Patents

Literature

33results about How to "Efficient rock breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

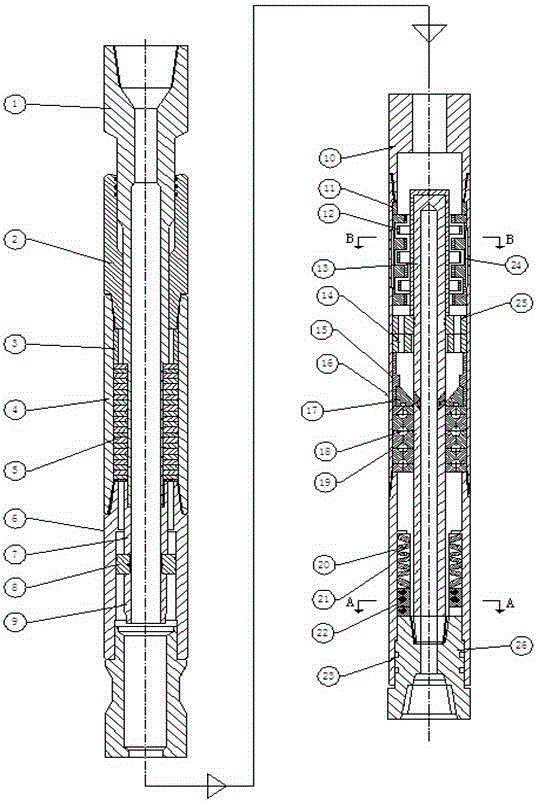

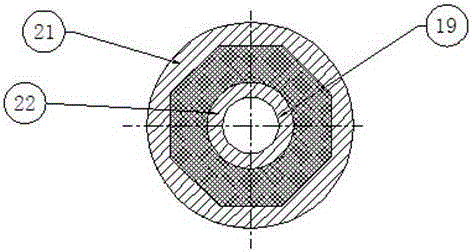

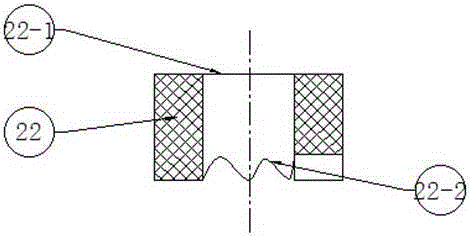

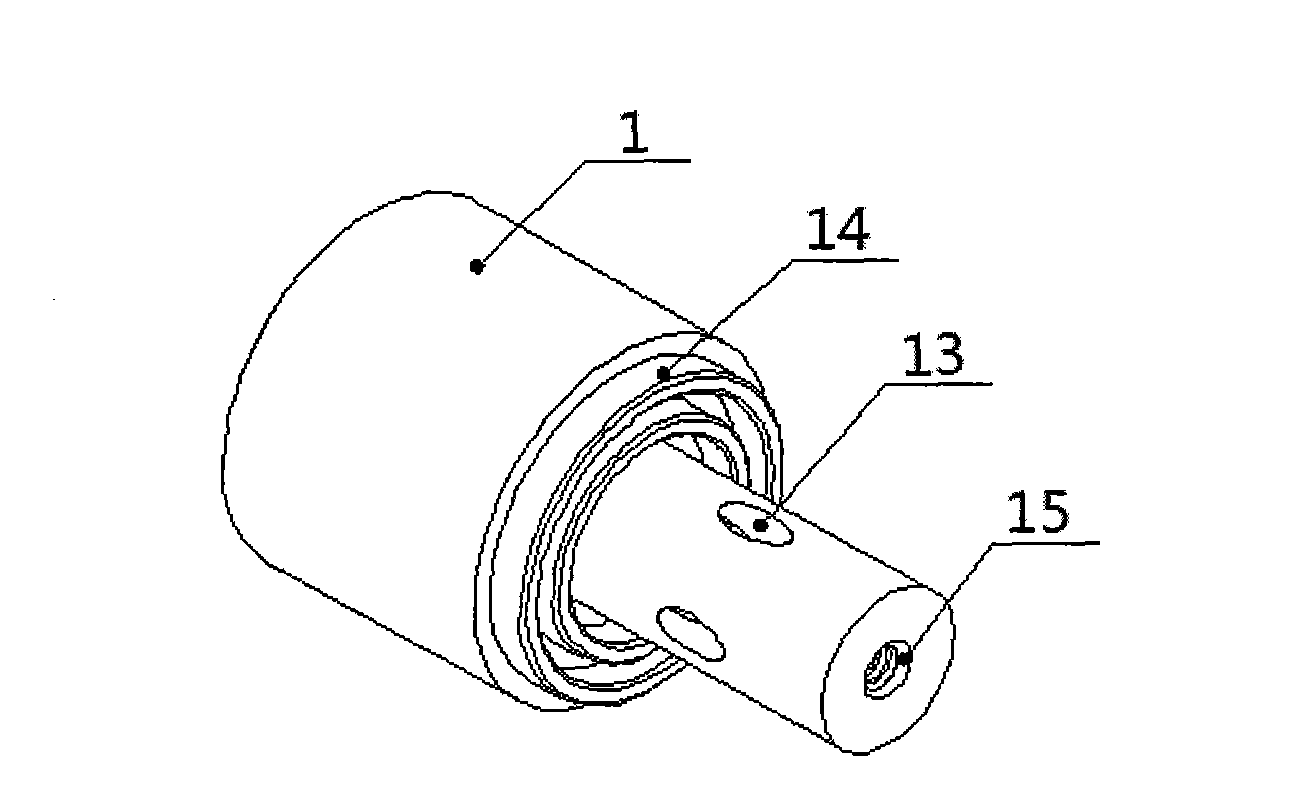

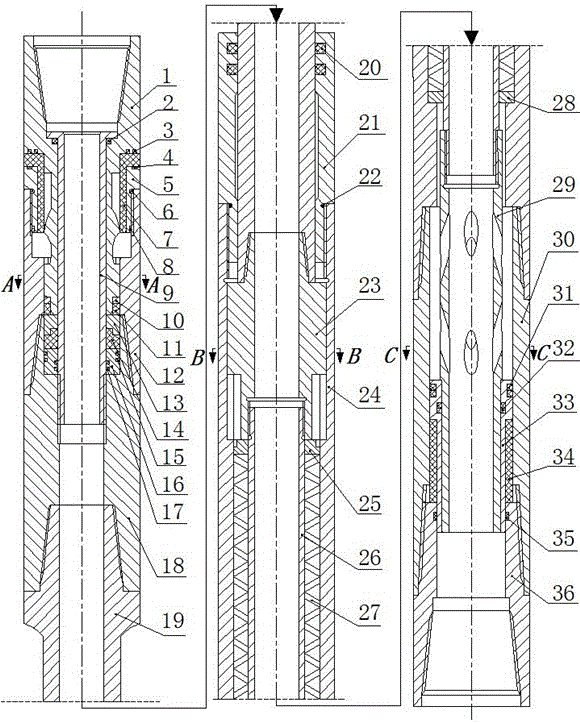

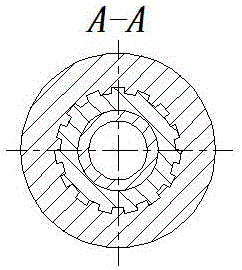

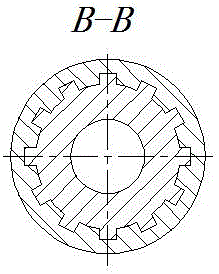

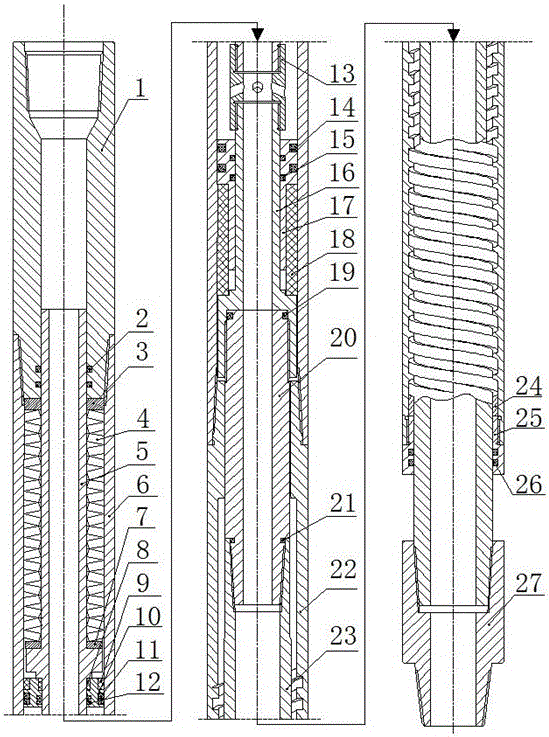

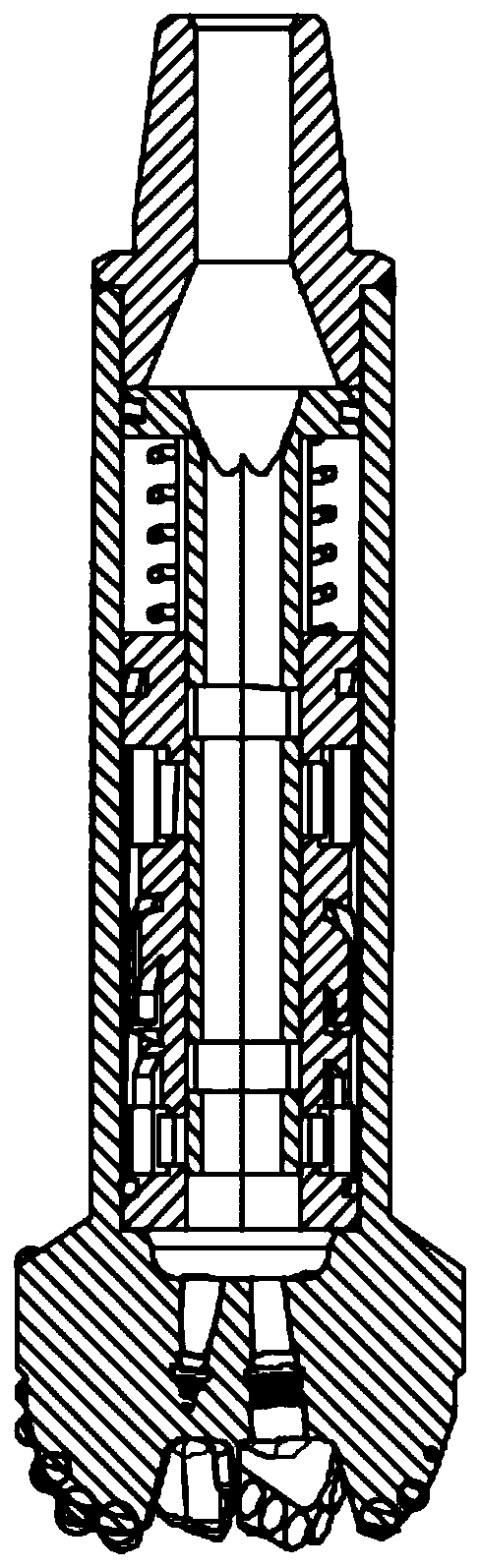

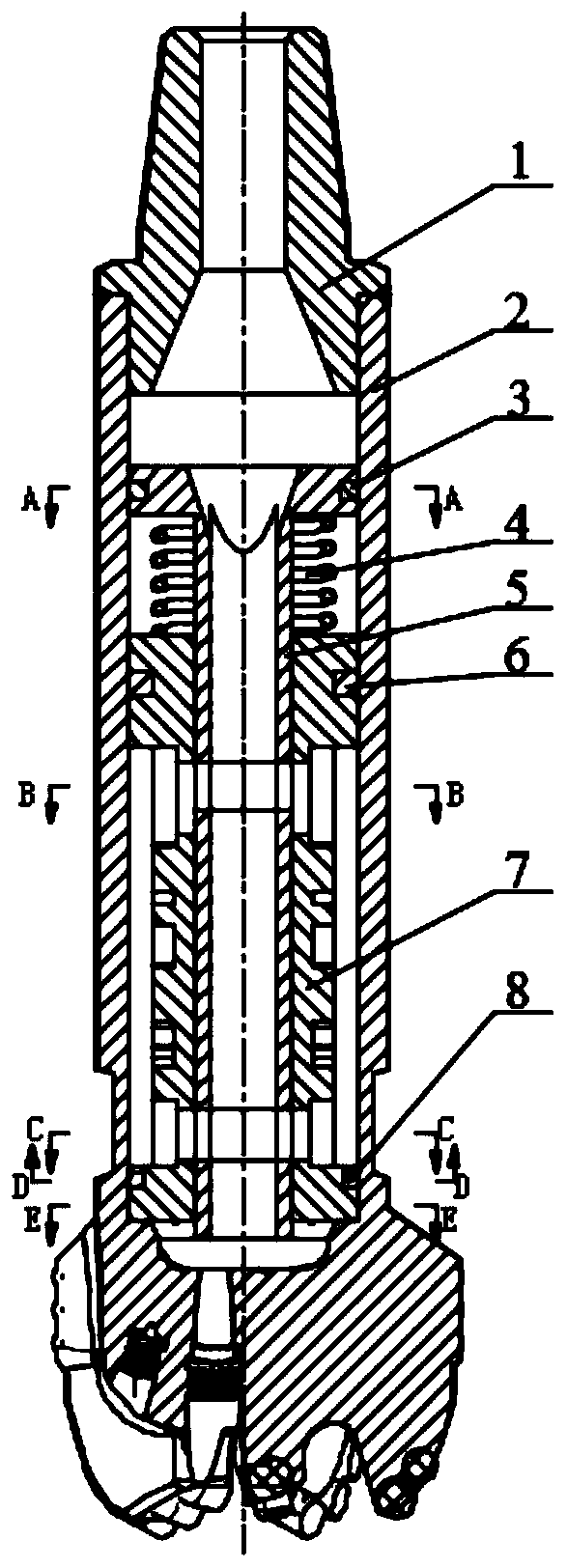

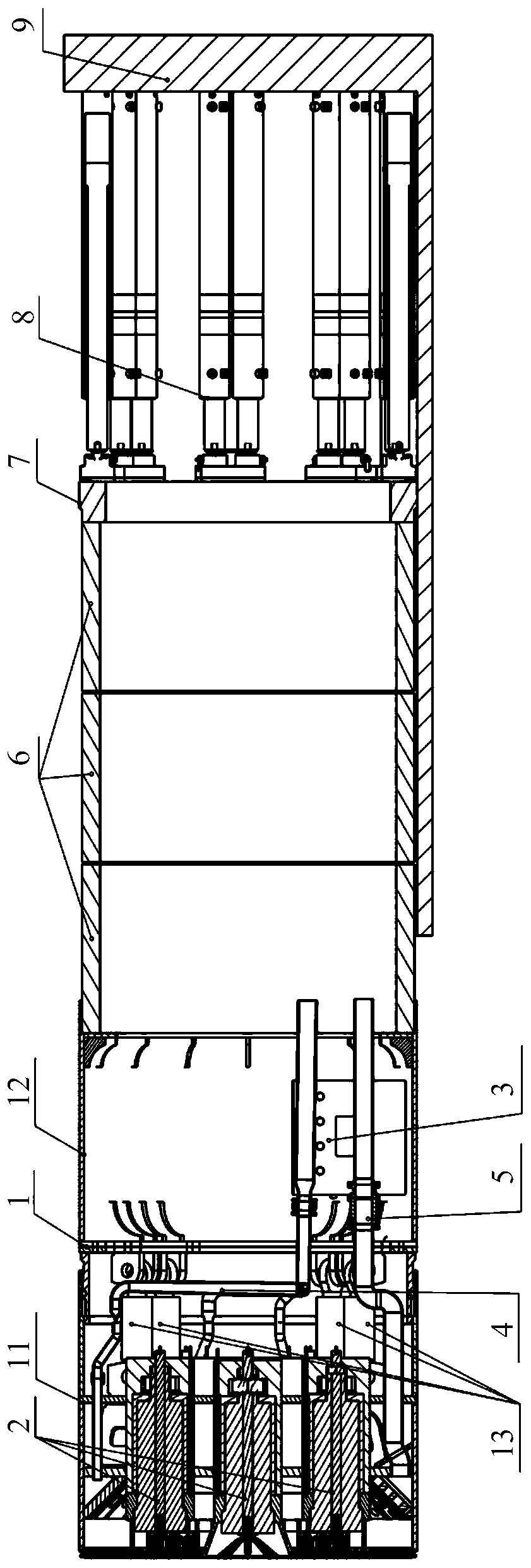

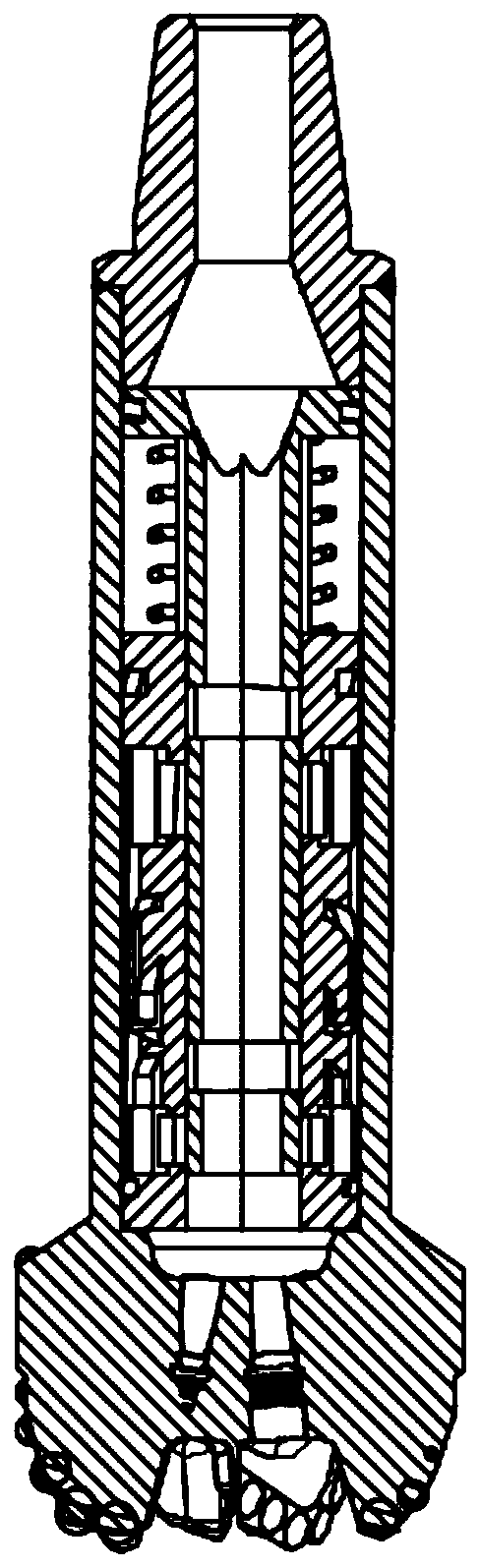

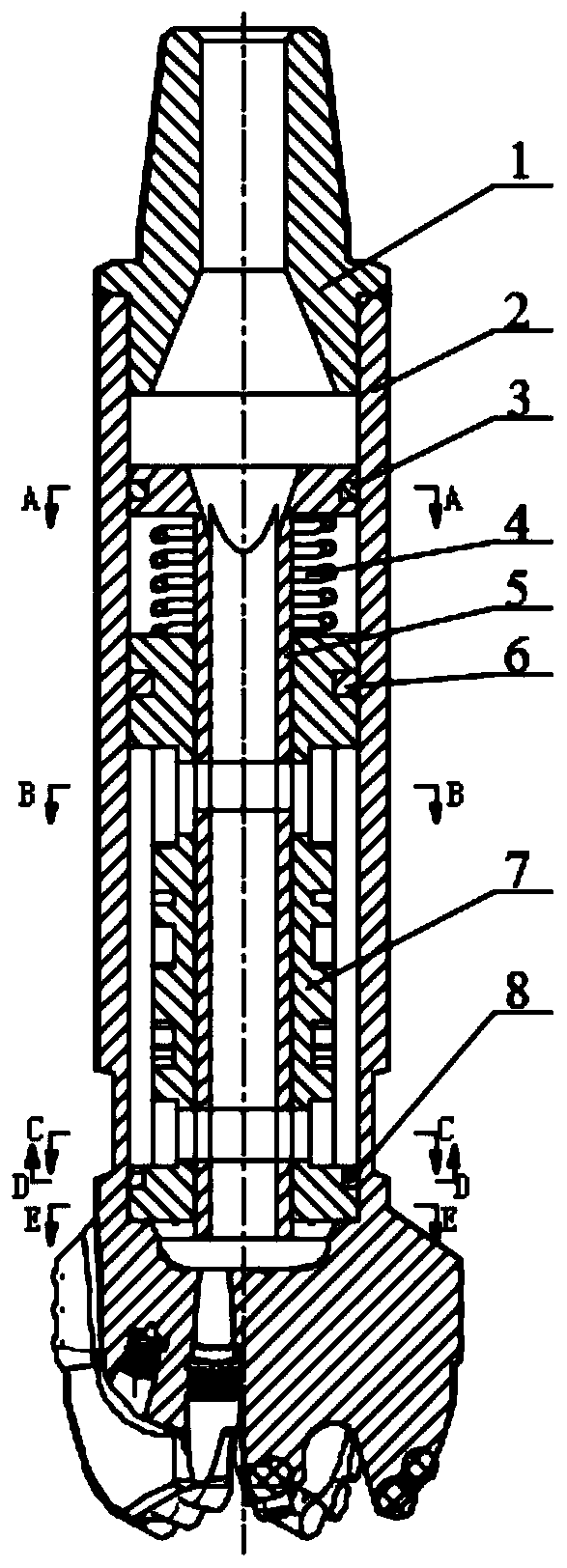

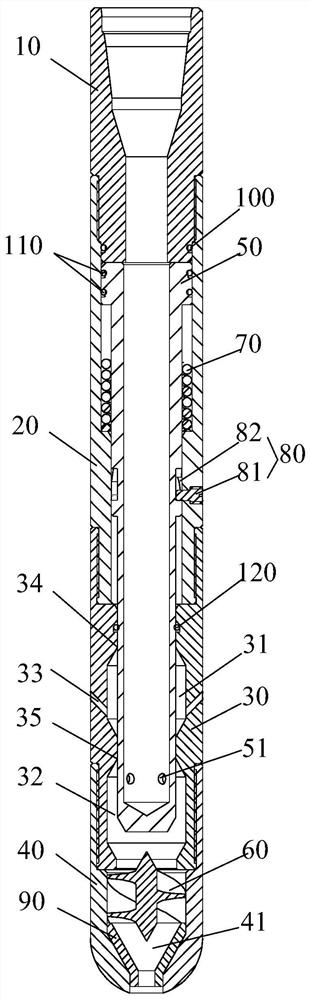

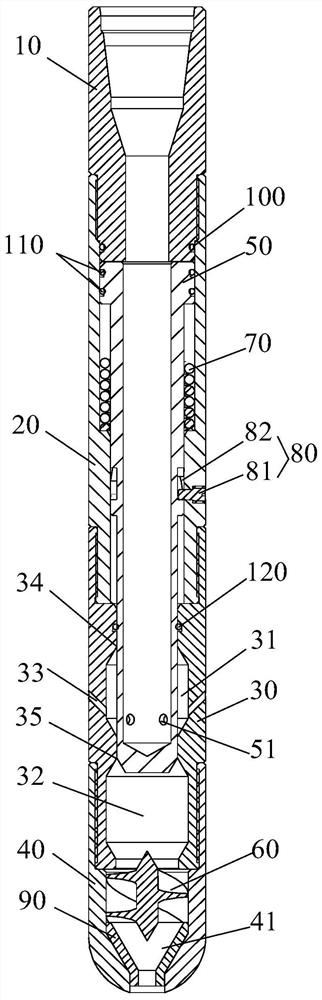

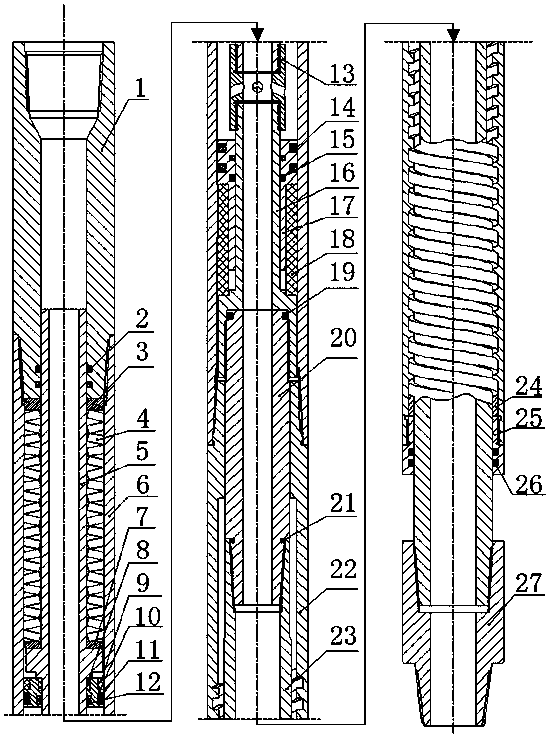

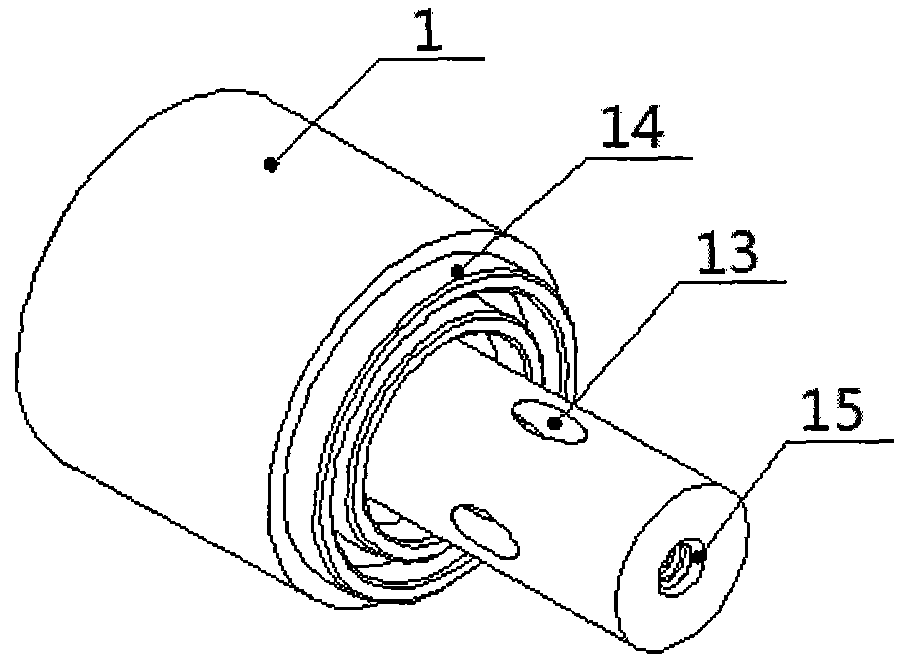

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

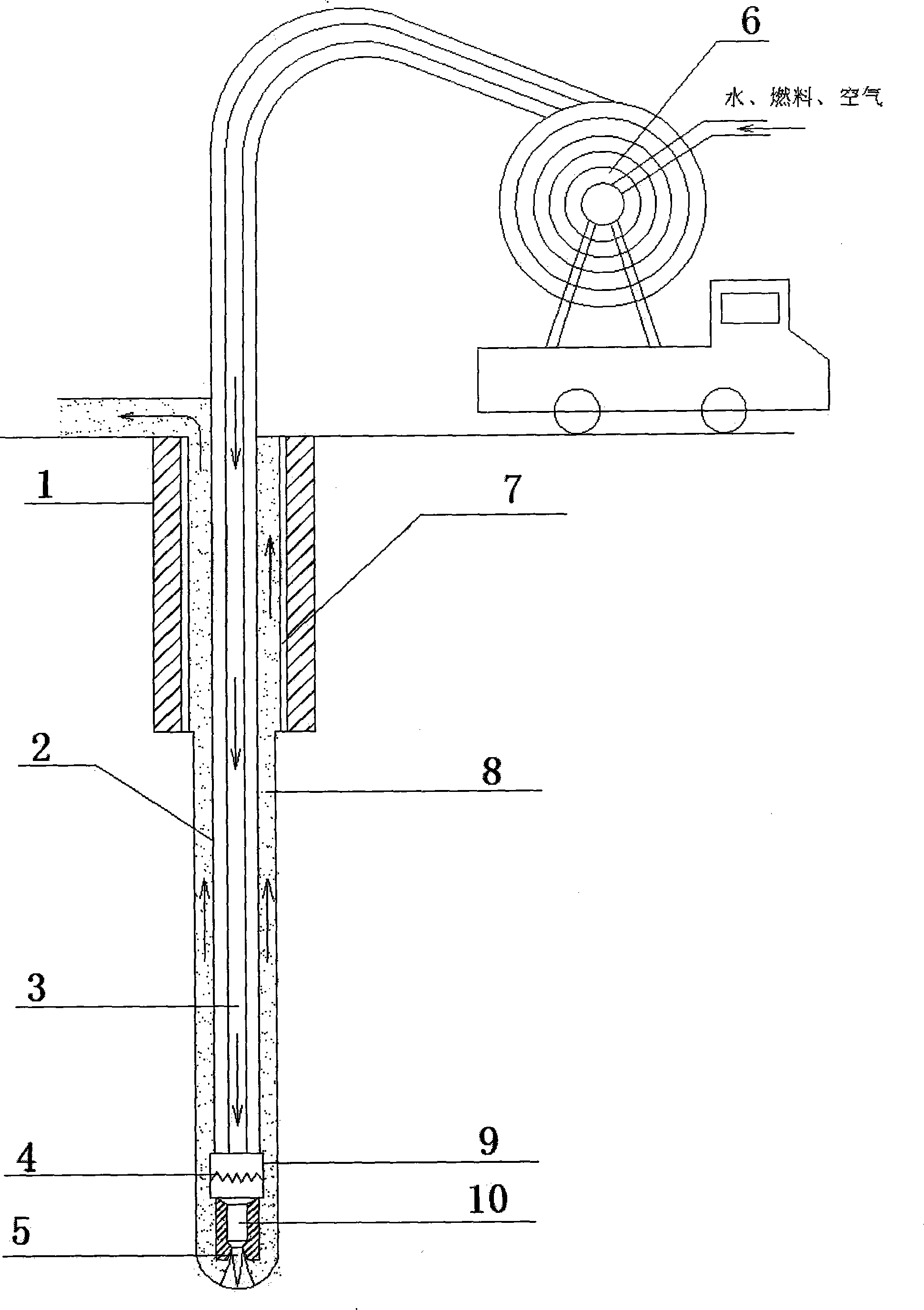

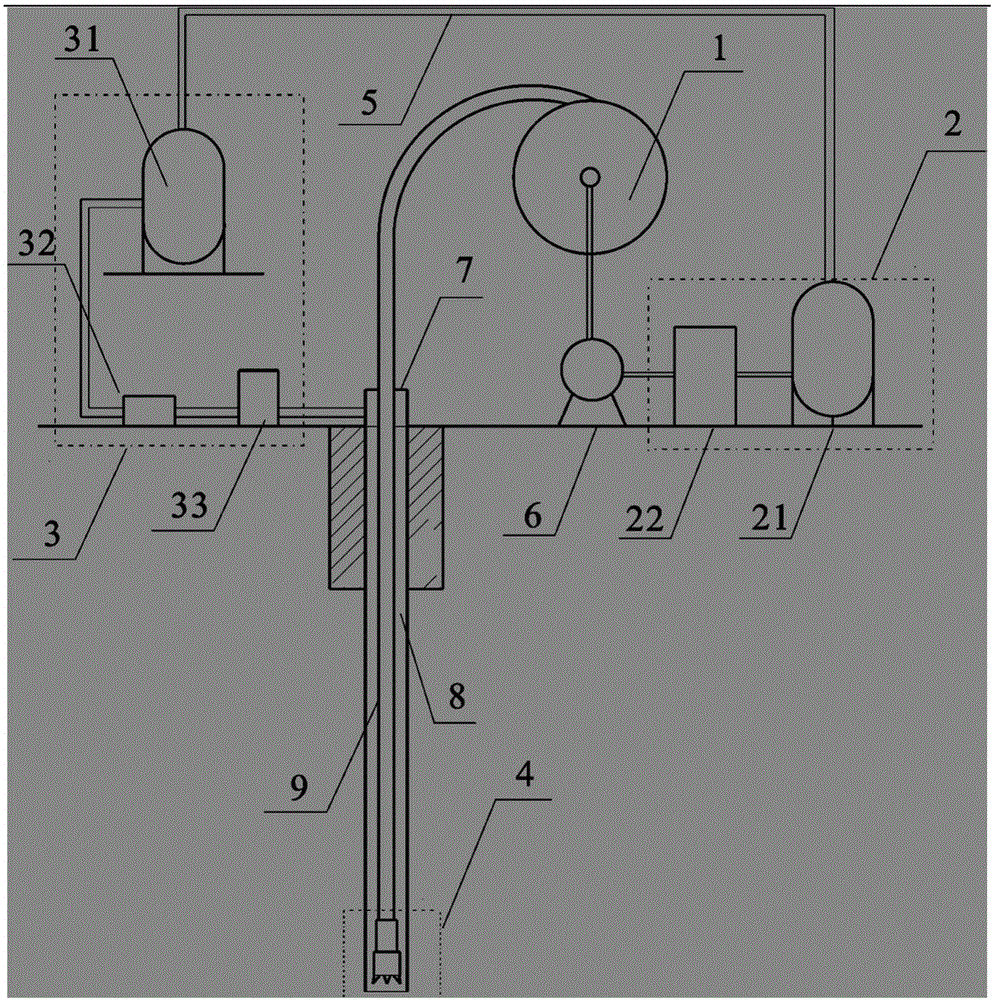

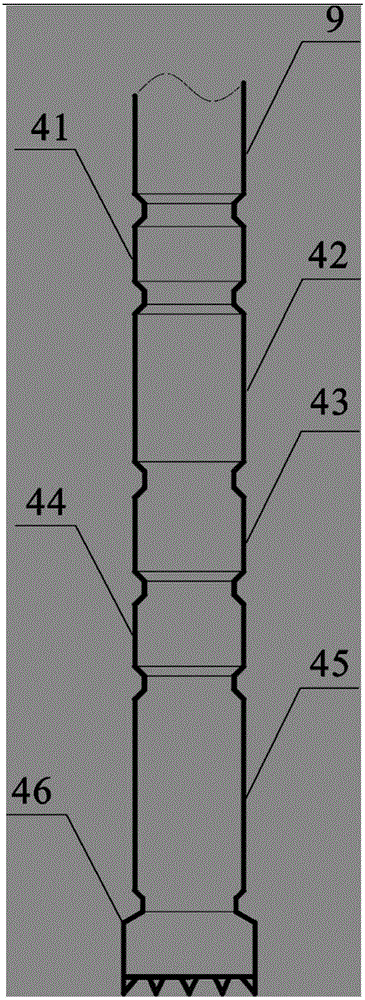

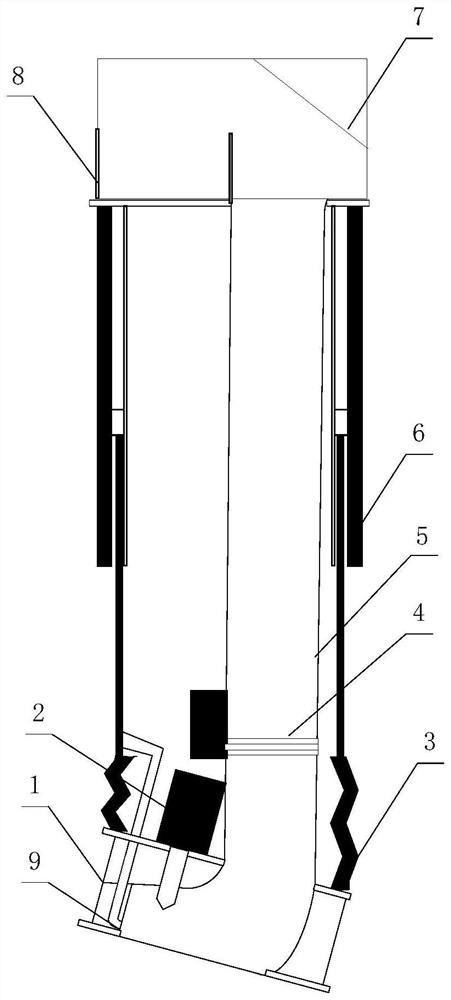

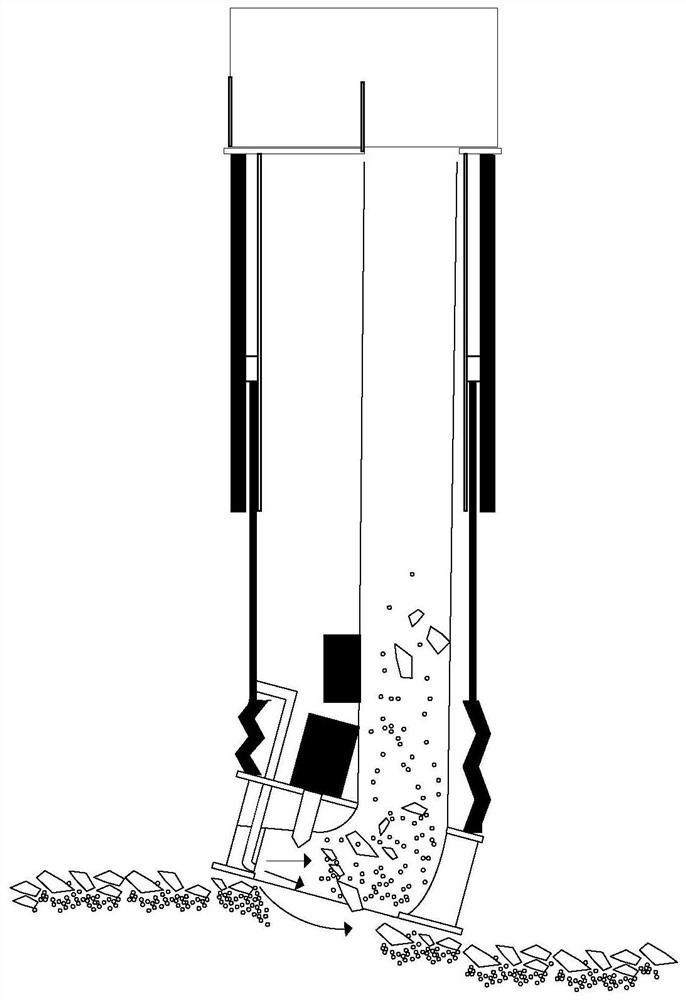

