Patents

Literature

91 results about "Rock breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rock breakage during the coring process is a well-known phenomenon. Often this fragmentation is called “core discing” when it involves formation of fractures that crosscut the core axis to form relatively thin discs.

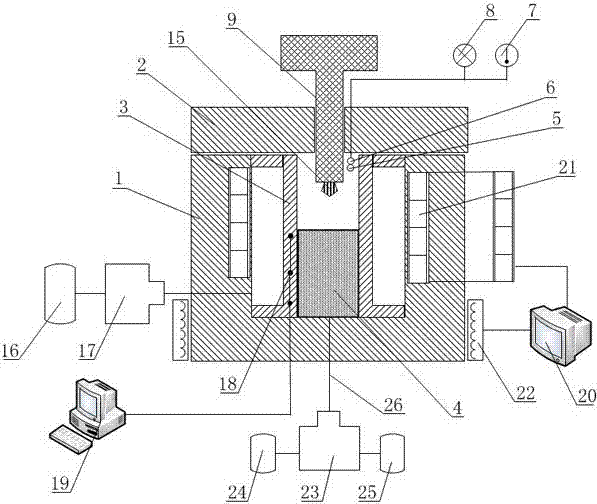

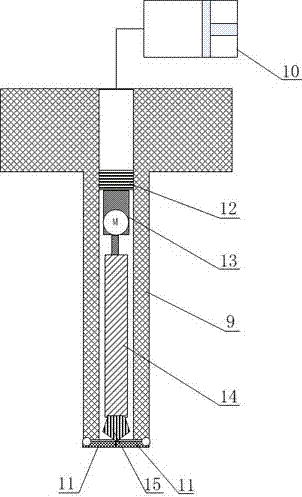

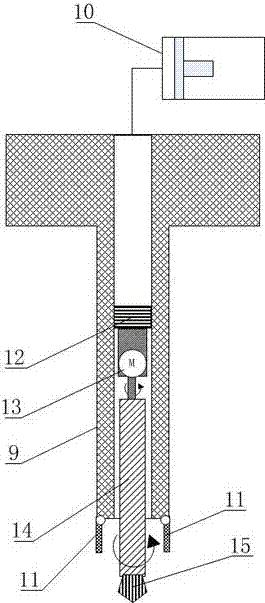

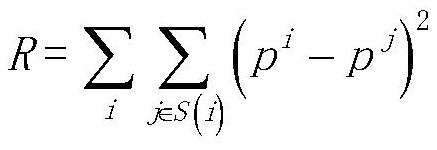

Multifunctional drill bit rock breaking experiment device and method capable of testing triaxial strength parameter of rock

ActiveCN107505207AIncrease profitShort timeMaterial strength using tensile/compressive forcesStress–strain curveRock sample

The invention discloses a multifunctional drill bit rock breaking experiment device capable of testing the triaxial strength parameter of rock. The device comprises a main body device, a pressure head structure, a confining pressure system, an acoustic emission system, a temperature control system and a pore material injection system. The device has the benefits as follows: the real temperature, crustal stress and pore pressure of a stratum can be simulated in a closed environment, a triaxial mechanical test and a drill bit rock breaking test can be completed simultaneously, a stress-strain curve of a rock sample, dynamic vibration of a drill bit and a drill column, bit pressure and influences of footage on the rock sample can be determined, an experiment basis is provided for research of mechanical properties of complex oil and gas reservoirs and drill bit rock breakage under multiple conditions, a rock breaking experiment can be conducted while conventional mechanical properties of the rock are tested, two experiments can be completed once after the designed temperature and pressure conditions are met, the total time consumption is reduced, and the utilization rate of underground rock cores can be effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV

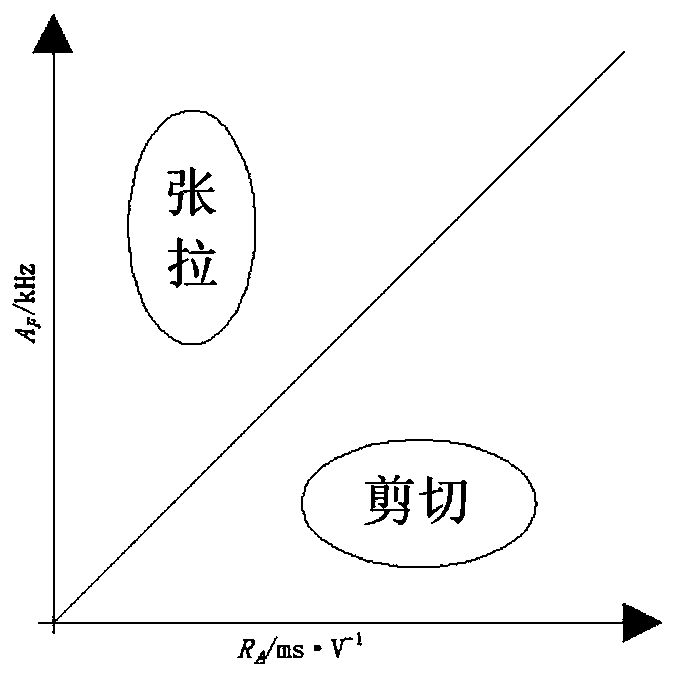

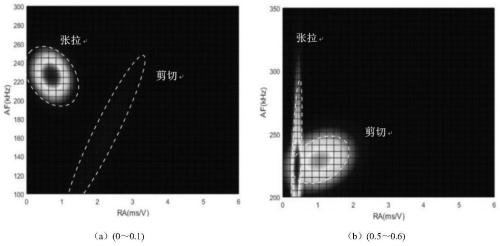

Rock fracture mode intelligent detection and identification method based on acoustic emission model

PendingCN111272883AMaterial analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionComputer science

The invention discloses a rock fracture mode intelligent detection and identification method based on an acoustic emission model. The method comprises the following steps: firstly, arranging an acoustic emission system used for testing acoustic emission parameters in the rock fracture process on a rock to be monitored; inputting the target characteristic data into a pre-trained signal identification model, wherein the signal identification model is obtained by training a training set of rock fracture acoustic emission in advance; then intelligently identifying the development ratio of tensionand shear cracks in the rock fracture process; and finally, according to the corresponding relation between the waveform characteristics determined by the rock fracture acoustic emission signals and rock fracture mode identification, providing a series of reliable detection thresholds for quantitative formulation of a rock mass disaster early warning scheme. Meanwhile, an analysis method is provided for deep research and identification of rock fracture instability precursor signal characteristics.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

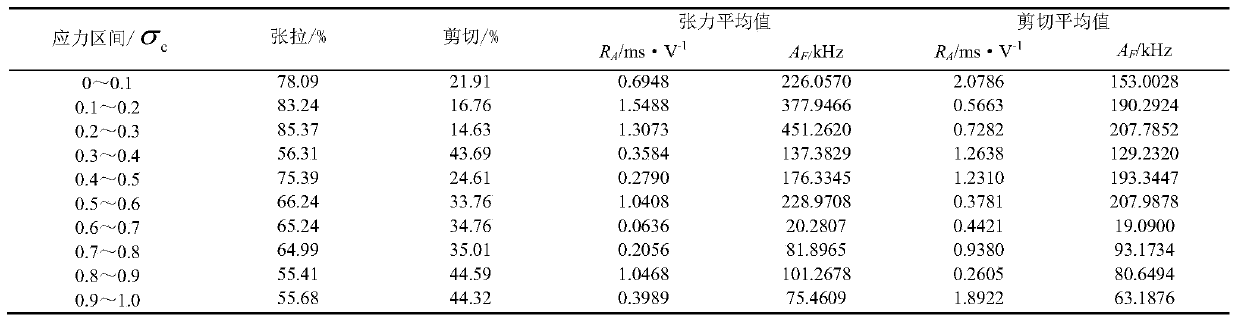

Path loading method used in determination of rock triaxial strength after failure

InactiveCN102221504AUnderstanding Mechanical BehaviorLoad method is simplePreparing sample for investigationMaterial strength using tensile/compressive forcesHydrostatic pressurePeak value

The invention discloses a path loading method used in the determination of rock triaxial strength after rock failure. The method comprises the following steps that: first, samples of engineering rock mass requiring testing are collected; the collected samples are prepared into cylindrical samples; upper and lower rigid loading terminals of the samples closely contact a pressure head of a testing machine; hydrostatic pressure is applied to the cylindrical sample, such that an initial confining pressure to the sample is loaded to a designed value; with the initial confining pressure maintained, axial load is then applied to the cylindrical sample, and the pressure to the sample is loaded to a control point after a peak value intensity, such that a rock failure sample is formed; hydrostatic pressure is then applied to the rock failure sample, such that final confining pressure to the sample is loaded to a higher value; with the final confining pressure maintained, axial load is then applied to the rock failure sample, such that a yielding failure is occurred to the rock sample. With the testing method, mechanical characteristics of rock re-failure after failure can be researched, triaxial strength characteristics of rocks after failures can be acquired, and corresponding technical measures can be provided for the problems in failed surrounding rock reinforcing in the field of deep underground engineering.

Owner:CHINA UNIV OF MINING & TECH

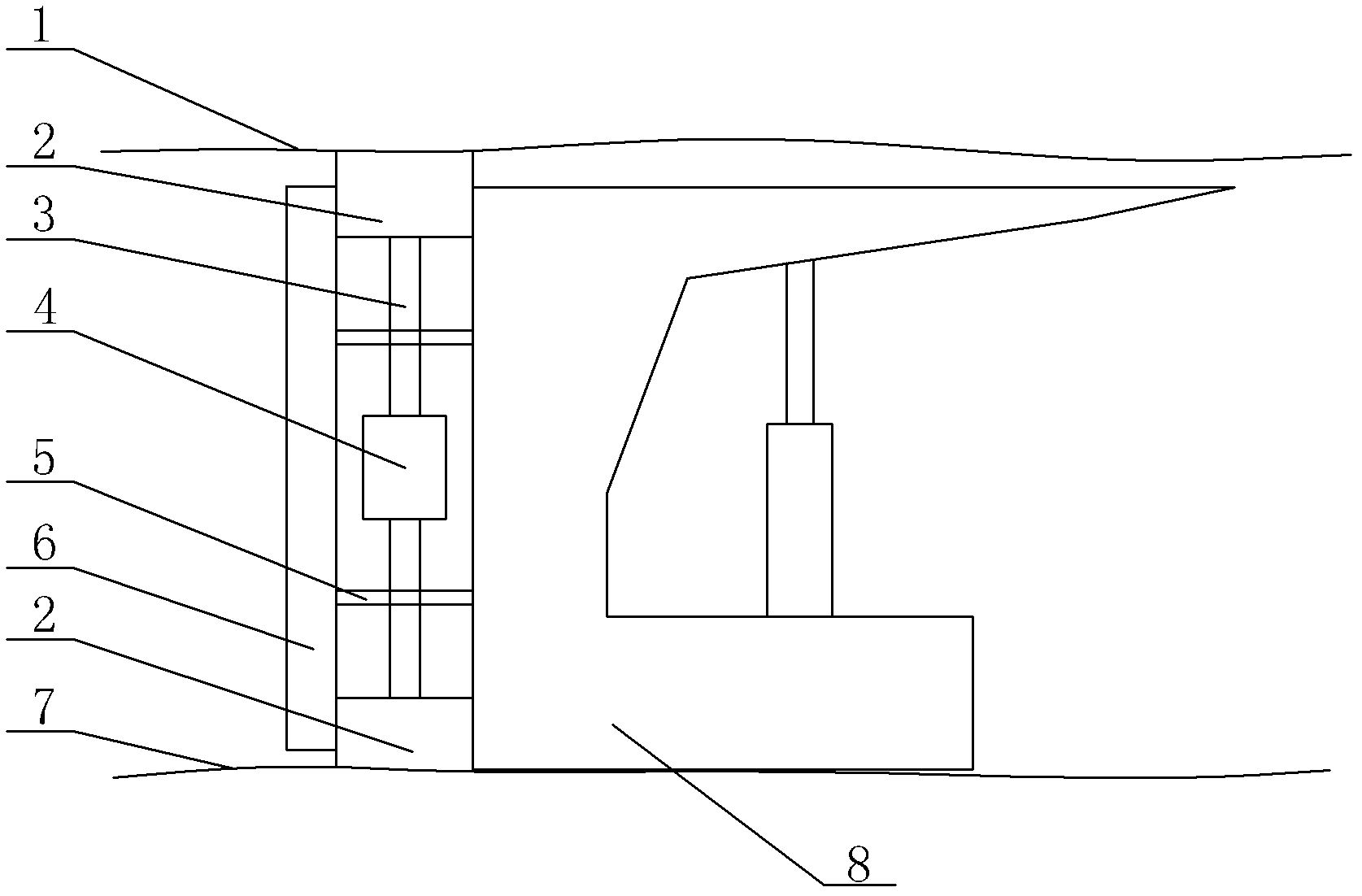

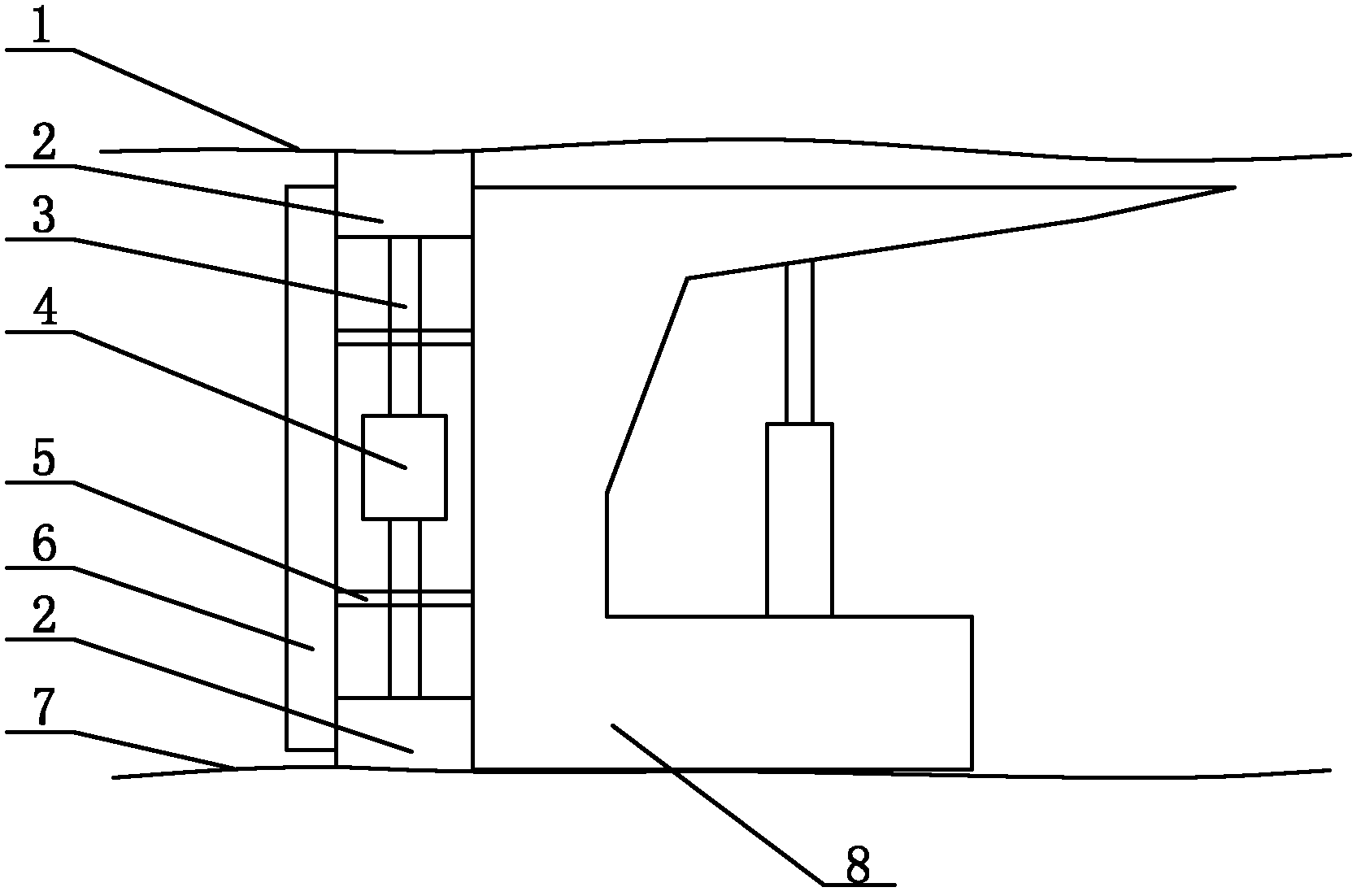

Underground cavity peeping device and method based on three-dimensional scanning and 3D printing

Disclosed is an underground cavity peeping device and method based on three-dimensional scanning and 3D printing. By using the underground cavity peeping device, the technical problem that conventional peeping devices cannot acquire cavity information in an omnibearing manner. The underground cavity peeping device comprises a three-dimensional probe and a connecting rod, and further comprises a 3D data collector, 3D printing equipment and a supporting frame, the three-dimensional probe is arranged on a first rotating structure which is fixed at one end of the connecting rod, the other end of the connecting rod is fixedly connected with the supporting frame through a second rotating structure, the three-dimensional probe is electrically connected with the 3D data collector through a data line, and the 3D data collector is electrically connected with the 3D printing equipment. The underground cavity peeping device is simple in structure, convenient for disassembly and assembly and convenient to operate, can detect position and surrounding rock breakage condition of an underground cavity in an omnibearing manner, can quickly re-demonstrate distribution range and spatial form characteristic of an actual cavity through 3D printing and has important practical value in reasonably determining underground cavity treatment methods of underground engineering of at present stage.

Owner:宿州学院

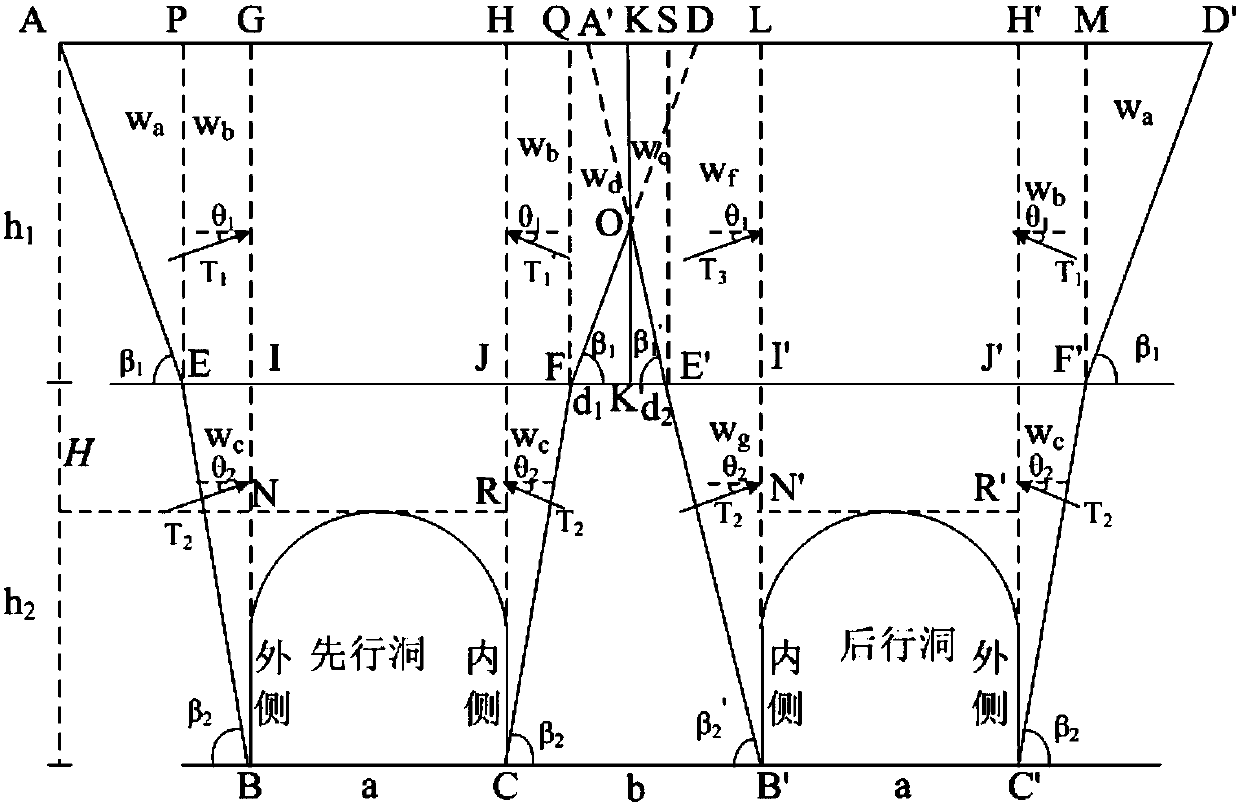

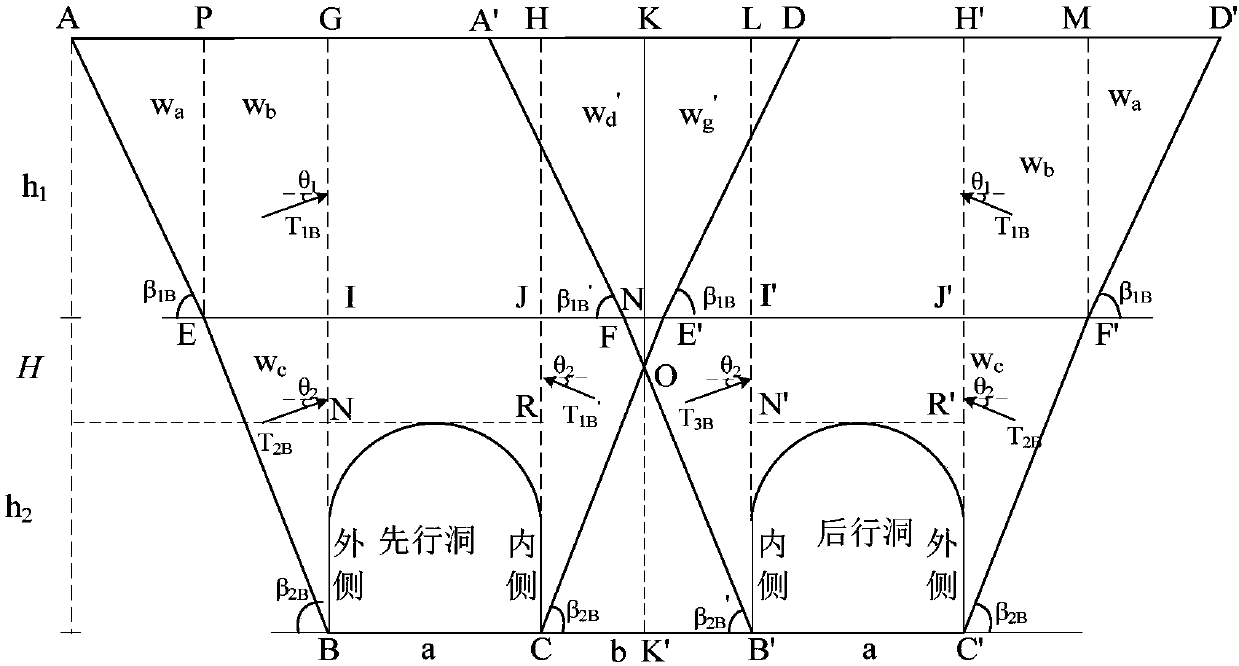

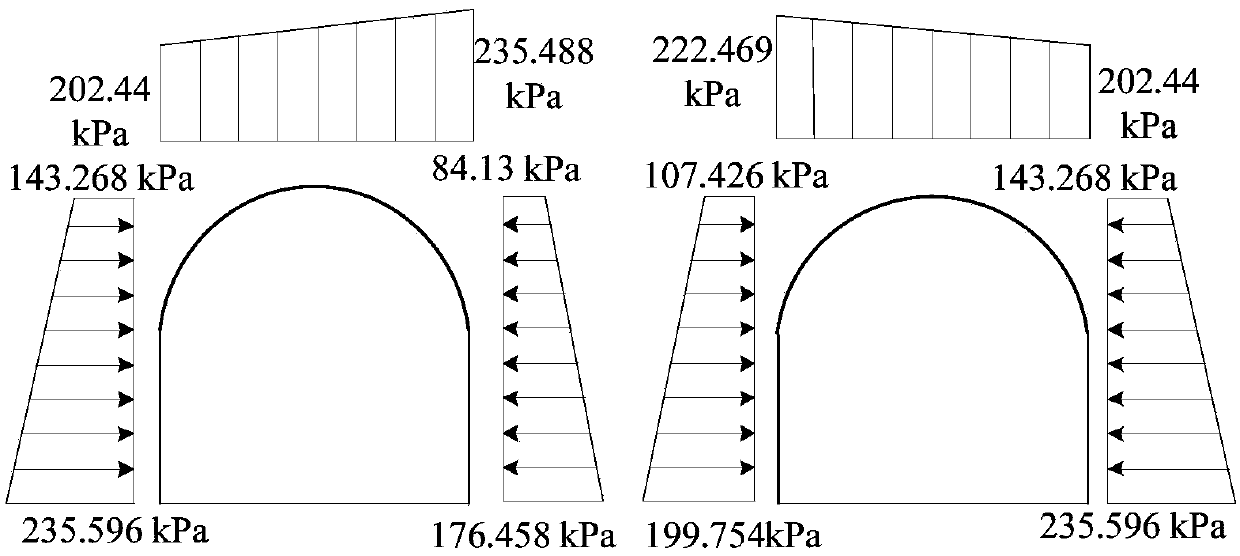

Method for determining pressure of surrounding rock of shallow-buried neighborhood tunnel in composite stratum

