Efficient static blasting auxiliary orienting device for grooving and large hole drilling and construction method

A static blasting, directional device technology, applied in blasting, building maintenance, construction and other directions, can solve the problems affecting construction safety and construction progress, uncertain blasting direction, small expansion pressure, etc., to reduce the waiting time for crushing and the response time is short. , the effect of large expansion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

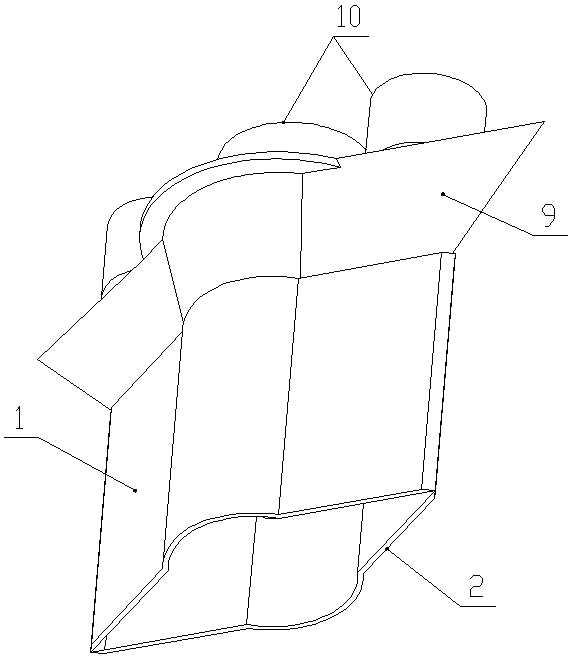

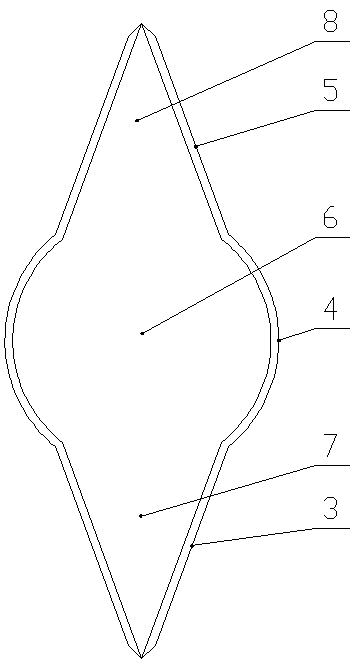

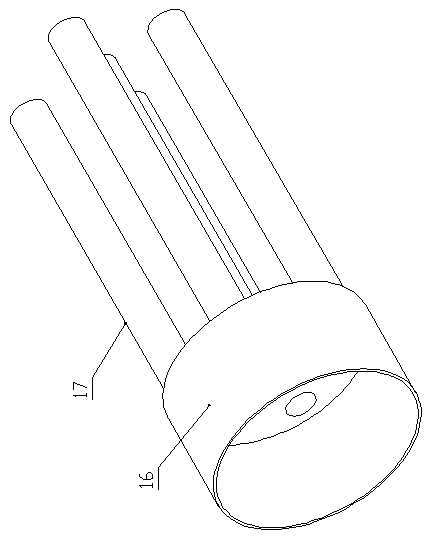

[0025] like Figure 1-Figure 5 As shown, the high-efficiency static blasting auxiliary orienting device for grooving and large drilling of the present invention includes a left guide plate 1 and a right guide plate 2 arranged vertically and left and right symmetrically, and the left guide plate 1 and the right guide plate 2 are arranged from the front to the The back is successively front plate 3, middle arc plate 4 and back plate 5, and the middle arc plate 4 of left guide plate 1 and right guide plate 2 forms cylindrical chamber 6 relatively left and right, and the left guide plate 1 and right guide plate 2 The front side of the front plate 3 contacts to form the front V-shaped cavity 7, the rear side of the rear plate 5 of the left guide plate 1 and the right guide plate 2 contacts to form the rear V-shaped cavity 8, the front V-shaped cavity 7, the cylindrical cavity 6 and The rear V-shaped cavity 8 is connected, and the front V-shaped cavity 7 and the rear V-shaped cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com