Method for manufacturing single-fracture rock specimen based on 3D printing

A 3D printing and manufacturing method technology, applied in the preparation of test samples, manufacturing tools, instruments, etc., can solve the problems of poor processing quality, reduced processing accuracy, and difficult construction, so as to improve accuracy, ensure processing accuracy, and ensure precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

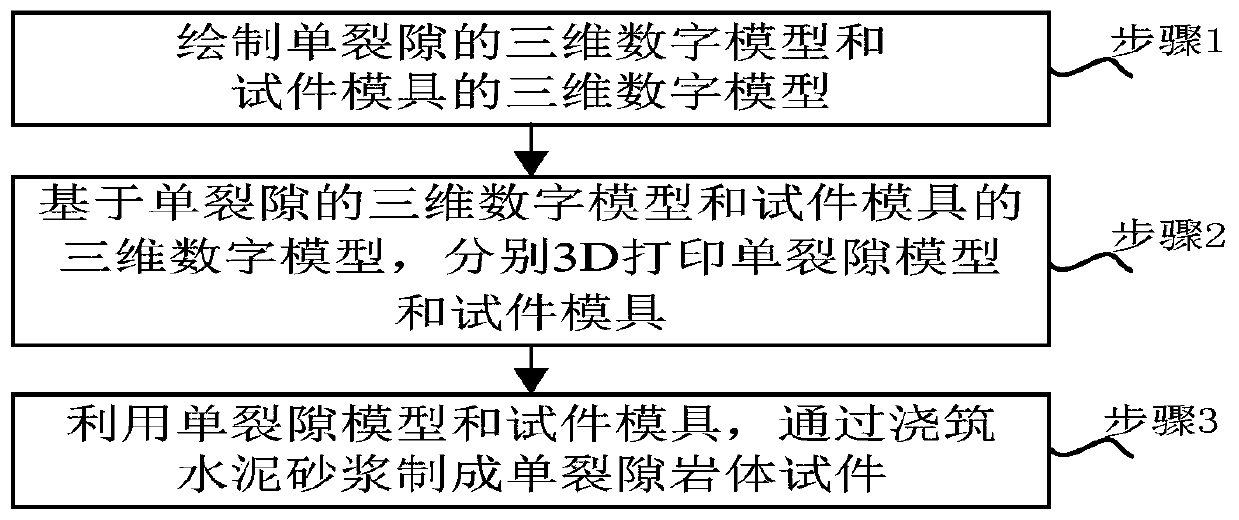

[0050] figure 1 A flow chart of a method for manufacturing a single-crack rock mass specimen based on 3D printing according to an embodiment of the present invention is shown.

[0051] Such as figure 1 As shown, the method of making a single-crack rock mass specimen based on 3D printing includes:

[0052] Step 1: Draw the 3D digital model of the single crack and the 3D digital model of the specimen mold;

[0053] After step 1, the three-dimensional digital model of the single crack and the three-dimensional digital model of the specimen mold are detected and repaired;

[0054] Step 2: Based on the 3D digital model of the single crack and the 3D digital model of the specimen mold, 3D print the single crack model and the specimen mold respectively;

[0055] Step 2 specifically includes:

[0056] Step 201: Determine the printing accuracy and slice layer thickness;

[0057] Step 202: Positioning and dividing the three-dimensional digital model of the single crack and the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com