ActiveCN108362562ASimple methodImprove applicabilityMaterial strength using tensile/compressive forcesStructure of the EarthDesign information

The invention provides a method for determining pressure of surrounding rock of a shallow-buried neighborhood tunnel in a composite stratum. The method comprises steps as follows: step 1, acquiring division information of a tunnel rock-soil body, physical and mechanics parameters of the rock-soil body and design information of a tunnel structure; step 2, determining the position of fracture surfaces of rock-soil bodies of two tunnels and a surrounding rock breakage mode; step 3, determining calculation parameters according to the breakage mode; step 4, determining tunnel arch distributed loadaccording to the breakage mode; step 5, determining the horizontal pressure of the tunnel according to the breakage mode. Breakage of the surrounding rock of the neighborhood tunnel in the composite stratum comprises two sliding breakage modes, namely, a breakage mode A and a breakage mode B; with the consideration of the influence of the excavation sequence of the composite stratum and the tunnelon the surrounding rock, the method for determining vertical arch pressure and lateral horizontal pressure of the shallow-buried neighborhood tunnel under the condition of the composite stratum is provided, and the method is simple and high in applicability.

Owner:SHANGHAI JIAO TONG UNIV

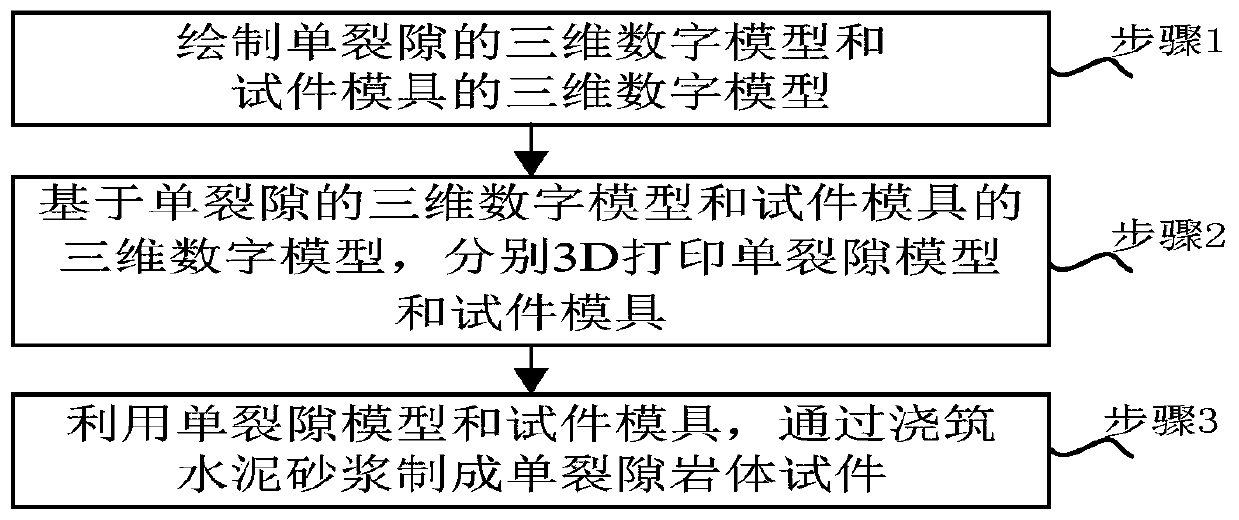

Method for manufacturing single-fracture rock specimen based on 3D printing

InactiveCN110044672AEnsure accurateAvoid the problem of broken and unable to carry out repeated experimentsPreparing sample for investigationCeramic shaping apparatusEngineeringDimensional modeling

The present invention discloses a method for manufacturing a single-fracture rock specimen based on 3D printing, including: step 1: drawing a three-dimensional digital model of a single fracture and athree-dimensional digital model of the specimen mold; step 2: respectively performing 3D printing on a single-fracture model and the specimen mold based on the three-dimensional digital model of thesingle fracture and the three-dimensional digital model of the specimen mold; and step 3: manufacturing the single-fracture rock specimen by pouring cement mortar by using the single fracture model and the specimen mold. In the present invention, in the method for manufacturing a single-fracture rock specimen based on 3D printing, a single fracture model and a mold model are obtained through a three-dimensional modeling technology and a 3D printing technology, and a single fractured rock specimen is obtained by pouring cement mortar, so as to avoid a problem that an experimental error is increased because a new fracture is produced when the specimen is sampled in the field, and repetitive experiments cannot be performed due to the rock breakage of natural rock sample, and processing precision is high, so that accuracy of the single-fracture rock specimen is ensured, and accuracy of a study of characteristics of fluid seepage in the fracture is improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

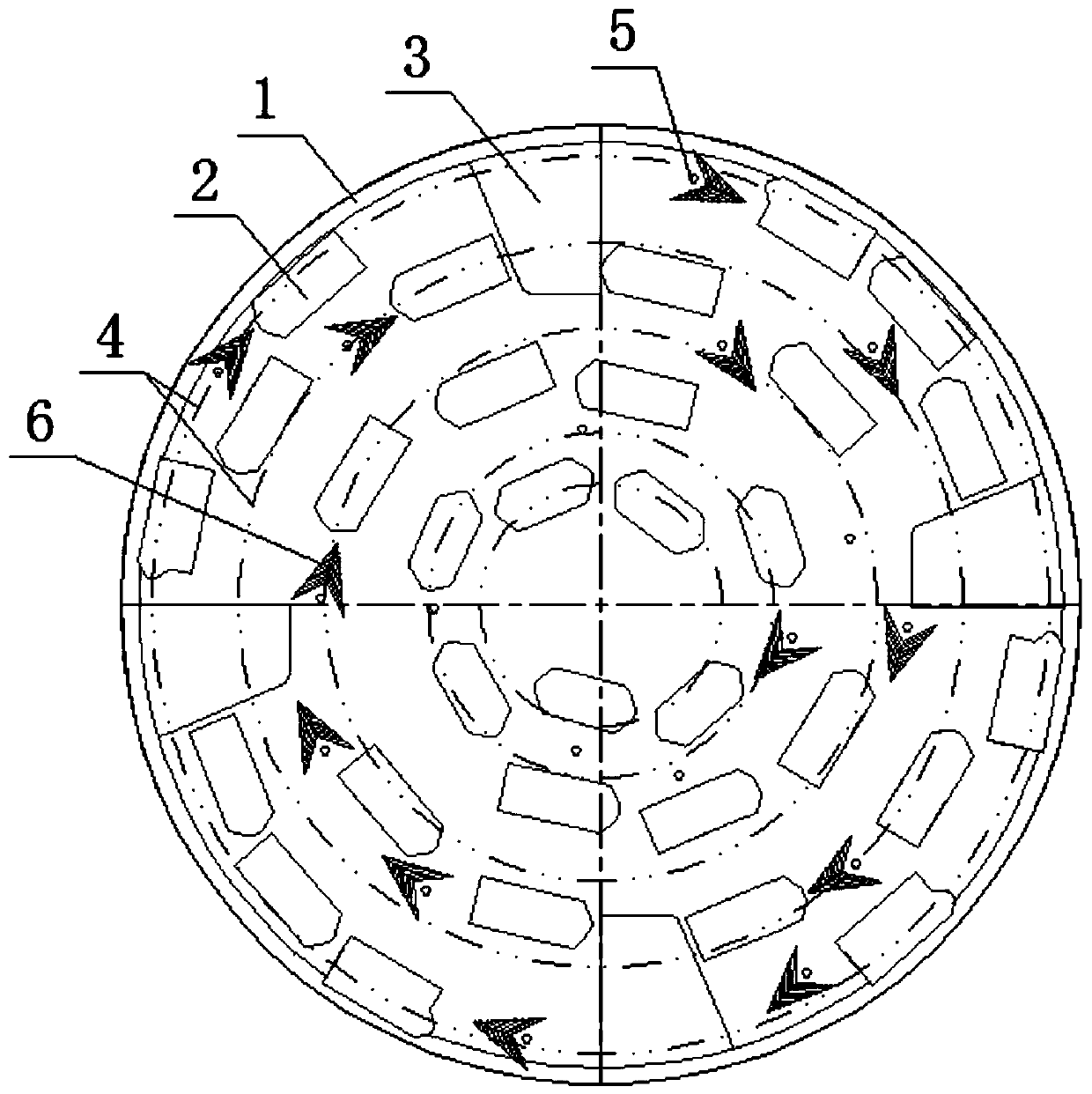

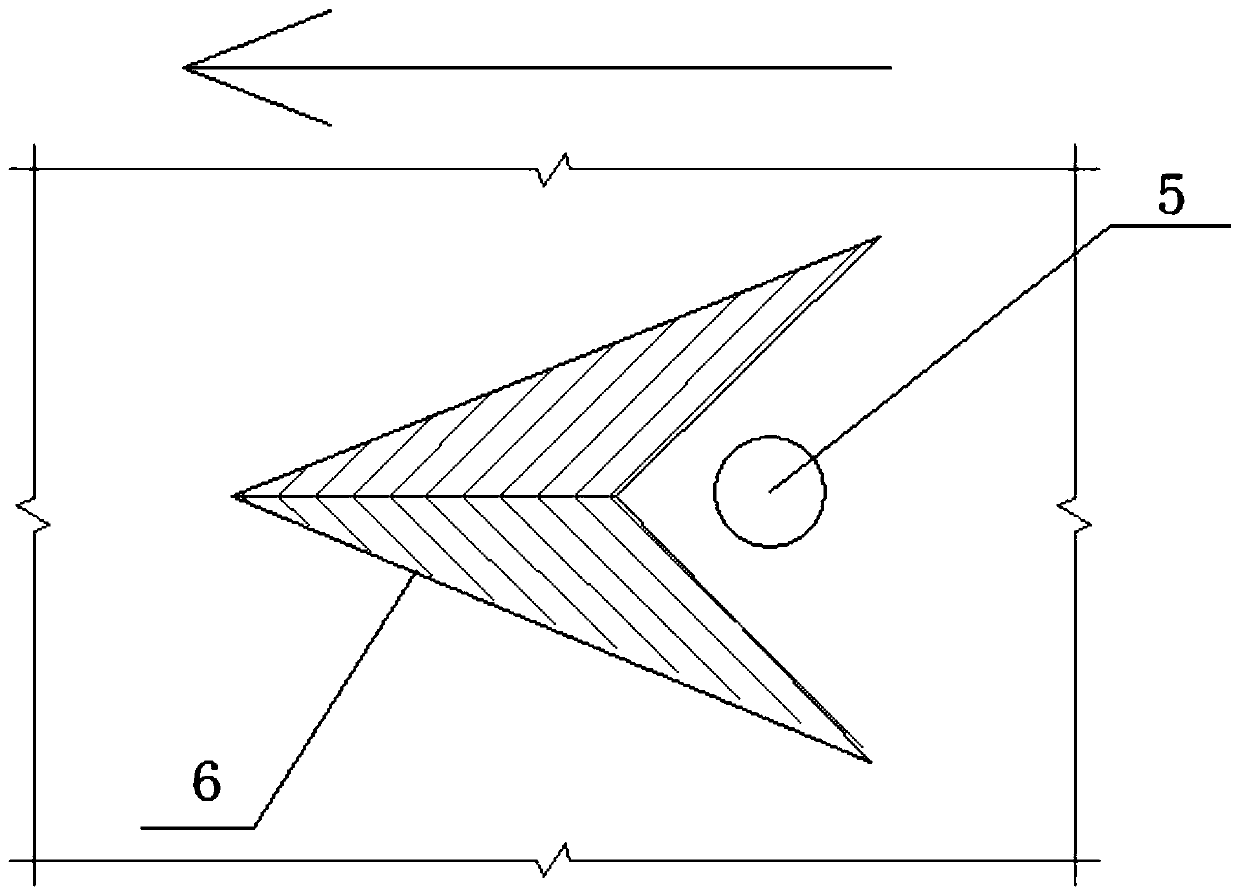

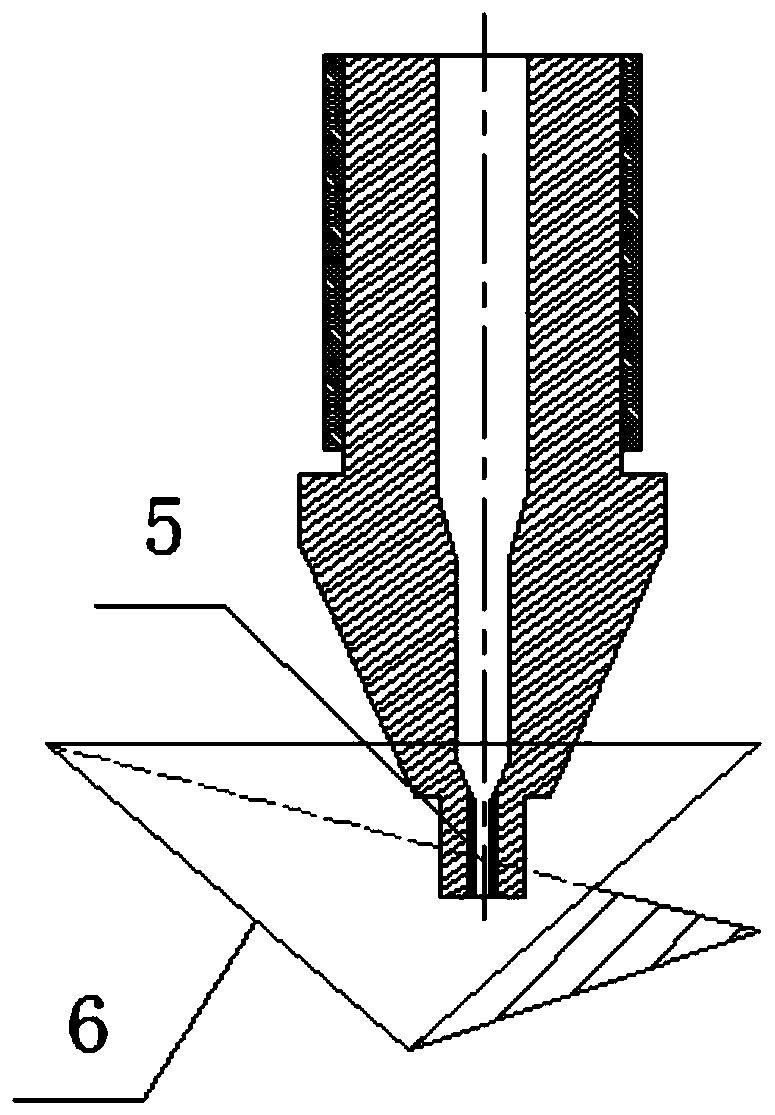

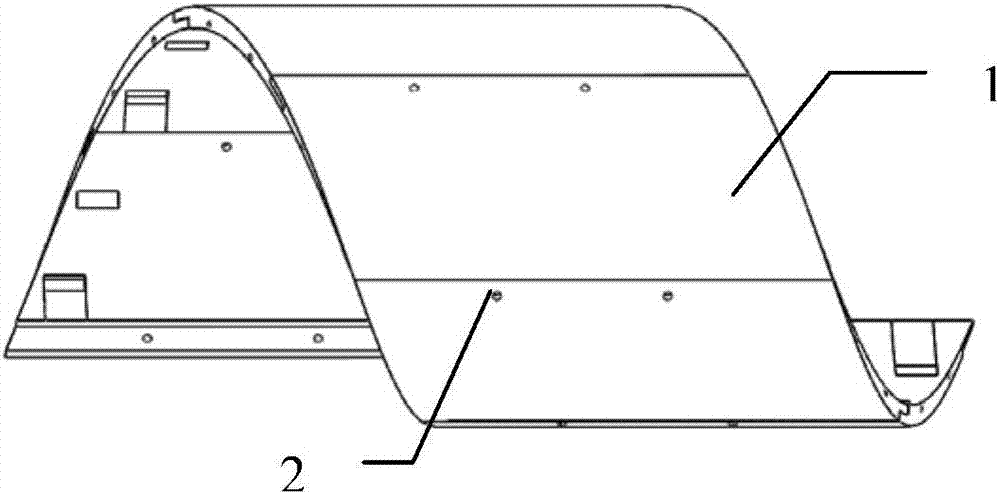

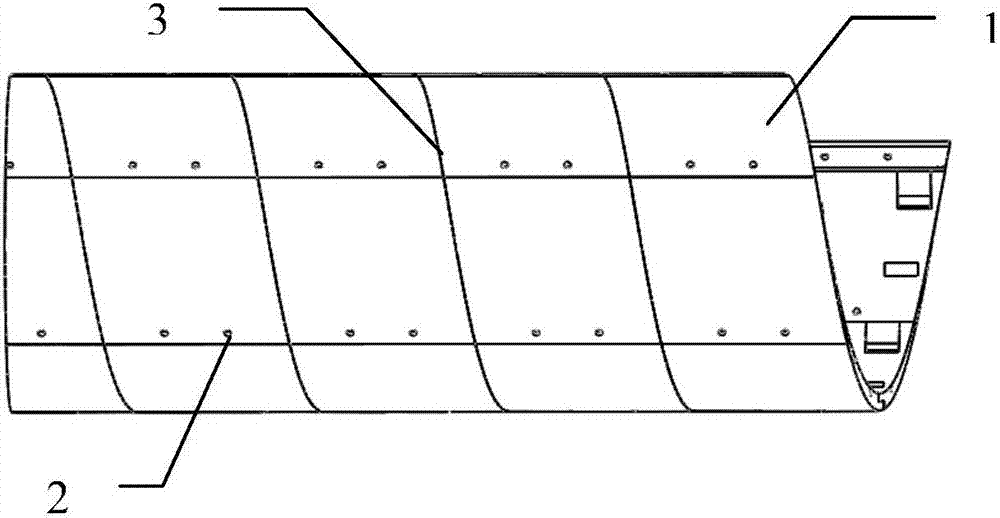

Tunneling machine for hard tunnel rock and cutterhead of tunneling machine

The invention discloses a tunneling machine for hard tunnel rock and a cutterhead of the tunneling machine. The cutterhead of the tunneling machine comprises a cutterhead (1), hobs (2) arranged on a working surface of the cutterhead (1), high-pressure water nozzles (5) arranged on the working surface of the cutterhead (1), and scrapers (6) arranged on the working surface of the cutterhead (1) andused for removing slag, wherein the scrapers (6) are arranged on the peripheries of the high-pressure water nozzles (5). According to the cutterhead of the tunneling machine, the scrapers used for removing slag are arranged on the working surface of the cutterhead and are located on the peripheries of the high-pressure water nozzles to remove earth and rock slag between the cutterhead and the tunneling face, so that it is guaranteed that water jet sprayed out of the high-pressure water nozzles can directly act on the tunneling face, rock is effectively cut, the rock breakage efficiency of high-pressure water is improved, and accordingly, the tunneling efficiency is improved; and the scrapers can prevent accumulated slag from moving towards the high-pressure water nozzles, so that hydraulicdevices (high-pressure water nozzles) are effectively prevented from being blocked, and the service life of the nozzles is prolonged.

