Hydraulic pulse supercharging underbalance drilling unit

An underbalanced drilling and hydraulic pulse technology, which is applied to drilling equipment, wellbore flushing, and vibration drilling, etc., can solve the problems of low rock-breaking energy assisted by high-pressure water jets, small device pulsation amplitude, poor life and stability, etc., and achieve Improve rock breaking efficiency, good effect, and less energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

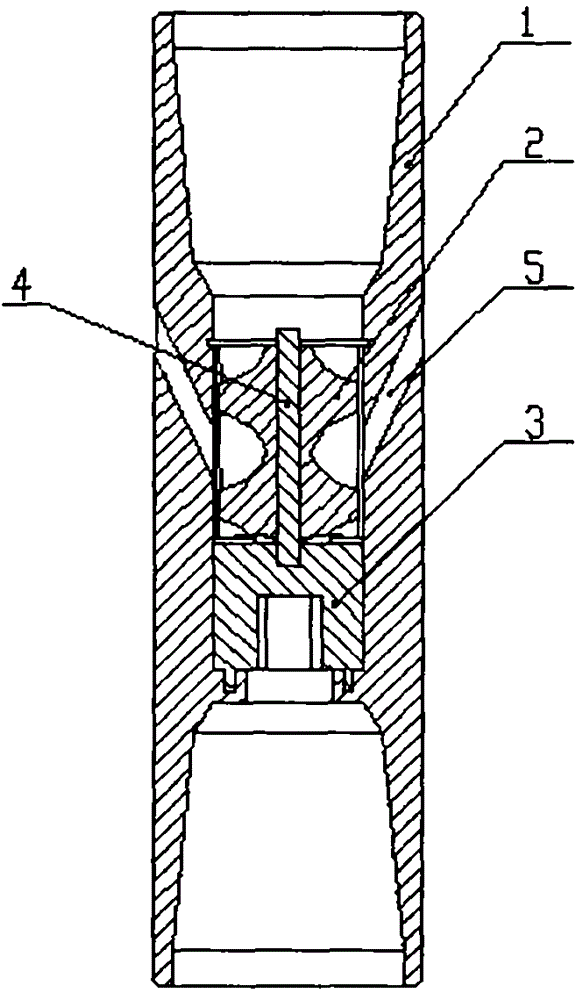

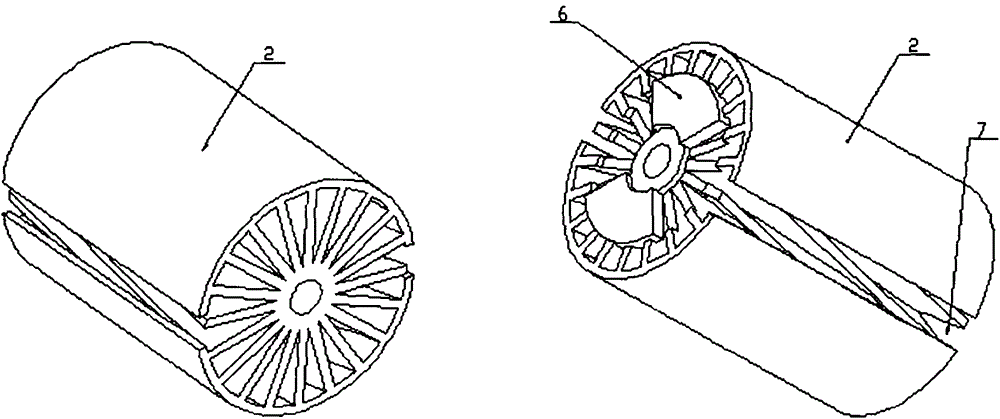

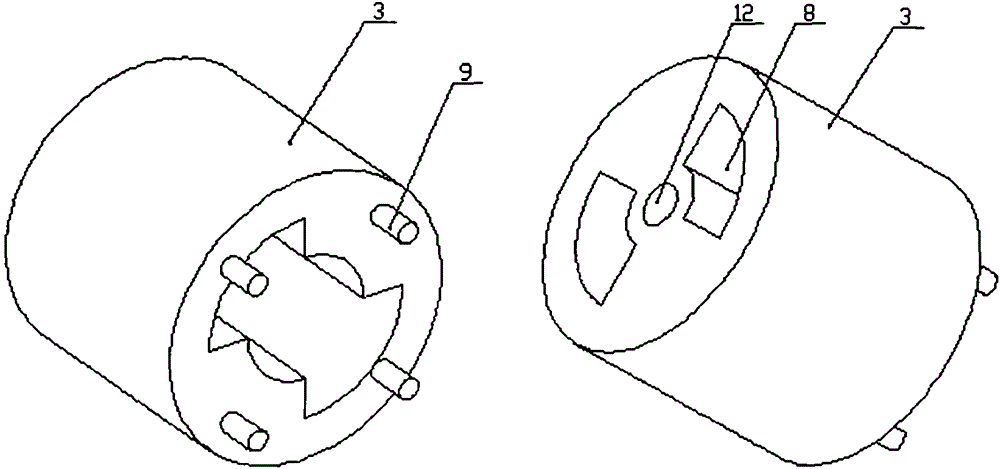

[0028] figure 1 It is a schematic diagram of the assembly of the hydraulic pulse pressurized underbalanced drilling device patented by the present invention, in figure 1 Among them, the base 3 is positioned through the positioning pin 9 and the positioning hole 10 of the body 1. When positioning, it is necessary to ensure that the two effusion channels on the base are symmetrical to the cross-sections of the two oblique flow channels on the body, and the impeller 2 is installed through the impeller shaft 4. On the shaft seat hole 12 of the base 3.

[0029] Figure 4 Schematic diagram of the body structure of the hydraulic pulse pressurized underbalanced drilling device patented by the present invention, in Figure 4 Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com