Mechanical self-excited interactive hydraulic pulse drill bit pup joint

An interactive and self-excited technology, applied to drill bits, vibration drilling, drilling equipment, etc., can solve the problems of complex structure and low reliability, and achieve the effect of good stability, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

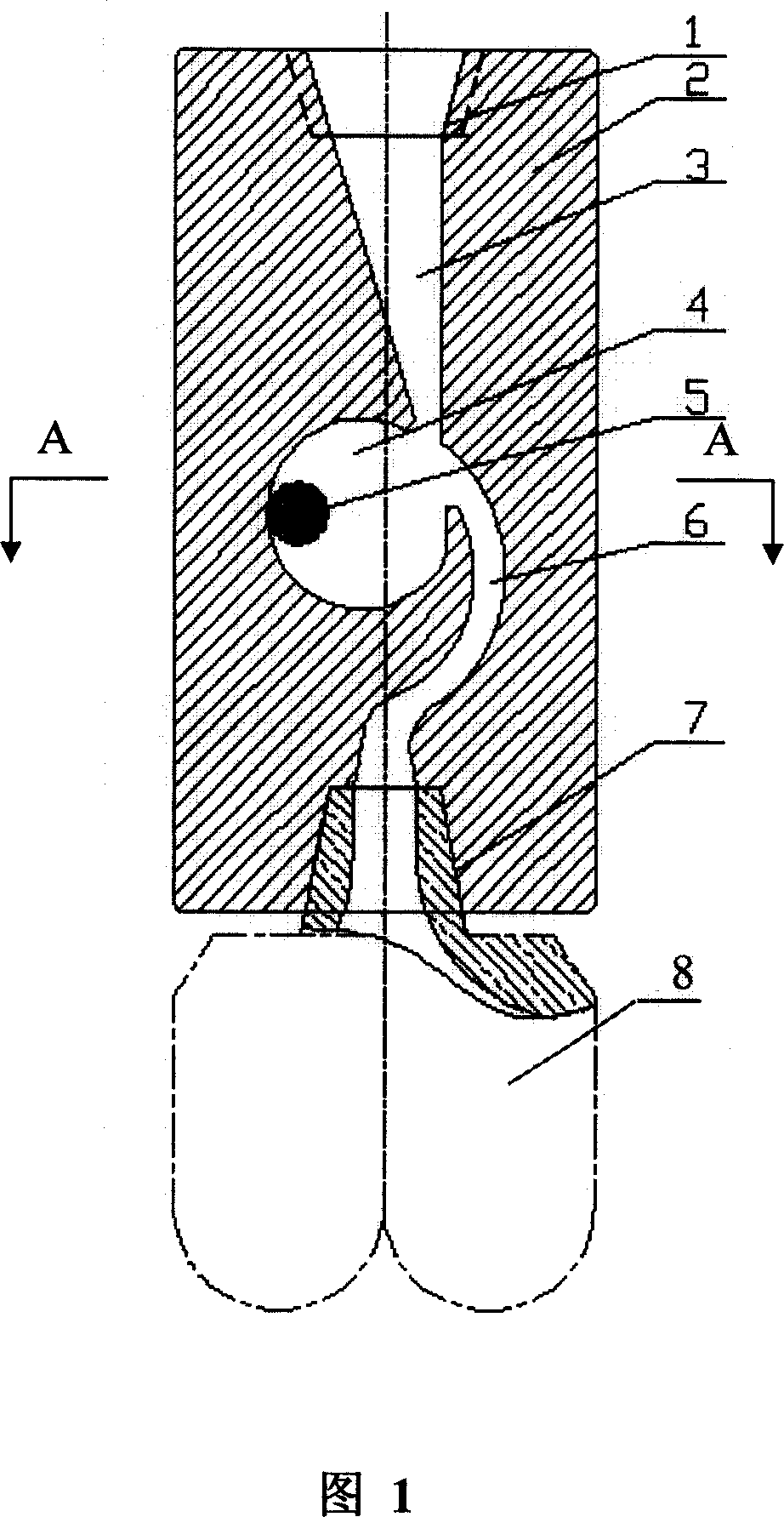

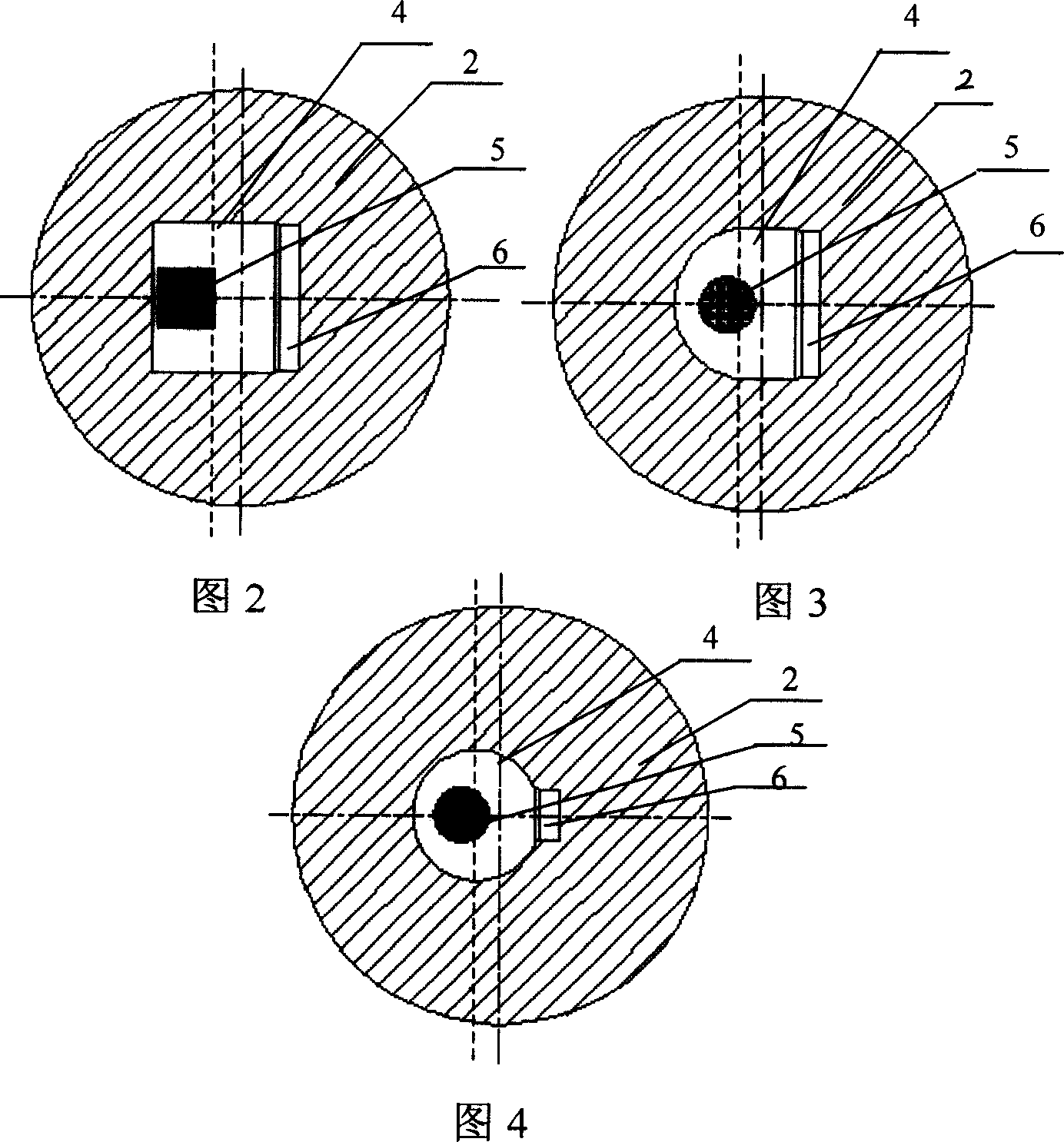

[0022] In this embodiment, the shape and structure of the sub-joint of the mechanical self-excited interactive hydraulic pulsation drill bit are shown in Figures 1 and 3, the sub-joint body 2 is an integral cylinder; the sub-joint body is provided with a mechanical self-excited pulsation cavity 4 , the mechanical self-excited pulsation chamber is placed with a spherical flow-around oscillating body 5, and the mechanical self-excited pulsation chamber is located in the middle of the pup joint body, and is a cavity formed by a combination of a hemisphere and a cylinder of equal diameter (as shown in Figure 3 ), the centerline of the cavity formed by the combination of the hemisphere and the equal-diameter cylinder is parallel to the centerline of the sub-section body 2 and moved to the left by a distance; The connecting screw hole I in the upper part communicates with the connecting screw hole II located at the lower part of the nipple body through the outlet flow channel 6. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com