Owner:YELLOW RIVER ENG CONSULTING

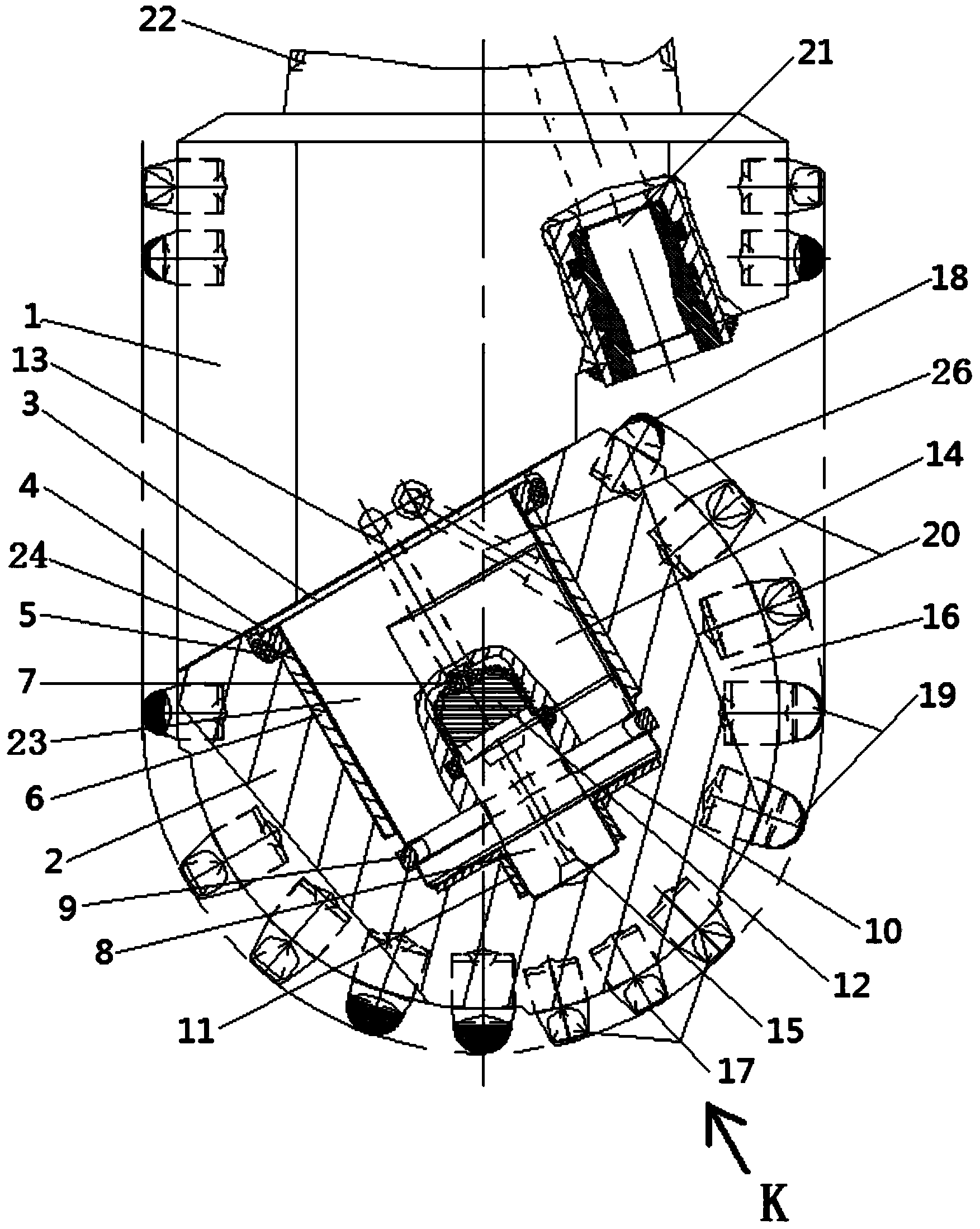

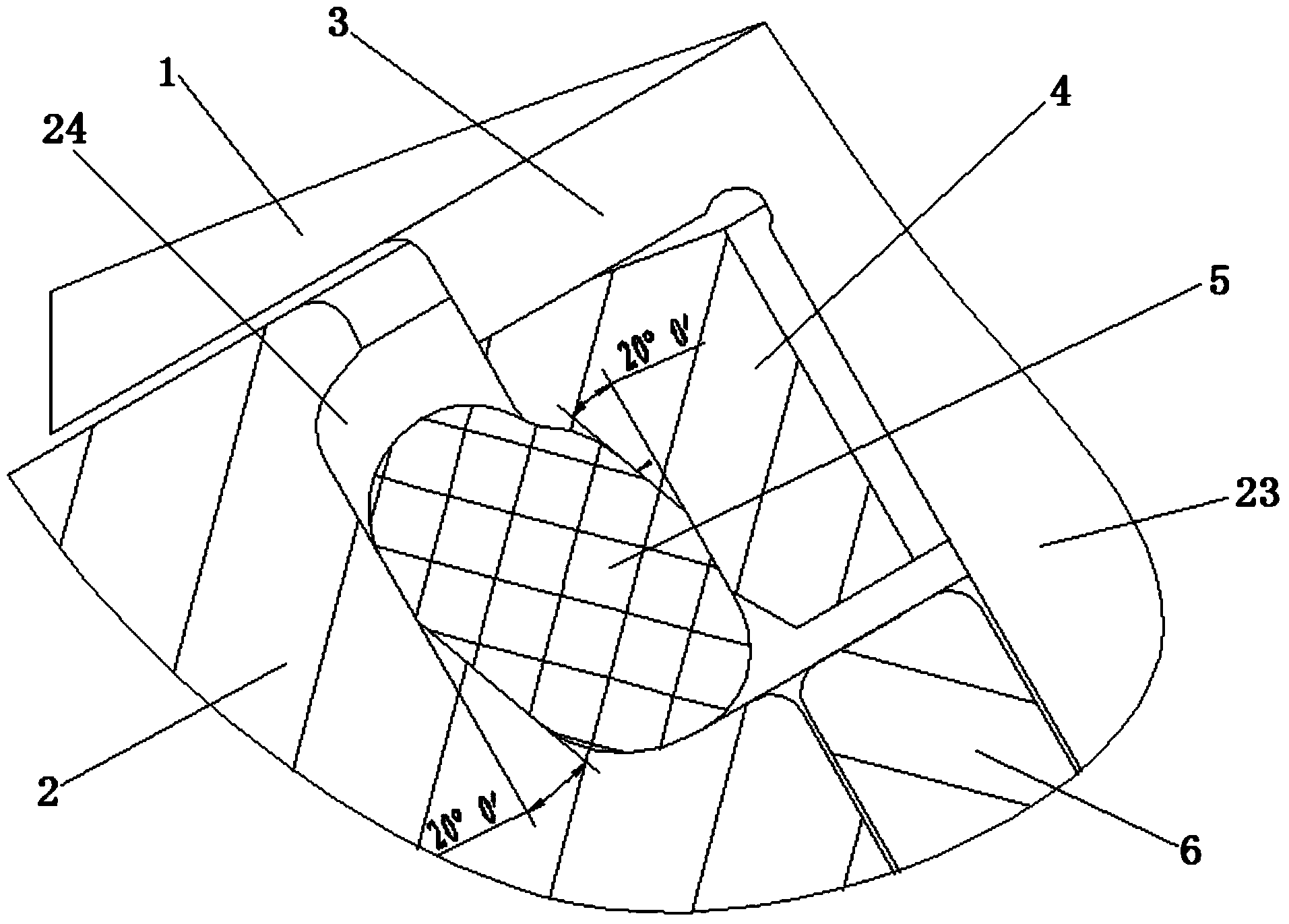

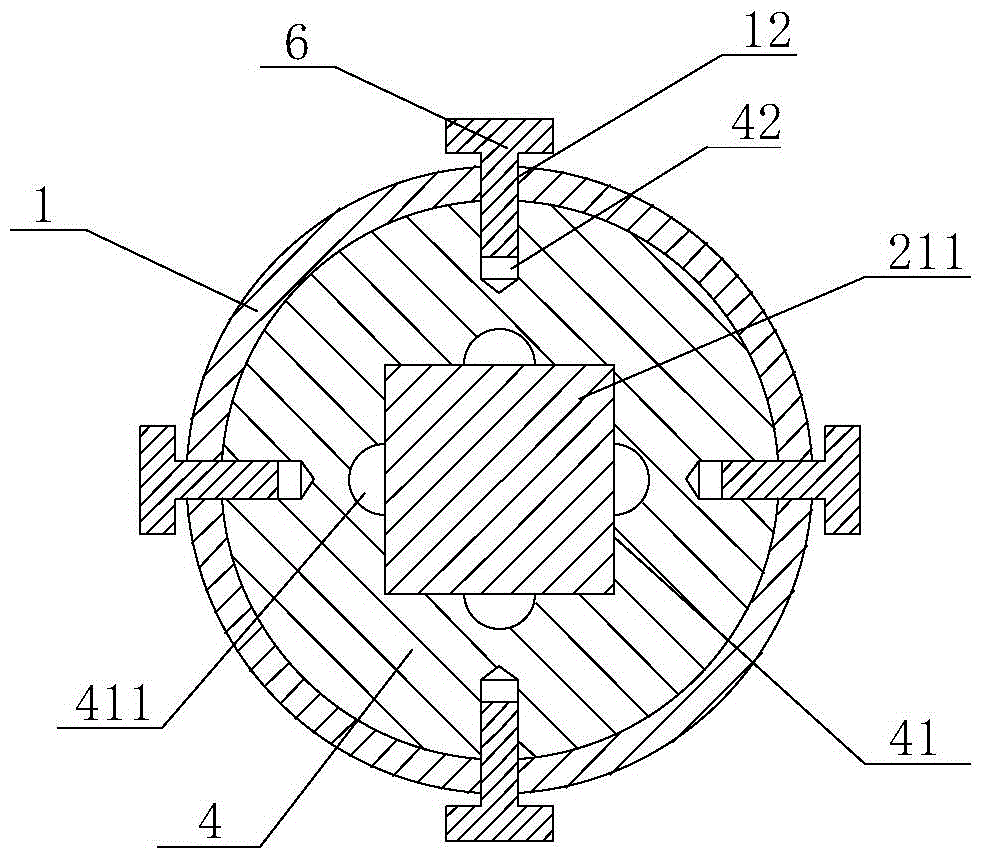

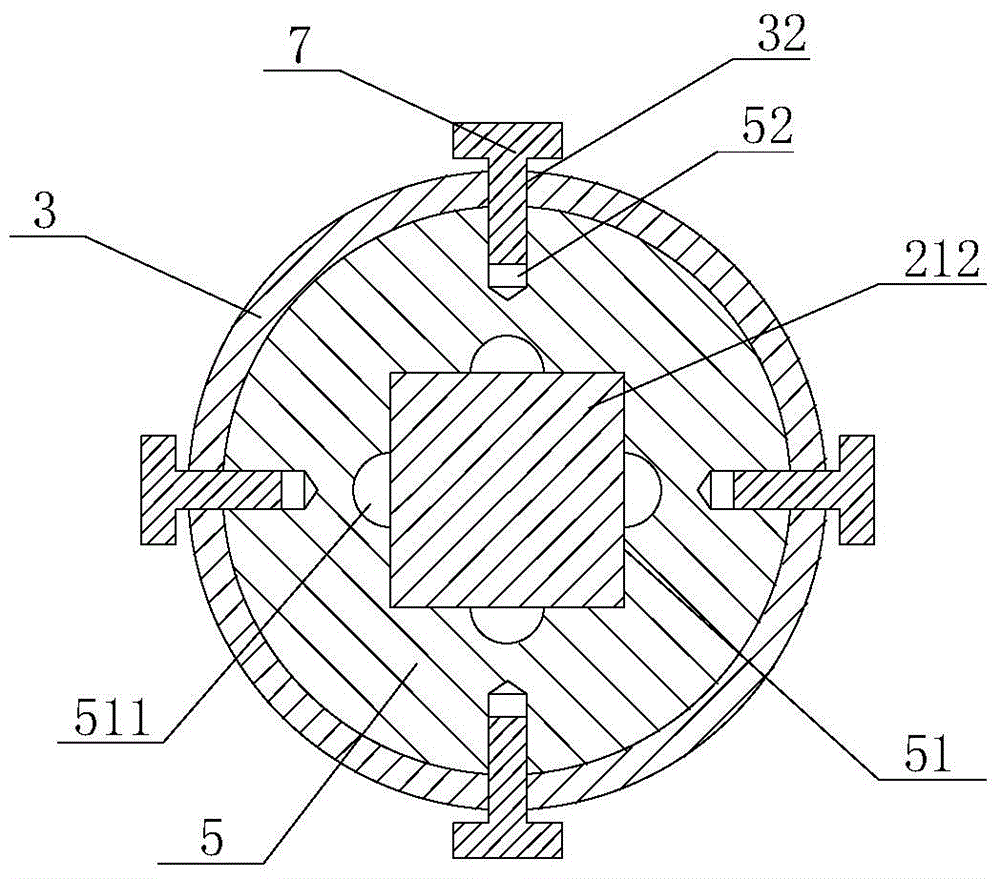

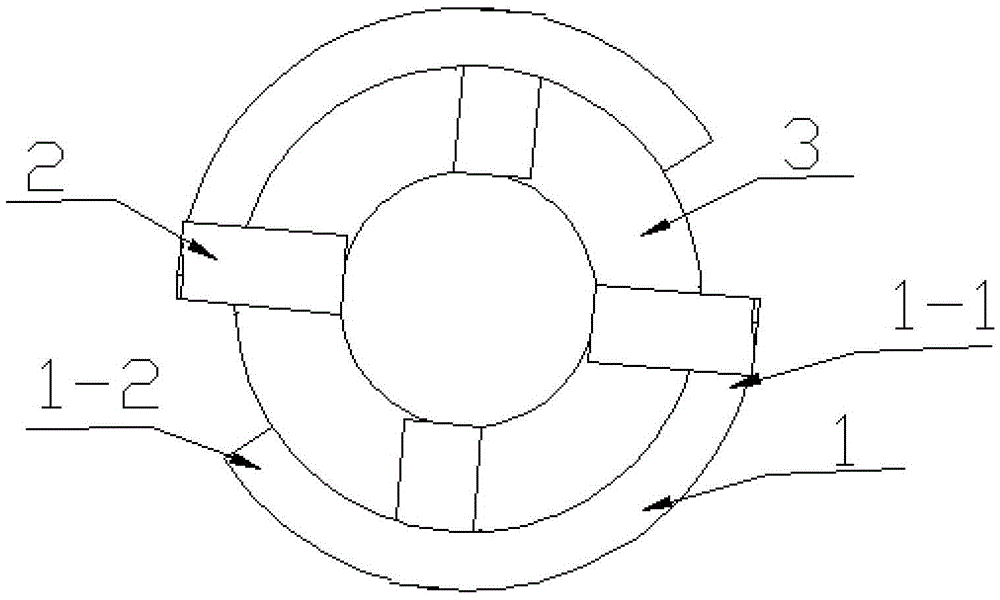

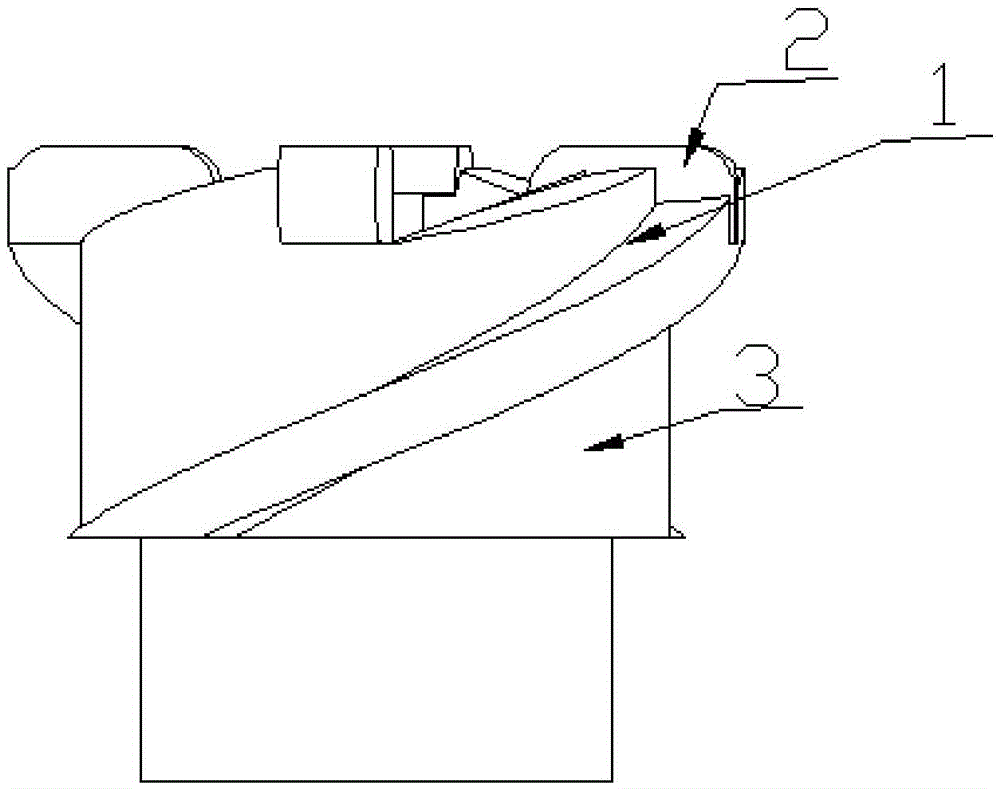

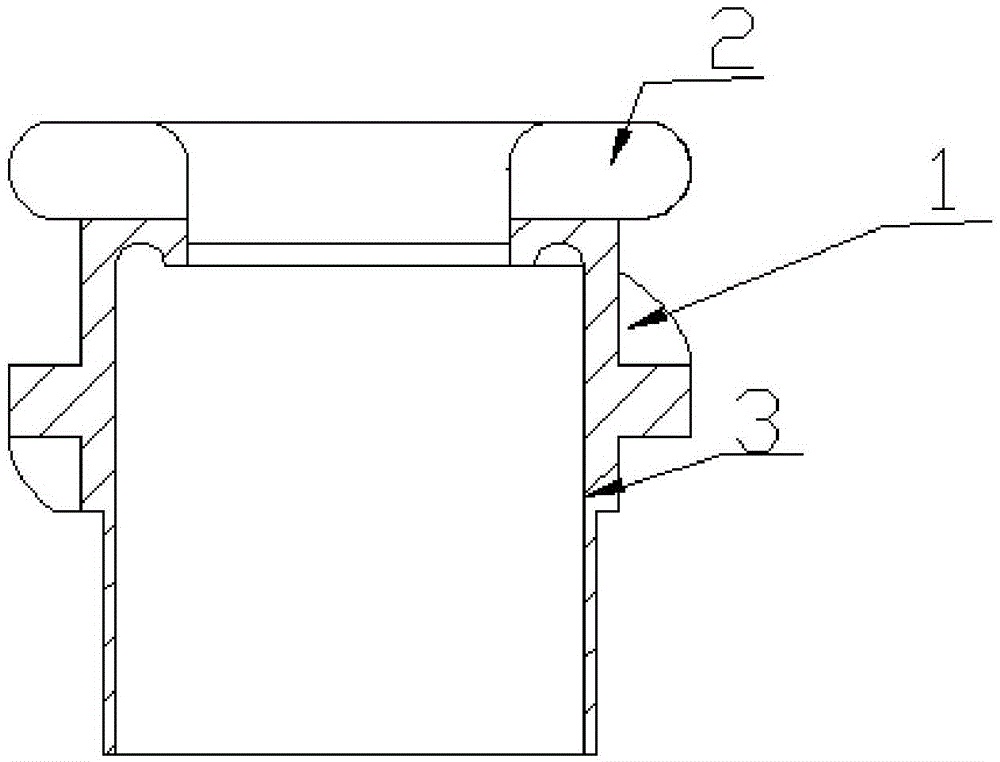

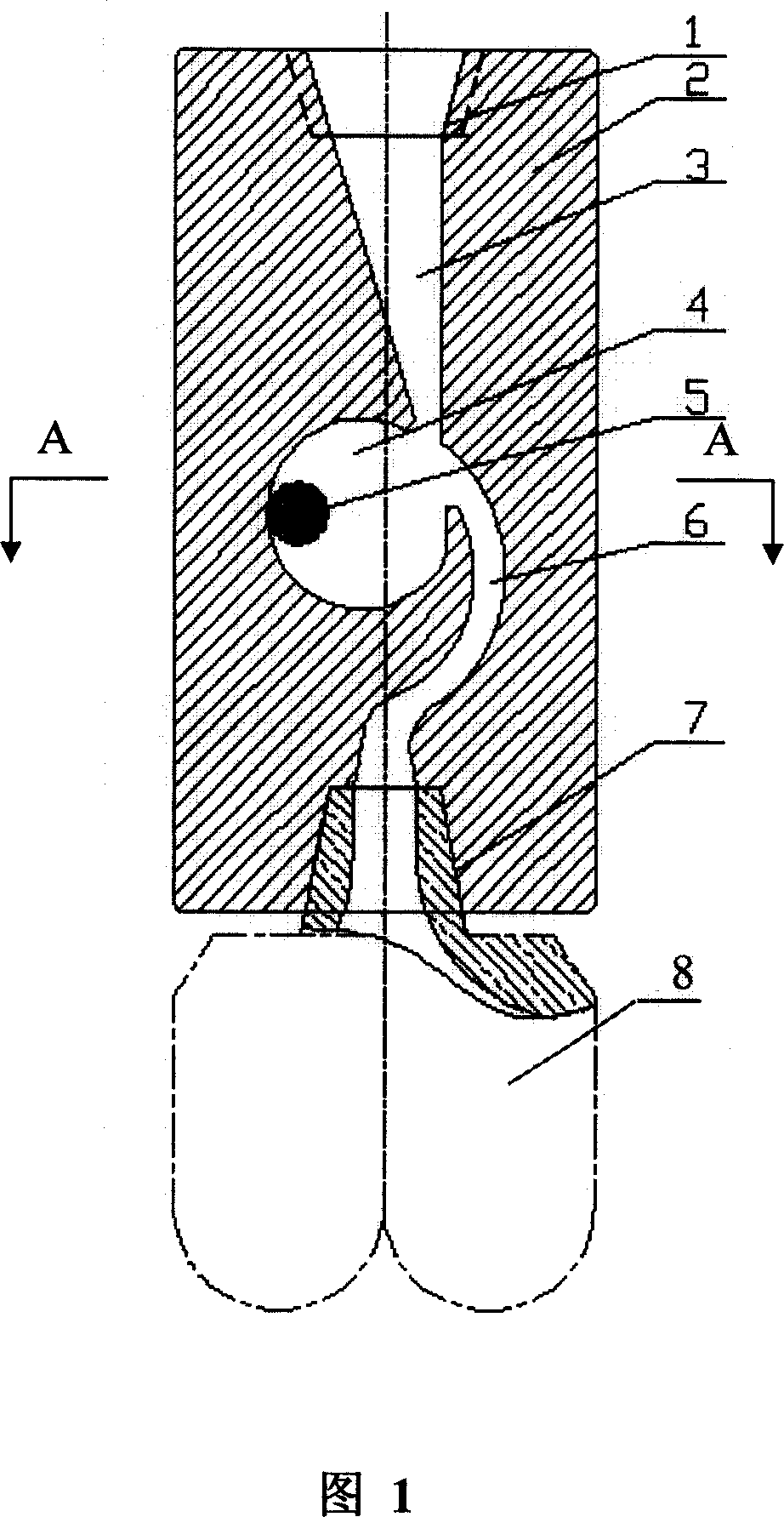

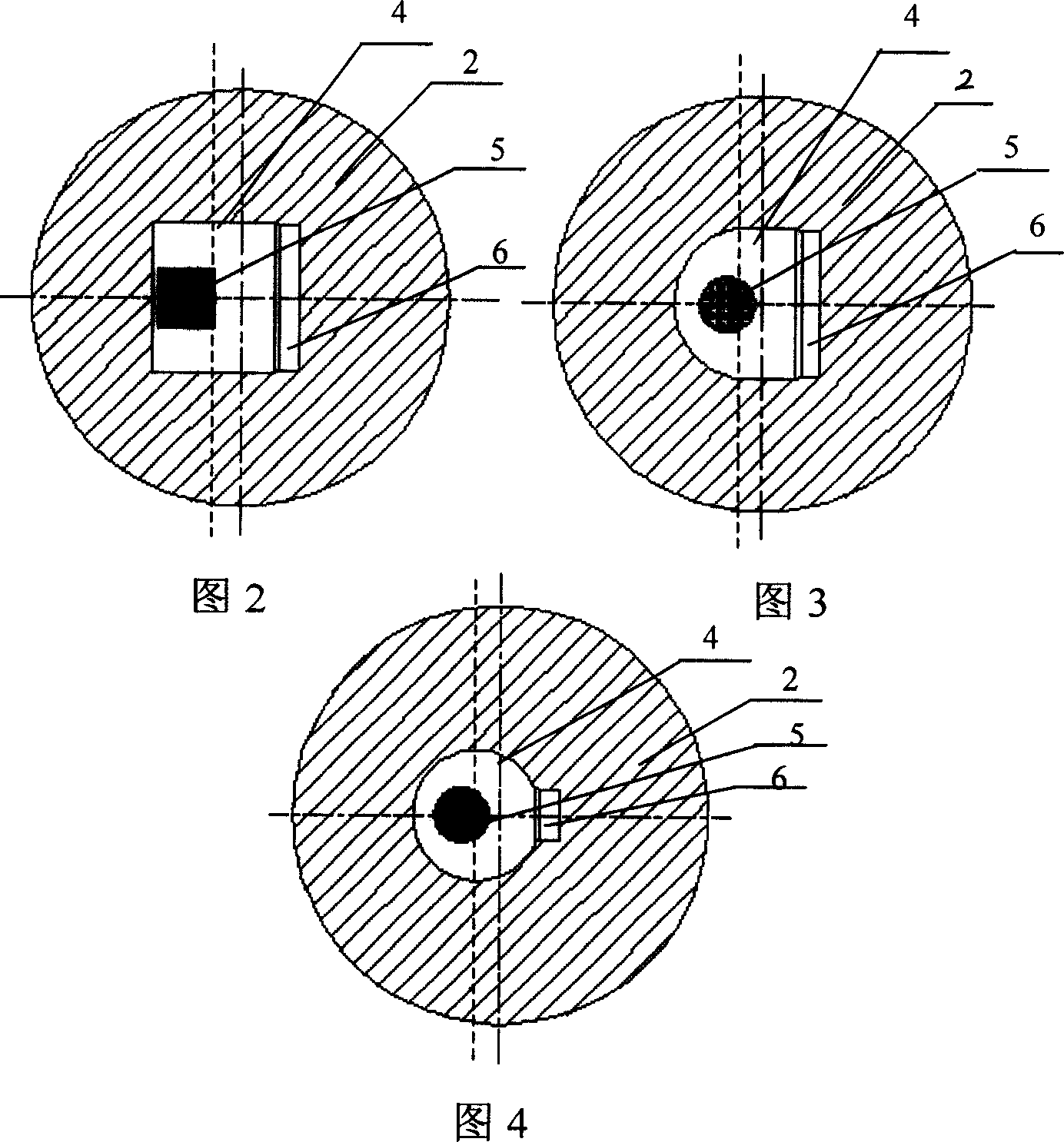

O-shaped loop and metal ring two-way combined sealed oil storage single-cone bit

ActiveCN103410448ASolve the sealing problemSolve the axial problemDrill bitsConstructionsUltra high speedAlloy

The invention discloses an O-shaped loop and metal ring two-way combined sealed oil storage single-cone bit. By means of the bit, two-way combined sealing of axial sealing of the end face of a cone metal ring (4) and radial sealing of a cone O-shaped loop (5) under the condition of ultra high speed rotation is achieved, a floating sleeve bearing communicated with an oil storage sac (7) is used, and PDC teeth and hard alloy teeth are inserted in a cone (2) and a body (1) directed at action zone differences, so that the comprehensive well bottom rock breakage efficiency is improved, the bit gauge protection effect is enhanced, the bit operation stability is improved, the drilling period is shortened, and the drilling cost is reduced.

