Large-aperture static breaking agent oriented rock breakage and spraying hole prevention integrated device and construction method thereof

A construction method and static breaking agent technology, applied in the field of large-aperture static breaking agent directional rock breaking and blowout prevention integrated device, can solve the problems of reduced crushing time, spray holes, high crushing efficiency, etc., and achieve large expansion pressure, The effect of high crushing energy and large crushing dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

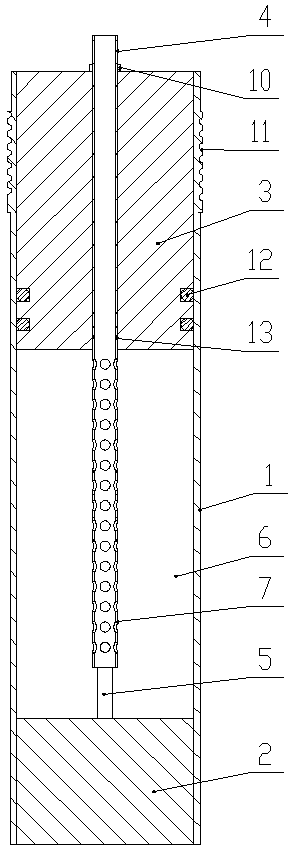

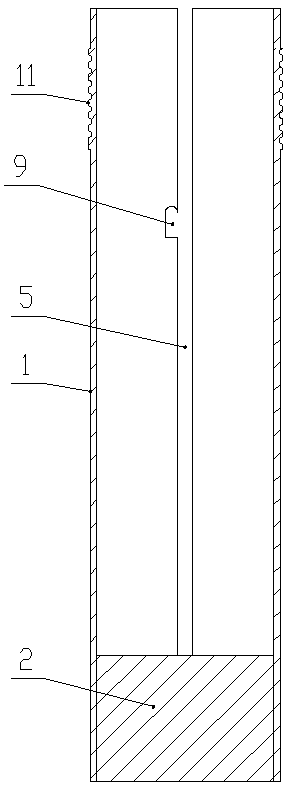

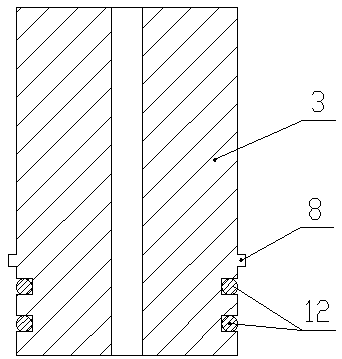

[0032] Such as Figure 1-Figure 4 As shown, the large-aperture static breaking agent directional rock breaking and blowout hole integrated device of the present invention includes a sleeve 1, a lower plugging head 2, an upper plugging head 3 and a water injection pipe 4, and the sleeve 1 is vertically Setting, the lower plugging head 2 and the upper plugging head 3 are both cylindrical structures, the lower plugging head 2 is fixedly arranged at the lower part of the sleeve 1, and the wall of the sleeve 1 is opened in the axial direction from top to bottom. Two directional cracks 5 are arranged symmetrically with respect to the center line of the sleeve 1, the lower end of the directional cracks 5 is flush with the upper side of the lower plugging head 2, and the upper plugging head 3 is coaxially assembled on the In the upper port of the sleeve 1, a static breaker filling cavity 6 is formed inside the sleeve 1 between the upper plugging head 3 and the lower plugging head 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com