Deep hole blasting charging method for passing through solution cavity and solution cavity detecting device

A deep-hole blasting and detection device technology, which is applied in blasting and other directions, can solve the problems of pressure reduction, difficulty in charging PVC pipes, and complicated charging process, etc., and achieve the effects of reliable detonation, avoiding the leakage of explosive energy, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

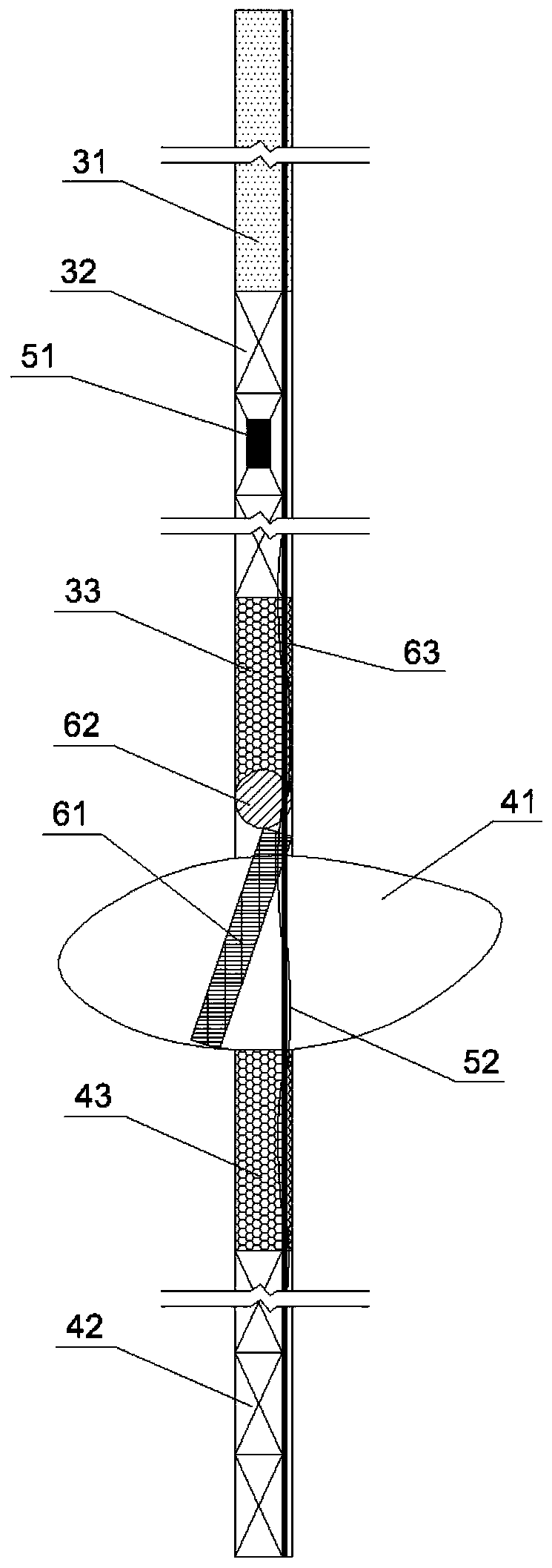

[0037] In this embodiment, the deep hole includes an upper section blasthole and a lower section blasthole, and there is a middle dissolution cavity between the upper section blasthole and the lower section blasthole, and the position and depth of the middle dissolution cavity are obtained by deep surveying.

[0038] see figure 1 , the charging method of the deep hole blasting through the dissolved cavity in this embodiment is:

[0039] In the upper section of the blasthole, from the upper section of the blasthole to the bottom of the upper section of the blasthole, there are successively the hole plugging section 31, the upper section of explosives 32 and the upper section of the dissolution cavity plugging section 33; The section is filled with lower explosives 42, and from the top surface of the lower explosives 42 to the bottom surface of the middle dissolution cavity 41, the lower block section 43 of the lower dissolution cavity is set to block the opening of the lower bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com