Owner:陕西金刚石油机械有限公司

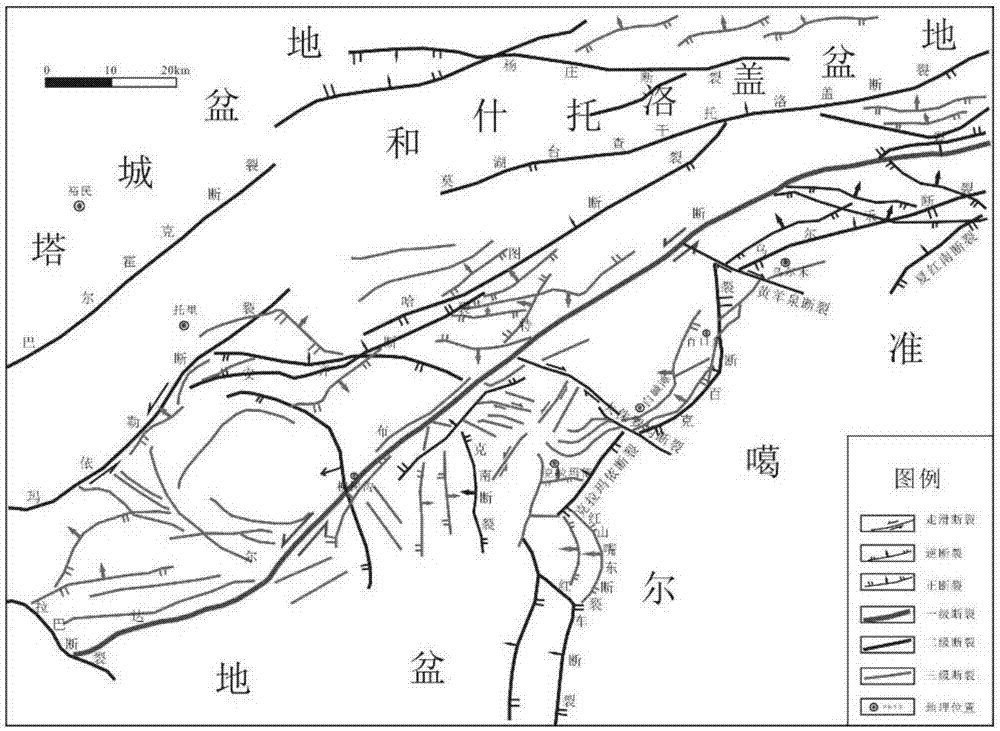

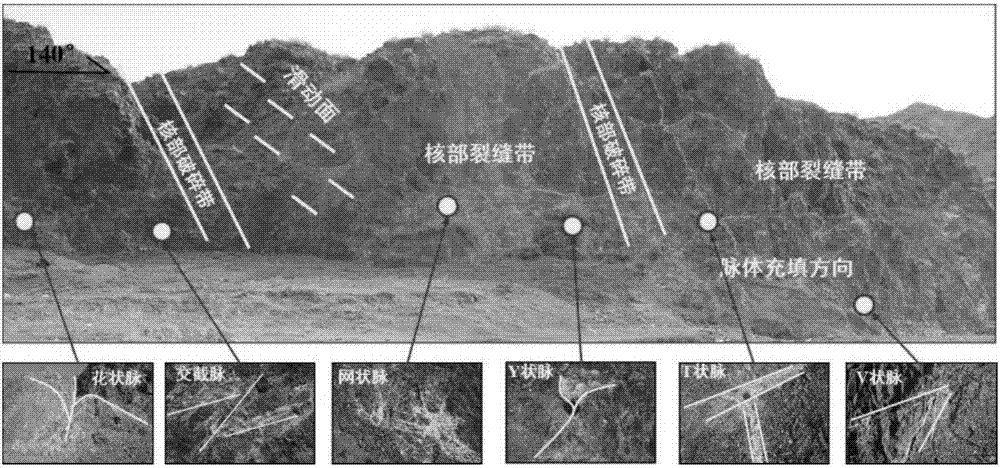

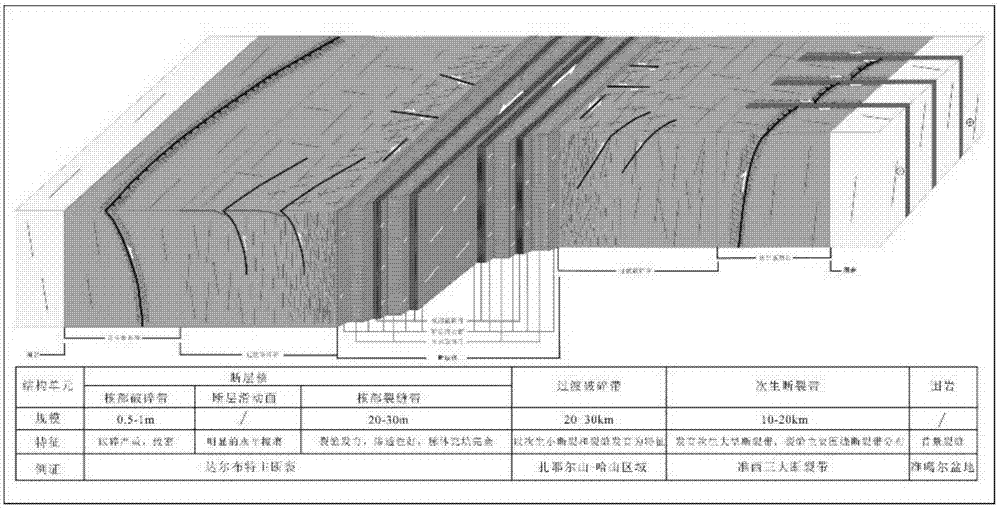

Hydrocarbon accumulation analysis method based on fracture structure

ActiveCN107390289ARich oil and gas accumulation theoryGuide explorationGeological measurementsOutcropFracture zone

The invention provides a hydrocarbon accumulation analysis method based on a fracture structure and relates to the hydrocarbon accumulation field. Oil-gas exploration can be effectively guided. The method comprises the following steps of selecting fractures of different levels, observing an internal structure characteristic, and according to a fractured zone rock breakage degree, dividing into two structure unit layers of a fracture zone and a crack zone; taking samples of the fracture zone and the crack zone to carry out field outcrop observation and microscope observation, and according to a condition that permeability of a fluid containing an oil gas is increased along with development of a crack, depicting a moving track of the fluid containing the oil gas in the above two structure unit layers; taking cements of the fluids containing the oil gas in different structure unit layers, through homogeneous temperature analysis of an inclusion, strontium isotope analysis and in-situ microelement analysis, determining a source and a phase of the fluid containing the oil gas; and through division of the above structure unit layers, the moving track of the fluid containing the oil gas, and the source and the phase of the fluid containing the oil gas, drawing a hydrocarbon accumulation mode pattern. Through the hydrocarbon accumulation mode pattern, hydrocarbon accumulation effect analysis is performed.

Owner:NANJING UNIV

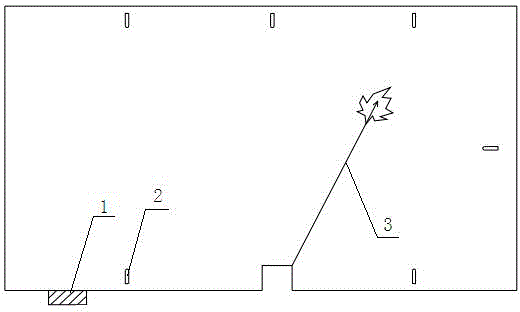

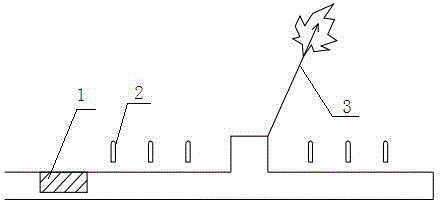

Hydrofracture secondary sound wave analogy method and fracturing fracture monitoring technology evaluation method

ActiveCN103091728AOptimize layoutImprove the transformation effectGeological measurementsEngineeringSound production

The invention discloses a hydrofracture secondary sound wave analogy method and a fracturing fracture monitoring technology evaluation method. The hydrofracture secondary sound wave analogy method and the fracturing fracture monitoring technology evaluation method can achieve effective evaluation to microseism monitoring technology and contribute to improvement of effects of a horizontal well multistage staged fracture. According to the hydrofracture secondary sound wave analogy method, at least two sound wave emission devices are arranged in a well which has know spatial locations, ground controls working parameters of the sound wave emission devices to simulate secondary sound wave characteristics created by rock fracture in the process of hydrofracture, spatial locations, sound production time, sound production orders and other parameters of the transmitted sound wave emission devices are assured and recorded, at the same time, an evaluated fracturing fracture monitoring technology is used for detecting the simulated secondary sound wave characteristics, locations and various transmitting information of the sound wave emission device are sought, sound wave information and explanation results received by the fracturing fracture monitoring technology are compared with known stimulated transmitting parameters, and accuracy and reliability of the monitoring technology are detected and evaluated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep hole blasting charging method for passing through solution cavity and solution cavity detecting device

The invention discloses a deep hole blasting charging method for passing through a solution cavity and a solution cavity detecting device. A deep hole comprises an upper blast hole section and a lowerblast hole section. A middle solution cavity exists between the upper blast hole section and the lower blast hole section, and the position and depth of the middle solution cavity are obtained through detection. In the upper blast hole section, a hole opening blocking section, upper section explosives and a solution cavity upper section blocking section are sequentially arranged from a hole opening to the hole bottom. In the lower blast hole section, the lower half section is filled with lower section explosives, and the upper half section is the solution lower section blocking section and blocks a hole opening of the lower blast hole section. A detonating cord communicates between the upper section explosives and the lower section explosives. According to the deep hole blasting chargingmethod, the blocking structure close to the middle solution cavity is utilized for carrying out delaying explosion to cause gas expansion, gas is extruded into the solution cavity to fill the solutioncavity after the upper section explosives and the lower section explosives are exploded, explosive energy leakage is effectively avoided, and the rock breakage effect is improved; and the remarkableadvantages of being convenient to construct, environment-friendly, efficient and economical are achieved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

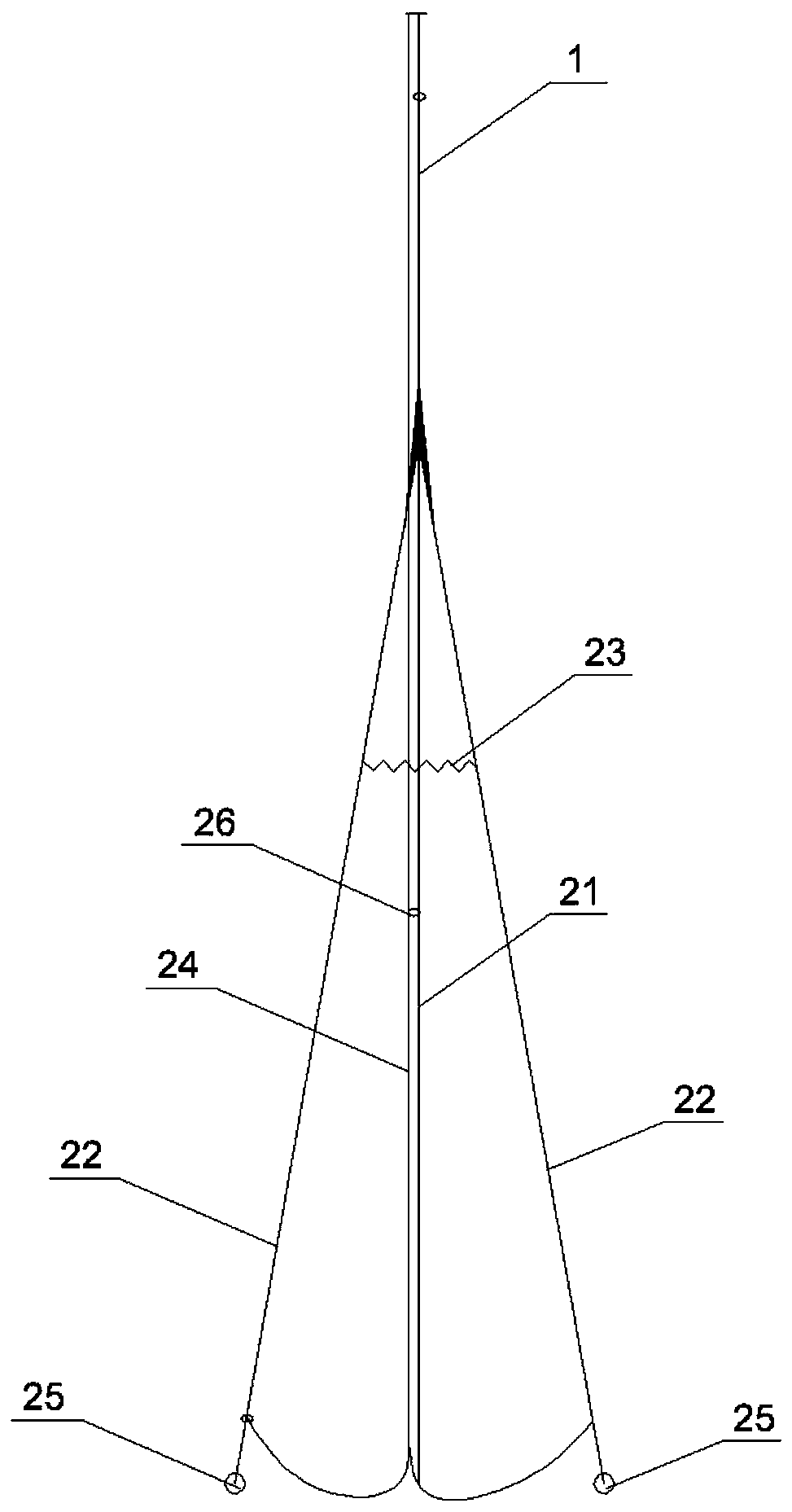

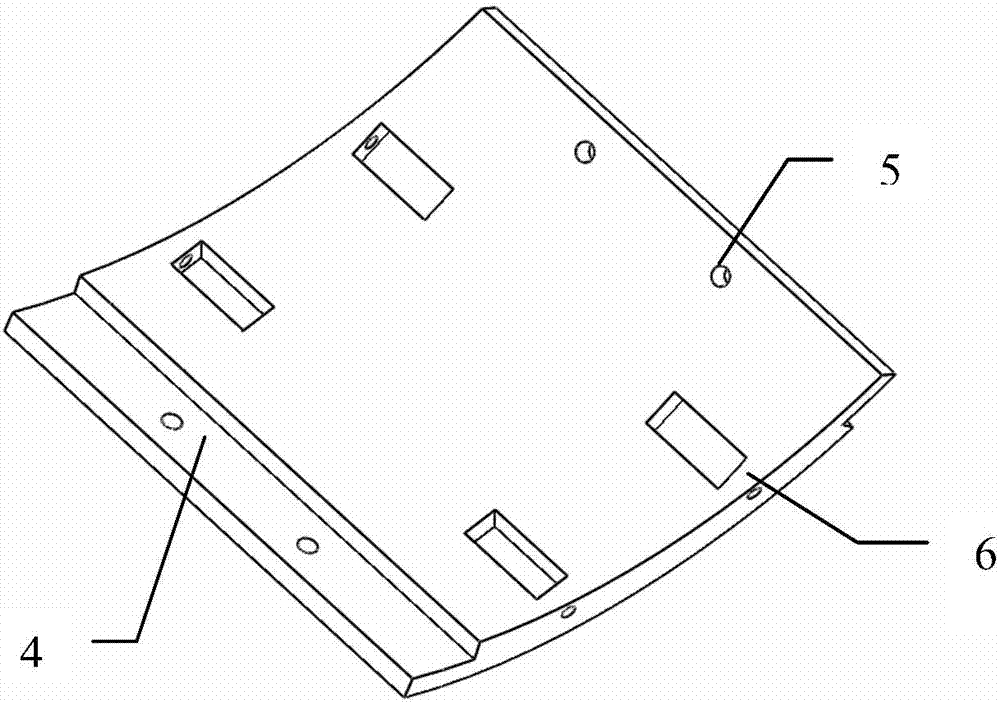

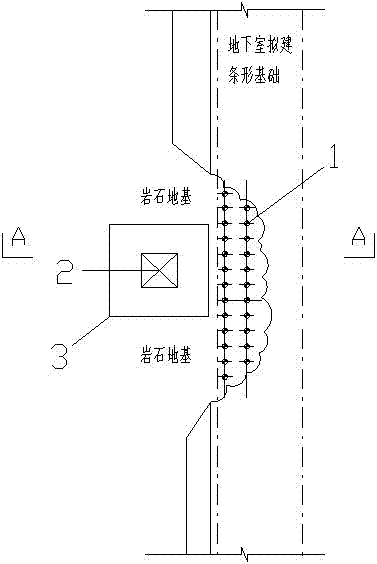

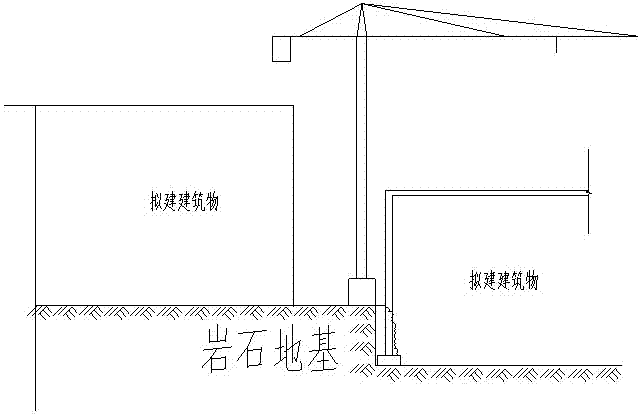

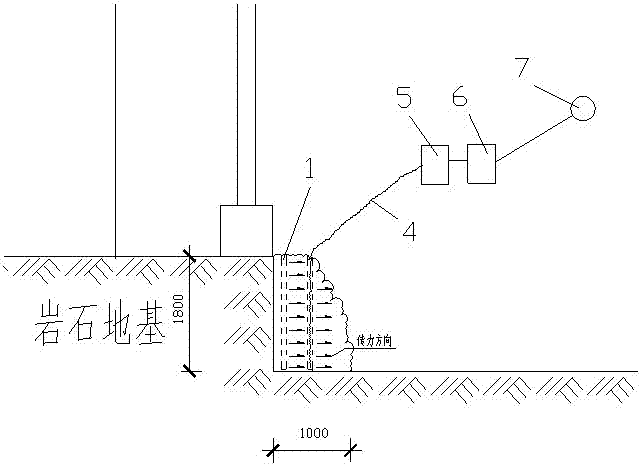

Large-aperture static breaking agent oriented rock breakage and spraying hole prevention integrated device and construction method thereof

PendingCN109489513ASolve Orifice ProblemsWide range of time and spaceBlastingRock breakageWater pipe

The invention discloses a large-aperture static breaking agent oriented rock breakage and spraying hole prevention integrated device and a construction method thereof. The device comprises a sleeve, alower blockage head, an upper blockage head and a water injecting pipe; the lower blockage head is fixedly arranged at the lower part in the sleeve; two oriented breakage gaps are formed in the wallof the sleeve from top to bottom in the axial direction, and are symmetrically arranged about the center line of the sleeve; the upper blockage head is coaxially assembled in an upper port of the sleeve; a static breaking agent filling cavity is formed between the upper blockage head and the lower blockage head in the sleeve; the upper blockage head is provided with a guide hole penetrating up anddown in the center line direction; the water injecting pipe is inserted in the guide hole; and the lower end of the water injecting pipe extends into the static breaking agent filling cavity. The device is simple in structure, convenient to manufacture and install, capable of being recycled and low in construction cost, can achieve such functions as efficient rock breakage by a static breaking agent, oriented rock breakage and spraying hole prevention, and effectively relieves the constraints of the aperture and the construction environment temperature on the rock breaking effect by the static breaking agent.

