Experiment control method for researching flexion damage of thermal curtain coating interface containing inner embedded interface defect under high temperature environment

A technology of interface defects and thermal barrier coatings, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of inability to determine the specific location and time of buckling failure, and the inability to accurately record experimental failure conditions , Difficult to observe in real time and other problems, to save manpower, shorten experiment time and improve experiment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

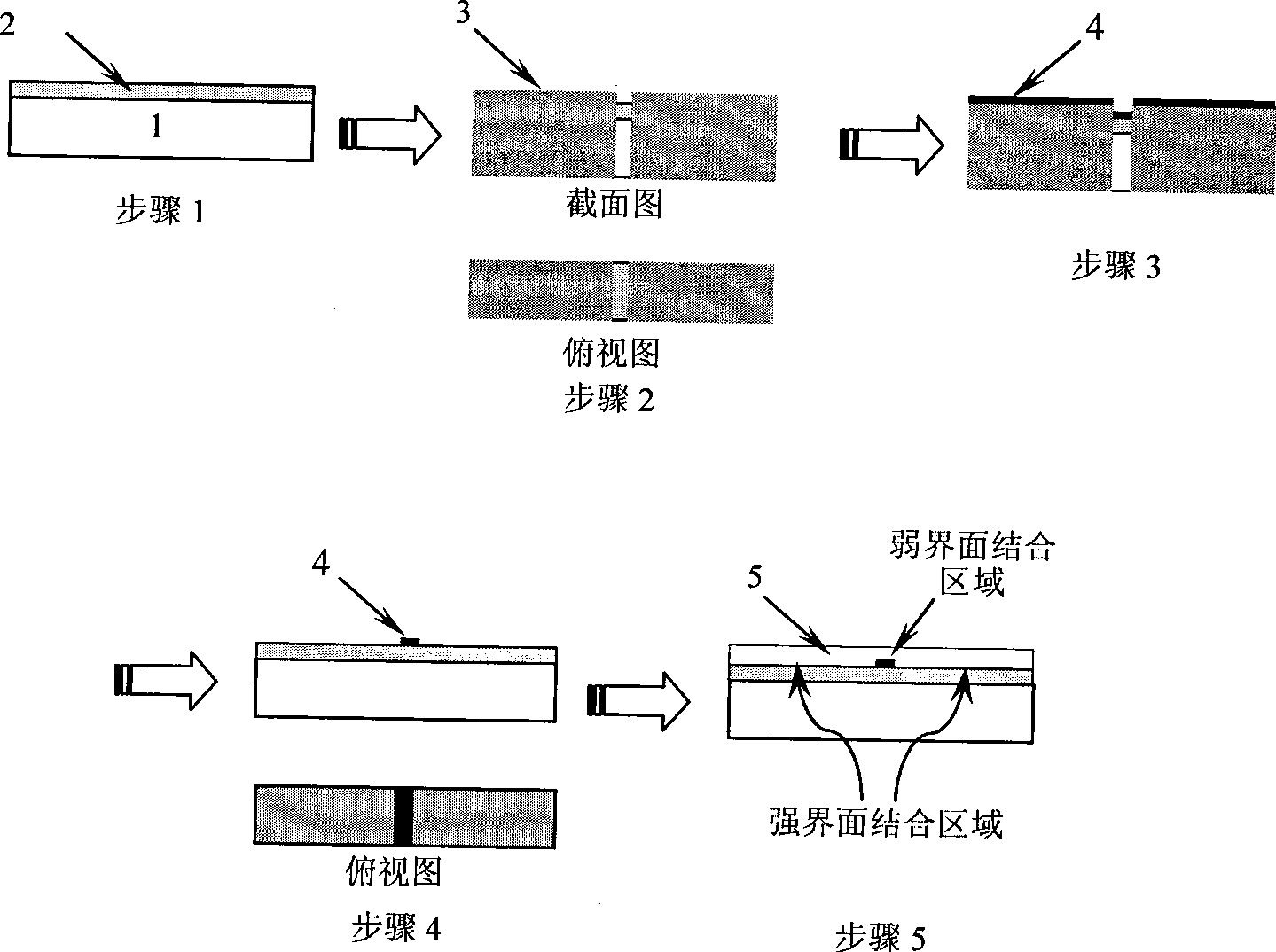

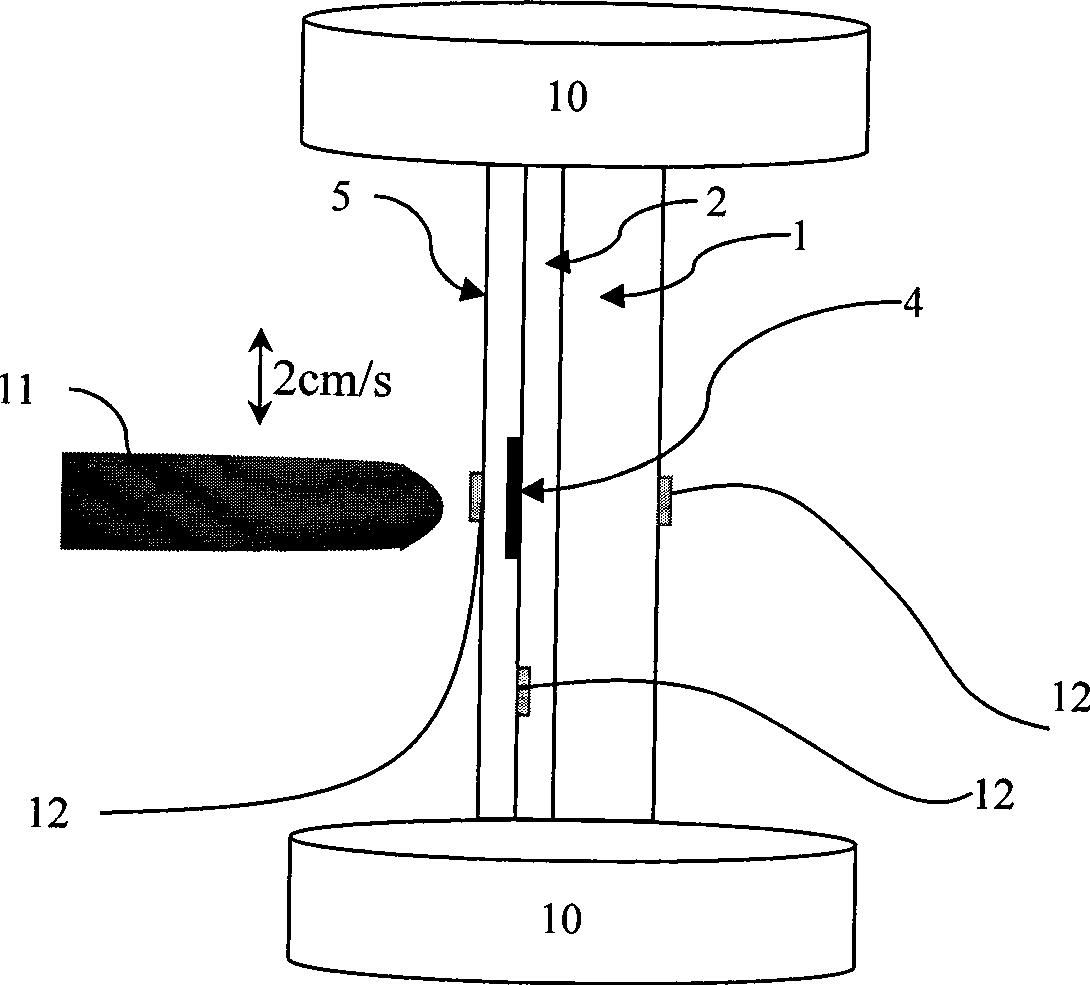

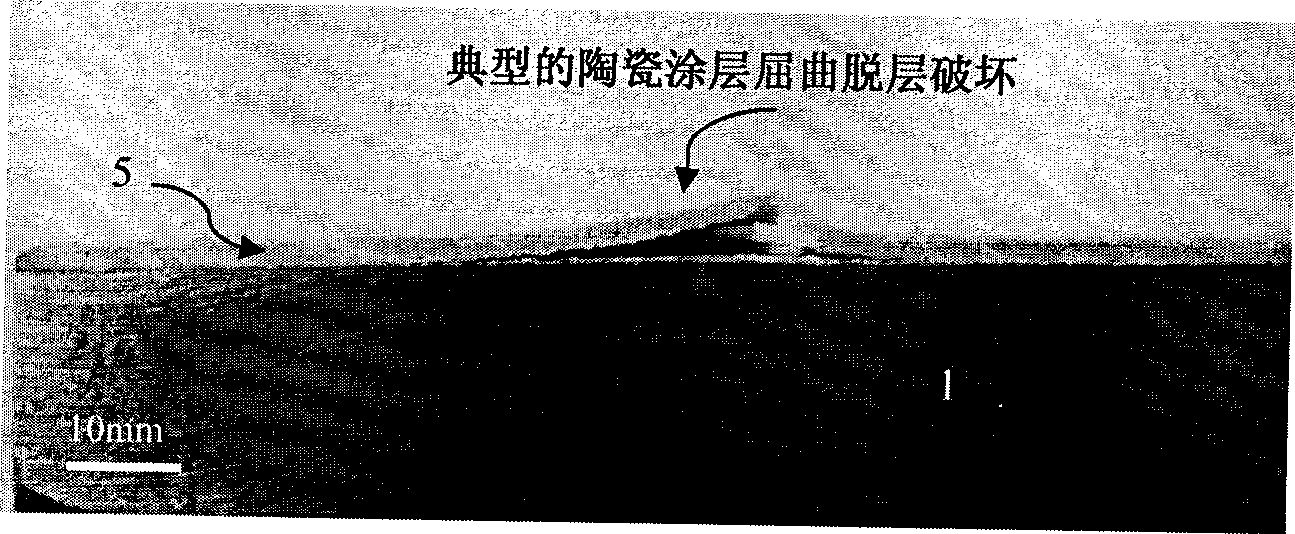

[0020] Since the thermal barrier coating system takes a long time to form interface defects and microscopic cracks in the actual application process, and the microscopic cracks continue to expand, and finally connect to macroscopic cracks, it also takes a long time. The ceramic layer The residual compressive stress can accumulate to the critical stress of ceramic layer buckling failure. In order to shorten the experimental time and improve the experimental efficiency, this embodiment adopts the plasma spraying