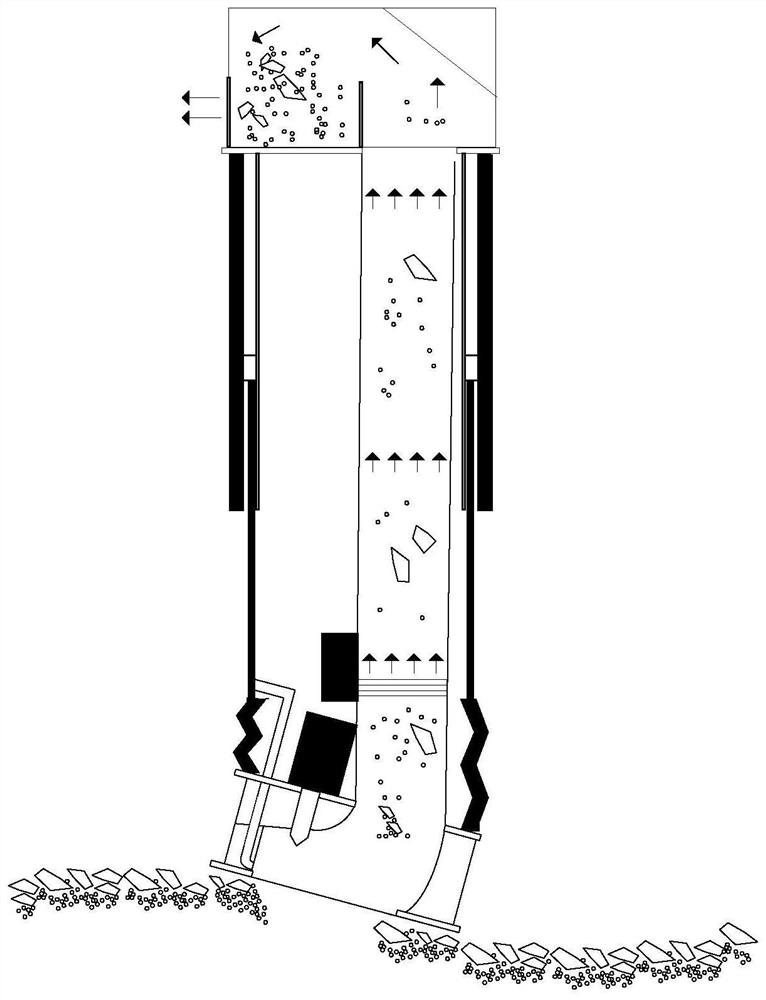

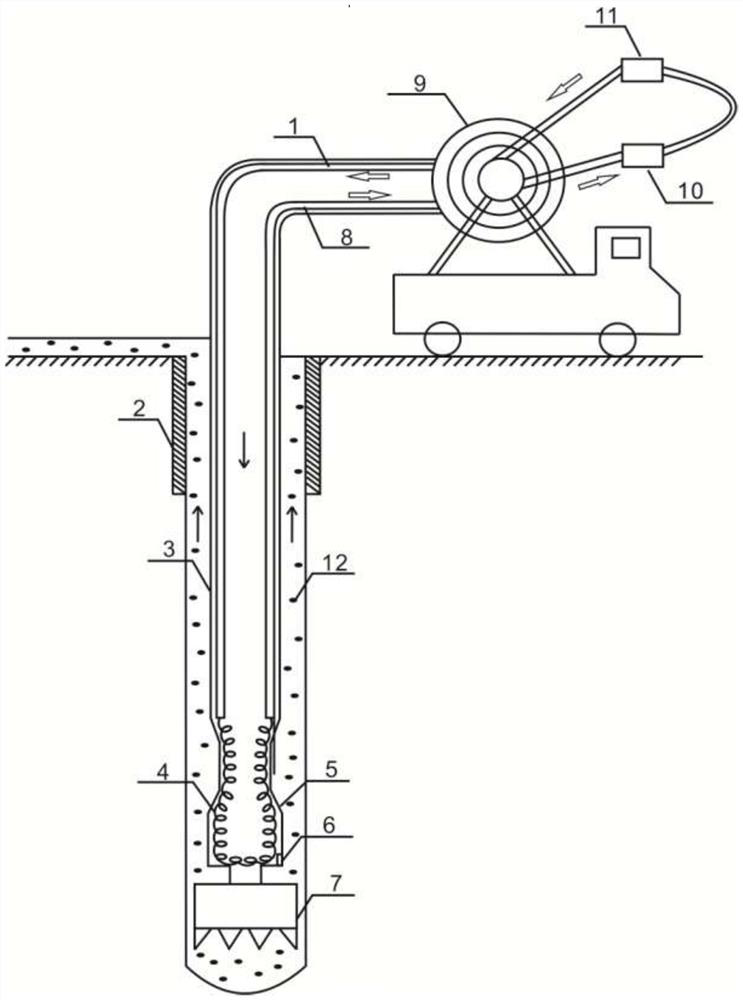

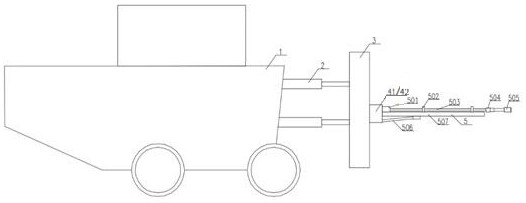

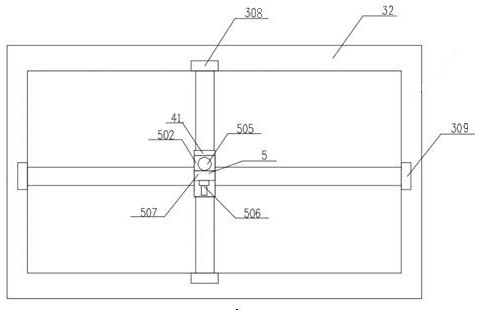

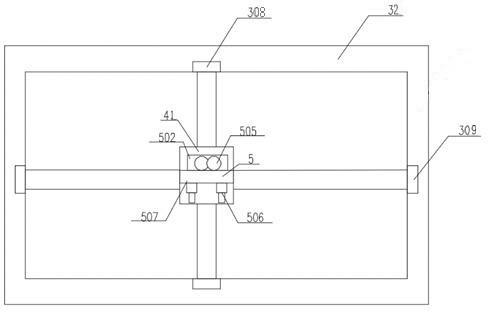

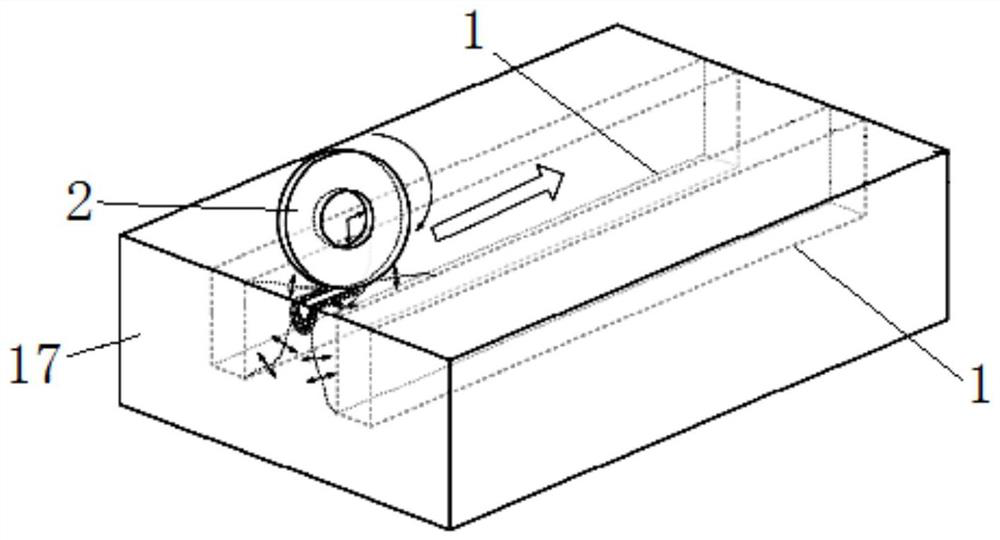

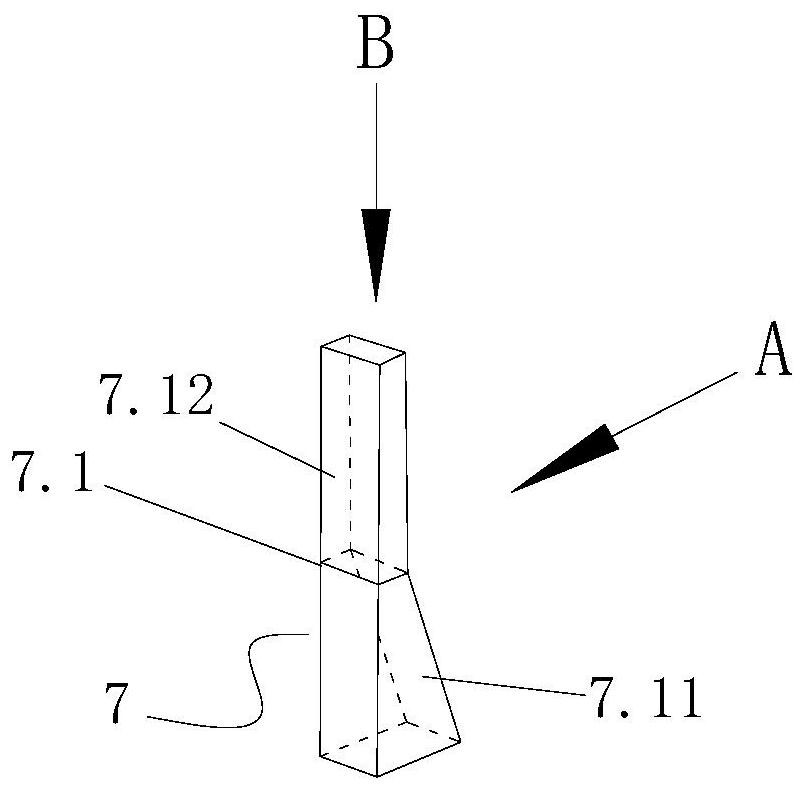

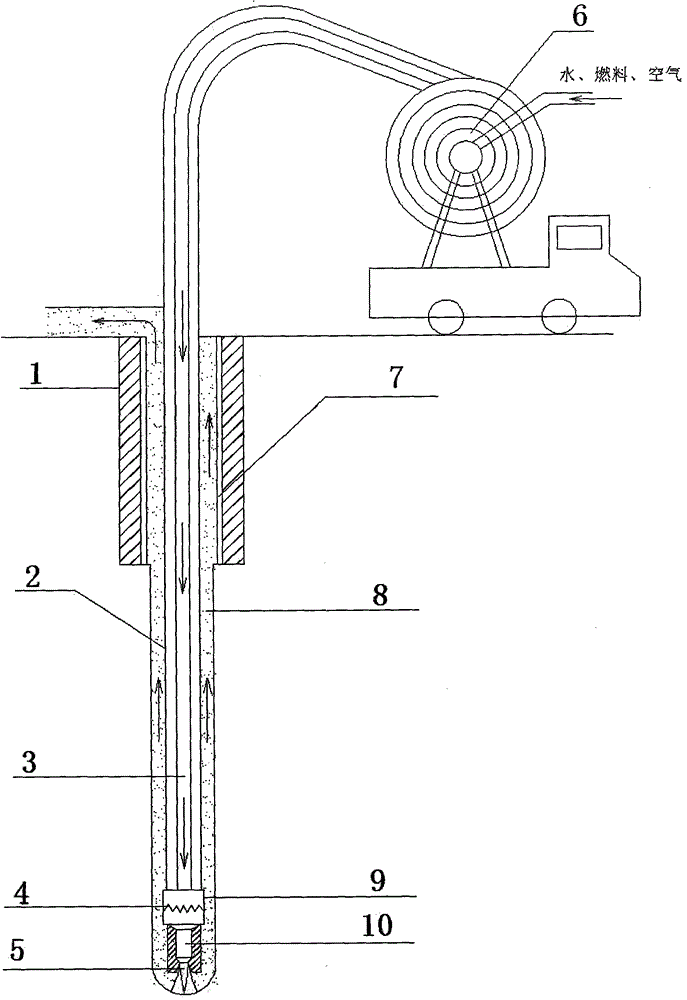

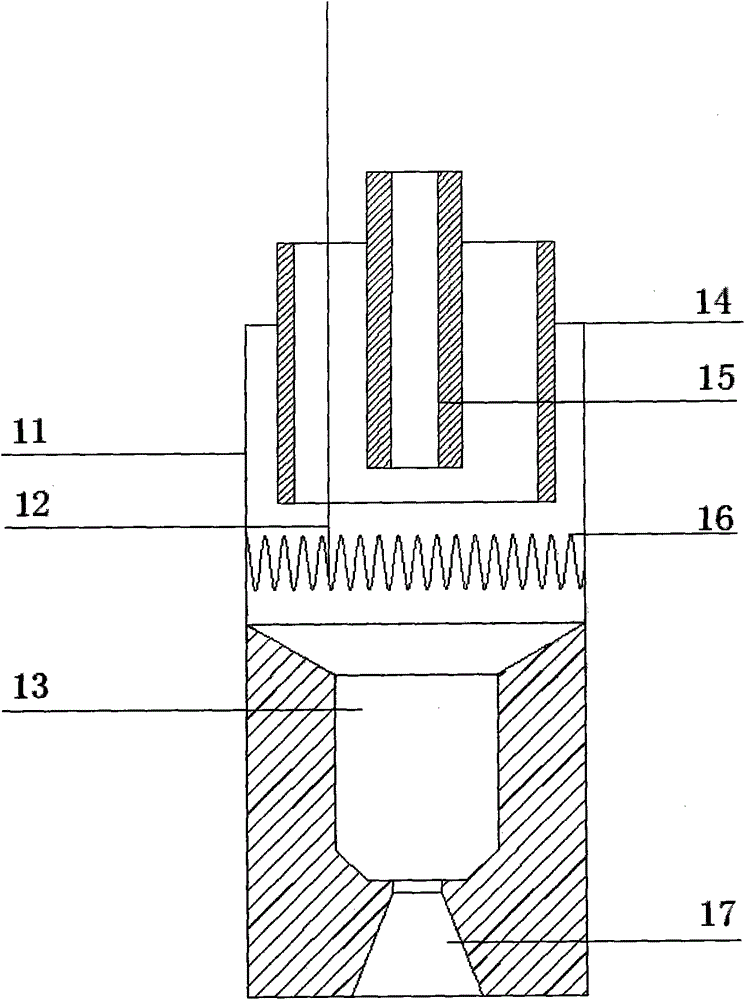

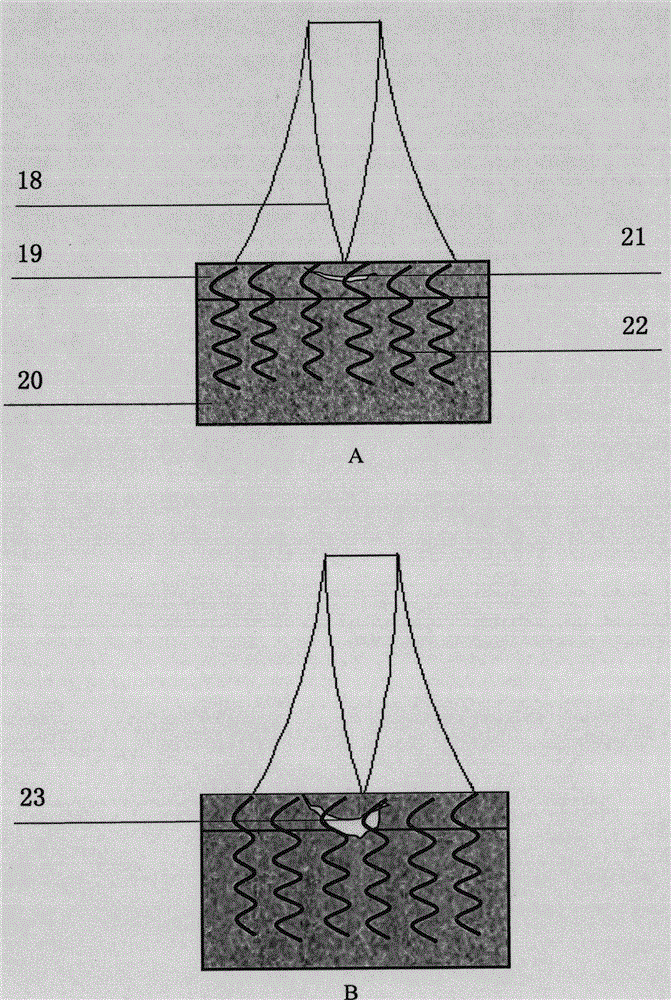

New well drilling method for efficient rock breaking by means of heating power jet flow

ActiveCN103790516AEfficient rock breakingIncrease profitLiquid/gas jet drillingElectric cablesHeating power

The invention relates to a new welling drilling method for efficient rock breaking by means of heating power jet flow, and a complete set of construction scheme. According to the system composition, a continuous coil tubing unit, an electric measuring instrument truck, a cable, an air injection pipeline, a fuel injection pipeline, a fuel reaction cavity, a heating power jet flow nozzle, a ground pump set and the like are included. According to the technology, on the basis of the principle that the continuous heated surfaces of rocks crack until the rocks are decomposed in a splitting mode, the heating power jet flow acts on the rocks on the deep well hard formation, the non-contact efficient rock breaking is achieved under heat transfer and impact force of high-temperature and high-pressure fluid media, and the energy utilization rate of the well bottom is improved; the technological process is simple, the continuous oil tube well drilling technology is combined, a drill bit does not need to be replaced, the time of the tripping operation is shortened, abrasion to a tubular column is reduced, and the cost of the drilling operation is reduced. According to the new welling drilling method for efficient rock breaking by means of heating power jet flow, the heating power jet flow technology is creatively guided into the continuous oil tube well drilling, popularization and application of the continuous tube technology are facilitated, and oil and gas resources are efficiently exploited.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