Owner:LULIANG UNIV

Moveable type mechanical seal filling exploitation bracket

InactiveCN102400700ALabor savingLow costMaterial fill-upMine roof supportsHydraulic cylinderEngineering

The invention belongs to the field of coal exploitation filling, is applicable to filling of high-water materials and in particular relates to a moveable type mechanical seal filling exploitation bracket. The moveable type mechanical seal filling exploitation bracket comprises a hydraulic bracket, wherein the rear red of the hydraulic bracket is connected with a vertical retaining wall of a hard plate through a transverse beam; an upper flexible sealing block and a lower flexible sealing block are arranged between the vertical retaining wall and the hydraulic bracket; two sides of each flexible sealing block are contacted with the vertical retaining wall and the hydraulic bracket; a double-head hydraulic oil cylinder is arranged between the two flexible sealing blocks; and two piston rods of the double-head hydraulic oil cylinder are connected with the two flexible sealing blocks. In the device, the vertical retaining wall at the rear end of the hydraulic bracket is used as a filling retaining wall, so the labor force (for building the retaining wall or a hanging bag) in the traditional filling process is saved, cost is low and filling efficiency is high. Displacement of the upper flexible sealing block and the lower flexible sealing block is adjusted by the hydraulic oil cylinder, so the flexible sealing blocks are tightly contacted with a top plate and a bottom plate, and filling sealability is guaranteed. Surrounding rock breakage and surface subsidence are controlled well in the mode of exploiting and filling at the same time.

Owner:ZIBO WANGZHUANG COAL MINE

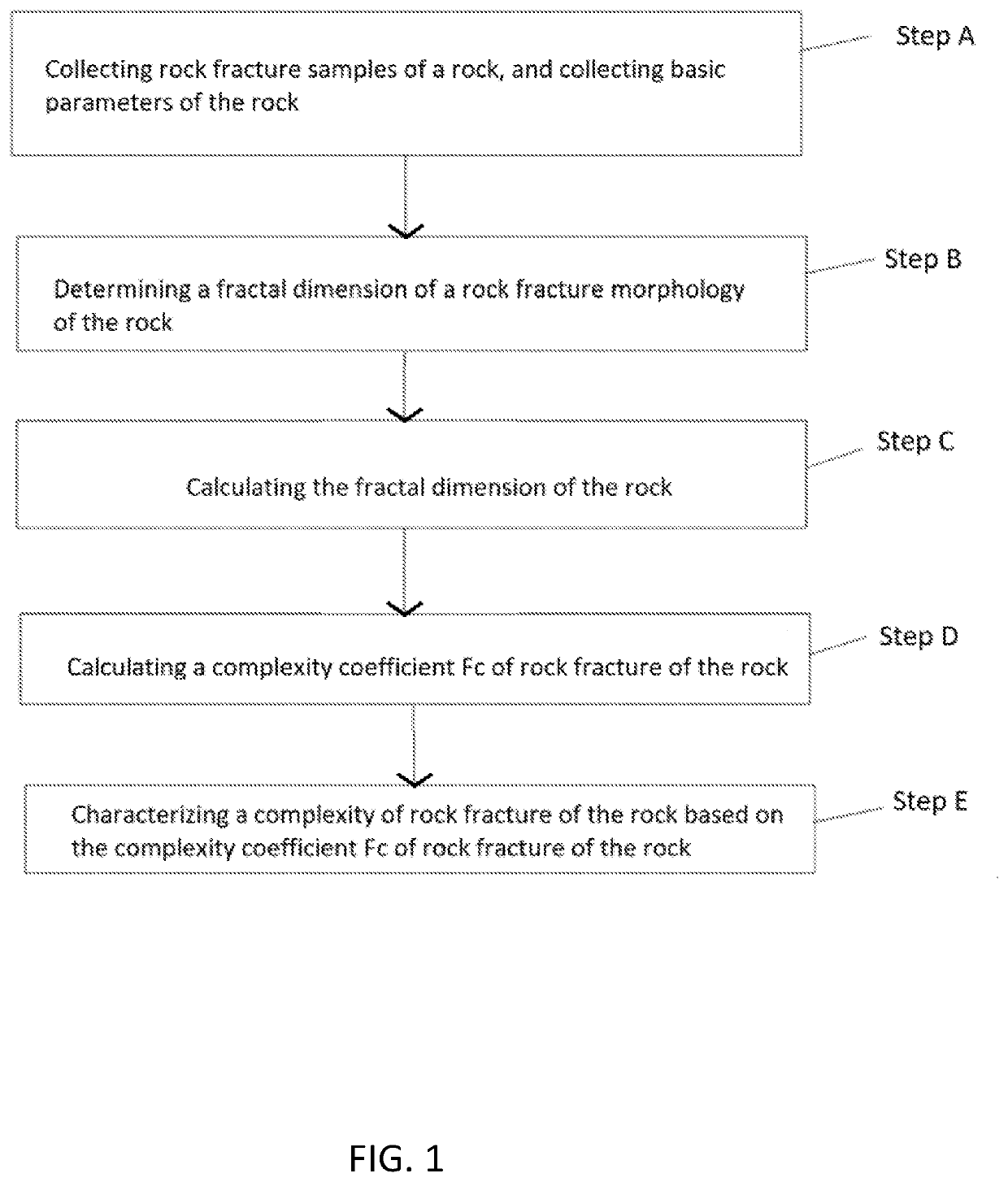

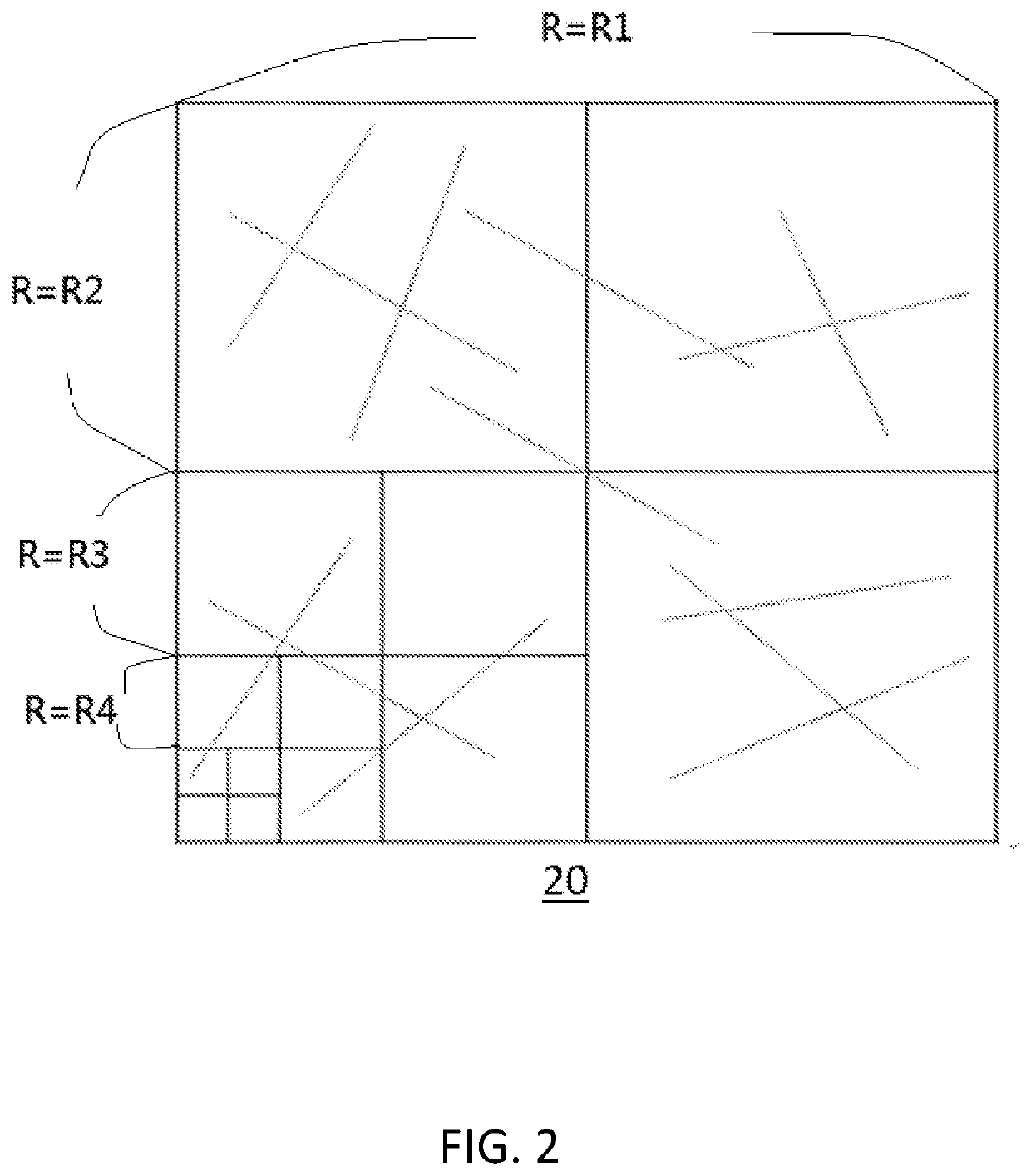

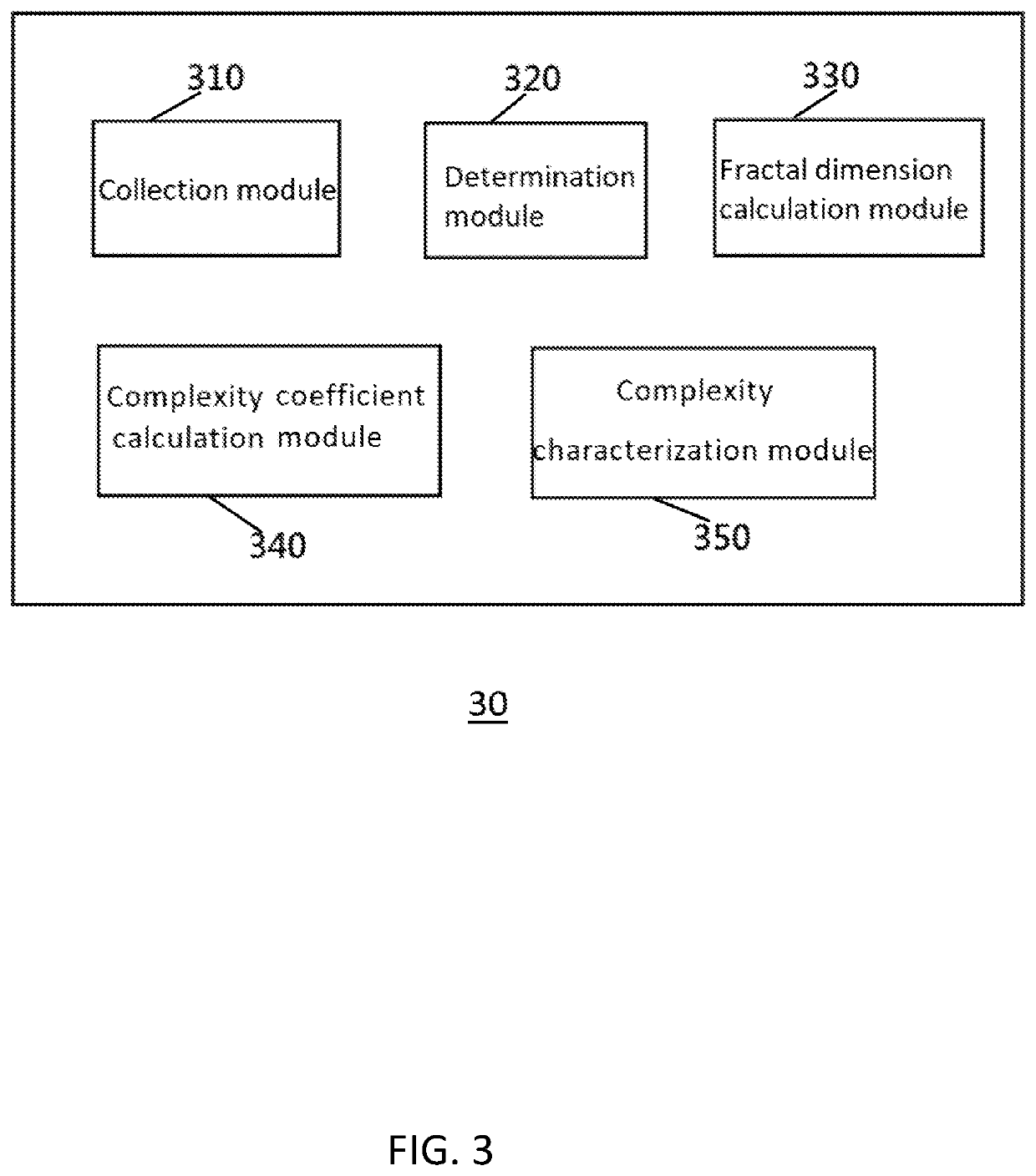

Method for characterizing complexity of rock fracture based on fractal dimension and device thereof

ActiveUS20200240251A1Accurate representationEarth material testingFluid removalRock breakageGeophysics

Owner:SOUTHWEST PETROLEUM UNIV

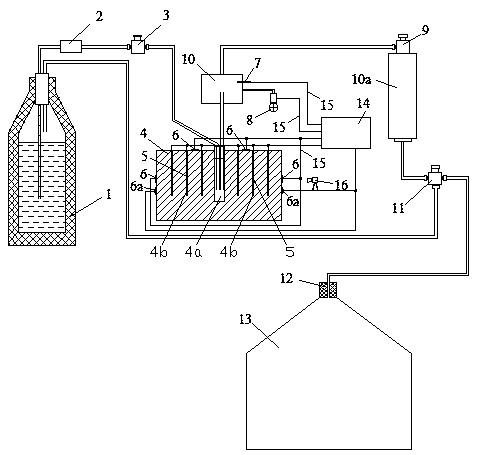

Experimental device for rock fracture under action of liquid nitrogen cold shock

PendingCN107741372ARealize real-time monitoringStrength propertiesLiquid nitrogen coolingHydraulic equipment

The invention discloses an experimental device for rock fracture under the action of liquid nitrogen cold shock, and belongs to the technical field of mechanical rock tests. The experimental device adopts the structure as follows: a liquid nitrogen cooling hole is formed in the central position of a rock sample; a plurality of temperature sensor holes are formed in the periphery of the liquid nitrogen cooling hole; rock sample temperature sensors are mounted inside the temperature sensor holes; a plurality of strain gauges and a plurality of sound transmitting and collecting units are arrangedon the surface of the rock sample; a Dewar flask is sequentially connected with hydraulic equipment, a first valve and the liquid nitrogen cooling hole in the rock sample through pipes; the liquid nitrogen cooling hole is sequentially connected with a first pressure reducer, a second valve, a second pressure reducer and a gas-liquid separator through pipes; a liquid-phase way of the gas-liquid separator is connected with the Dewar flask through a pipe, and a gas-phase way of the gas-liquid separator is connected with a gas collector with a sealing plug through a pipe. The experimental devicecan achieve a rock fracture process experiment under the action of low-temperature liquid cold shock, can measure the variation and the distribution of the temperature of the rock sample in a liquid nitrogen cooling environment, and can achieve real-time monitoring on rock destruction in a continuous low-temperature environment.

Owner:DALIAN UNIV OF TECH

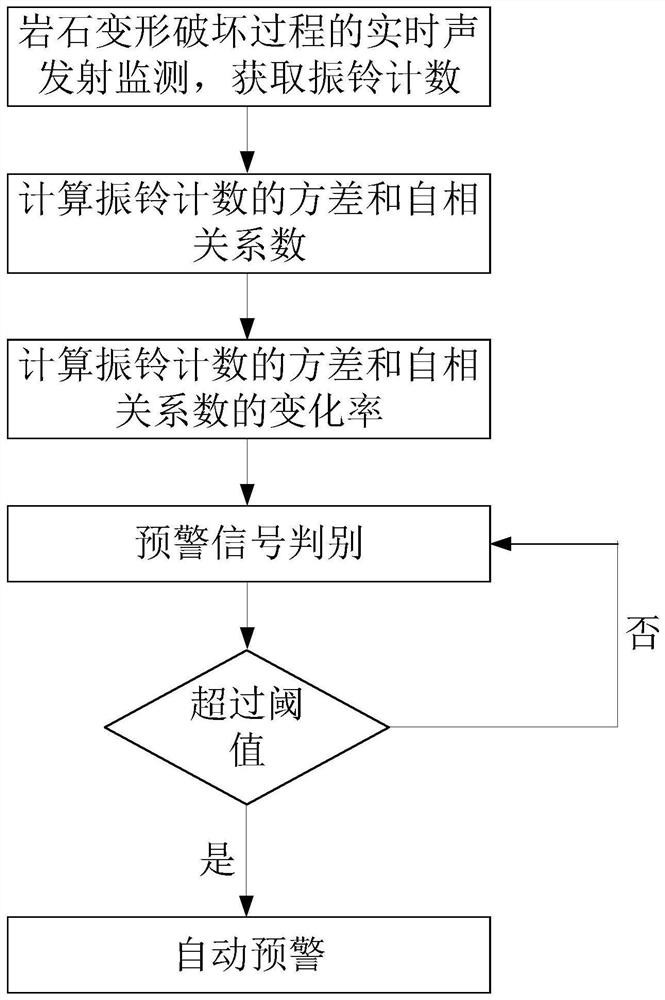

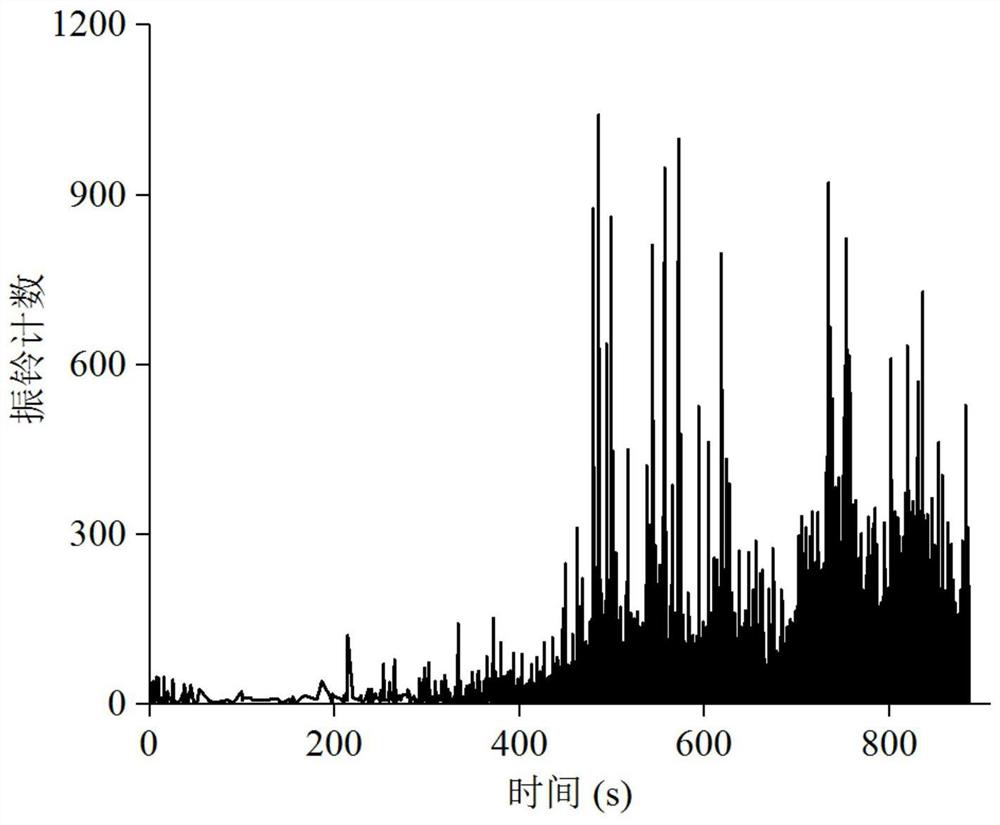

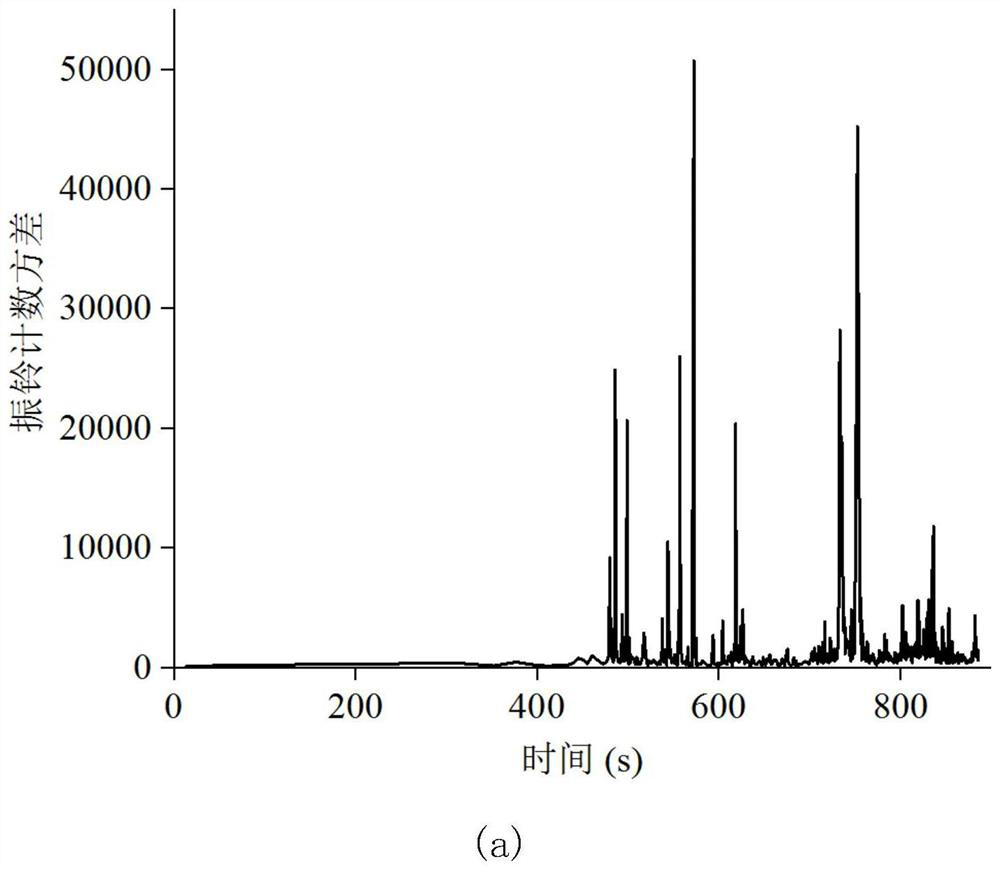

Rock fracture early warning method based on acoustic emission signal statistical analysis

ActiveCN112444564AEnsure objectivityGuaranteed accuracyMaterial analysis using acoustic emission techniquesProcessing detected response signalSoil scienceMineral Sources

The invention discloses a rock fracture early warning method based on acoustic emission signal statistical analysis, and belongs to the field of rock mechanics and geotechnical engineering. Firstly, real-time acoustic emission monitoring is carried out on the rock deformation and damage process, and ringing counts are recorded and obtained; secondly, the characteristic statistics, including variance and autocorrelation coefficient,of ringing counts is calculated through a formula, and the variance of ringing counts and the change rate of autocorrelation coefficient are calculated; and finally,early warning signal discrimination is carried out according to the variance of ringing counts and the change rate of the autocorrelation coefficient. When the change rate is greater than the threshold, the system automatically gives an alarm to indicate that the rock is about to crack. If the change rate does not exceed the threshold, monitoring and judging are continuous. According to the earlywarning method, early warning signal points are easy to identify and stable in calculation, and objectivity and accuracy of the early warning method can be ensured; the calculation process is simpleand convenient to operate; real-time tracking and early warning can be achieved, and the method can be widely applied to rock damage early warning in the engineering fields of water conservancy and hydropower, transportation, mineral resource exploitation, underground space development and the like.

