC reduction motor, a screw, a coupling, a left and right limit switch and a belt to drive the movement of the trolley; the drug pushing mechanism is composed of a pushing cylinder, a turning cylinder, and a solenoid valve. All electrical components are connected through a terminal box. Replaceable PLC unit. During the training and teaching, the students' hands-on ability can be cultivated. According to the design of the automatic dispensing system and the power part, the assembly and connection are based on the mesh plate base frame; then the teaching computer is used for pro...

Embodiment 3

[0041] Embodiment three, constant pressure water supply simulation:

[0042] In this embodiment, the experimental control object is a variable frequency constant pressure water supply unit composed of an aluminum profile platform, three variable frequency motors, a frequency converter, a pressure transmitter and a junction box, and the pressure transmitter is equipped with water collection The frequency converter is connected with the variable frequency motor, and the signal output end of the pressure sensor and the controlled end of the frequency converter are connected to the modular replaceable PLC unit through the junction box. In the training and teaching, after completing the training of the practical ability of assembly and connection, let the students understand the principle and purpose of the experiment: collect water pressure information through the pressure sensor, convert the signal by the pressure transmitter to the PLC, and then by the PLC Commands are issued to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com