Path loading method used in determination of rock triaxial strength after failure

A loading path and strength technology, applied in the direction of applying stable tension/compression to test the strength of materials, preparation of test samples, etc., can solve the problem that the impact mechanism is not very clear, and achieve the loading method is simple, easy, and widely practicable , good simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

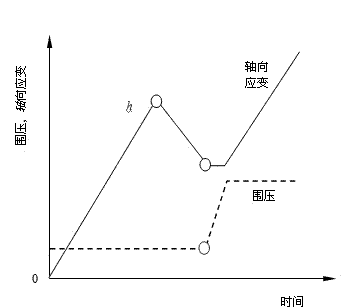

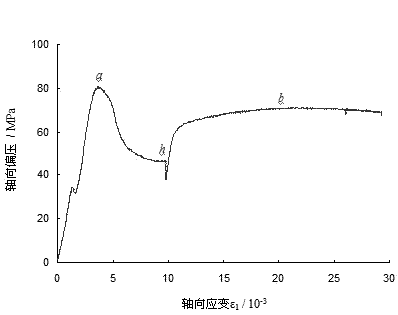

[0021] Example 1: figure 2 Shown is the initial confining pressure σ in the loading path experiment 31 =5MPa and final confining pressure σ 32 = 2 times the initial confining pressure σ 31 time experimental curve. First, place the Φ50×100mm marble cylindrical sample in the three-axis airtight pressure cylinder of the servo testing machine. Fill the interior with hydraulic oil until it is completely filled, and apply hydrostatic pressure to the marble cylindrical sample at a loading rate of 0.5MPa / s, so that the confining pressure of the cylindrical sample is loaded to the design initial confining pressure σ 31 =5MPa, keep the initial confining pressure σ 31 = 5MPa remains unchanged, apply an axial bias (σ 1 -σ 31 ), so that the sample is loaded to the control point after the peak strength h ( h The axial strain corresponding to the point is 9.8 ×10 -3 ), to form a rock sample after cracking, apply a hydrostatic pressure of 0.5MPa / s to the rock sample after cracking...

Embodiment 2

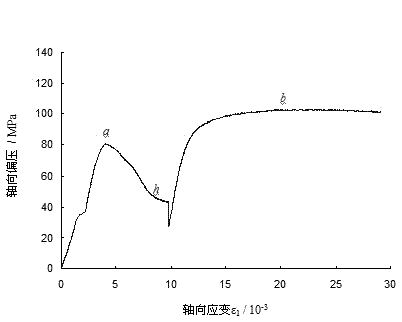

[0022] Example 2: image 3 Shown is the initial confining pressure σ in the loading path experiment 31 =5MPa and final confining pressure σ 32 = 4 times the initial confining pressure σ 31 time experimental curve. First, place the cylindrical marble sample (Φ50×100mm) in the triaxial airtight pressure cylinder of the servo testing machine. The pressure cylinder is filled with hydraulic oil until it is completely full, and the hydrostatic pressure is applied to the marble sample at a loading rate of 0.5MPa / s, so that the confining pressure of the sample is loaded to the design pressure value σ 31 =5MPa, keep the initial confining pressure σ 31 = 5MPa remains unchanged, apply an axial bias to the marble sample according to the displacement loading rate of 0.002mm / s (σ 1 -σ 31 ), so that the sample is loaded to the control point after the peak strength h ( h The axial strain corresponding to the point is 9.8 ×10 -3 ), to form a rock sample after fracture, apply a hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com