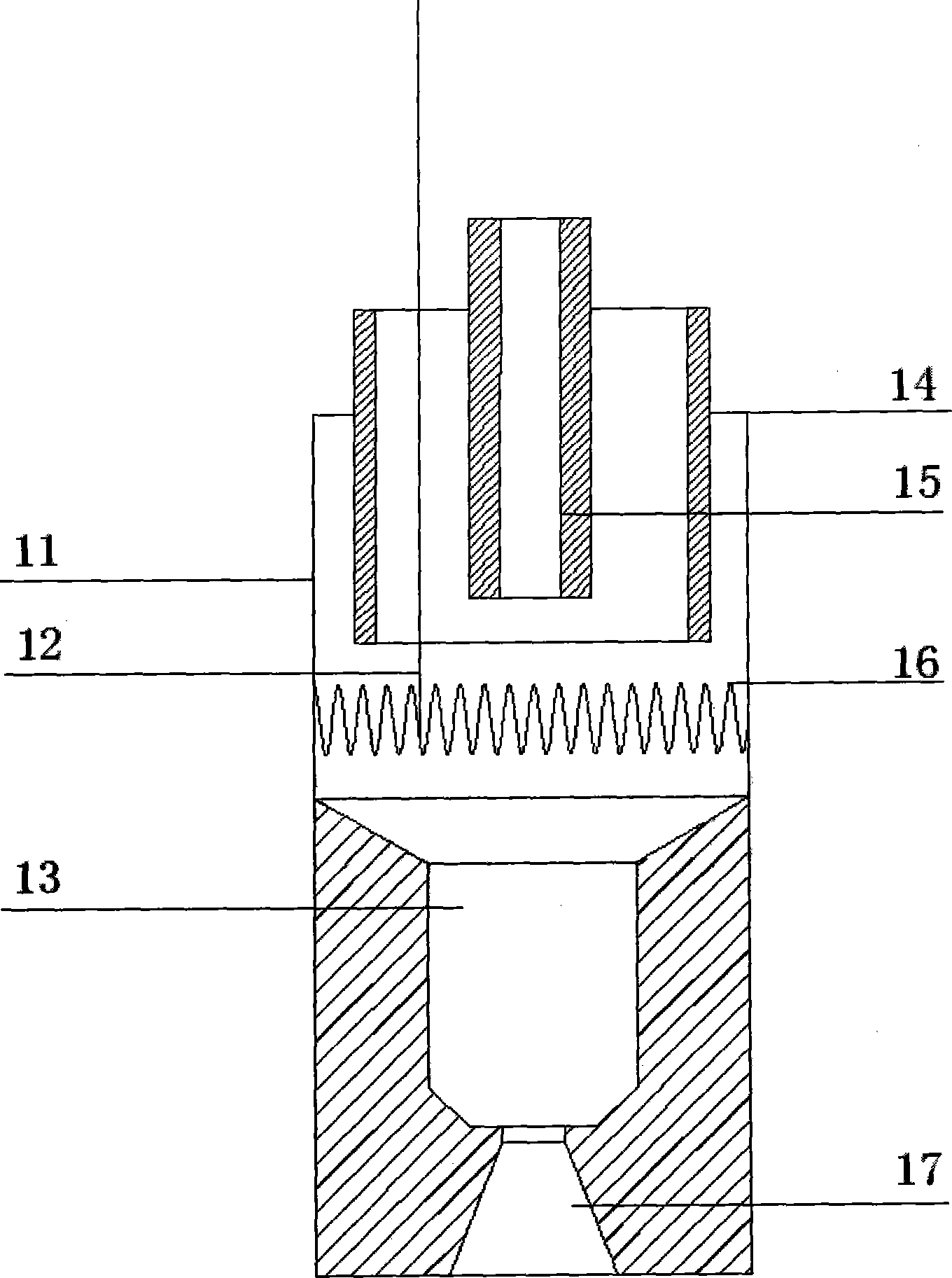

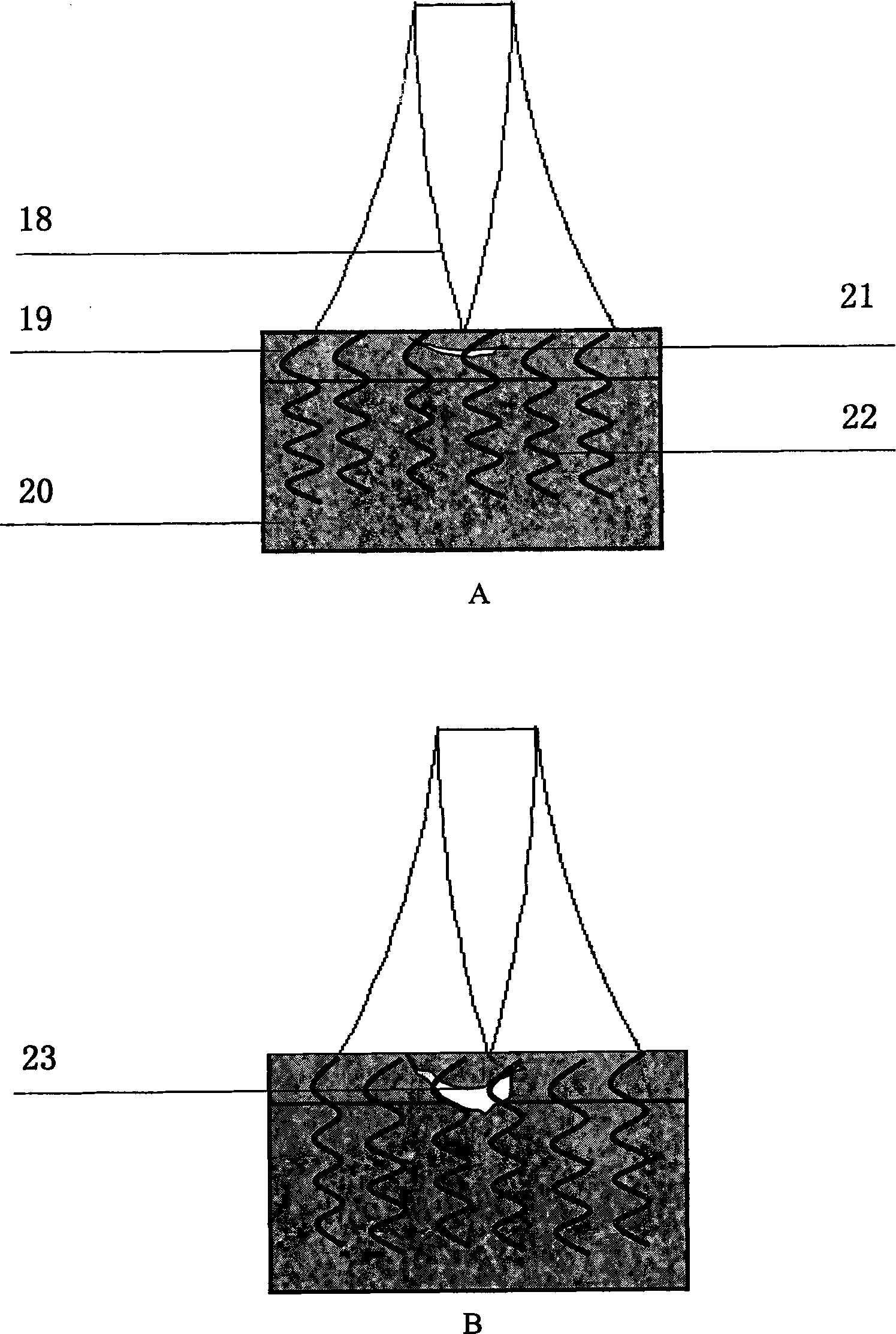

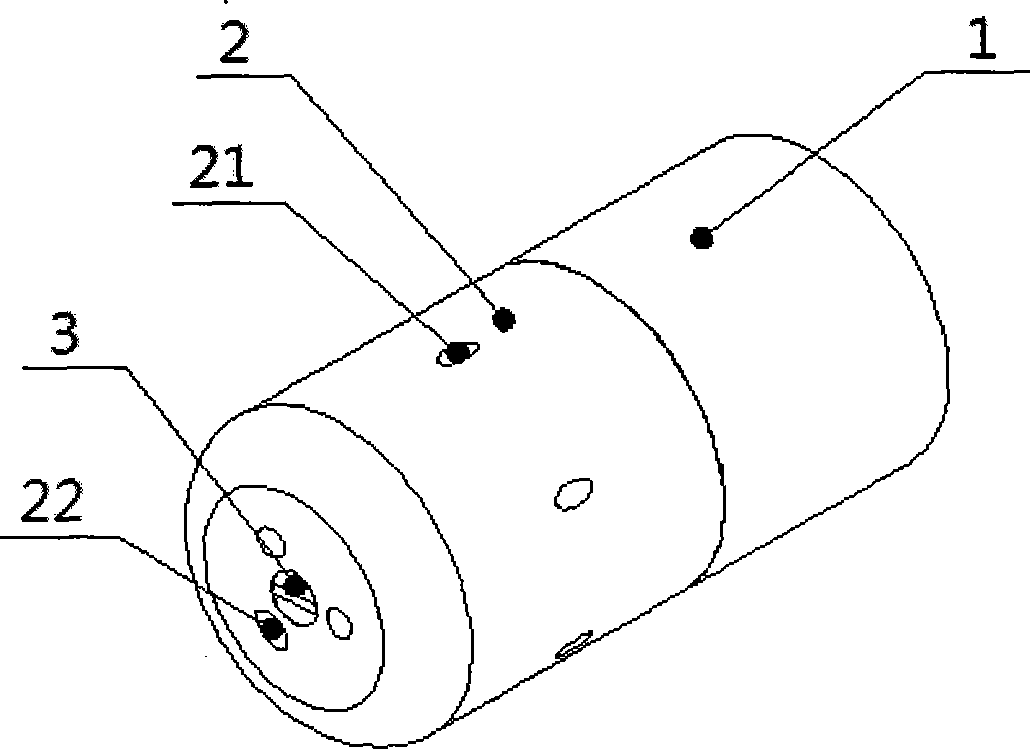

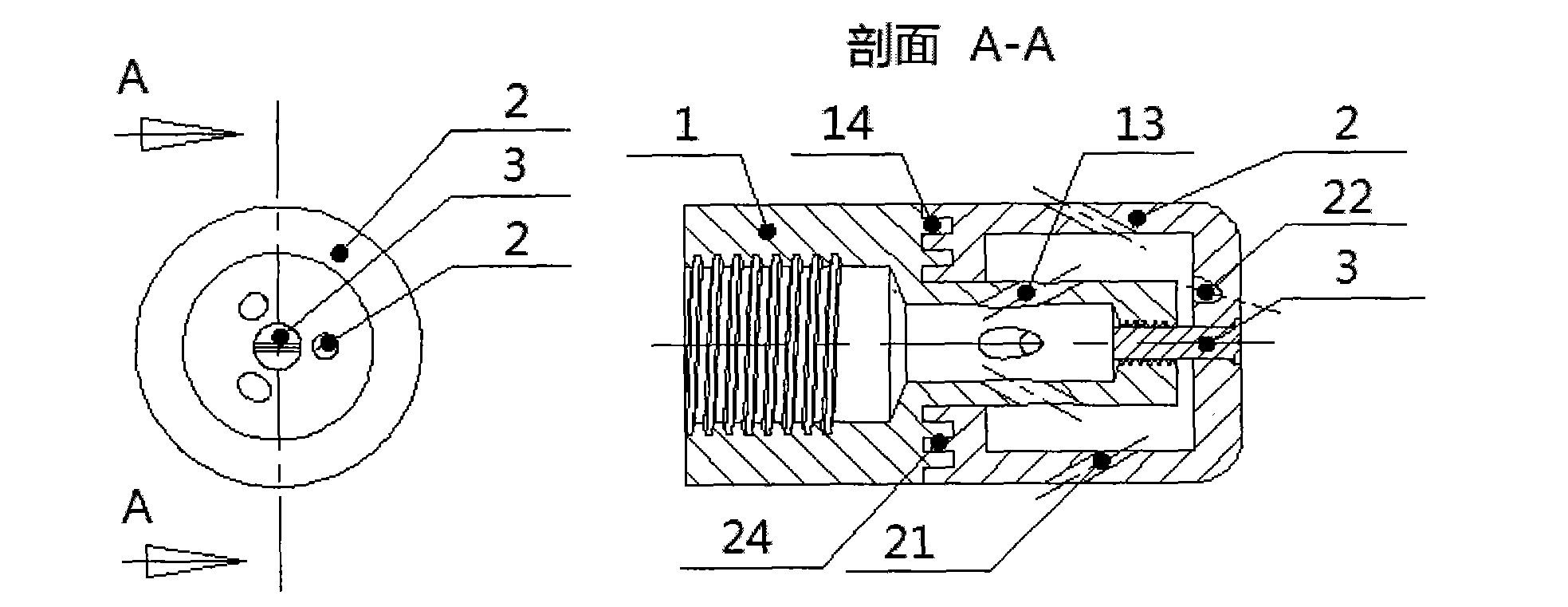

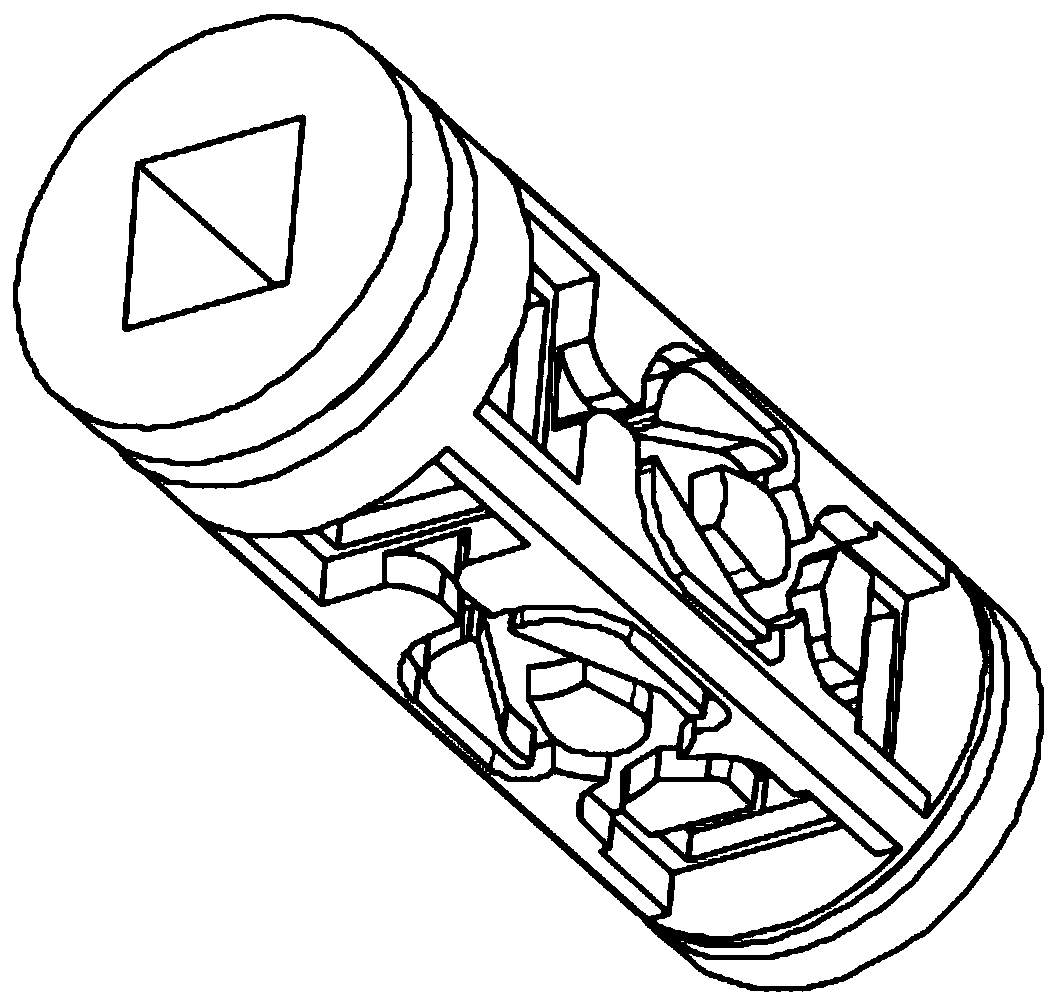

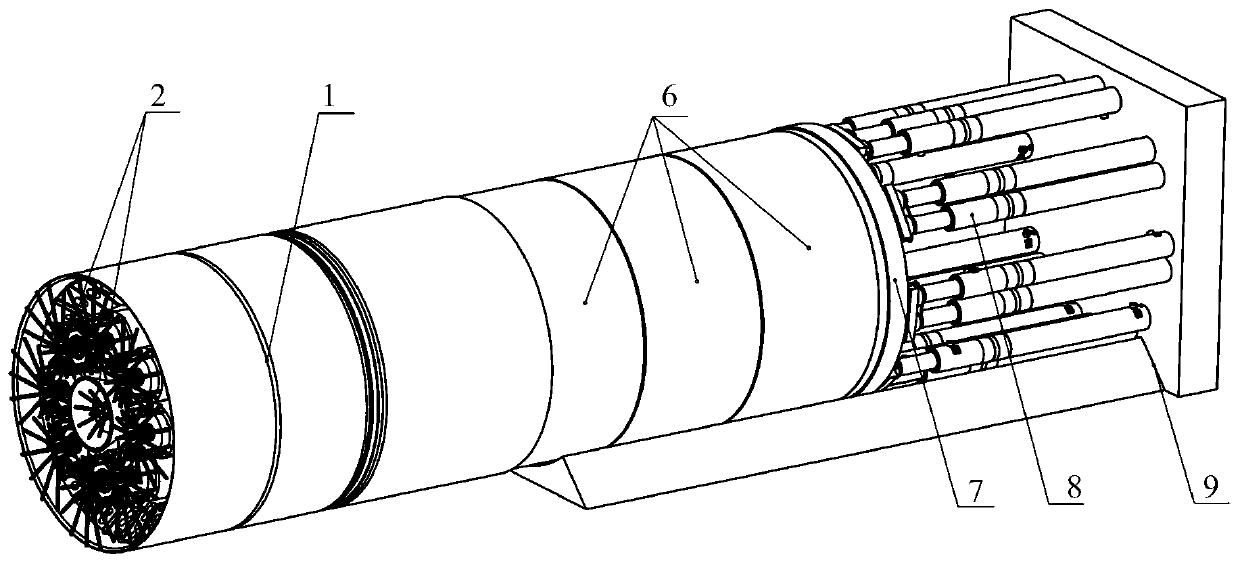

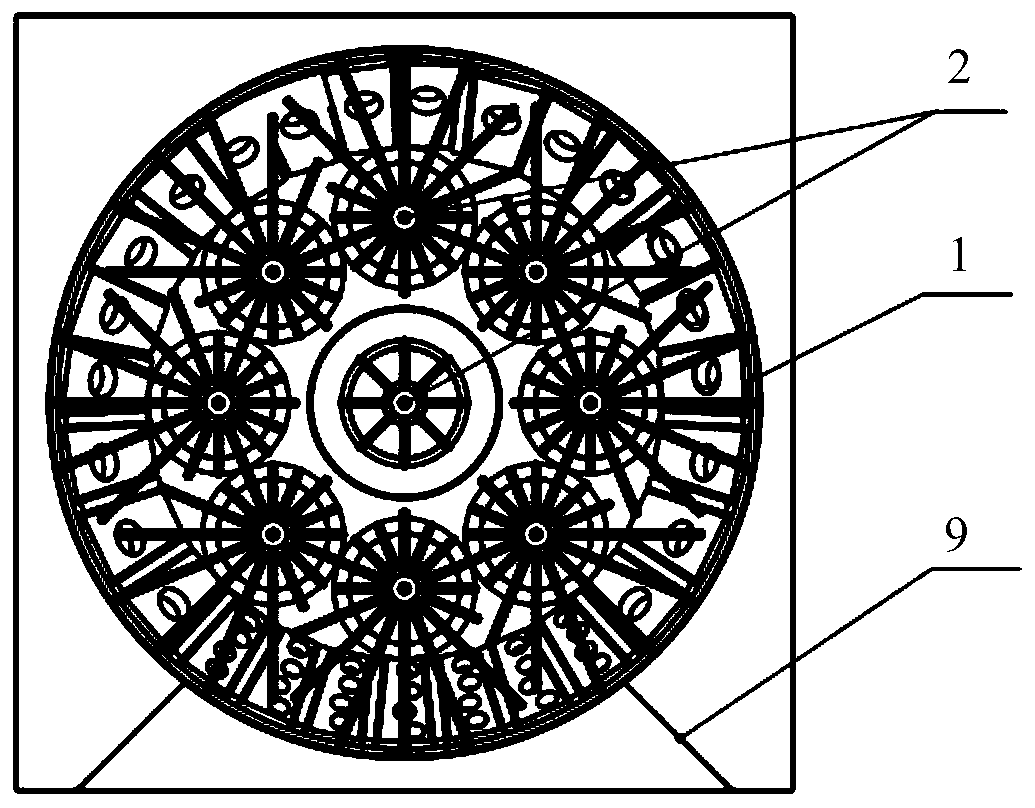

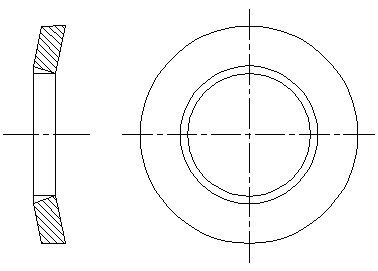

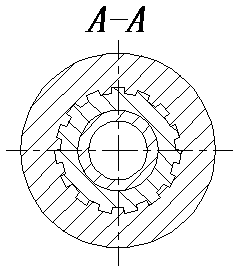

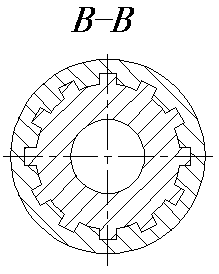

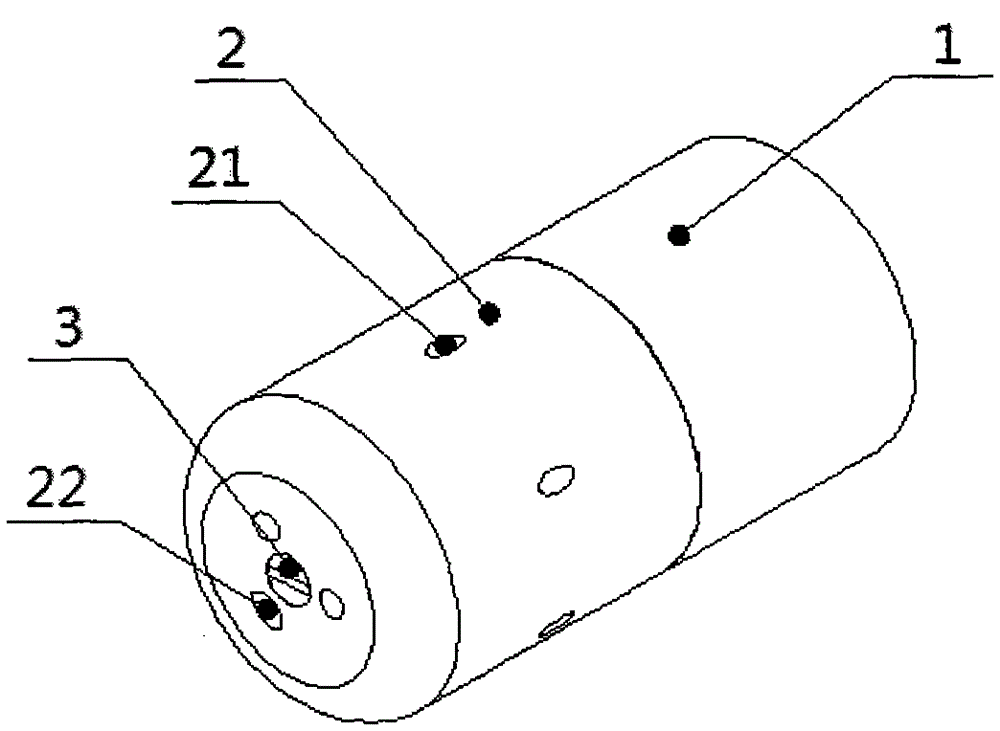

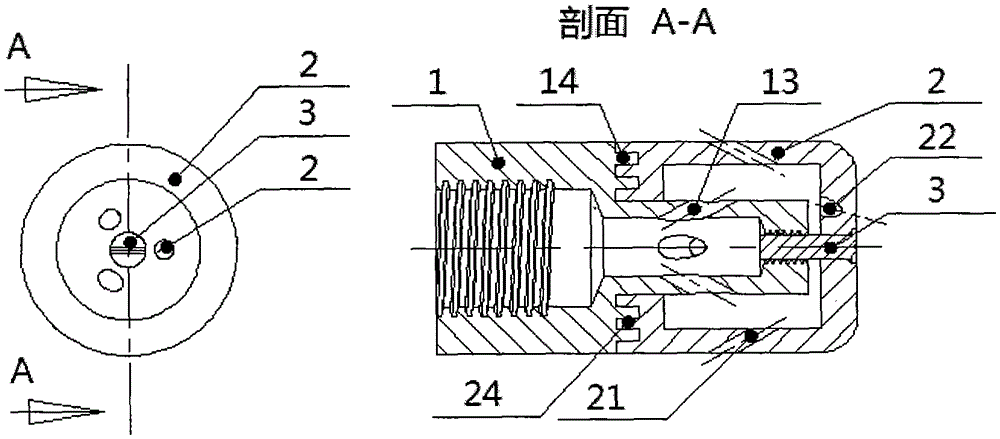

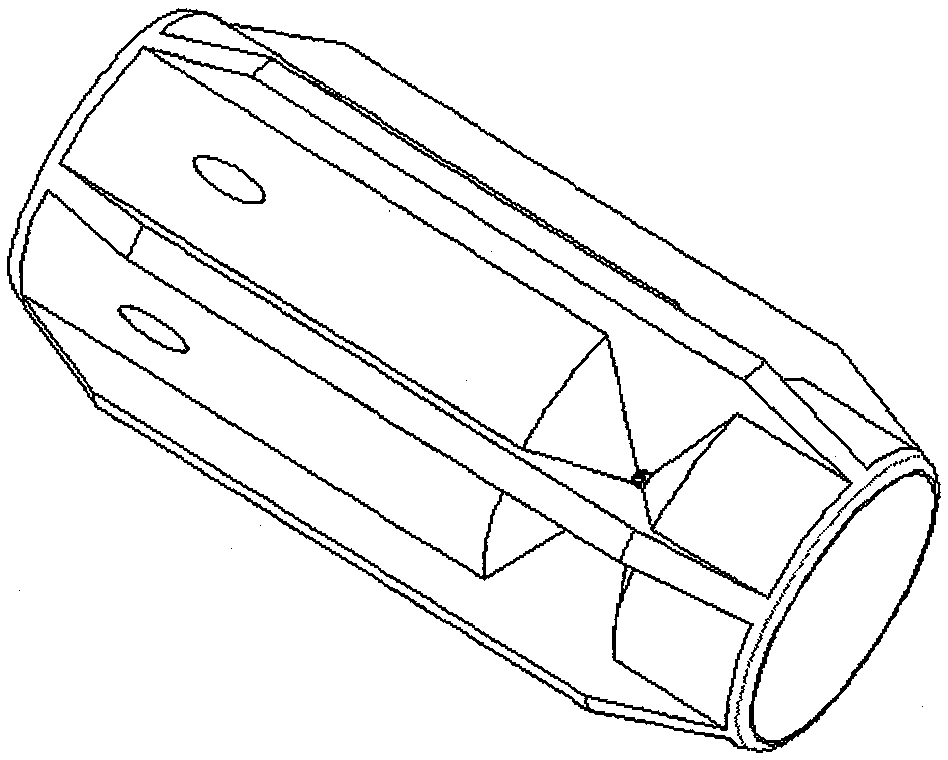

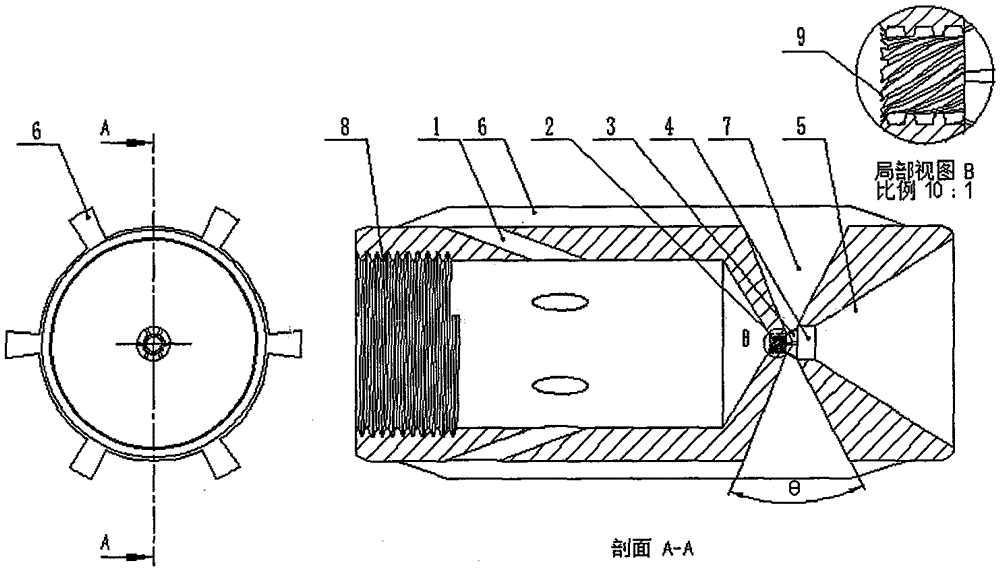

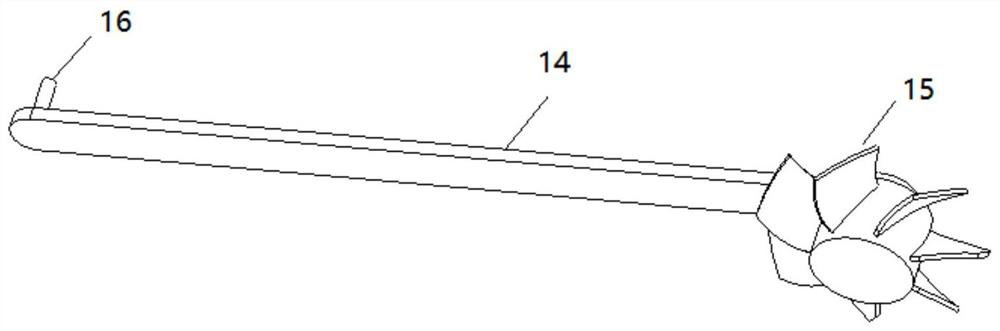

Self-feeding rotary jet flow multi-hole spray nozzle

ActiveCN103806836AGuaranteed reliabilitySimple structureLiquid/gas jet drillingFeeding forceJet flow

The invention relates to a self-feeding rotary jet flow multi-hole spray nozzle, which comprises a spray nozzle cap, a back end shaft, a screw and the like. The self-feeding rotary jet flow multi-hole spray nozzle has the basic work principle that a plurality of forward holes are uniformly formed in a certain circle, leaving away from the center for a certain distance, of the front end surface of the spray nozzle, a plurality of center axes of the holes are in the located plane of a certain tangent line of the circle and are distributed in a way of forming different angles with an axial line of the spray nozzle cap, and the projection of the axial lines of the holes in the front end surface is a tangent line of the same circle, so the jet flow has high tangential speed, and the efficient rock breaking is favorably realized; the jet flow dispersion is realized, the acting range is wide, and large-aperture holes are favorably formed; the spray nozzle cap realizes autorotation through the jet flow reaction, each hole is scanned along the self rail for completing the rock breaking, and the formed holes are more regular; the spray nozzle cap realizes the autorotation, and the self feeding of the spray nozzle is favorably realized. The backward spray nozzle provides the self-feeding force, and meanwhile, the autorotation of the spray nozzle cap can be controlled. The self-feeding rotary jet flow multi-hole spray nozzle has the advantages that the structure is simple, the efficient rock breaking can be realized, and large-diameter regular holes are formed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

