Experimental control method for evaluating service life of transformer oil

A technology of transformer oil and control method, applied in the direction of material thermal development, etc., can solve the problems of inability to simulate the application environment of transformer oil, failure to protect, etc., and achieve the effects of correct results, precise control, and high system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

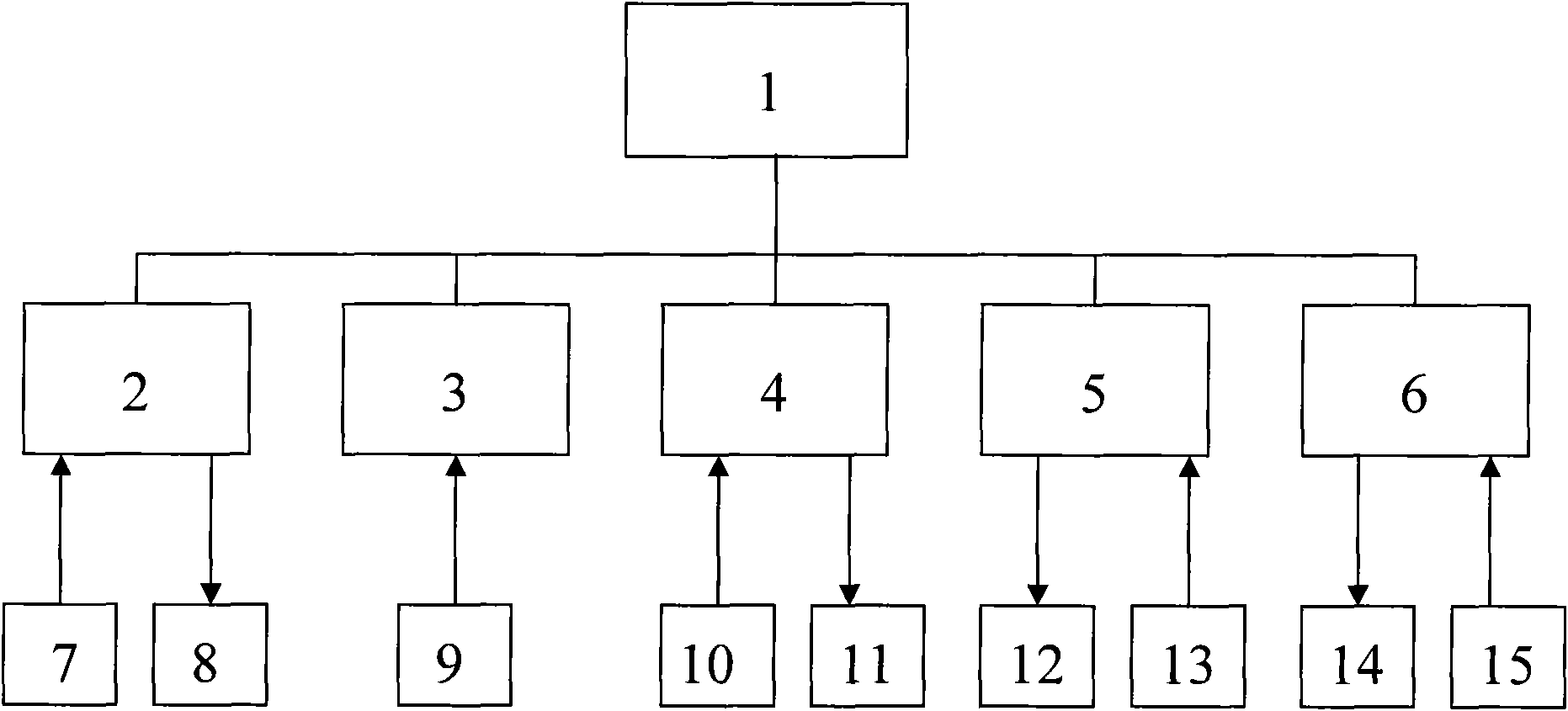

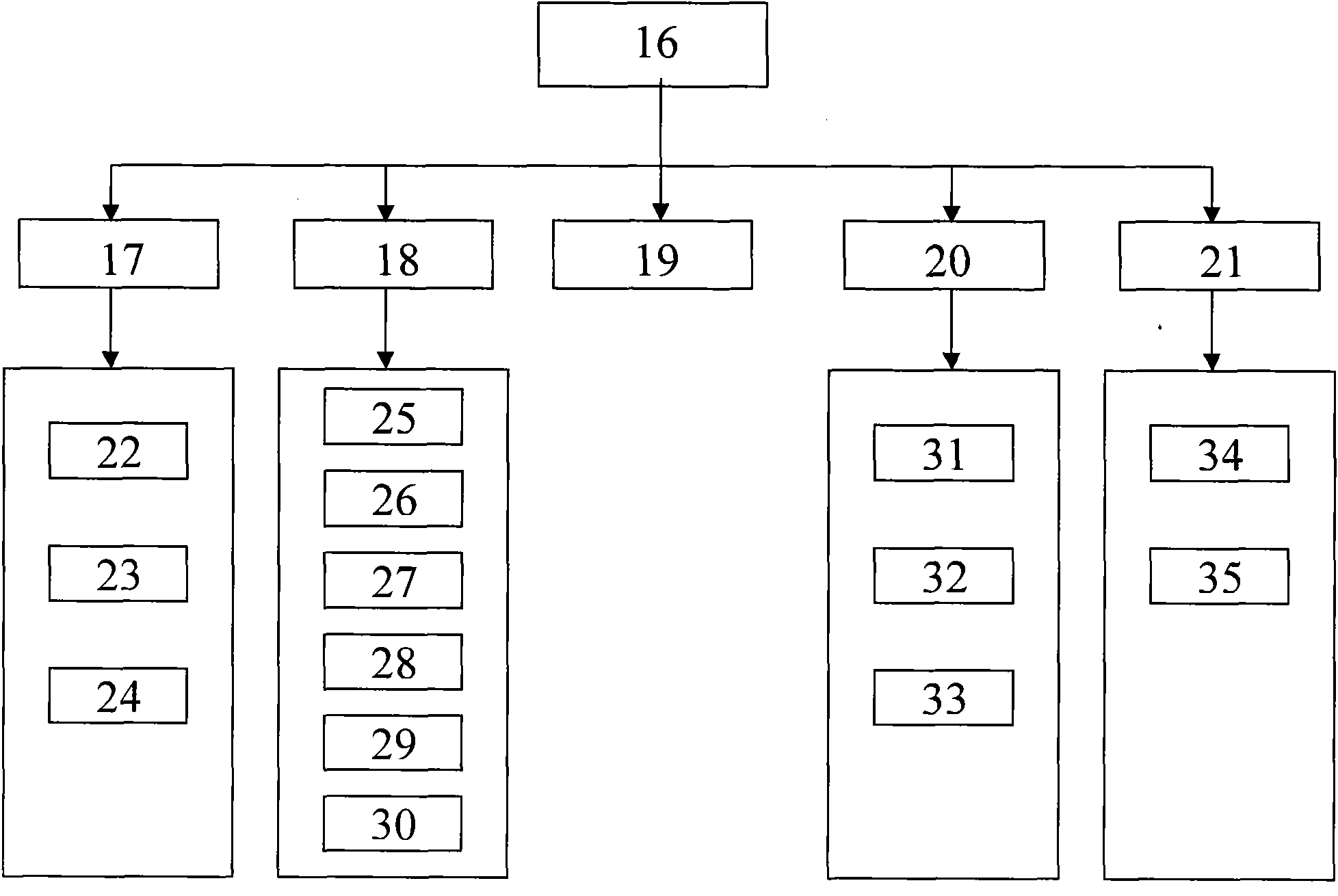

[0053] Attached figure 1 And attached figure 2 The test control method designed to evaluate the service life of transformer oil has been operated continuously for 8,500 hours in the actual test, and the control of various test parameters is stable. The temperature is 95°C, the oxygen flow rate is 34 ml / min, and the transformer operating voltage is 330 volts. , The test voltage is 8100 volts. The error of temperature control is less than 0.5%, and the error of oxygen flow control is less than 0.3%. The long-term durability test of the system is safe, reliable and error-free, with zero failure rate. There is no need to worry about the high test risk of high temperature and high pressure and the high test cost of 24-hour manual duty.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com