process to artificially and reasonably prepare the experimental sample of the thermal barrier coating containing an interface defect, and adopts the experimental method proposed by the present invention to test the sample containing the interface defect in a high temperature environment. Experimental research was carried out on the thermal barrier coating samples, and the experimental phenomena of interface buckling failure were obtained, and then the experimental contr...

Embodiment 2

[0047] Using the same preparation process to prepare thermal barrier coating samples containing interface defects, only the prefabricated original length of the interface defects is changed, that is, in this specific embodiment, a is set to 4mm, 5mm, 6mm, 8mm and 10mm respectively, The number of samples of each type is 5. Using the same experimental method and experimental procedure, the thermal barrier coating sample containing interface defects was subjected to high-temperature compression experiments to obtain the experimental conditions and control methods for the interface buckling failure of the ceramic layer, and the processing method for the results was the same as in Example 1.

[0048] In the experiment, it was found that the larger the pre-designed original defect length a, the easier the interface buckling failure of the sample at high temperature; and the smaller the pre-designed original defect length a, the harder the sample is to undergo interfacial buckling...

Embodiment 3

[0050] In this embodiment, the normal plasma spraying preparation process and preparation procedures are used to prepare the thermal barrier coating sample. The materials of the thermal barrier coating sample are respectively: the substrate (1) is a nickel-based superalloy material, and the bonding layer (2) It is a NiCrAlY alloy; the material of the ceramic layer (5) contains 6-8wt% Y 2 o 3 ZrO 2 .

[0051] Its concrete preparation steps are as follows:

[0052] The first step substrate (1) pretreatment

[0053] Sand blast the selected substrate (1) to make the surface roughness of the substrate (1) Ra<0.7, and the geometric dimensions of the substrate (1) are 40×5×5mm.

[0054] The second step is to prepare the bonding layer by plasma spraying process (2)

[0055] The substrate (1) treated in the first step is installed on the workbench of the spraying equipment, and the first substrate with an adhesive layer is prepared under the first group of plasma sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com