Owner:DALIAN UNIV OF TECH

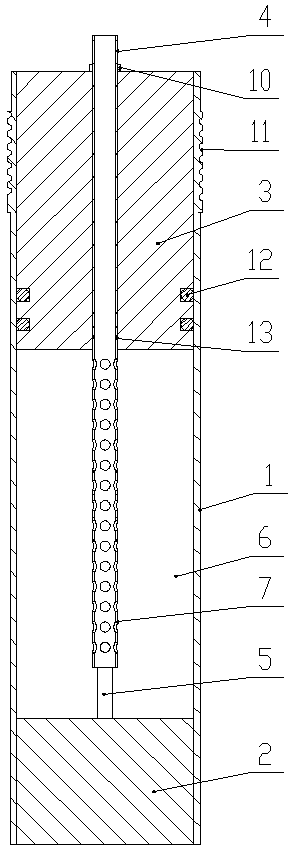

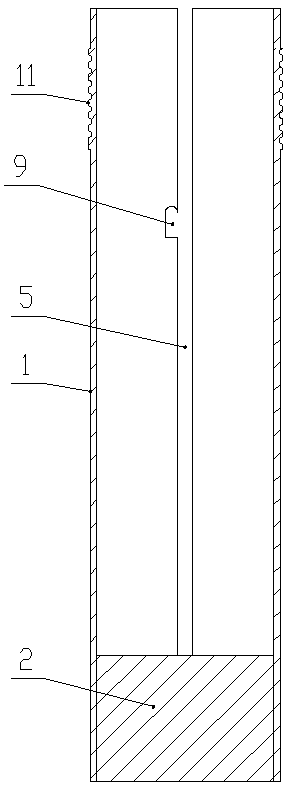

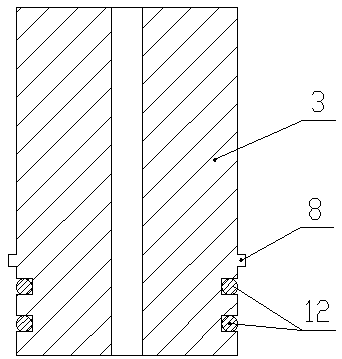

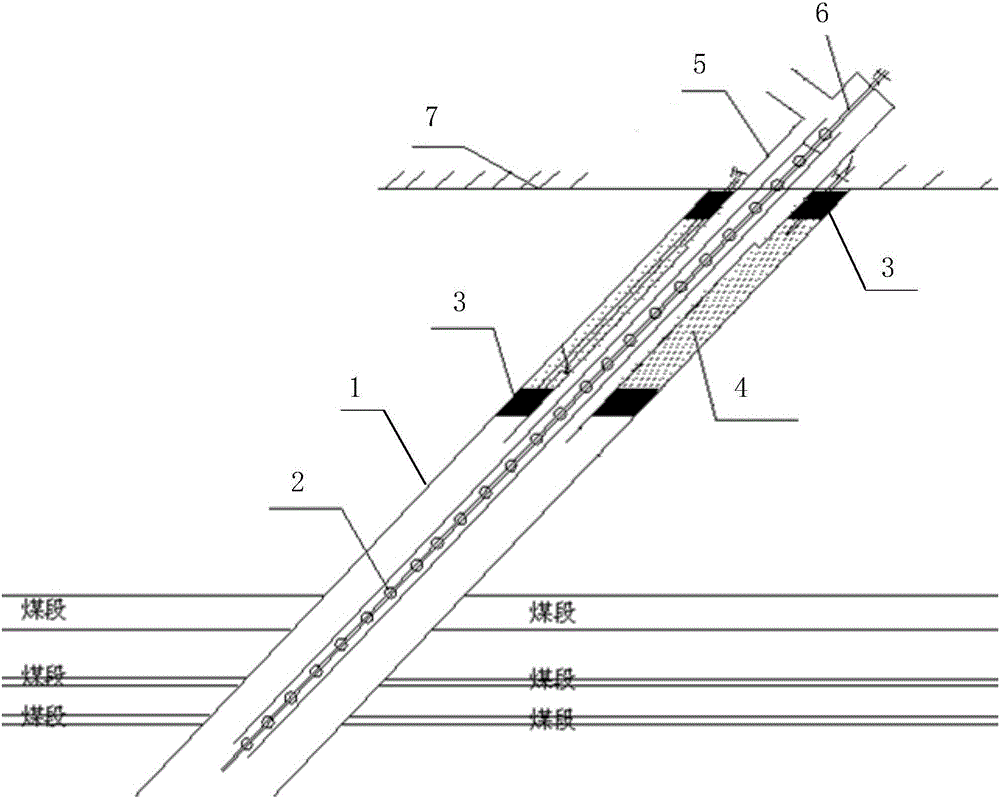

Deep-level and high-ground-stress coal uncovering and drilling construction device and method

InactiveCN106437522AImprove construction efficiencyImprove the pumping effectDrilling machines and methodsDeep levelRock breakage

The invention belongs to the technical field of coal mine safety production and construction and particularly relates to a deep-level and high-ground-stress coal uncovering and drilling construction device and method. The device comprises a drill bit, wherein a through hole is formed in the center of the drill bit, a movable door capable of opening or closing a front-end hole opening of the through hole is arranged at the front end of the drill bit, the rear end of the drill bit is connected with a drill machine through a hollow drill rod, a central hole of the drill rod is communicated with the through hole of the drill bit to form a channel for a casing to penetrate through. The deep-level and high-ground-stress coal uncovering and drilling construction device utilizes a whole-process casing hole-protecting process, a casing is put down in place before the drill rod is pulled out, drill hole collapse caused by rock breakage is very well prevented, and the construction efficiency of pumping and drainage drilling and a pumping and drainage effect are greatly improved.

Owner:HUAINAN MINING IND GRP

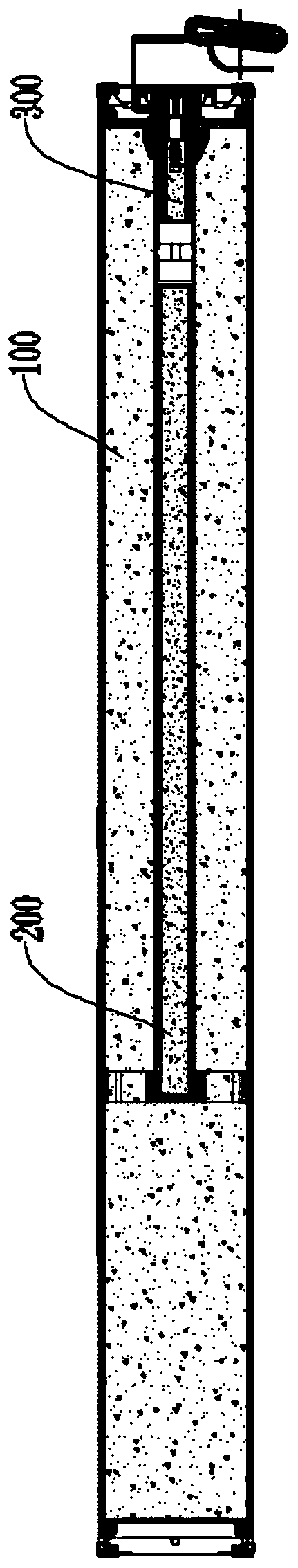

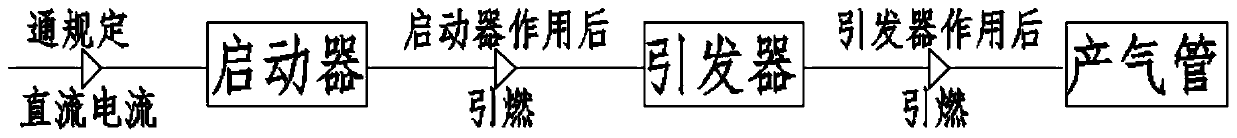

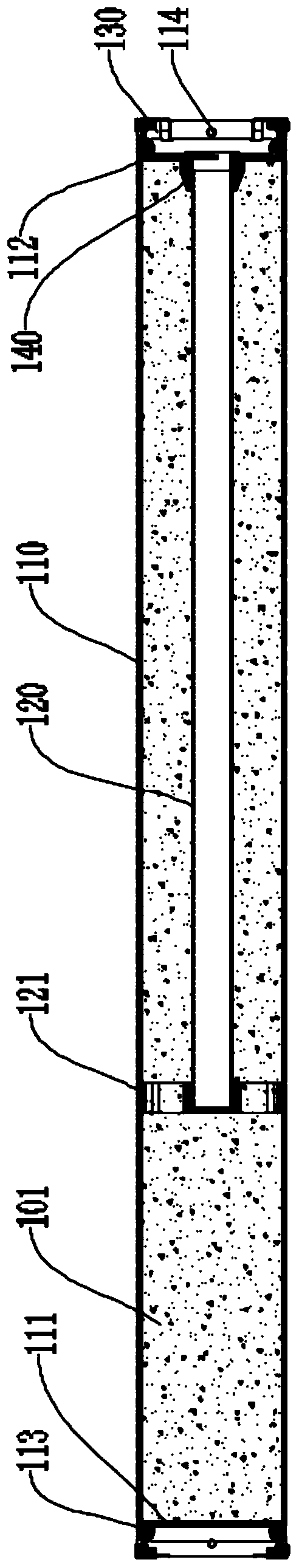

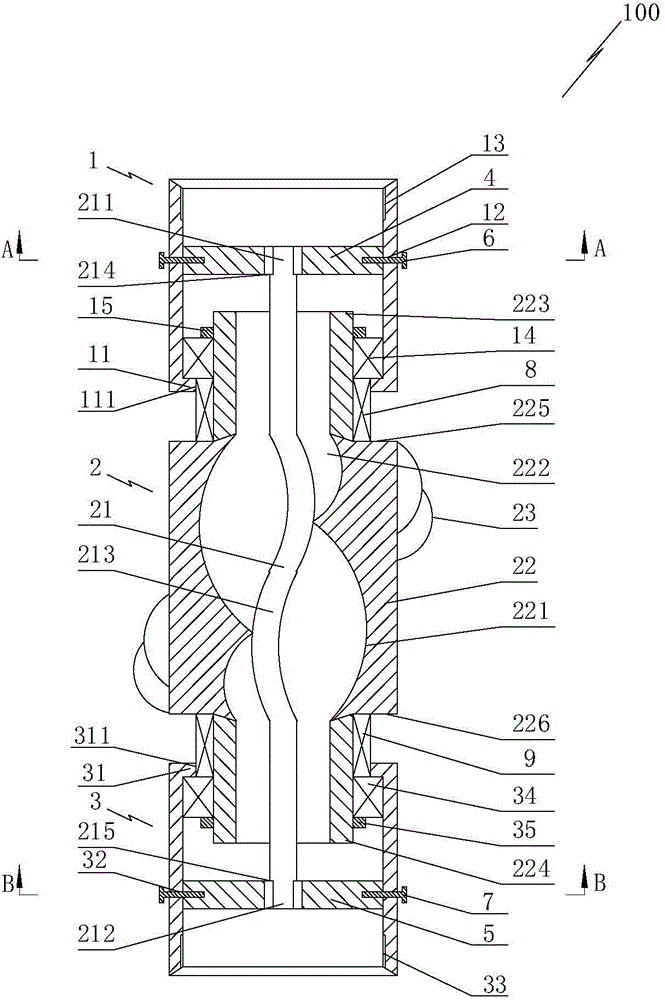

Rock breakage gas generator and gas generating agent rock breaking method

ActiveCN109813184AImprove securitySimple construction workBlasting cartridgesBlastingPower flowEngineering

The invention provides a rock breakage gas generator and a gas rock breaking method. The rock breakage gas generator comprises a gas generation pipe, a trigger device and a starter independently dismounted; the starter comprises a start pipe, a start head and an electric conducting lead; the start pipe is filled with a first gas generating agent; and direct-current starting current generated by anexternal electric exploder is started by the electric conducting lead to ignite the first gas generating agent. The trigger device is filled with a second gas generating agent, which is ignited by energy generated by the first gas generating agent; and the gas generation pipe comprises an outer cylinder, and an inner cylinder supported inside. The trigger device is positioned in the inner cylinder; and the starter at least partially extends into the inner cylinder. The gas generation pipe is filled with a third gas generating agent, which is ignited by energy generated by the second gas generating agent. Shell materials of the gas generation pipe, the trigger device and the starter all adopt low-mass paper pipe bodies or plastic pipe bodies for holding; and the gas generating agents inside are located in a non-pressure constraint state, so that the safety is high. The construction operation is simple and feasible, free of the lowest-pressure limitation and high in efficiency, and automatically adapts to the strength of construction objects.

Owner:SANMING COFFER FINE CHEM IND

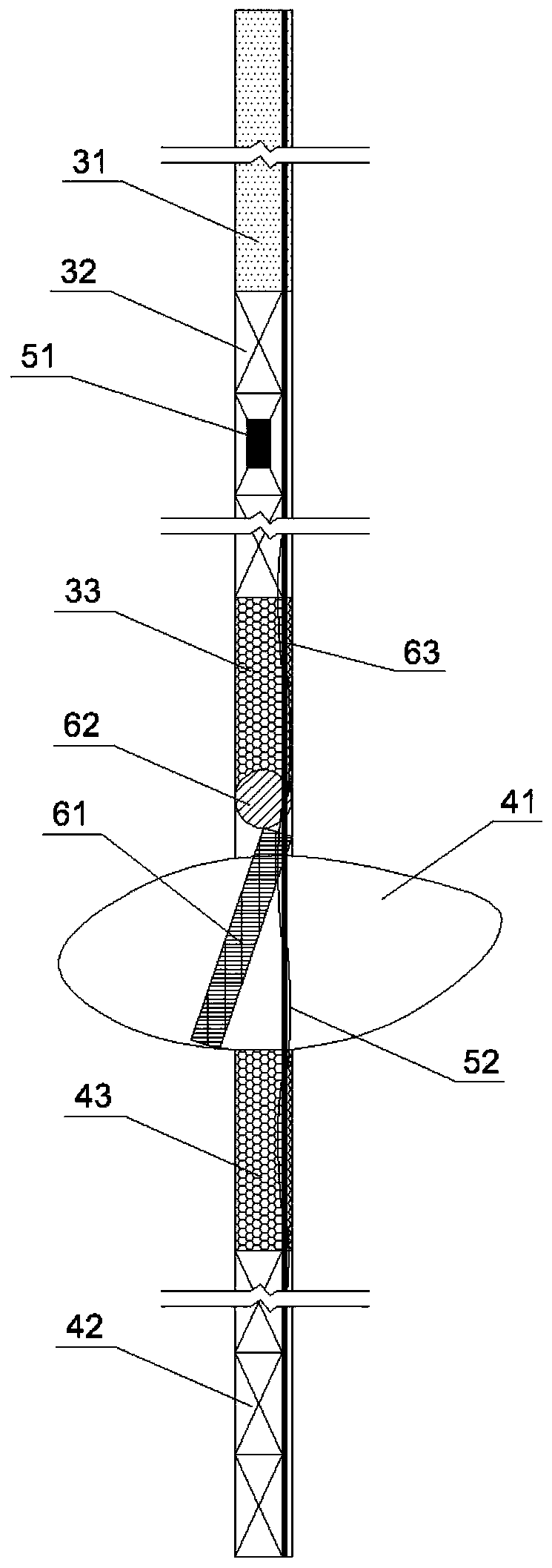

Near-bit local pressure reduction short joint

ActiveCN104481433AReduce local pressureReduce differential pressureDrilling rodsFlushingWell drillingSpiral blade

The invention provides a near-bit local pressure reduction short joint which sequentially comprises an upper connector, a spiral rising flow generator and a lower connector from top to down. A first torque transfer block is fixedly connected inside the upper connector, and a second torque transfer block is fixedly connected inside the lower connector. The spiral rising flow generator comprises a transmission mandrel, a rotary outer sleeve and spiral blades, wherein the upper end of the transmission mandrel penetrates through and is fixed to a first torque transfer through hole formed in the first torque transfer block, the lower end of the transmission mandrel penetrates through and is fixed to a second torque transfer through hole formed in the second torque transfer block. A spiral section is arranged in the middle of the transmission mandrel and is sleeved with the rotary outer sleeve, and a screwing hole is formed in the rotary outer sleeve. The spiral blades are arranged on the outer wall of the rotary outer sleeve. The near-bit local pressure reduction short joint effectively reduces well bottom pressure difference, reduces hold-down effect and rock breakage strength and improves well drilling speed. In addition, the near-bit local pressure reduction short joint is simple in structure, convenient to use, safe and reliable.

Owner:PETROCHINA CO LTD

Spiral type fabricated tunnel structure and construction method thereof

ActiveCN107023306AReduce exposure timeReduce sizeUnderground chambersHydro energy generationStructure of the EarthMechanical equipment

The invention discloses a spiral type fabricated tunnel structure and a construction method thereof. The spiral type fabricated tunnel structure is formed by assembling pipe pieces through connecting bolts, and the longitudinal length and the circular width of the pipe pieces can be determined according to the stability of a rock and earth mass. The construction method of the spiral type fabricated tunnel structure comprises the steps as follows: firstly, a pipe piece space is spirally excavated in the tunnel circumferential direction with a method for rock breakage through tools or a manual excavation method, then one pipe piece is assembled and is filled through grouting, the steps are repeated, and thus the tunnel structure extends forwards along the spiral line. The rock and earth mass in a tunnel is excavated with a borehole-blasting method, with a static blasting method or with general machinery such as an excavator and a milling excavator after the tunnel structure is advanced by a certain distance. With the structure and the method, the single-time excavated section is reduced, the time that the face is exposed to the air is shortened, and the mass of construction mechanical equipment is reduced.

Owner:CENT SOUTH UNIV +3

Rapid and silent rock breaking method

ActiveCN107976130AIncrease temperatureIncrease breaking speedBlastingHydration reactionTemperature control

The invention relates to a rapid and silent rock breaking method. The rapid and silent rock breaking method comprises the steps that 1), the range needing to be broken is drawn firstly, and then the drilling positions are marked; 2), drilling is performed; 3), heating cables are put into holes and are connected in series, and then the heating cables are sequentially connected with a temperature controller, a switch and a power source; 4), a mixed breaking agent is poured into the outermost row of holes, and the holes are covered with linen bags after pouring is completed; 5), the heating cables are electrified, and the breaking agent reaches the optimum reaction temperature stated in the specification; 6), the rock surface crack change condition is observed and recorded according to the set time period; 7), when rocks are broken to a certain degree and no longer change, the heating cables are closed, and rocks start to be cleaned; and 8), and the steps mentioned above are carried out till all the rocks are broken. According to the rapid and silent rock breaking method, the purpose of increasing the temperature in the holes through auxiliary heating and control of the temperature controller is achieved, the breaking agent is promoted to accelerate a hydration reaction, and therefore the purposes of rapid expansion and breaking are achieved, and the construction process is accelerated.

Owner:CHINA FIRST METALLURGICAL GROUP

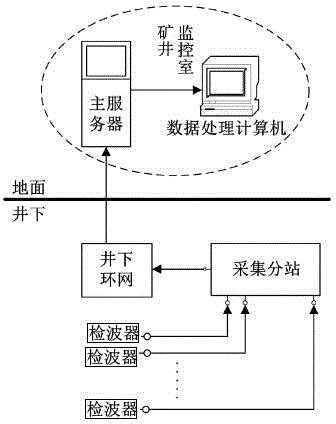

Downhole drilling trajectory microseism description method

The invention discloses a downhole drilling trajectory microseism description method, and relates to the technical field of downhole drilling description methods. The method comprises the steps that 1, a set of microseism detectors are arranged on the periphery of the downhole drilling hole position and connected to downhole microseism collection substations through cables, and therefore a complete monitoring unit is formed; 2, the downhole collection substations are connected with a mine looped network through optical fibers, and monitoring data are transmitted to a ground main server in real time to be analyzed and processed; 3, the ground main server describes and displays the drilling trajectory according to the microseism event time-space distribution situation caused by drilling and rock breakage. The downhole drilling trajectory microseism description method can describe the downhole drilling trajectory with no well measuring conditions, is accurate in description, is used for follow-up search, and has the great practical significance.

Owner:HEBEI COAL SCI RES INST

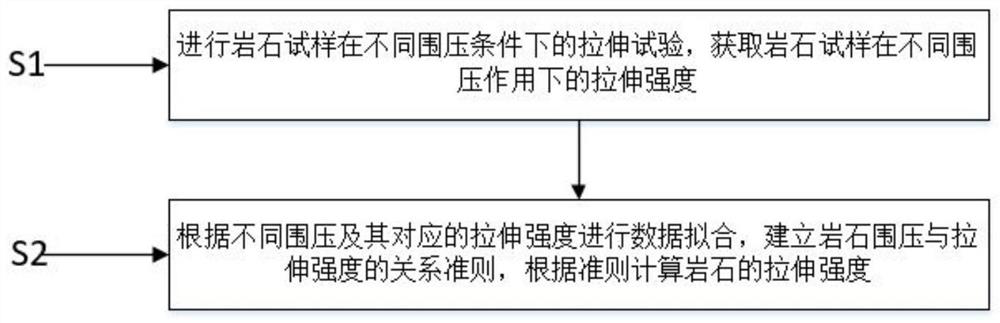

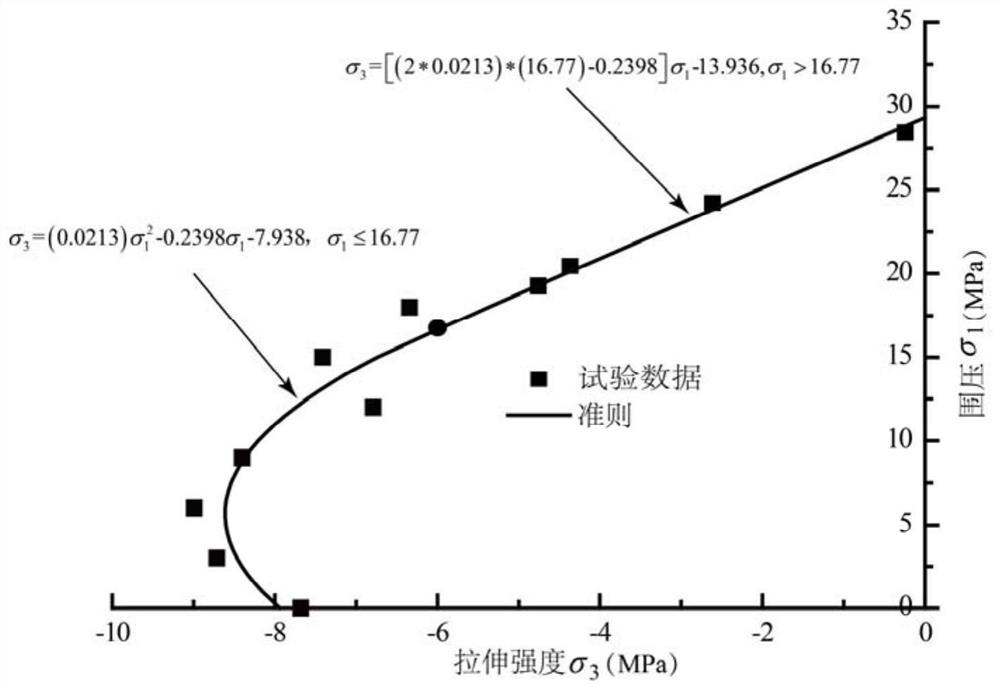

Method for calculating tensile strength of rock under confining pressure condition and application

ActiveCN112198052ATensile Strength PredictionSimple methodMaterial strength using tensile/compressive forcesClassical mechanicsStructural engineering

The invention discloses a method for calculating the tensile strength of rock under a confining pressure condition. The method is used for calculating the tensile strength of the rock according to a relation criterion of the confining pressure and the tensile strength of the rock. The method comprises the following steps: S1, carrying out tensile tests on a rock sample under different confining pressure conditions to obtain the tensile strength of the rock sample under the action of different confining pressures; and S2, performing data fitting according to different confining pressures and the corresponding tensile strength, determining a constant value related to the current rock material attribute, and calculating the tensile strength of the current rock under different confining pressure conditions according to the determined relationship criterion of the rock confining pressure and the tensile strength. The rock confining pressure and tensile strength relation criterion provided by the method provides a basis for rock fracture identification, a comparison reference is provided for judging rock fracture through tensile strength, and a theoretical basis is provided for stabilitycontrol and instability early warning of engineering rock mass.

