Momentum balance seal

A technology of sealing device and momentum balance, which is applied in blasting and other directions, can solve problems such as complicated procedures, and achieve the effects of high energy utilization rate, fast reaction time, and large expansion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

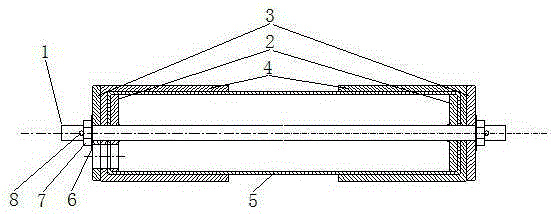

[0015] combine figure 1 , a momentum balance sealing device, including a steel bar 1, an inner top plate 2, an outer top plate 3, a silicone sealing sleeve 4, a non-woven bag 5, a rubber gasket 6, a nut 7 and a steel pin 8; two cup-shaped The cup openings of the silicone sealing sleeve 4 are placed facing each other, the cylindrical non-woven fabric bag 5 is set in two cup-shaped silicone sealing sleeves 4 placed opposite to each other, and the two inner top plates 2 are respectively set in the cylindrical non-woven fabric bag 5 , and are respectively located at the cup bottom of the cup-shaped silicone sealing sleeve 4, and the two outer top plates 3 are respectively arranged on the outer walls of the cup bottom of the two silicone sealing sleeves 4, the steel bar 1 runs through the center of the two outer top plates 3, and the two ends of the steel bar 1 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com