A kind of deep silt foundation reinforcement method

A silt foundation, deep technology, applied in the direction of solid waste management, infrastructure engineering, sustainable waste treatment, etc., can solve the problems of structural damage, construction difficulties, etc., to improve strength, resist water erosion, improve physical adsorption and chemical reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this example, a typical foundation pit project in Zhuhai area adopts FLAC 3D The software performs calculations to establish a three-dimensional calculation model of the foundation pit and the enclosure structure. Through numerical simulation, the influence of the reinforcement depth, reinforcement width, arrangement spacing, admixture content and other parameters of the reinforcement soil in the pit on the stability of the foundation pit is studied. Provide theoretical basis for the design and construction of soil reinforcement in pits.

[0049] A deep silt foundation reinforcement method, comprising the following steps:

[0050] Step 1): Use the percussion drilling method to conduct geological survey on the construction site, determine the soil layer and division information, and then drill the core to determine the size of the silt layer and determine the construction area.

[0051] Determine the soil layer from top to bottom as:

[0052]Plain fill, the layer th...

Embodiment 2-5

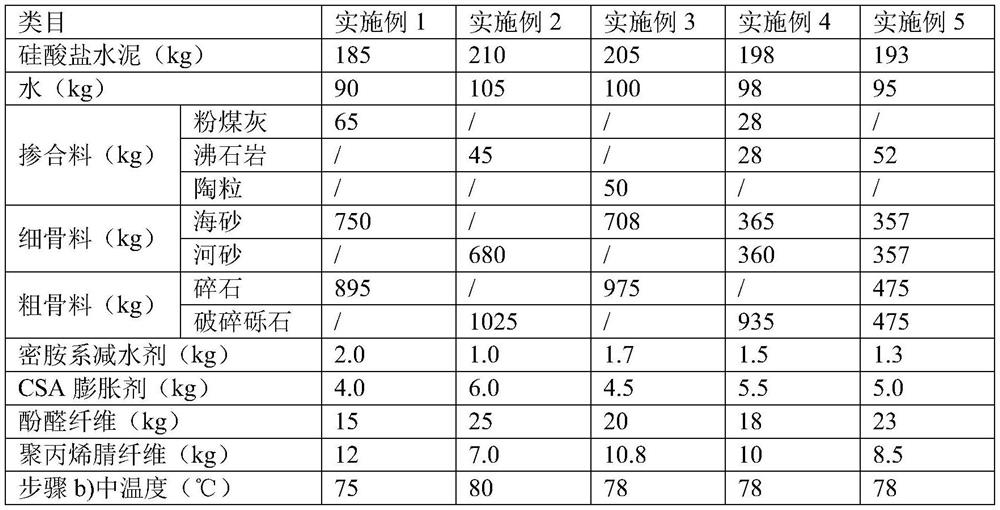

[0073] A kind of deep silt foundation reinforcement method, the difference with Embodiment 1 is,

[0074] The consumption and selection of each raw material are different, and the temperature in step b) is different, see Table 2 for details, and various parameters of Example 1 are also summarized in Table 2.

[0075] Table 2

[0076]

Embodiment 6

[0078] A kind of deep silt foundation reinforcement method, the difference with embodiment 5 is,

[0079] The admixture is fly ash, zeolite rock and ceramsite, and the weight ratio of fly ash, zeolite rock and ceramsite is 0.15:1:1.3, that is, the input amount of fly ash is 3.2kg, and the input amount of zeolite rock is 21.2kg, the input amount of ceramsite is 27.6kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com