Owner:HEBEI UNIV OF TECH

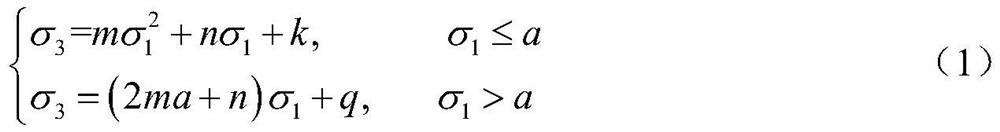

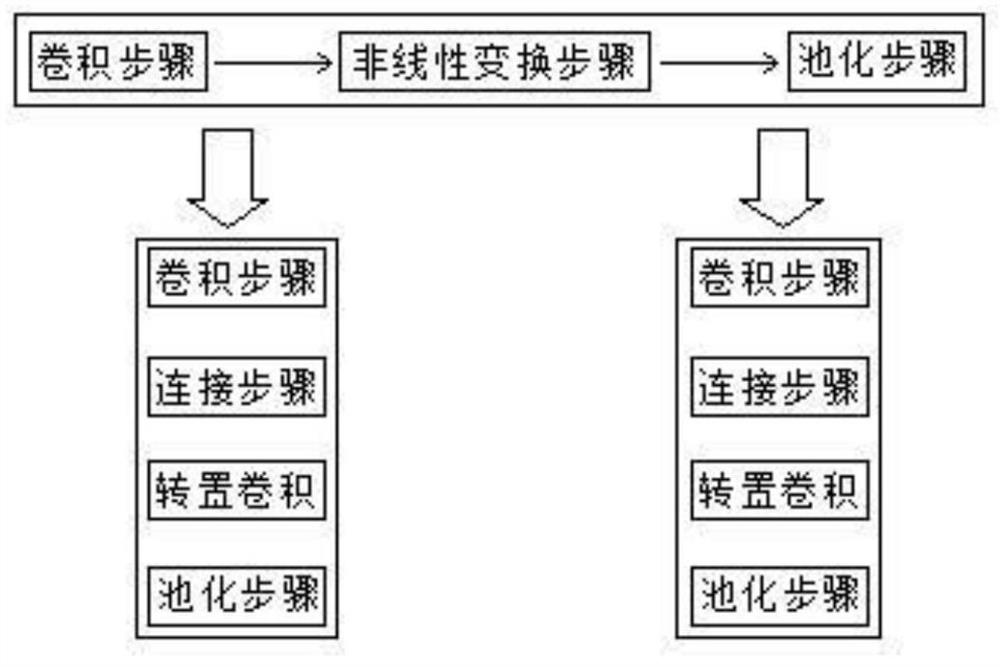

Rock fracture detection method under in-situ real-time pressurization of earth-rock mixture

PendingCN111754471AMaster the mechanism of deformation and fractureRealize disaster prevention and mitigationImage enhancementImage analysisThresholdingRock breakage

The invention relates to the technical field of rock fracture detection, and provides a rock fracture detection method under in-situ real-time pressurization of an earth-rock mixture, which comprisesthe following steps: a segmentation marking step: carrying out threshold segmentation on an image acquired by image equipment, and carrying out segmentation marking on soil, stones and bonding surfaces between the soil and the stones according to a segmentation result; and a full-strain field acquisition step: acquiring the full-strain field according to the full-displacement field of the rock. Byadopting the technical scheme, the stress change of the bonding surface between the soil and the stone can be obtained through the steps of segmenting and marking and obtaining the full strain field,and the stress change trend is quantified, so that the deformation fracture mechanism of the soil-stone mixture is mastered, and disaster prevention and reduction are realized.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

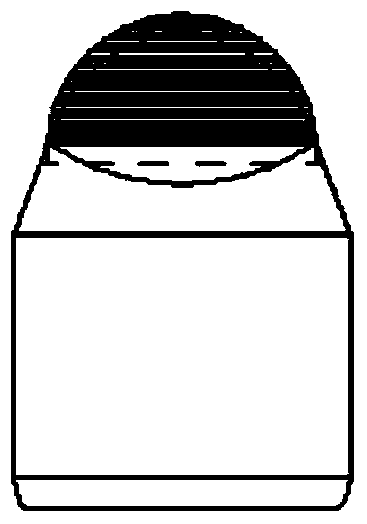

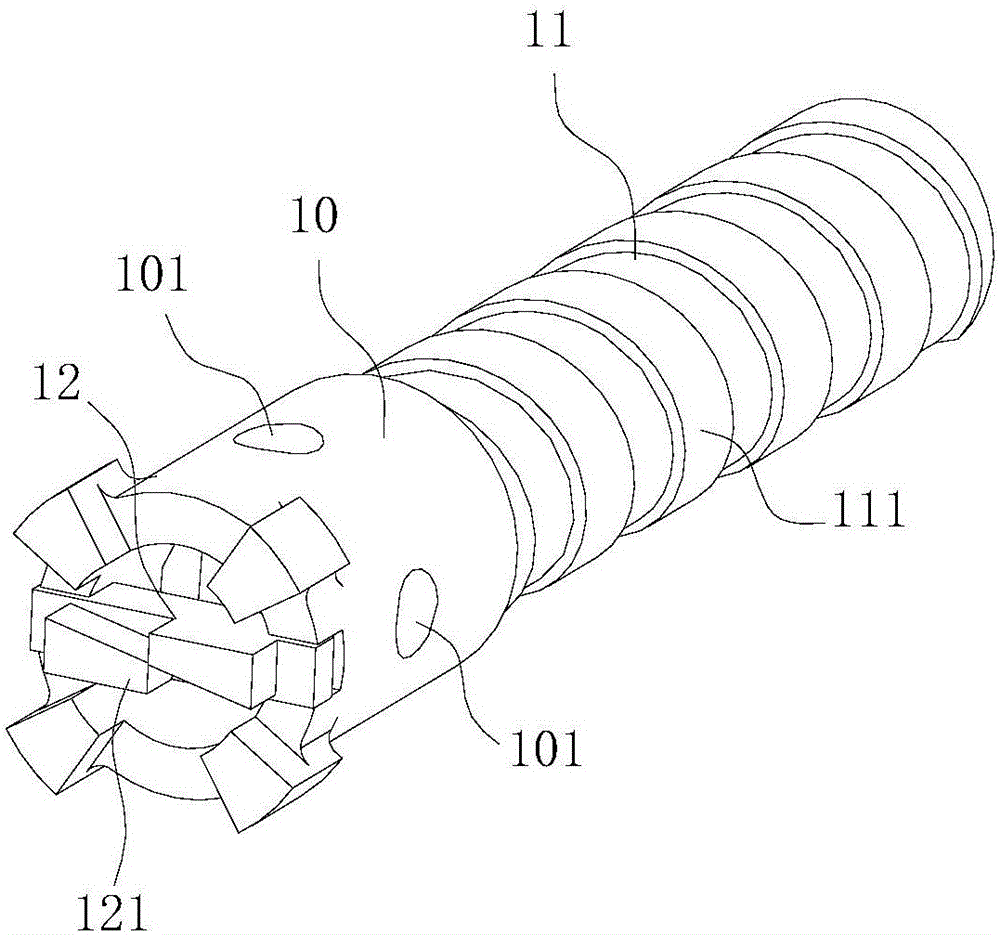

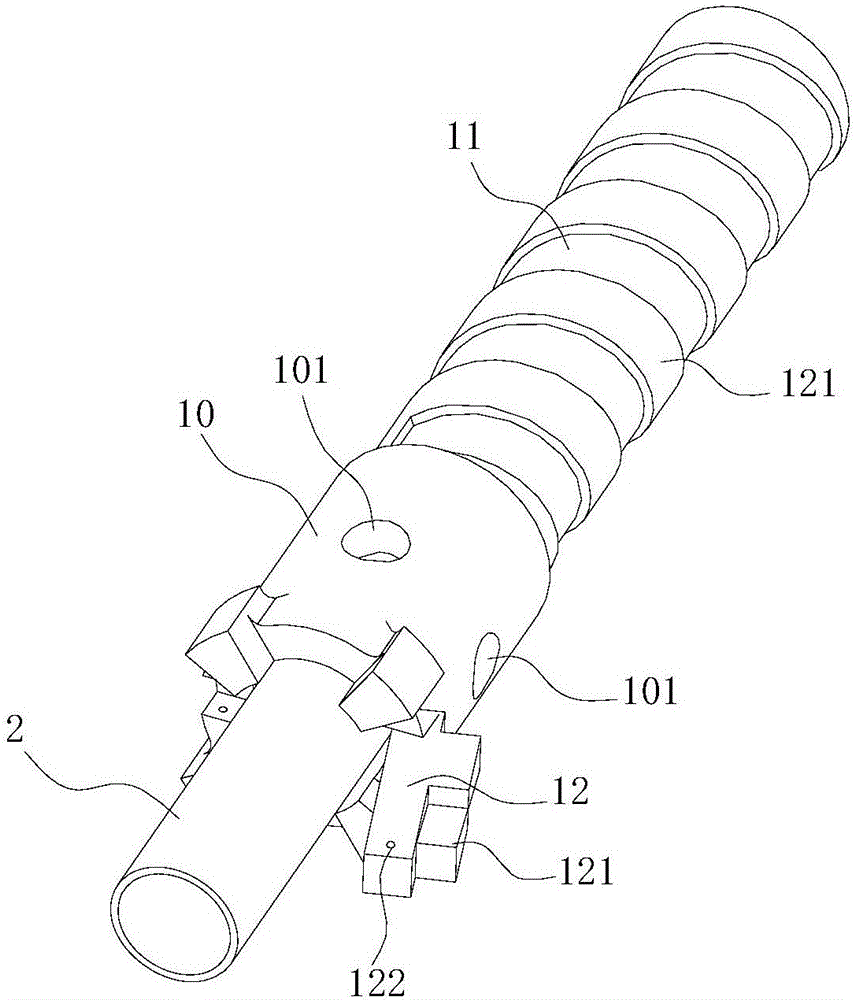

PDC drill bit applicable to core drilling of moon

InactiveCN105569573ASmooth excretionMeet the needs of drillingDrill bitsFailure rateGeological exploration

The invention discloses a PDC drill bit applicable to core drilling of the moon and belongs to the field of drilling tools for geological exploration of the moon. The PDC drill bit comprises a drill bit matrix, PDC cutting teeth and spiral rock debris channels, wherein the PDC cutting teeth are symmetrically inlaid and welded at the front of the drill bit matrix, the spiral rock debris channels are two spiral grooves which ascend spirally along the peripheral wall of the drill bit matrix and are correspondingly fixedly connected with the peripheral wall, lower ports of the two spiral grooves are correspondingly connected with the PDC cutting teeth, and upper ports are rock debris discharge ports. When the PDC drill bit is adopted to drill to break rock, on one hand, the rock debris produced through rock breakage ascends gradually along with the spiral grooves and is discharged out of holes smoothly, and the moon core drilling efficiency is increased; on the other hand, along with smooth discharge of the rock debris, heat generated at the bottom of drilled holes is released and emitted, the failure rate of the drill bit is reduced remarkably, the service life of the drill bit is prolonged, accordingly, the moon core drilling efficiency is increased comprehensively, and the PDC drill bit is not limited by specifications.

Owner:WUHAN DIDA CHANGJIANG BIT

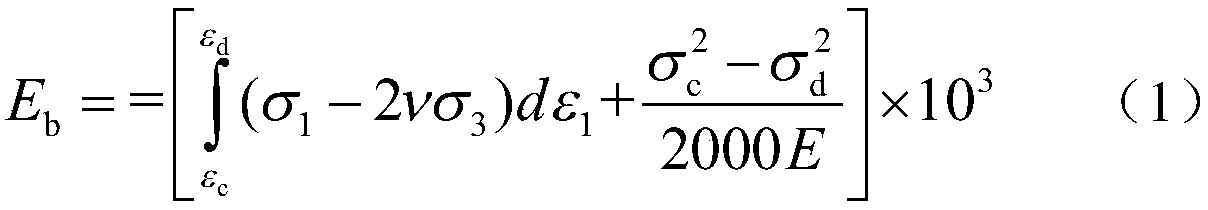

Tight reservoir compressibility evaluation method for determining fractured rock crack areas

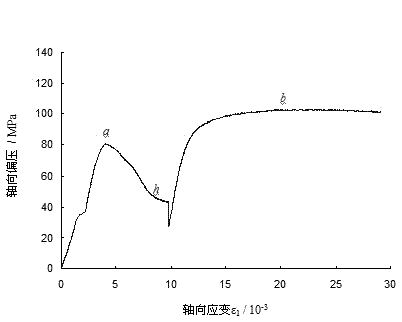

ActiveCN109238854ASimple methodEfficient use ofMaterial strength using tensile/compressive forcesStress–strain curveCompressibility

The invention relates to a tight reservoir compressibility evaluation method for determining fractured rock crack areas. The method comprises the steps of 1, selecting a rock of certain block and preparing a tight rock sample; 2, carrying out a triaxial compression test on the tight rock sample through utilization of a triaxial compression tester; 3, computing surface energy consumed when the tight rock sample is fractured according to an axial stress-strain curve of the triaxial compression test; 4, preparing a disk-shaped rock sample, carrying out a Brazilian split test on the disk-shaped rock sample, recording load when the disk-shaped rock sample is fractured, and computing tensile strength of the rock sample; 5, computing specific surface energy of the disk-shaped rock sample; 6, computing a crack area after the tight rock sample is fractured in the triaxial compression test; and 7, selecting a plurality of tight rock samples at different positions of the block, repeating the steps 1-6, and carrying out compressibility evaluation on the tight rock samples at the different positions. According to the method, the crack area formed at the interior after the rock is fractured is taken as a compressibility evaluation index, so physical connotation of compressibility can be reflected scientifically.