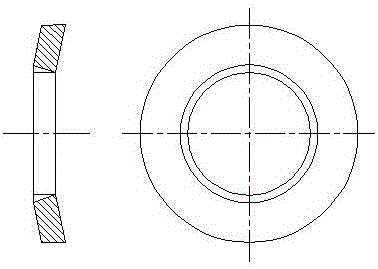

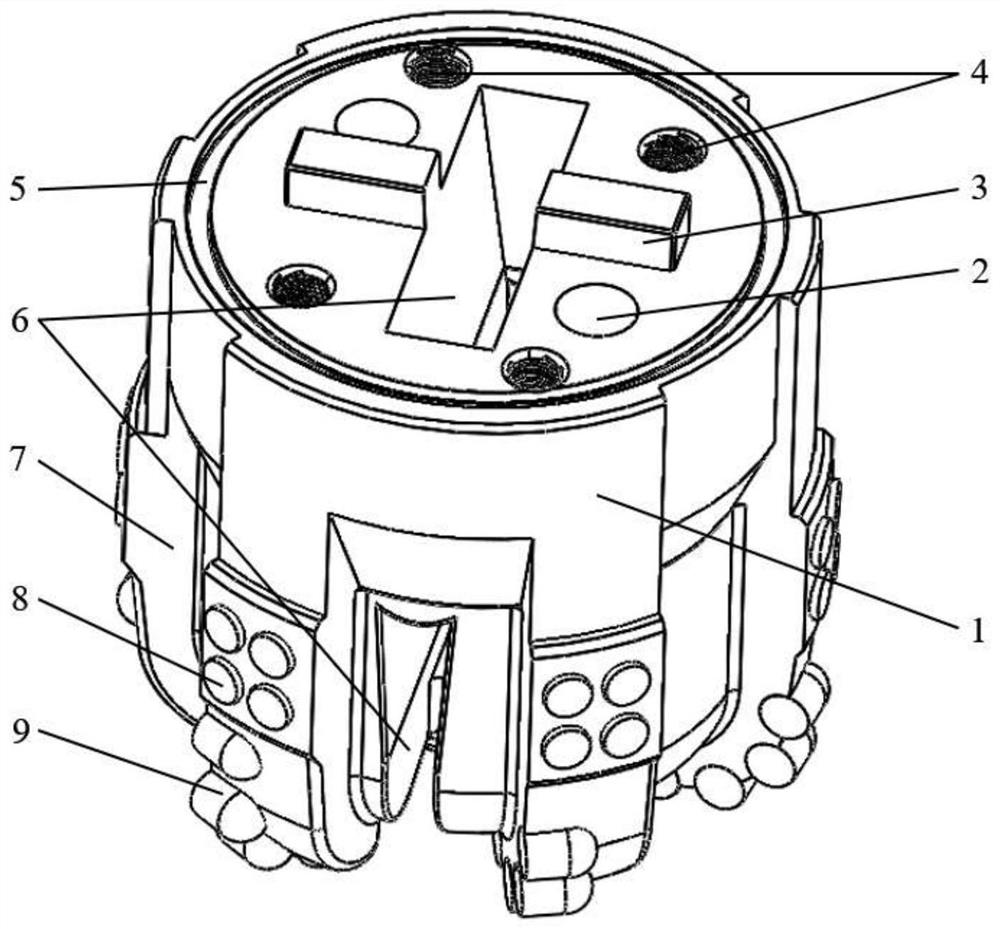

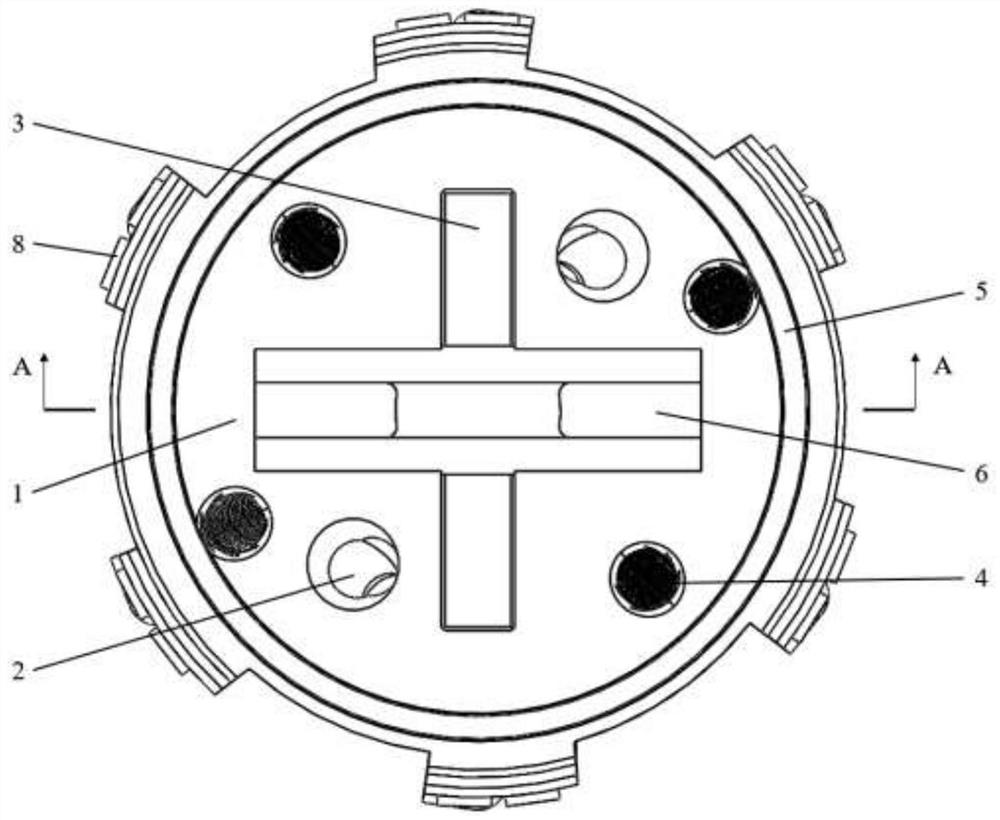

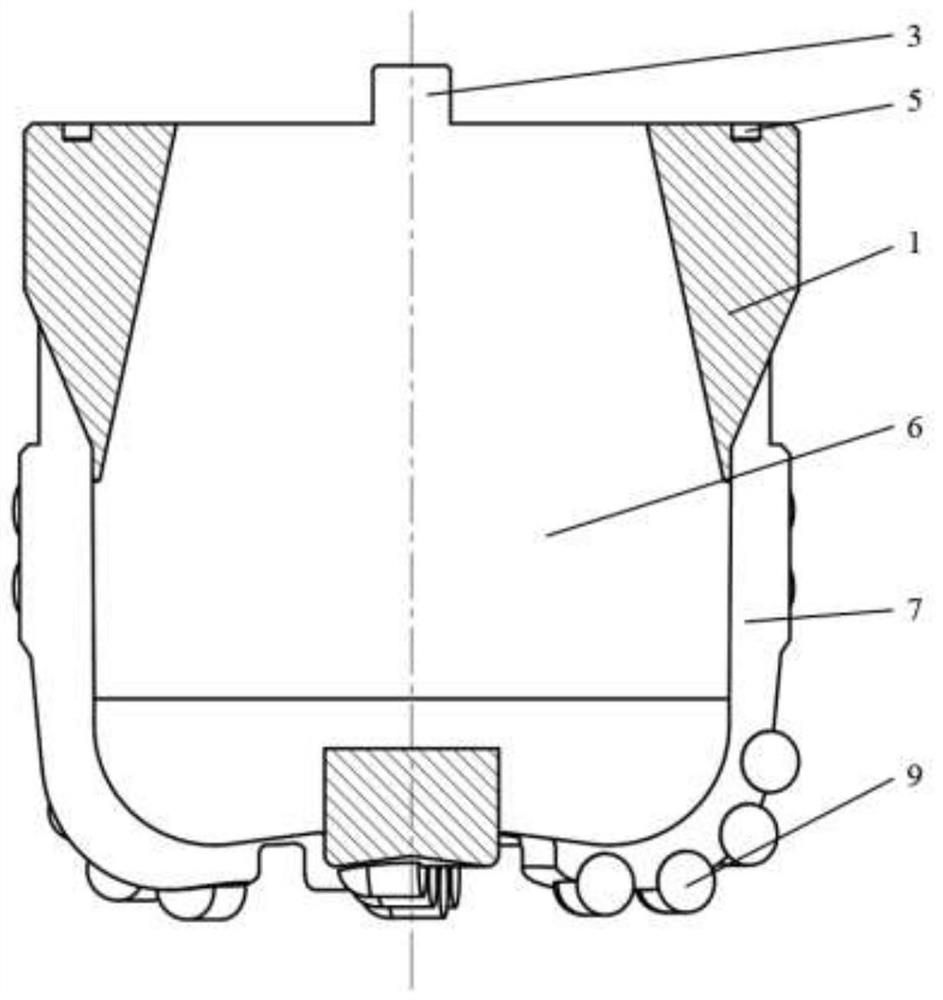

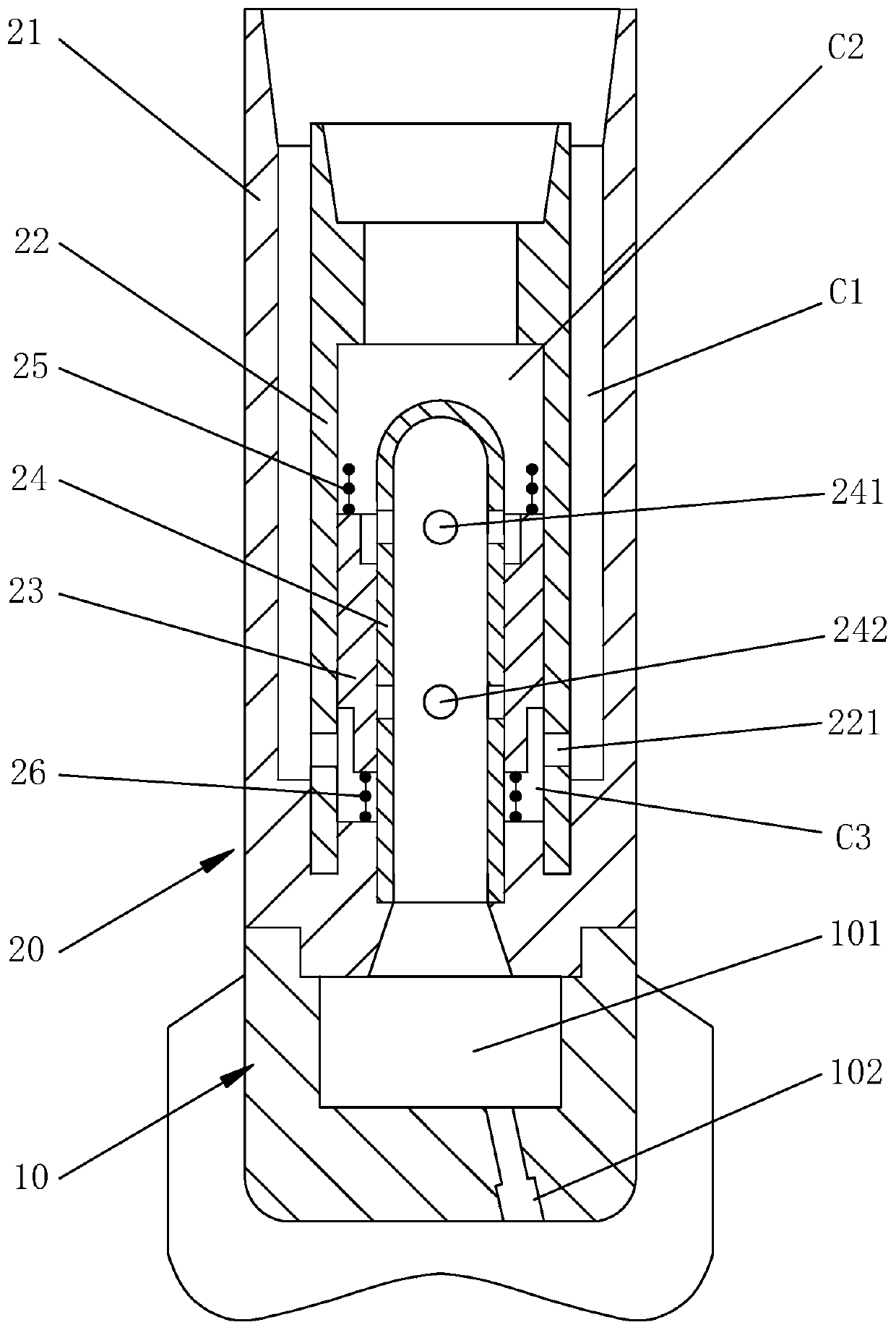

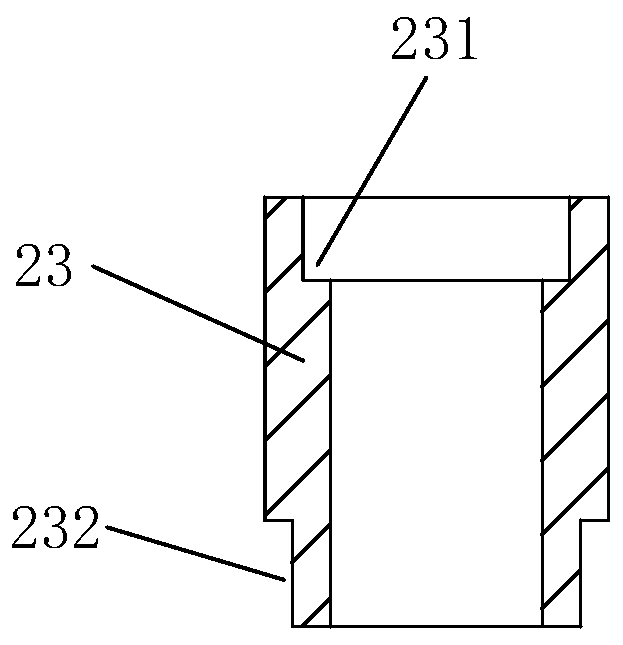

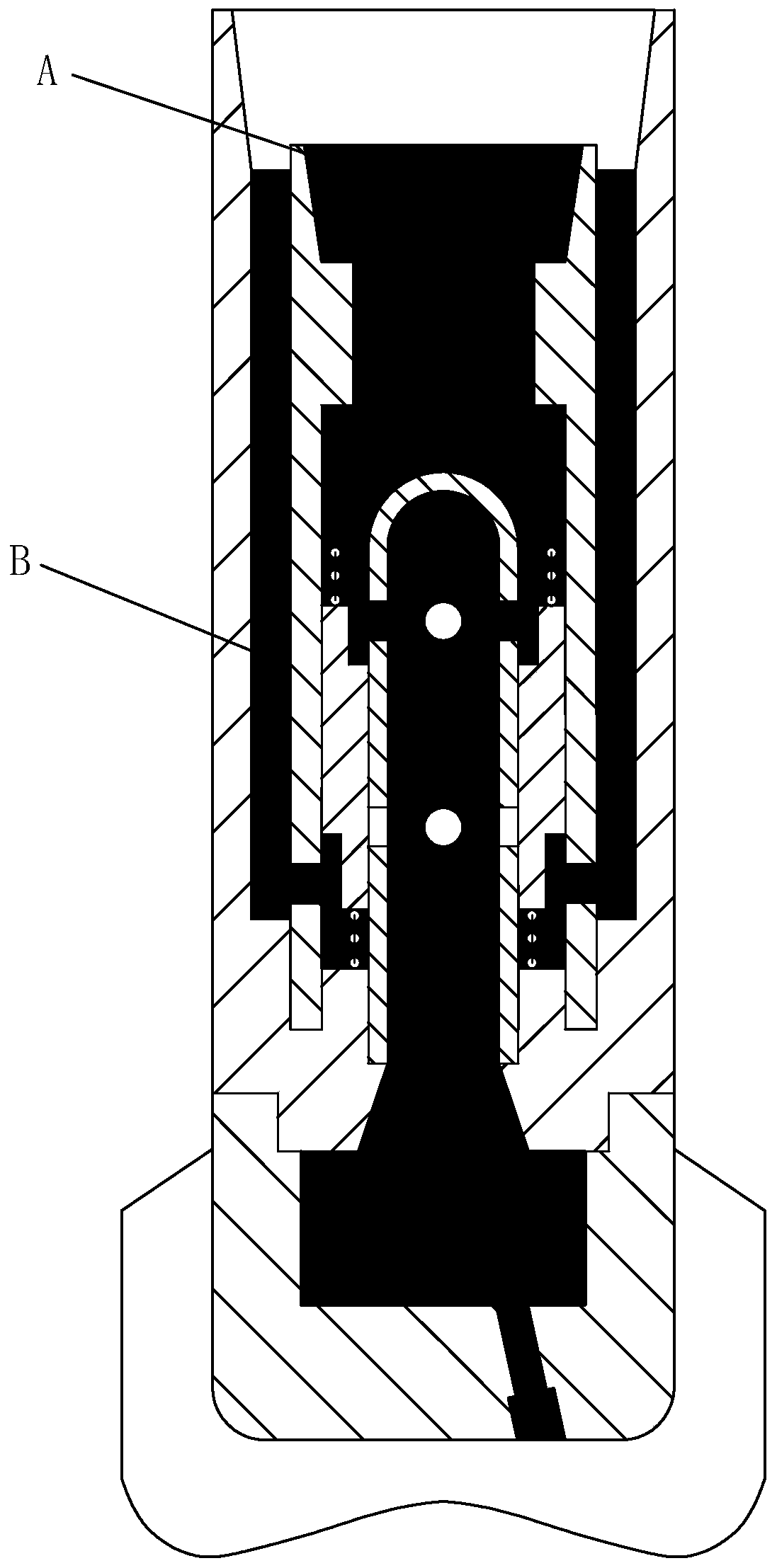

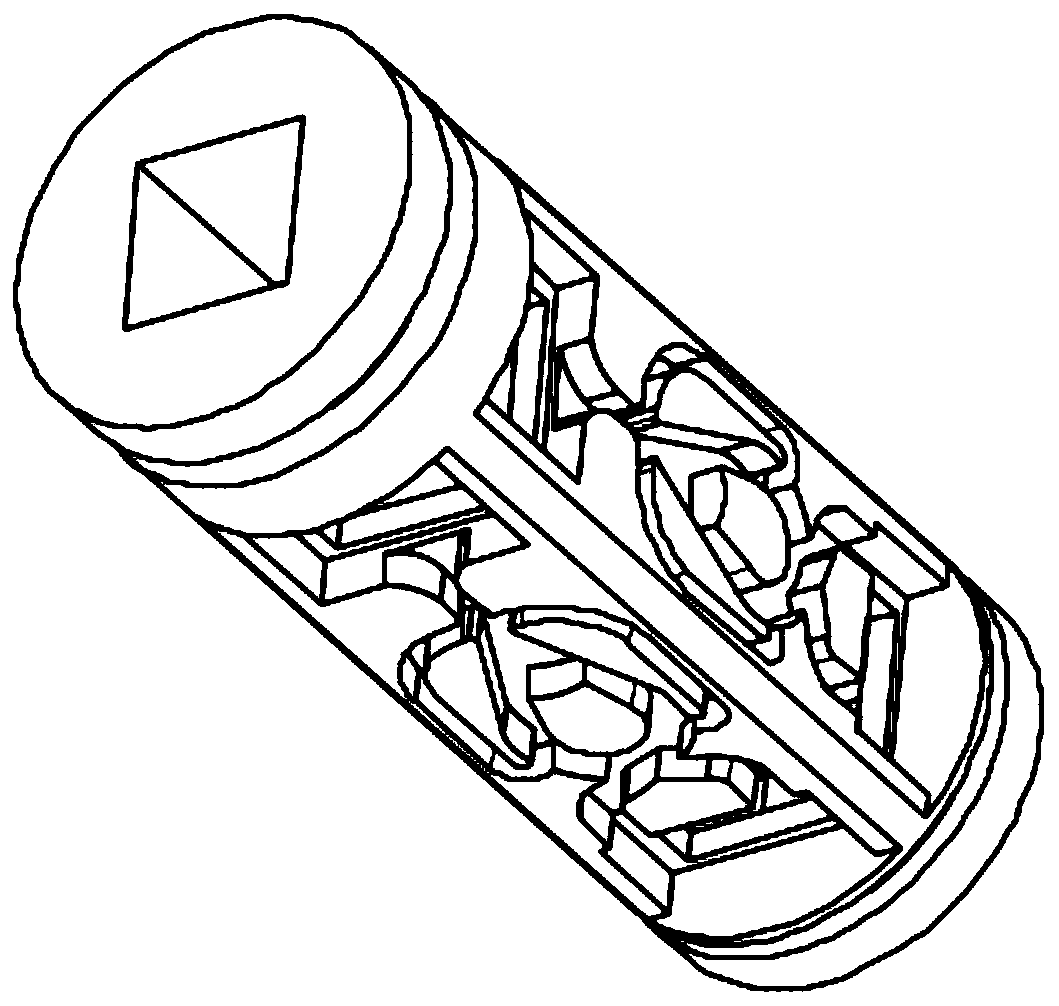

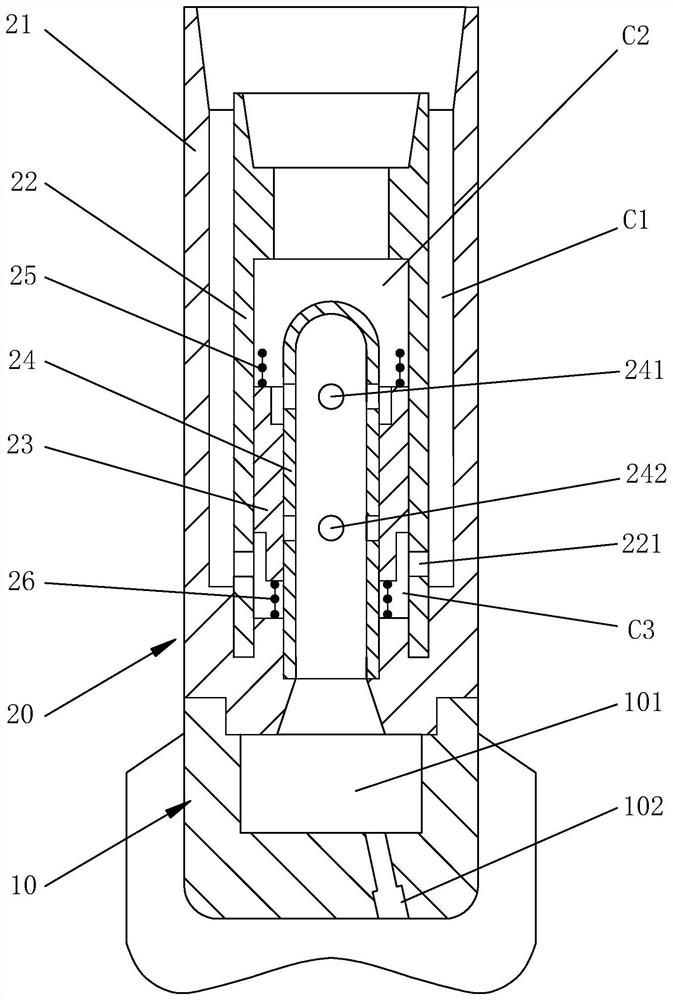

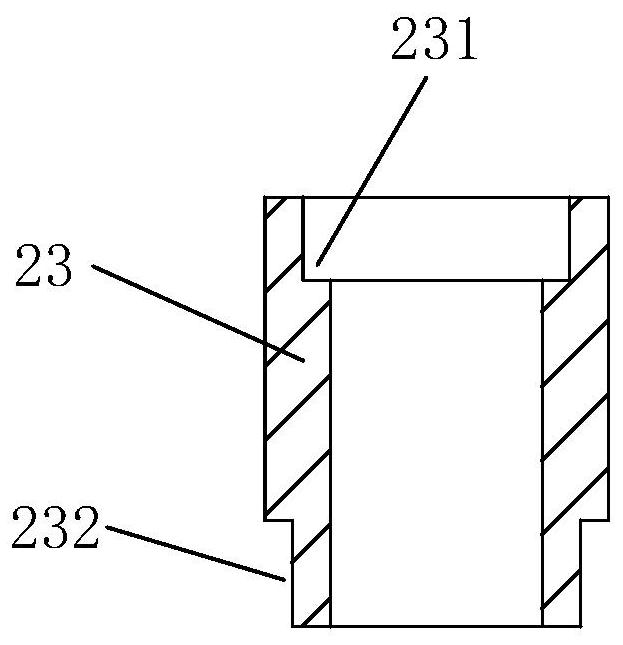

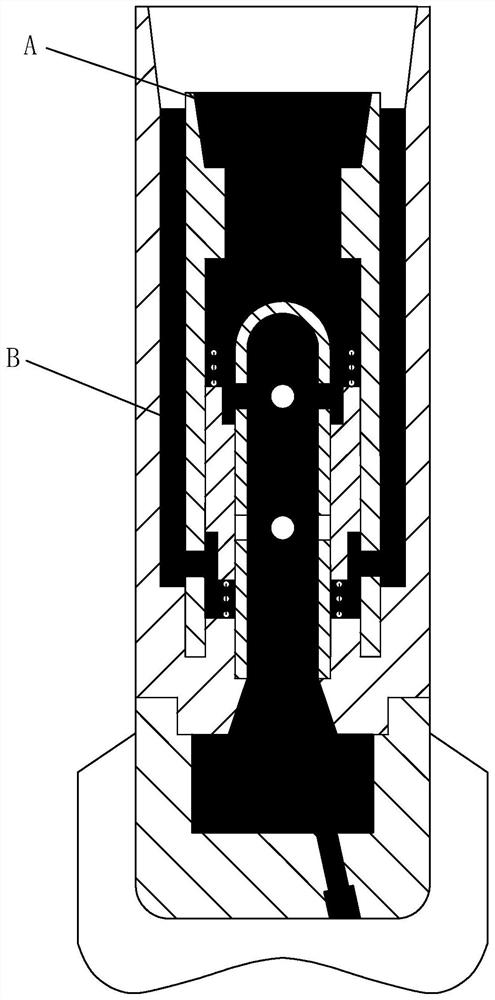

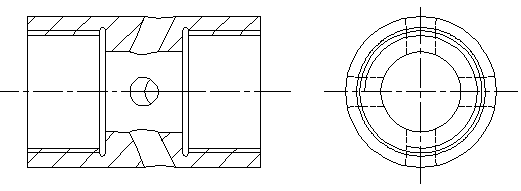

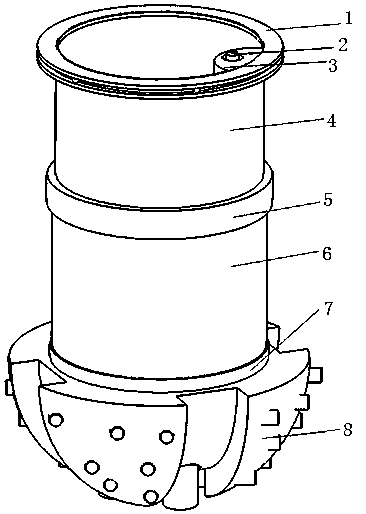

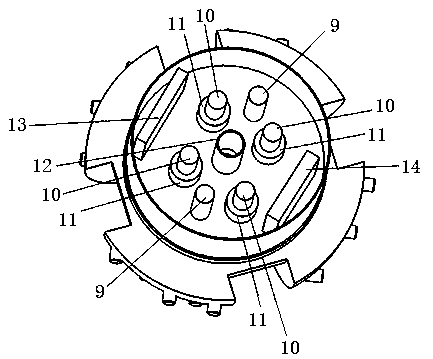

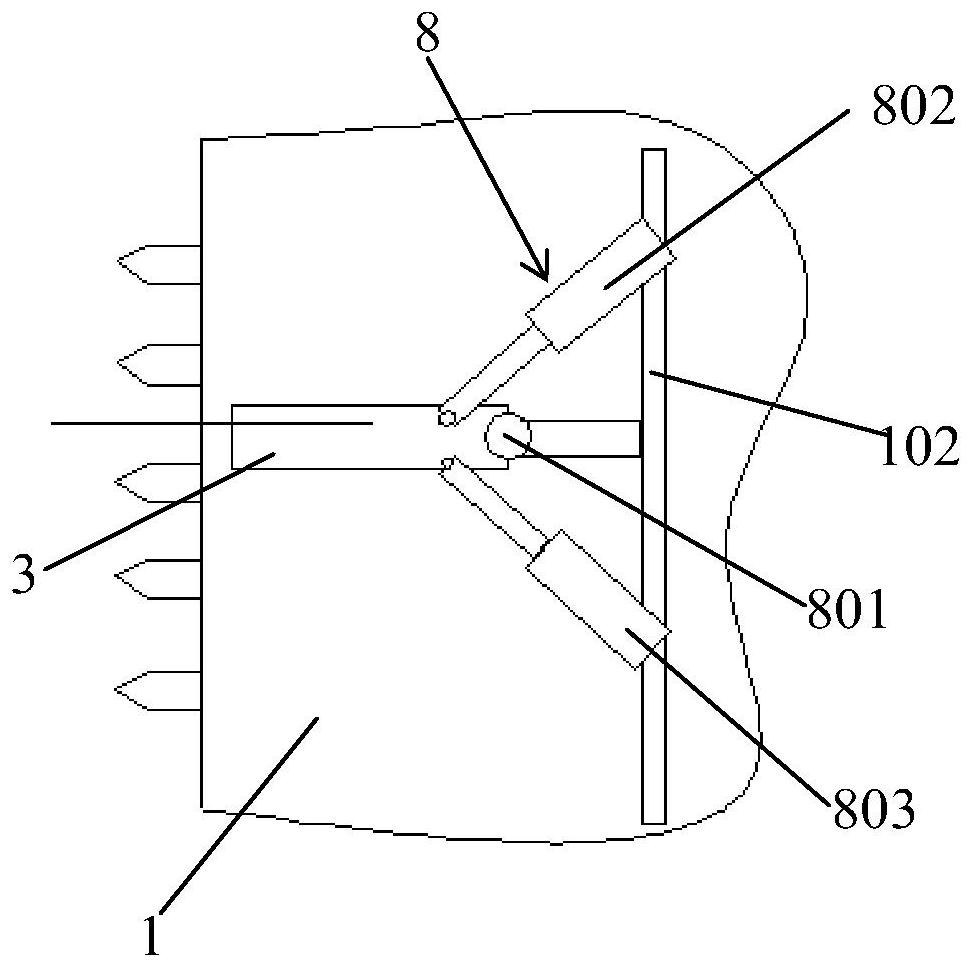

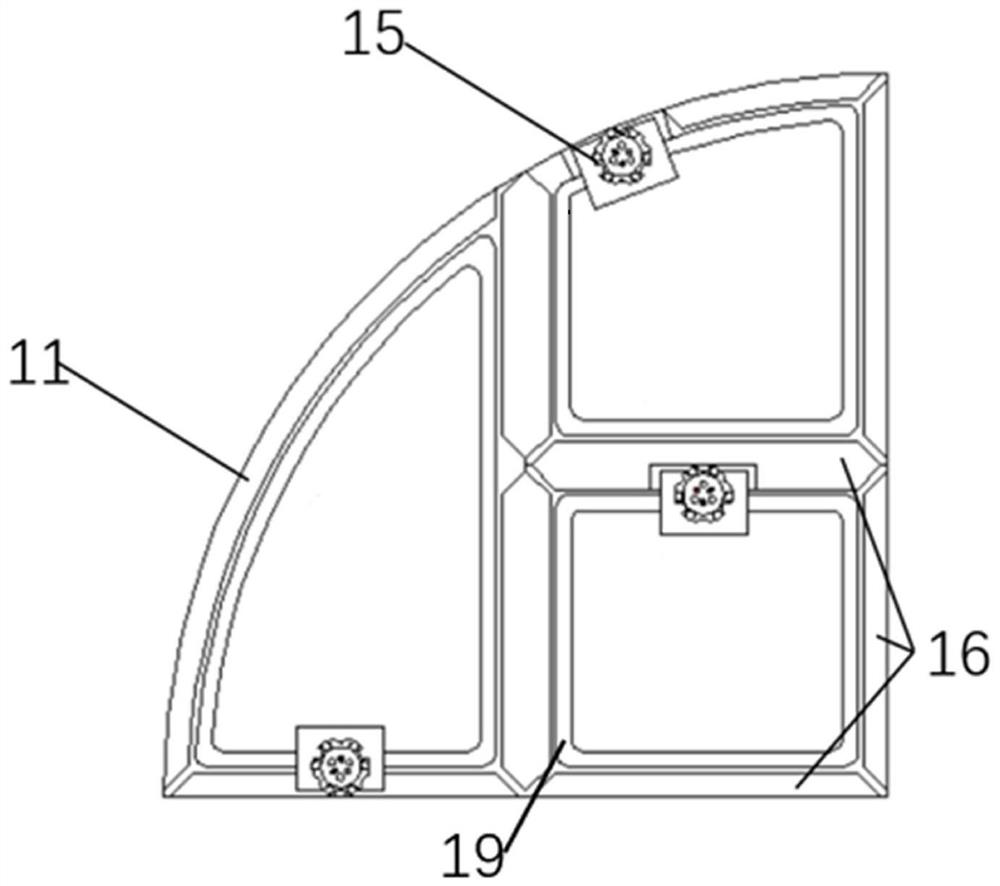

Novel hydraulic oscillator with energy gathering and damping functions

ActiveCN106014317AReduce horizontalReduce torsional vibrationDrilling rodsVibration devicesWell drillingDamping function

The invention relates to a novel hydraulic oscillator with energy gathering and damping functions. The novel hydraulic oscillator is fixedly mounted in the position close to a drill bit and comprises a damping assembly, a transmission assembly and an oscillating assembly. The oscillating assembly is mounted at the front end of the transmission assembly. The damping assembly is mounted at the rear end of the transmission assembly. Vibration generated on an upper tool by the oscillator during operating is absorbed through multiple stages of vibration absorption rings; bit pressure and torque are transmitted through a disk spring and splines, and the disk spring and the splines are connected in series. When flowing through a flow guide pipe, drilling fluid flows into a pressure chamber through flow guide holes in the circumference of the flow guide pipe and then flows back to a central flow channel, pressure pulsation of the drilling fluid fluctuates, and the oscillating assembly generates an oscillating effect. The novel hydraulic oscillator with the energy gathering and damping functions can generate the oscillating frequency of a certain range to reduce friction drag borne by a drilling tool in the rock breaking process of the drill bit, automatically absorb vibration and reduce the influence of the oscillating assembly on the upper drilling tool during operating, so that the well drilling efficiency is improved.

