Hydraulic punching and drilling three-grade coal breaking hole-blockage preventing device and method

A hydraulic punching and coal breaking technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problem of not being able to effectively solve the problem of the injection hole, and achieve the effect of solving the problem of the injection hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

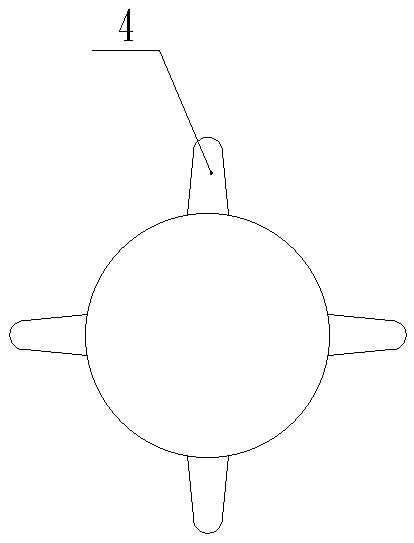

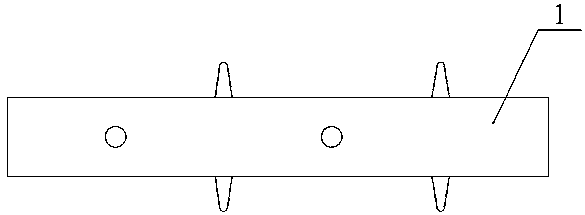

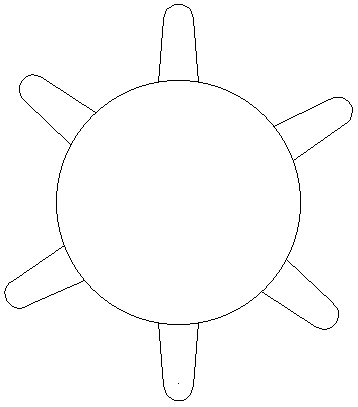

[0026] like Figure 1-Figure 6 As shown, the present invention is a three-stage coal breaking and anti-blocking device for hydraulic punching and drilling, which is used to break the blocked coal blocks produced by hydraulic punching. Coal breaker 2 and third-level coal breaker 3, each level of coal breaker is composed of drill pipe and coal breaking nail 4 fixed on the cylinder surface of the drill pipe, first-level coal breaker 1, second-level coal breaker 2 and third-level coal breaker The number of coal-breaking spikes 4 on the first-stage coal breaker 3 increases sequentially. When the device rotates at high speed, the first-stage coal breaker 1 breaks large coal bodies into medium-sized coal bodies, and then the second-level coal breaker 2 The coal body is broken into small pieces, and finally the three-stage coal breaker 3 breaks the coal body into small coal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com