Rapid and silent rock breaking method

A soundless crushing and rock-breaking technology, applied in blasting and other directions, can solve problems such as insufficient reaction of crushing agents, delay in construction progress, long crushing time, etc., and achieve good control, speed up construction progress, and improve the effect of breaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

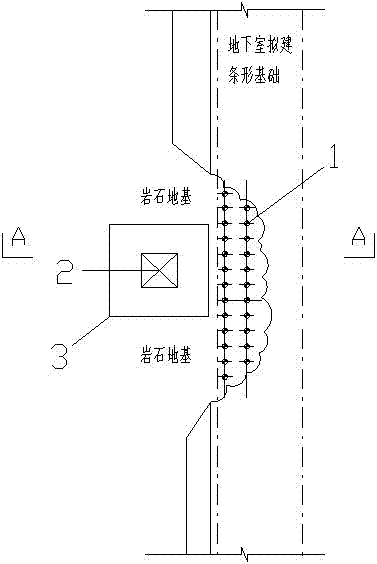

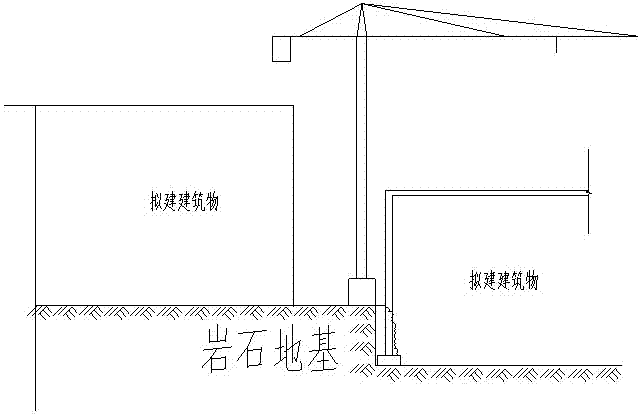

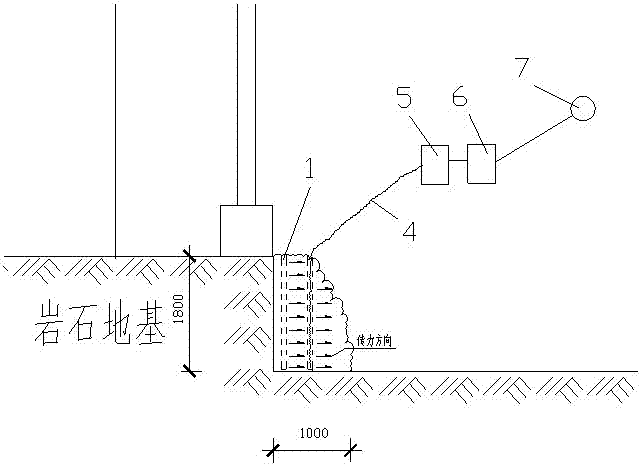

[0019] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with embodiments and drawings (such as figure 1 Shown).

[0020] A method for rapid and silent rock fragmentation, characterized in that it includes the following steps:

[0021] 1) First, put out the area that needs to be broken at the construction site with a white line, and then mark the location (with paint) that needs to be drilled according to the crushing agent manual (make sure that the vertical and horizontal rows of the holes are straight);

[0022] 2) Use an electric pick to drill to the specified depth (the order of drilling is from outside to inside), and clean the slag in the hole after drilling (blow clean with a pneumatic pick);

[0023] 3) Put heating cables in the outermost row of holes, connect all heating cables in series, and then connect them to the temperature controller, switch and power supply in turn. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com