Owner:江苏弘业检测技术有限公司

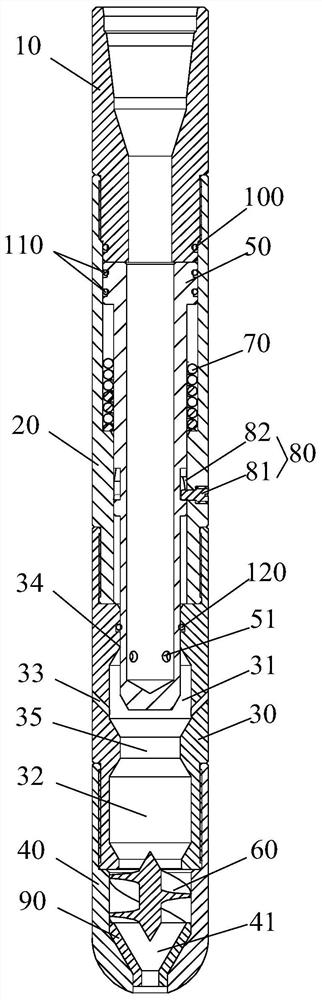

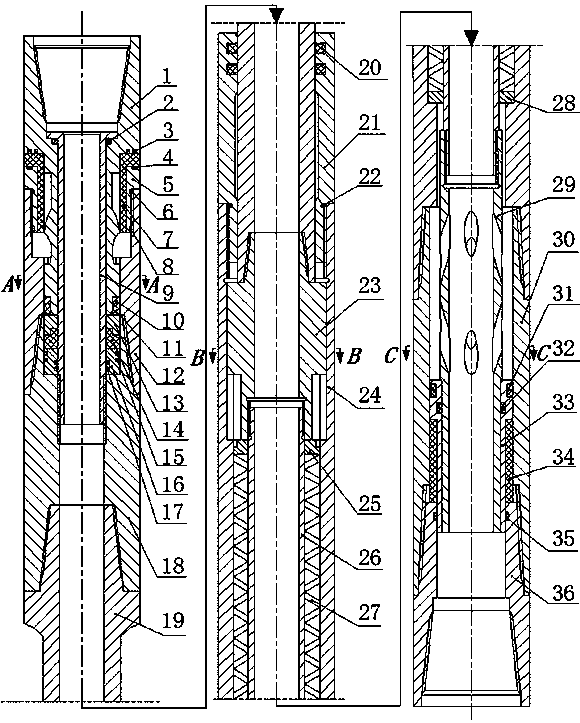

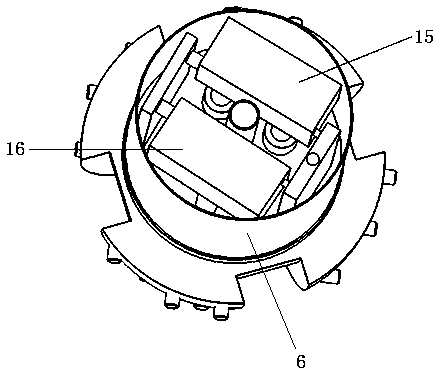

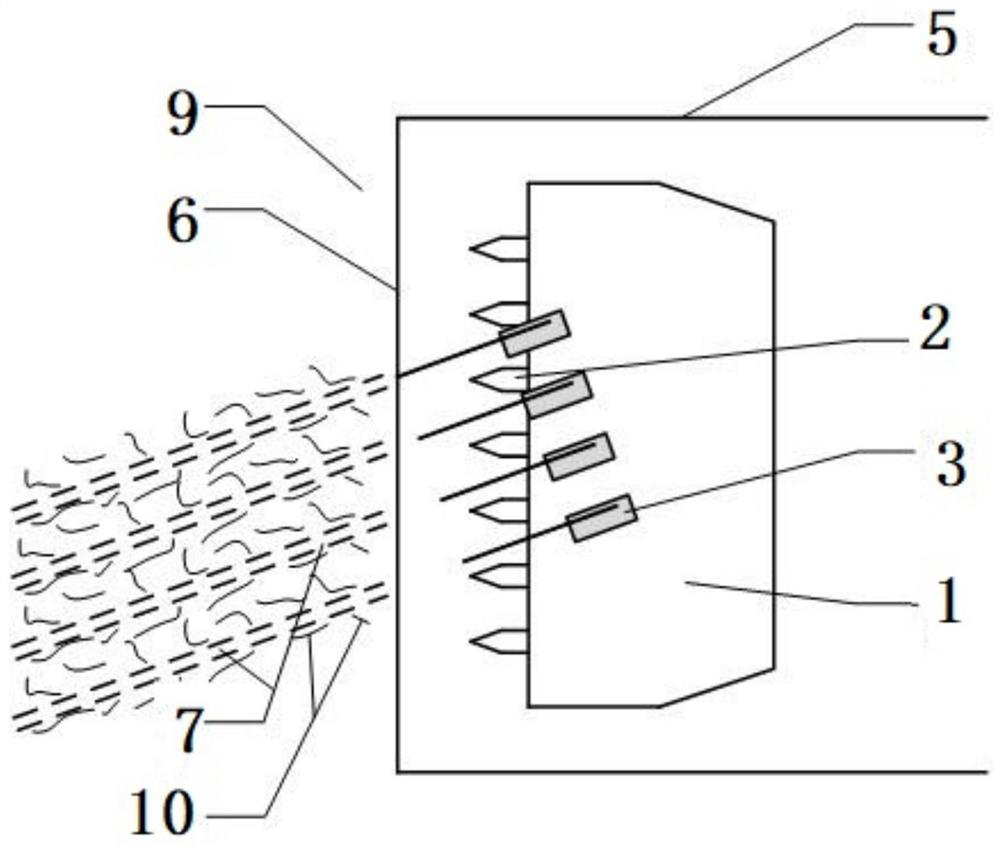

Stagnation-prevention drilling tool capable of reducing stick slip phenomenon through multi-head helical pair

ActiveCN106050160AIncreased versatilityRealize reciprocating motionDrilling rodsDrilling casingsSmall amplitudeDrive shaft

The invention relates to a stagnation-prevention drilling tool capable of reducing a stick slip phenomenon through a multi-head helical pair. The stagnation-prevention drilling tool is installed on the upper portion of a drill bit in a thread connection mode and comprises an upper assembly, a vibration absorption assembly and a lower assembly. The rear end of the vibration absorption assembly is provided with an upper connector assembly, and the front end of the vibration absorption assembly is provided with the lower assembly. Vibration generated in the work process of the tool is absorbed through disc springs connected in series, a pressure cavity and a rubber spring. Through matching of a spiral outer shell and a spiral transmission shaft, the multi-head helical pair is formed. When the reaction torque acting on the drill bit is increased and a stick slip or clamping phenomenon occurs, the spiral transmission shaft rotates backwards relative to the spiral outer shell, and therefore small-amplitude reverse rotation is applied to the drill bit. The reaction force of the ground to the drill bit is lowered, stress of the drill bit reaches balance again, and therefore efficient rock breaking with the drill bit is realized. According to the stagnation-prevention drilling tool capable of reducing the stick slip phenomenon through the multi-head helical pair, the vibration generated during rock breaking with the drill bit can be absorbed, the stick slip phenomenon is reduced, and continuous drilling of the drill bit is guaranteed.

Owner:沛县东宝机电设备有限公司

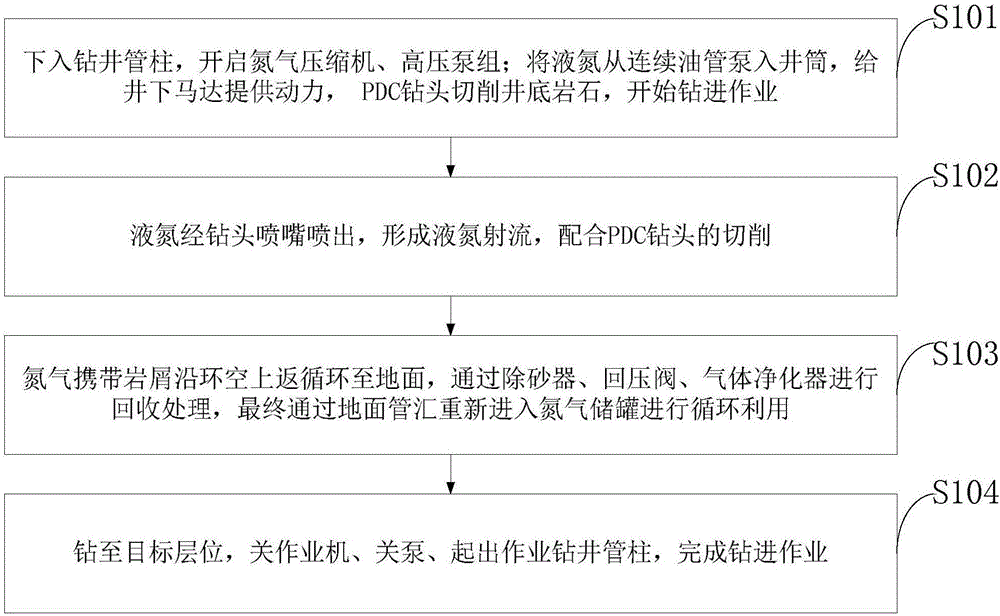

Drilling system and method for improving tundra drilling efficiency

InactiveCN106401463AImprove drilling efficiencySolve complex underground problemsIce drillingInsulationDecompositionHydrate decomposition

The invention discloses a drilling system and method for improving tundra drilling efficiency. The drilling method comprises the following steps of: adopting a downward drilling pipe column, starting a nitrogen gas compressor and a high-pressure pump unit; pumping liquid nitrogen into a shaft from a continuous oil pump, providing power to an underground motor, cutting shaft-bottom rocks by a PDC drill bit, and starting drilling operation; spraying out the liquid nitrogen through a spray nozzle of the drill bit to form liquid nitrogen jet flow which is matched with cutting of the PDC drill bit; upwards returning and circulating nitrogen gas along with rock debris to ground along an annular space, and recycling through a sand remover, a back pressure valve and a gas purifier; and drilling to a target layer, thereby completing drilling operation. Liquid-nitrogen fracturing effect is beneficial for expanding cracks generated inside rocks, so that rock breaking efficiency is effectively improved; the temperature of liquid nitrogen is extremely low, and liquid nitrogen is vaporized to absorb heat in an upward return process, so that decomposition of natural gas hydrates is effectively restrained, a well wall is kept stable, and underground complexity is prevented; and in an operation process, liquid nitrogen is recycled, so that the process is simple, is economical and is good in field applicability.

Owner:SOUTHWEST PETROLEUM UNIV

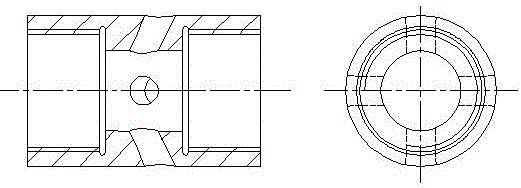

Adjustable and controllable pulse oscillation PDC drill bit

ActiveCN110029939AExtended service lifeSimple structureDrill bitsDrilling rodsOscillatory functionPiston

The invention discloses an adjustable and controllable pulse oscillation PDC drill bit. The adjustable and controllable pulse oscillation PDC drill bit comprises a drill bit joint, a drill bit body, arectangular sealing ring a, a support spring, a sliding piston, a rectangular sealing ring b, a pulse oscillation nipple, a rectangular sealing ring c and a cylindrical pin. Drilling fluid enters thedrill bit from the drill bit joint, passes through the sliding piston and then flows out of a drill bit water hole, when the drill bit does not need to have a pulse oscillation function, the conventional drilling fluid pressure only needs to be kept, and the sliding piston is kept to make contact with the drill bit joint; and when the drill bit needs to have the pulse oscillation function, the drilling fluid pressure is increased, the sliding piston is pushed to move downwards and communicates with the pulse oscillation nipple, and the drilling fluid enters the pulse oscillation nipple, so that the pulse oscillation nipple generates a pulse oscillation effect, and thus efficient rock breaking of the drill bit is achieved. According to the adjustable and controllable pulse oscillation PDCdrill bit, the pulse oscillation function can be adjusted and controlled, the application range is wide, the phenomena of stick slip, bit balling and the like of the drill bit can be relieved, and theservice life of the drill bit is prolonged.

Owner:四川保瑞特钻头有限公司

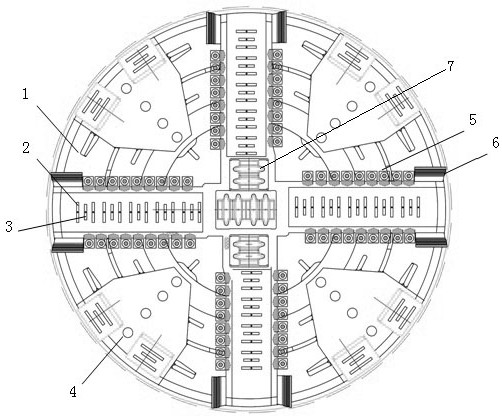

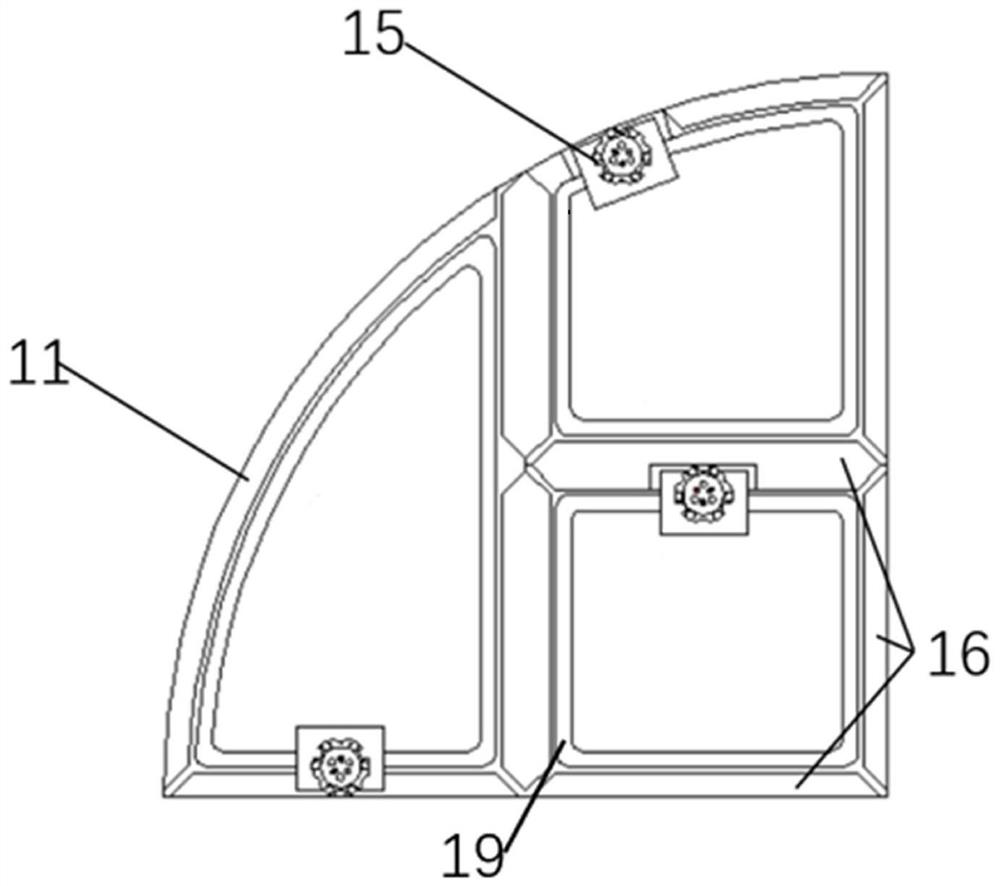

Composite rock breaking method, cutterhead and heading machine

ActiveCN112360491AEfficient rock breakingTo achieve the effect of phase change crackingTunnelsWater jetMining engineering

The invention discloses a composite rock breaking method. The method comprises the following steps of generating a crack in a rock body by adopting high-speed water jetting, jetting supercritical carbon dioxide into the crack, heating the supercritical carbon dioxide in the crack by adopting a microwave generation system so as to achieve the rapid phase change of the supercritical carbon dioxide,and breaking the rock body subjected to phase change of the supercritical carbon dioxide in the crack by adopting a cutter system. The invention further discloses a composite rock breaking cutterhead.The composite rock breaking cutterhead comprises a cutterhead panel, the cutter system and a high-speed water jet system are arranged on the cutterhead panel, and a supercritical carbon dioxide jet system and the microwave generation system are arranged on the cutterhead panel. The invention further discloses a composite rock breaking heading machine. The composite rock breaking heading machine comprises a cutterhead which is the same as the composite rock breaking cutterhead. According to the composite rock breaking method, cutterhead and heading machine, the technical problems that an existing composite rock breaking heading machine is large in thrust, large in torque, high in loading efficiency and serious in cutter abrasion.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

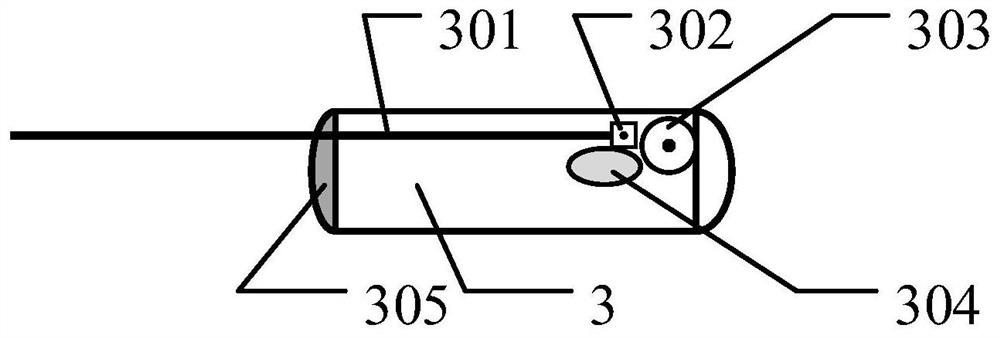

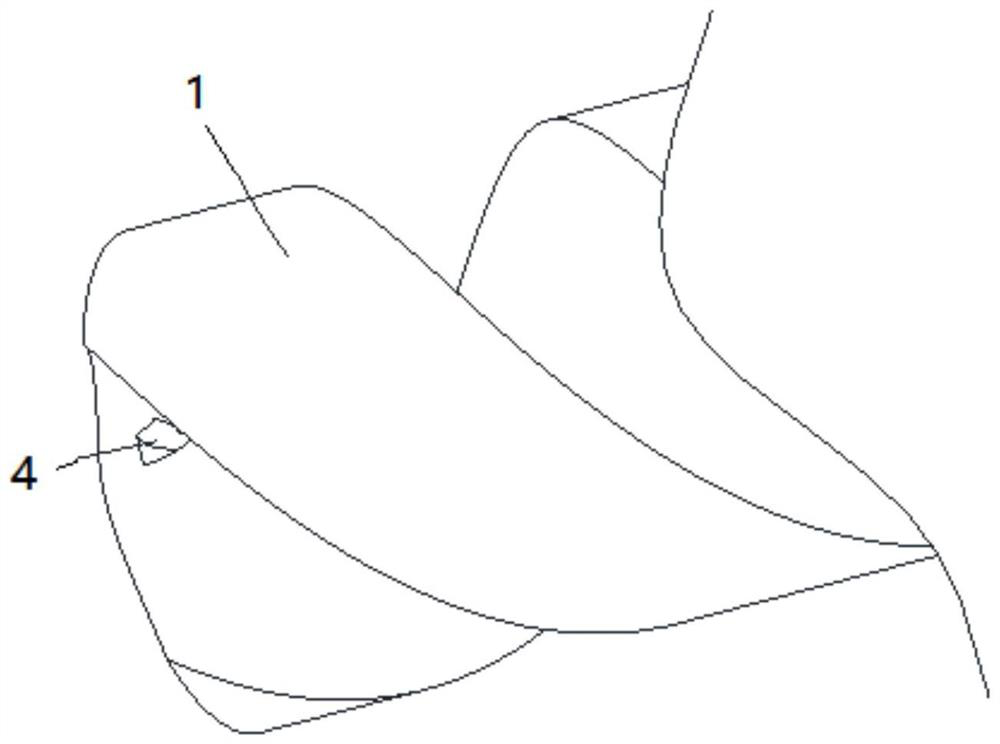

Touch sampler suitable for extraterrestrial celestial body

ActiveCN111947965ASampling implementationSampling multiple working conditionsWithdrawing sample devicesWater resource assessmentStar catalogueCelestial body

The invention relates to a touch sampler suitable for an extraterrestrial celestial body. The touch sampler comprises a sampling flow guide cover, a pneumatic impact rock breaking mechanism, a flexible spring and the like; wherein the sampling flow guide cover is located at the bottom end of the touch sampler, the gas excitation nozzle is located on the inner side of the sampling flow guide cover,the pneumatic impact rock breaking mechanism is installed on the inner side of the sampling flow guide cover, the flexible spring is installed at the upper end of the sampling flow guide cover, the pneumatic unfolding mechanism is installed at the upper end of the flexible spring; the sample channel is installed in the pneumatic unfolding mechanism, wherein one end is connected with a cavity in the sampling flow guide cover, and the other end is connected with the sample container; the sealing door is installed in the sample channel, and the sample container is fixed to the upper end of the pneumatic unfolding mechanism. According to the invention, the pneumatic impact rock breaking mechanism is used for breaking and stripping the surface of a star, meanwhile, a surface sample is blown into the sample container through gas excitation and transmission, recovery is completed, and the device has the advantages of being short in sampling time, high in star catalogue adaptability, capableof achieving repeated sampling and reliable in sampling.