Owner:NORTHEAST GASOLINEEUM UNIV

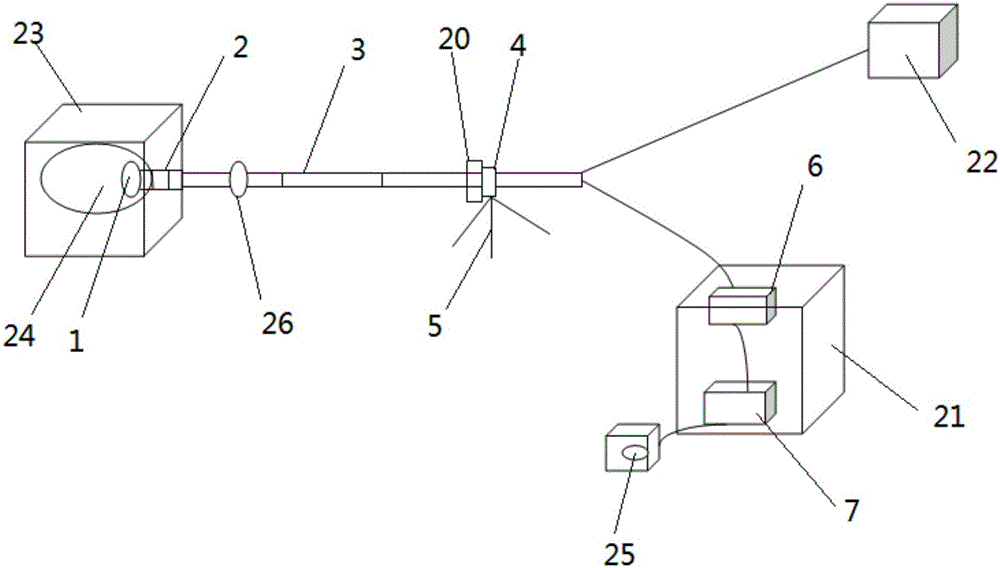

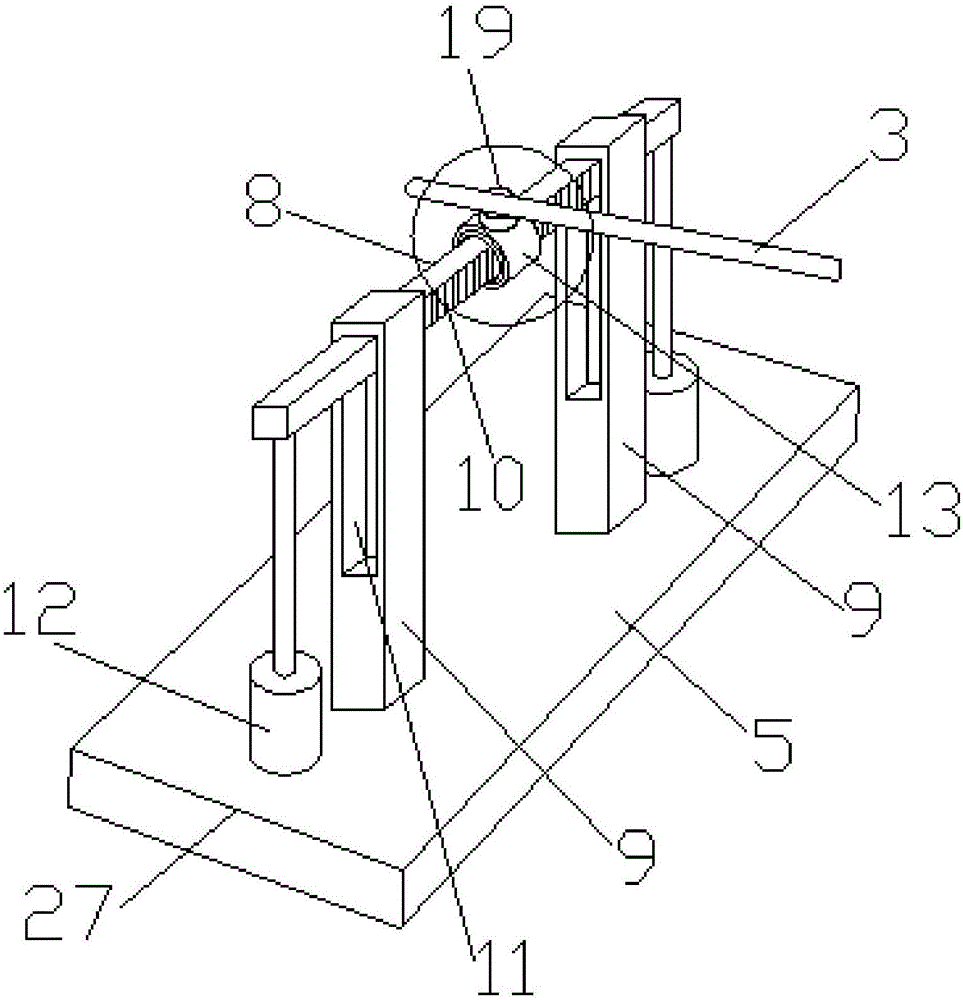

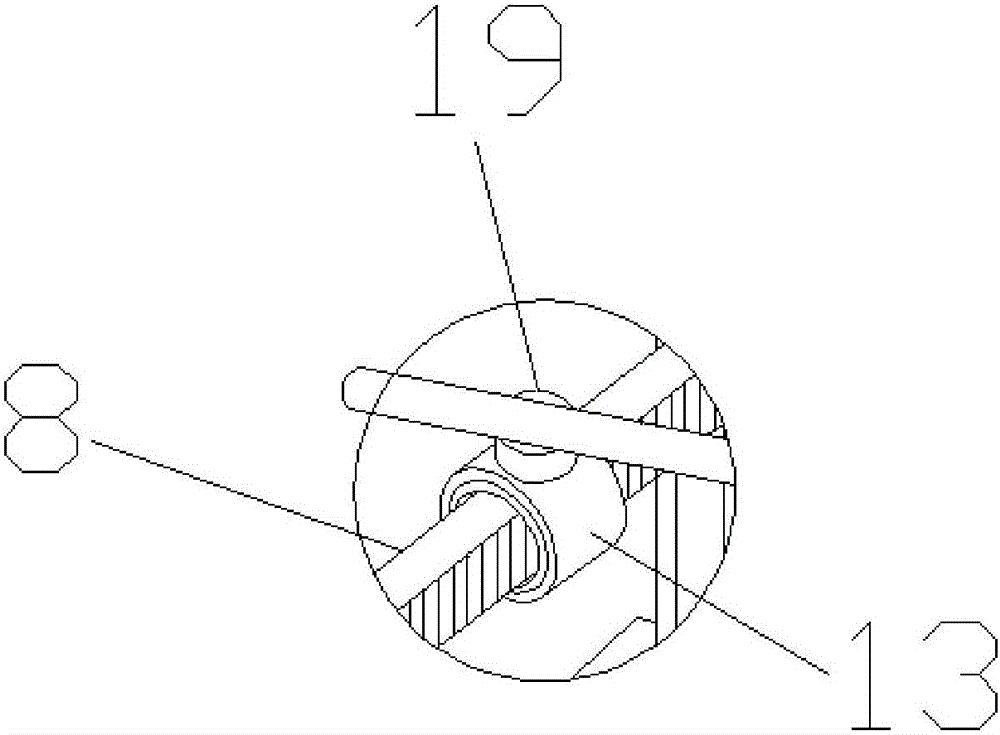

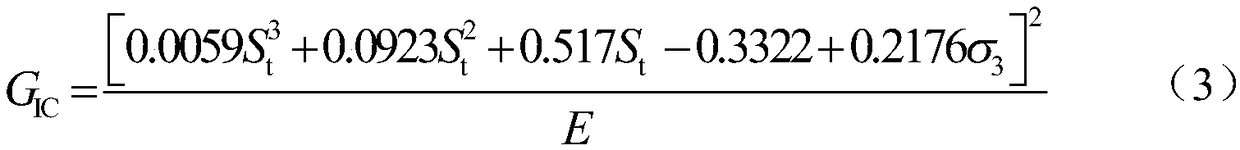

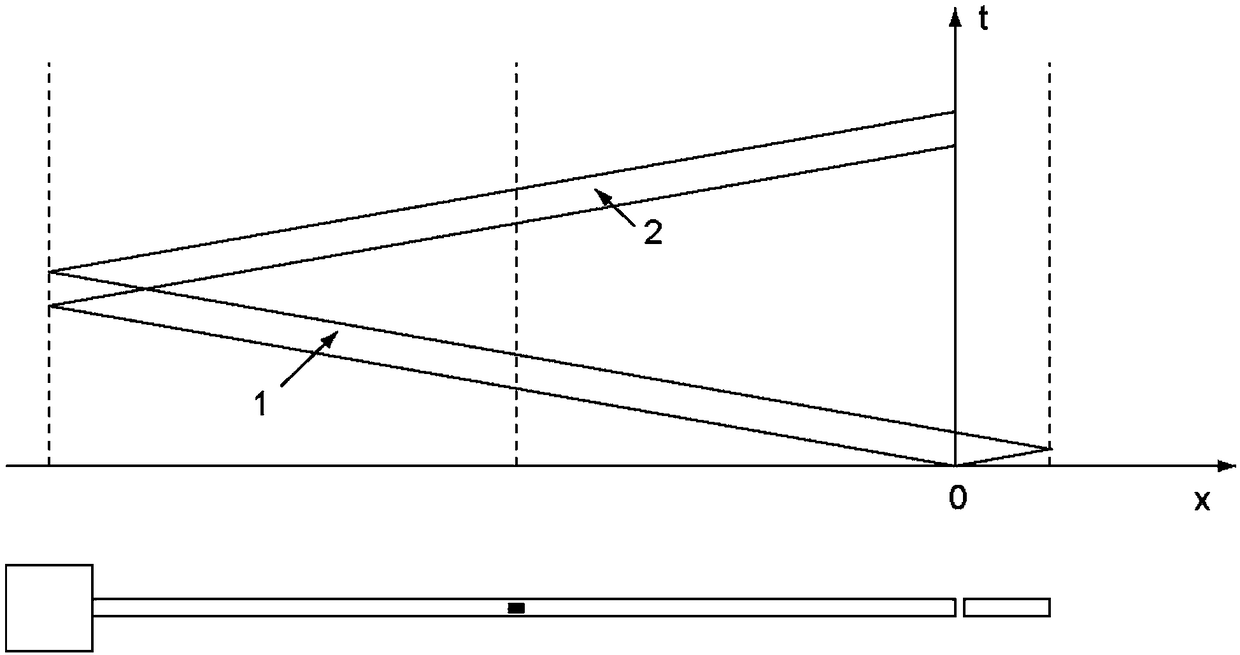

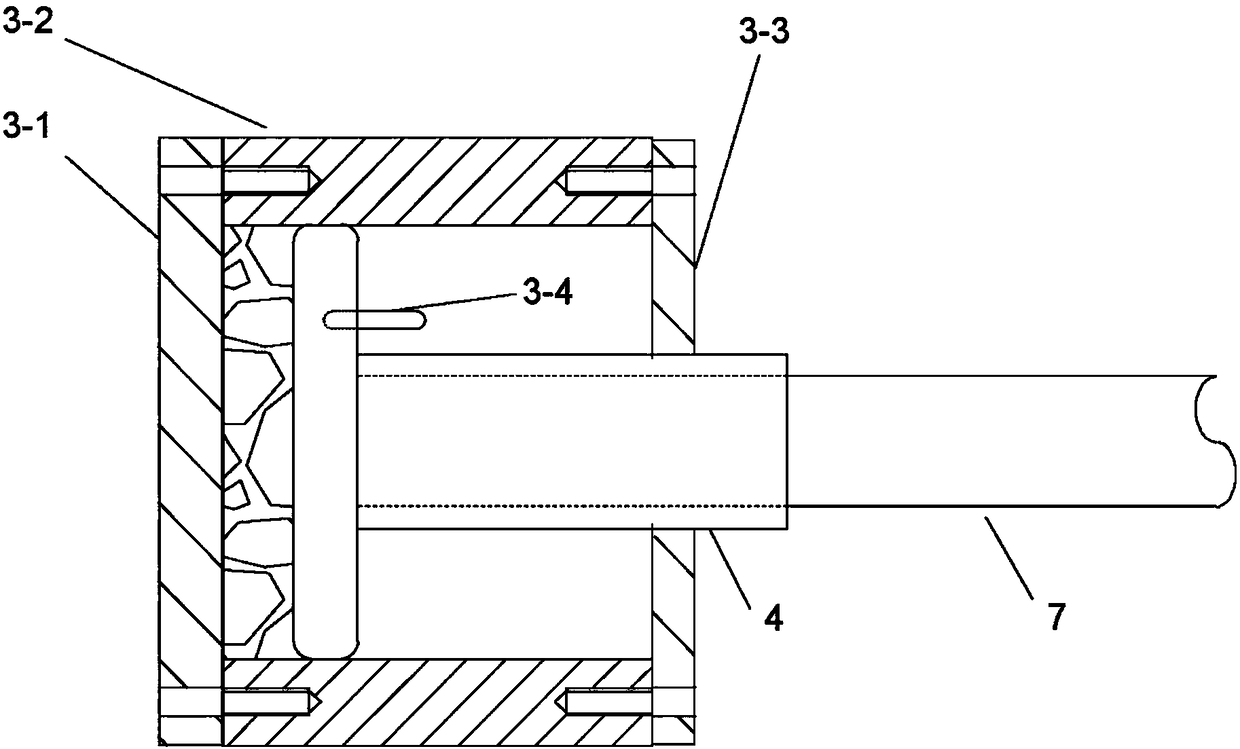

Experiment device for testing rock breakage and method for calibrating impact speed and loss energy

ActiveCN108225949AOptimize design parametersIncrease power consumptionStrength propertiesReflected wavesEngineering

The invention relates to an experiment device for testing rock breakage and a method for calibrating impact speed and loss energy. The device mainly comprises a test piece chamber, an impact loading system and an experimental test system, wherein a multi-granule rock test piece is arranged in the test piece chamber; the impact loading system comprises a test pole, an emission bar, an emission sleeve and an air compression system; the experimental test system comprises a linear speed meter, a strain gauge, a dynamic strain gauge and an oscilloscope. The method for calibrating impact speed and loss energy comprises the steps of recording the impact speed of a piston by using the linear speed meter and the oscilloscope; respectively recording the time-variable signals of shock-loaded waves and reflected waves in the test pole by time using the dynamic strain gauge and the oscilloscope; calculating the collected data to obtain the energy loss in an experiment process. After the device andthe method are adopted, the relationship between rock breaking effect and energy consumption can be studied under the different loading rates by changing the air pressure. The simulation experiment device has the characteristics of being simple in structure, high in simulation authenticity and good in repeatability of a test process.

Owner:TIANJIN UNIV

Mechanical self-excited interactive hydraulic pulse drill bit pup joint

InactiveCN1952343AImprove rock breakingImprove efficiencyDrill bitsLiquid/gas jet drillingInlet channelSelf excited

The invention relates to a short section of mechanical interactive hydraulic ripple drill bit, comprising short section body. Mechanical interactive ripple cavity, in which flowing oscillating body is set, is set in the short section body. The mechanical interactive ripple cavity is connected with connecting screw hole I on the upper of short section body by the inlet channel and it is connected with connecting screw hole II on the lower of short section body. Connecting screw hole I is used to connect drill collar and connecting screw hole II is used to connect drill bit. Under the effect of high speed liquid flow oscillating body rotates in the mechanical interactive ripple cavity at a high speed and generates cyclical wallop so that flow oscillating body and mechanical interactive ripple cavity become vibration sources in working. Encouragements of the mechanical interactive ripple cavity and generated by mechanical interdiction from flow oscillating body have a common influence to form ripple liquid with high frequency, which is jetted from the nozzle connected with inner cavity of drill bit. The efficiency of rock breakage is improved largely.

Owner:SICHUAN UNIV

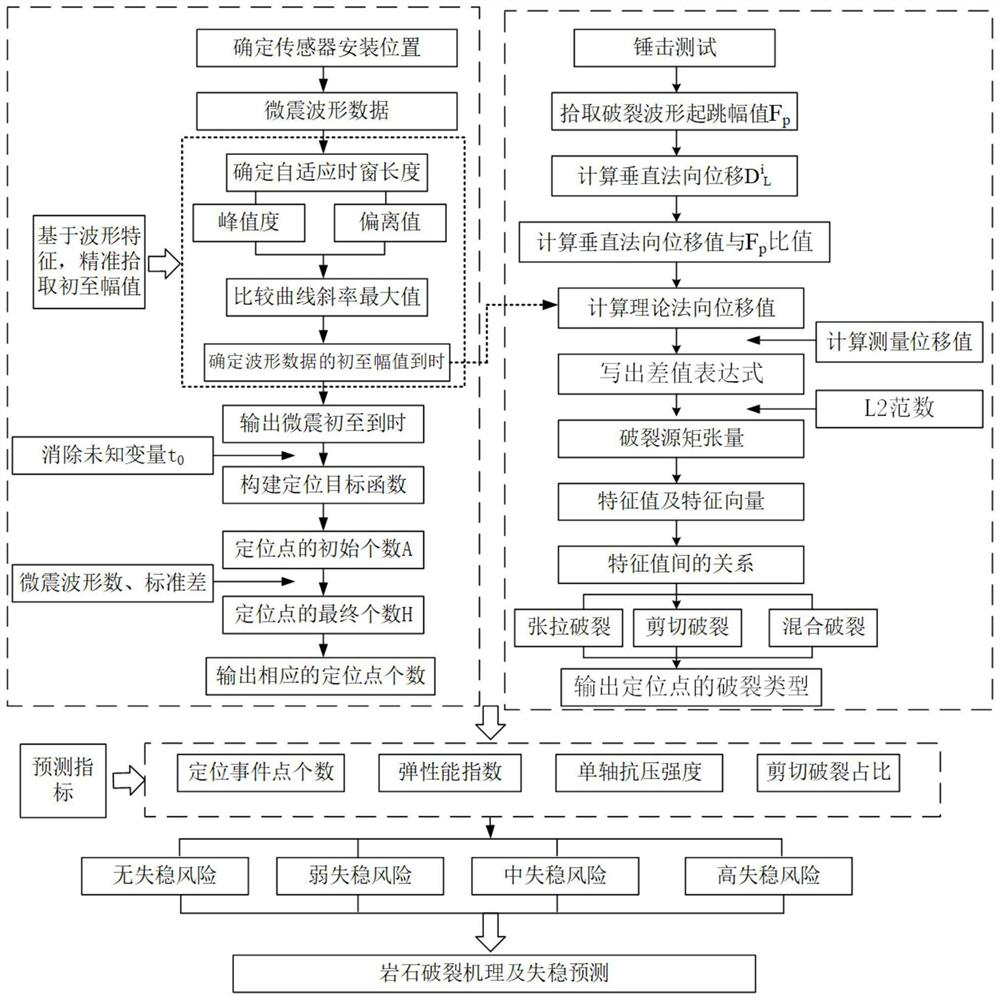

Method for inversion of rock fracture mechanism and instability prediction by using micro-seismic monitoring data

ActiveCN114137600APrevent picking inaccurate issuesEasy accessEarthquake measurementSeismic signal processingLandslideRock breakage

The invention discloses a method for inverting a rock fracture mechanism and predicting instability by using micro-seismic monitoring data, and the method comprises the steps: determining the first arrival amplitude and first arrival time of a micro-seismic waveform according to the characteristics of the micro-seismic waveform; constructing a new positioning target function based on the microseismic waveform first arrival time, solving the coordinates of the fracture source, and eliminating positioning points which do not meet the requirements by considering the microseismic waveform number and the standard deviation of the first arrival time and the inverse calculation of the first arrival time difference; calculating a theoretical normal displacement value of the microseismic waveform, solving a rupture source moment tensor and regularizing the rupture source moment tensor through a difference expression of the theoretical normal displacement value and a measured displacement value, and directly judging a rock rupture mechanism through the property of a rupture surface; on the basis, rock fracture instability prediction indexes are established, the rock fracture instability risk is predicted according to the risk evaluation grade, and monitoring and early warning are provided for disasters such as working face rock burst, rockburst, coal and gas outburst water inrush, collapse and landslide.

Owner:CHINA UNIV OF MINING & TECH

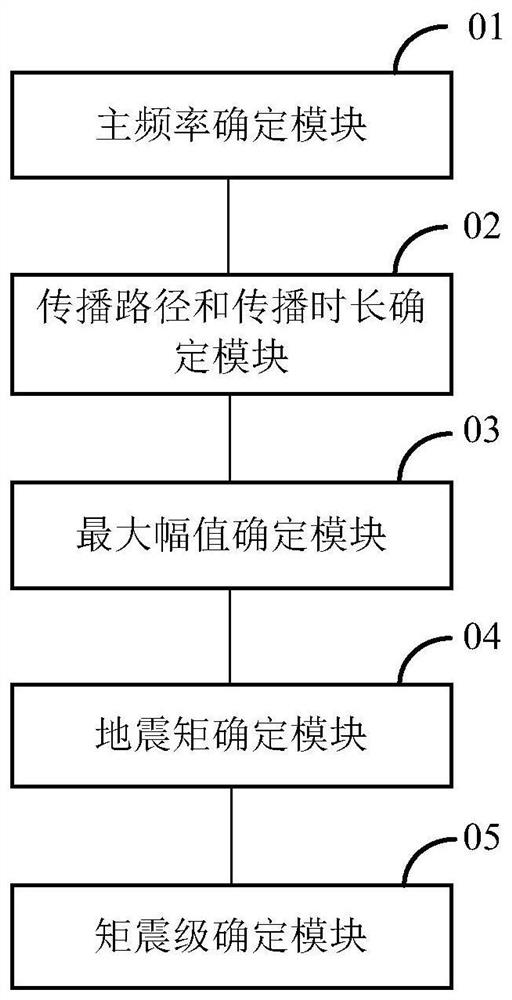

Method and device for determining moment magnitude of microseism event

PendingCN112379423AImprove calculation accuracyImprove accuracySeismic signal processingGeophoneMaximum amplitude

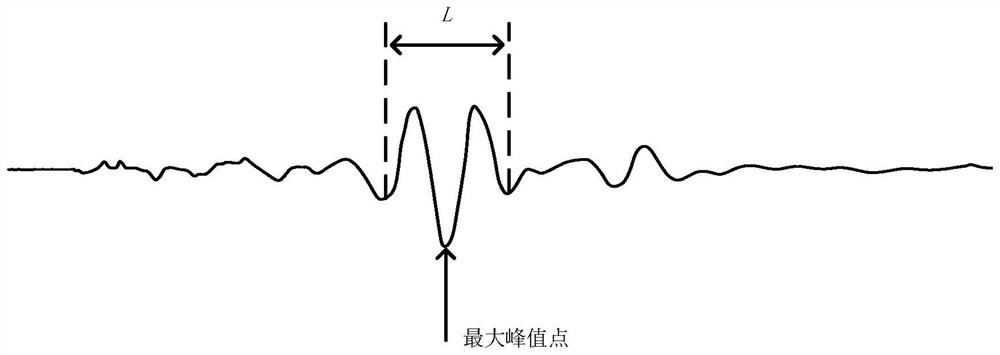

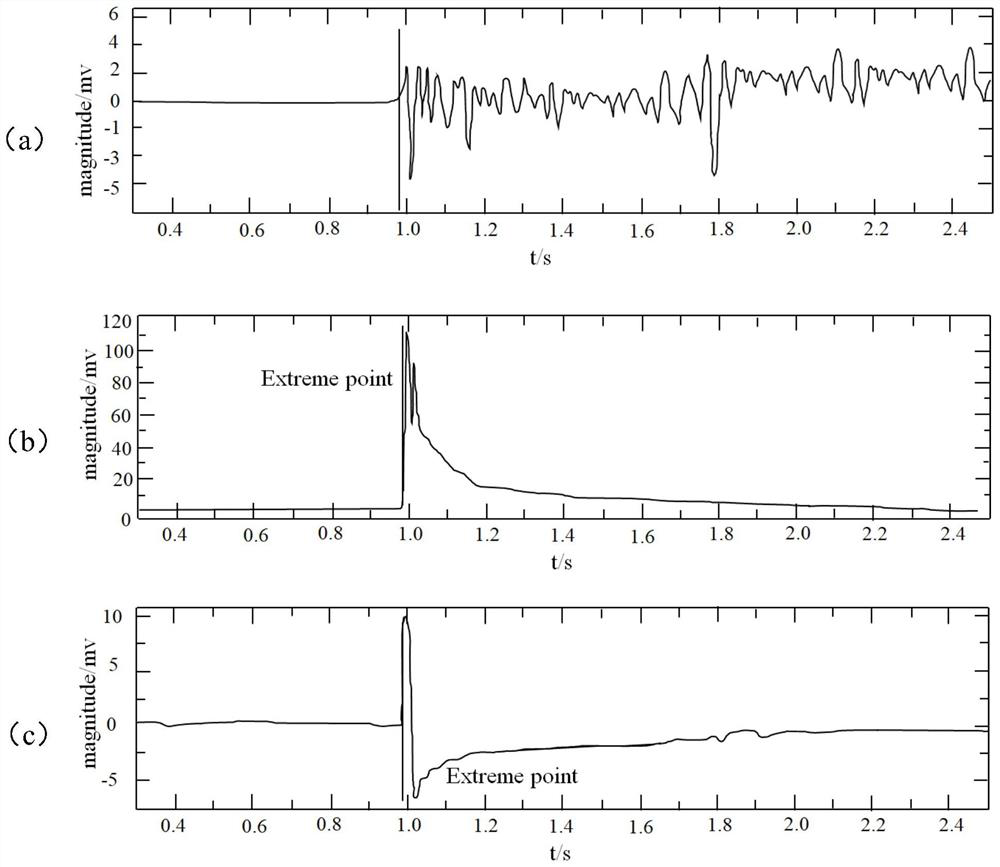

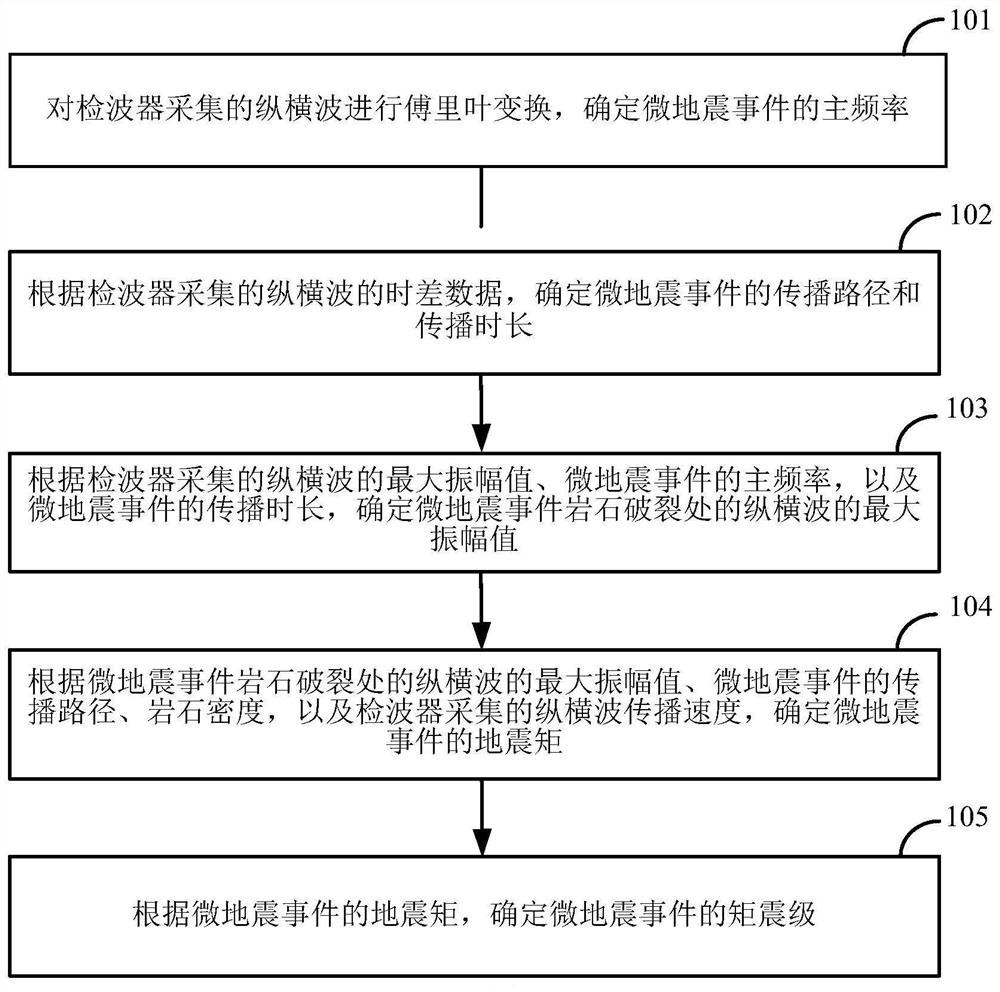

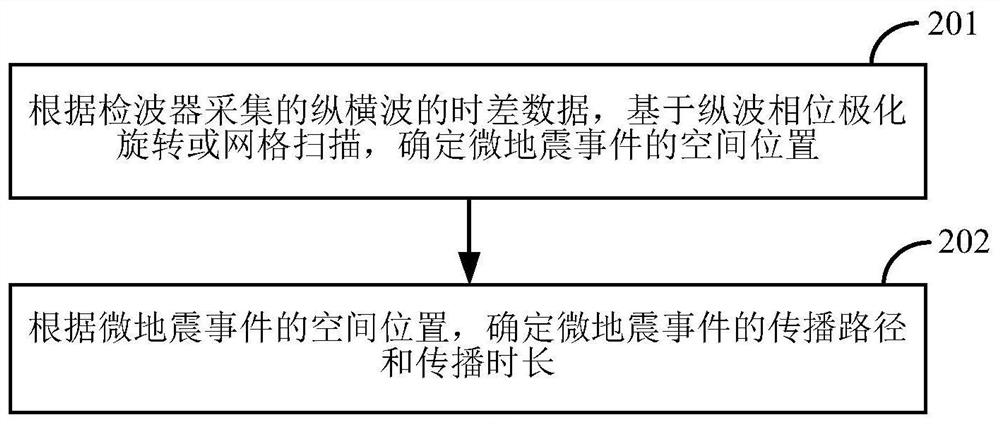

The invention discloses a method and device for determining the moment magnitude of a microseism event, and the method comprises the steps: carrying out the Fourier transform of longitudinal and transverse waves collected by a detector, and determining the main frequency of the microseism event; determining a propagation path and propagation duration of the microseism event according to the time difference data of the longitudinal and transverse waves acquired by the detector; according to the maximum amplitude value of the longitudinal and transverse waves collected by the detector, the mainfrequency of the microseism event and the propagation duration of the microseism event, determining the maximum amplitude value of the longitudinal and transverse waves at the rock fracture position of the microseism event; determining the seismic moment of the microseism event according to the maximum amplitude value of the longitudinal and transverse waves at the rock fracture position of the microseism event, the propagation path of the microseism event, the rock density and the propagation speed of the longitudinal and transverse waves collected by the detector; and determining the momentmagnitude of the microseism event according to the seismic moment of the microseism event. The calculation precision of the moment magnitude of the microseism event can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com