Large-hole-diameter static blasting blowout prevention device and using method thereof

A static blasting and large-aperture technology, which is applied in blasting and other directions, can solve problems affecting construction safety and construction progress, slow response speed, and low expansion pressure, and achieve large crushing dose, short reaction time, and high expansion pressure in a single hole Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

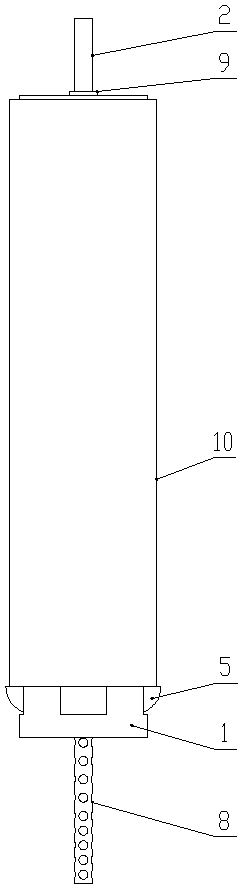

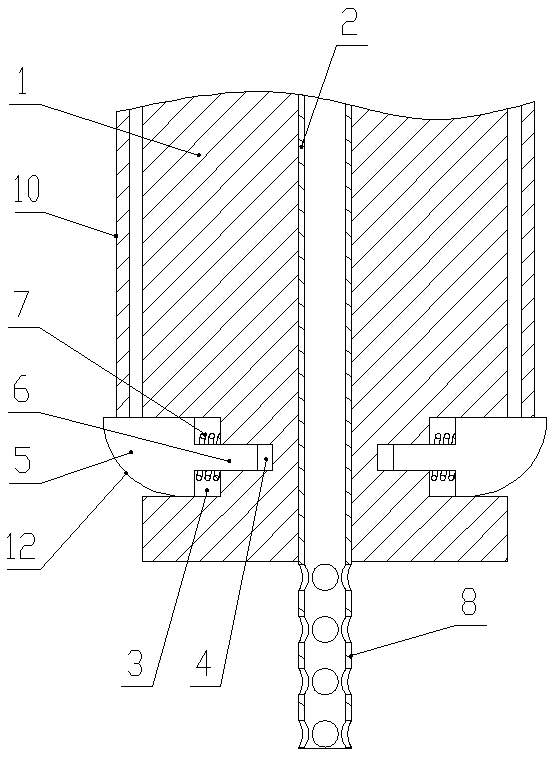

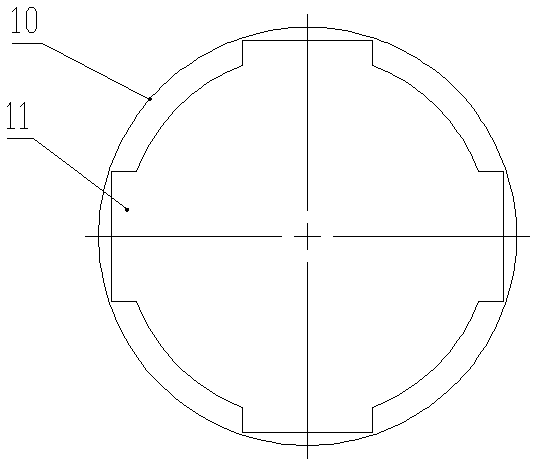

[0027] Such as Figure 1-Figure 3 As shown, the large-diameter static blasting blowout prevention device of the present invention includes a push rod 1 and a water injection pipe 2. The outer circle of the lower part of the push rod 1 is evenly provided with four rectangular grooves 3 along the circumferential direction, and the bottom of the rectangular groove 3 is arranged along the radial direction. A guide groove 4 is opened in the direction, and a positioning block 5 is slidingly arranged in the rectangular groove 3. The inner end surface of the positioning block 5 is fixedly connected with a guide post 6 extending into the guide groove 4, and a spring 7 is set on the guide post 6. The spring 7 The two ends are respectively in contact with the bottom of the rectangular groove 3 and the inner end surface of the positioning block 5; when the spring 7 is not stressed, the outer end of the positioning block 5 protrudes from the rectangular groove 3, and when the spring 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com