Owner:BEIJING SATELLITE MFG FACTORY

Horizontal tunneling device

InactiveCN110500105AImprove rock breaking efficiencyNot easy to wearTunnelsElectrical impulseHardness

The invention discloses a horizontal tunneling device which comprises a tunneling device host machine, at least one electric pulse drill bit and an electric pulse generator, wherein the tunneling device host machine comprises a front shield tube body; a front separation plate and a back separation plate are arranged in the front shield tube body; the electric pulse drill bits are used for crushingrock through mechanical effects of plasma channels, jet flow or pulse waves generated through pulse power discharging, and are all fixed onto the front separation plate and the back separation plate;and the electric pulse generator is connected with the electric pulse drill bit and is used for providing high-voltage electric pulse for the electric pulse drill bit. The horizontal tunneling devicecan realize the rock crushing without the rotation of the electric pulse drill bit; the drill bit cannot easily be abraded; and the pulse discharging energy of the electric pulse drill bits is used for crushing the rock. Compared with mechanical cutting rock crushing through hobbing cutters, the horizontal tunneling device has the advantages that the influence by external factors such as rock hardness is small, so that the efficient rock crushing under the extreme work conditions can be realized; and the rock crushing efficiency is high.

Owner:CHINA RAILWAY CONSTR HEAVY IND

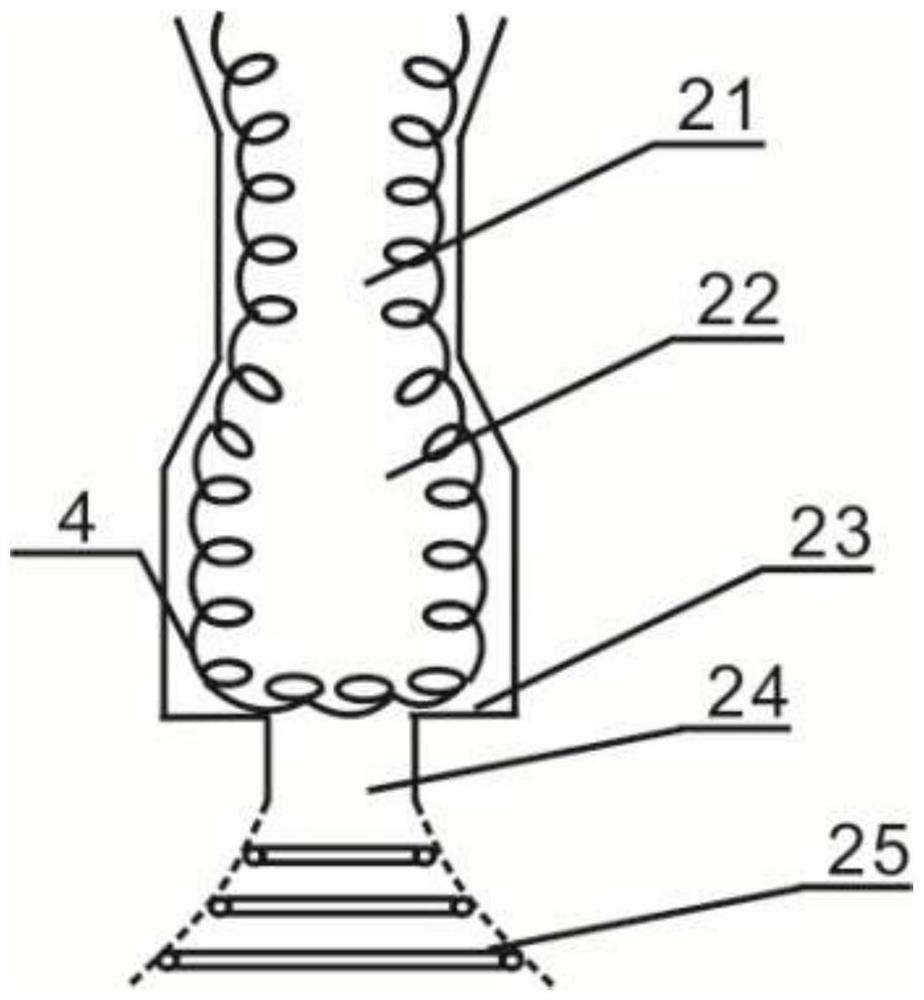

Drilling system and method and application thereof

PendingCN113090189AExtended service lifeImprove heat transfer efficiencyLiquid/gas jet drillingFlushingDrilling systemRock breaking

The invention relates to a drilling system and method and application thereof in the field of oil exploration and development. The drilling system comprises a cold fluid circulation pipeline, a continuous oil pipe and a fluid temperature control cavity. According to the method, drilling fluid in the fluid temperature control cavity is cooled through cold fluid in a heat exchange pipe; the fluid temperature control cavity is designed to be of an organ pipe structure, the drilling fluid forms a strong natural vibration cavitation effect in the cavity, the natural vibration cavitation low-temperature drilling fluid is sprayed out of a nozzle at a high speed to act on dry and hot rock at the bottom of a well, and micro cracks are generated on the surface of the rock under the action of tensile stress. Meanwhile, the drilling fluid forms strong cavitation vortex flow under the action of natural vibration cavitation, cavitation is broken to generate a strong destructive effect, and the rock breaking capacity is further improved. The problems that a dry and hot rock drilling machine is low in drilling speed, high in drilling cost and short in service life of downhole tools and instruments are solved, and efficient development and utilization of dry and hot rock resources in China can be effectively guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Frame type drilling device and construction method

The invention provides a frame type drilling device and a construction method, and the frame type drilling device comprises a supporting frame which is movably and deflectively arranged on a drilling trolley to provide support for drilling equipment; the drilling equipment is movably arranged on the supporting frame, and the drilling equipment can move in all directions in a plane limited by the supporting frame; and the moving mechanism drives the drilling equipment to move on the supporting frame, and continuous hole drilling in the rock mass in any direction is achieved. The device faces an excavation face, multiple arms do not need to be adjusted, and drilling point positions are rapidly positioned; through omni-directional coordinate movement, concentric circle rotation and the like, efficient positioning of drill bits in different forms is achieved, efficiency is improved, and any formed hole contour is drilled; the device works alternately, does not need synchronous work, is simple to operate, and can realize intelligent hole forming to form a required contour.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

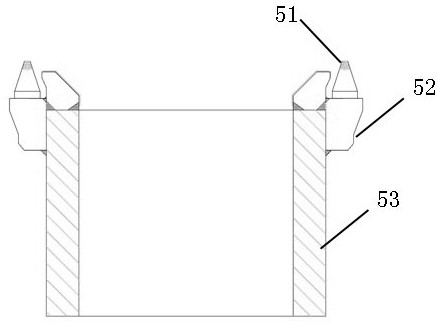

Laser-mechanical drill bit for laser-mechanical combined efficient rock breaking

PendingCN113653447AGuaranteed positioning accuracyEfficient rock breakingDrill bitsConstructionsClassical mechanicsLight beam

The invention relates to a laser-mechanical drill bit for laser-mechanical combined efficient rock breaking. The laser-mechanical drill bit is mainly composed of a drill bit body and a fixed cutting structure; the fixed cutting structure is composed of blades extending from the drill bit body, cutting teeth and gauge protection teeth; the cutting teeth and the gauge protection teeth are fixedly connected to the blades; the blades and the drill bit body are integrally machined and formed; a through dovetail-groove-shaped laser channel is formed in the drill bit body; two symmetrical bosses and four inclined threaded holes are formed in the connecting end; and an annular sealing groove is formed, so that gas leakage can be effectively prevented, and the cleaning and rock-carrying effects in the drilling process are guaranteed. According to the drill bit, the positioning precision of a laser beam can be ensured, the shaped linear laser beam is enabled to accurately irradiate a specified position on the surface of rock, the laser beam rotationally irradiates the rock along with the drill bit, the laser beam is ensured not to interfere with the interior of the drill bit in the drilling process, and laser-mechanical combined efficient rock breaking is realized.

Owner:SOUTHWEST PETROLEUM UNIV

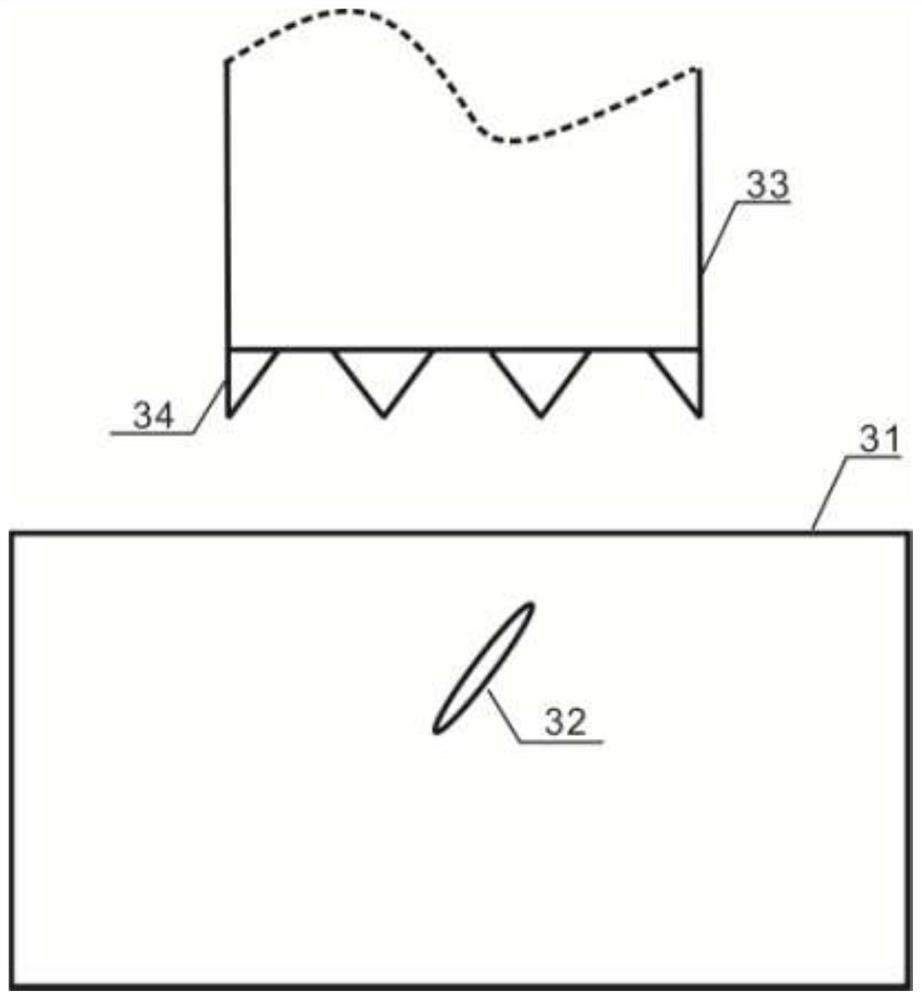

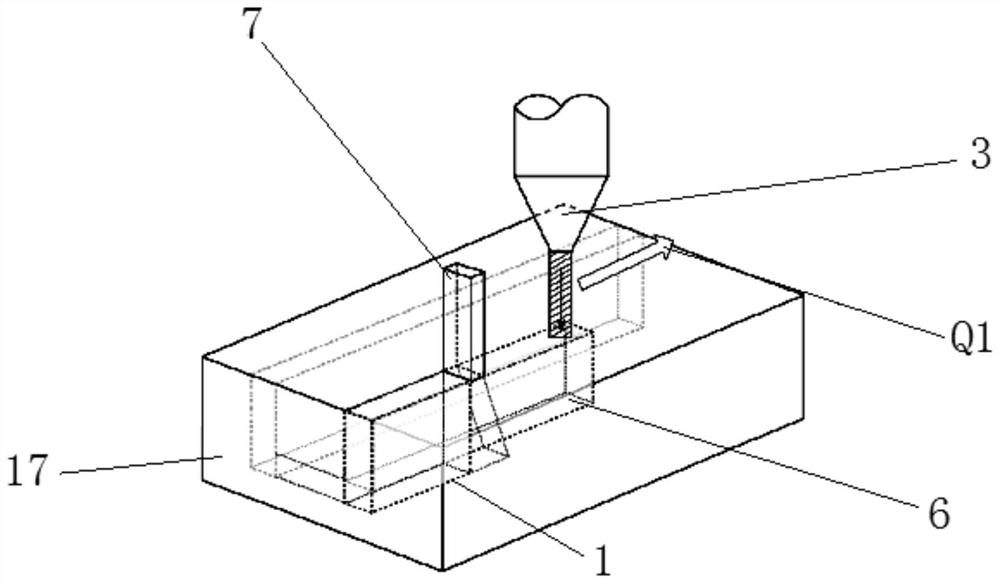

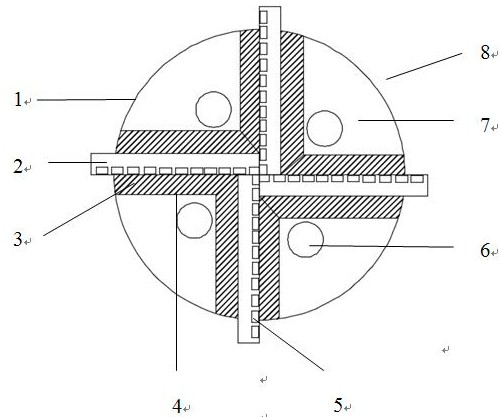

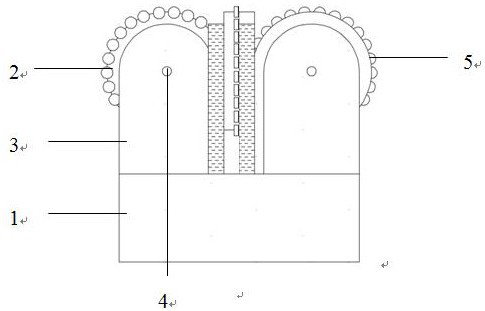

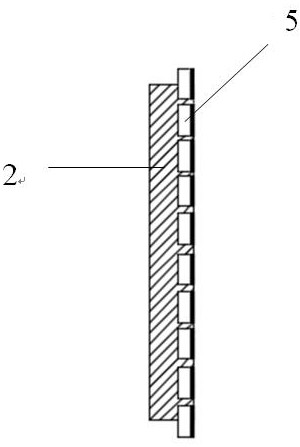

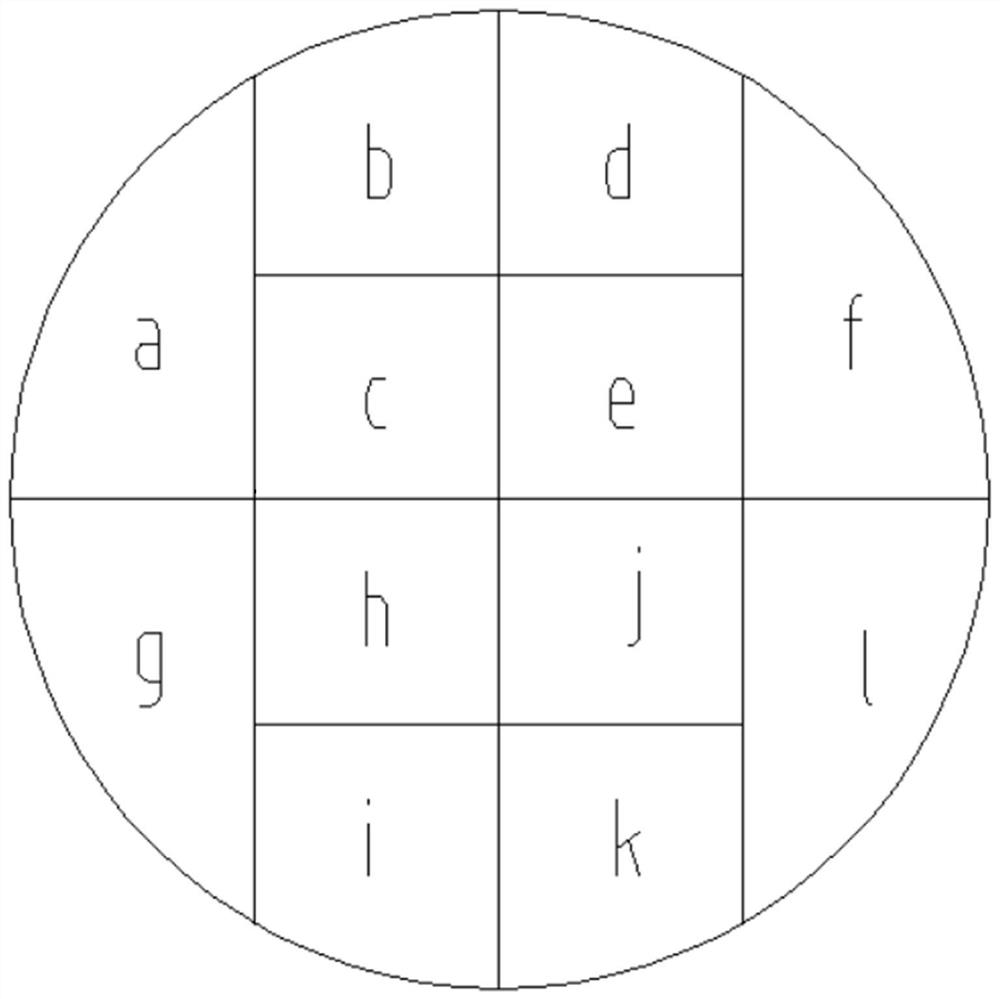

Combined rock breaking test device based on high-pressure water jet and cutter sequential operation and application

ActiveCN112504897AEasy to crackEfficient rock breakingInvestigating machinabilityStructural engineeringHigh pressure water

The invention discloses a combined rock breaking test device based on high-pressure water jet and cutter sequential operation. The device comprises a cutterhead, a mechanical hob structure, a high-pressure water jet structure and a scraper structure, wherein the mechanical hob structure, the high-pressure water jet structure and the scraper structure are all installed on the cutterhead; the mechanical hob structure, the high-pressure water jet structure and the scraper structure are sequentially installed and arranged on the cutterhead according to the sequence that the high-pressure water jetstructure jets water jet to form a water jet cutting groove, the scraper structure broadens and deepens the water jet cutting groove and the mechanical hob structure rolls the water jet cutting groove; and the high-pressure water jet structure, the scraper structure and the mechanical hob structure form a working group in sequence. According to the invention, the problem that the grooving depth of the rock is small when the rock is cut by high-pressure water jet in a high-speed moving cutting state is solved; and the device has the advantages of high efficiency, low energy consumption, low abrasion, improvement of working face operation environment and the like. The invention further discloses application of the combined rock breaking test device based on high-pressure water jet and cutter sequential operation.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

A Drilling Method Using Thermal Jet to Break Rock Efficiently

ActiveCN103790516BEfficient rock breakingIncrease profitLiquid/gas jet drillingMeasuring instrumentEngineering

The invention relates to a new welling drilling method for efficient rock breaking by means of heating power jet flow, and a complete set of construction scheme. According to the system composition, a continuous coil tubing unit, an electric measuring instrument truck, a cable, an air injection pipeline, a fuel injection pipeline, a fuel reaction cavity, a heating power jet flow nozzle, a ground pump set and the like are included. According to the technology, on the basis of the principle that the continuous heated surfaces of rocks crack until the rocks are decomposed in a splitting mode, the heating power jet flow acts on the rocks on the deep well hard formation, the non-contact efficient rock breaking is achieved under heat transfer and impact force of high-temperature and high-pressure fluid media, and the energy utilization rate of the well bottom is improved; the technological process is simple, the continuous oil tube well drilling technology is combined, a drill bit does not need to be replaced, the time of the tripping operation is shortened, abrasion to a tubular column is reduced, and the cost of the drilling operation is reduced. According to the new welling drilling method for efficient rock breaking by means of heating power jet flow, the heating power jet flow technology is creatively guided into the continuous oil tube well drilling, popularization and application of the continuous tube technology are facilitated, and oil and gas resources are efficiently exploited.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Dual-channel drill bit with drilling fluid switching function

ActiveCN110644927ADrilling achievedRealize variable temperature drillingDrill bitsFlushingSpool valveWell drilling

The invention discloses a dual-channel drill bit with a drilling fluid switching function. The dual-channel drill bit includes a drill bit body and a dual-channel joint which are connected, the dual-channel joint includes a joint outer pipe, a joint inner pipe and a slide valve assembly located in an inner cavity of the joint inner pipe, an annular passage is arranged between the joint inner pipeand the joint outer pipe, and the joint inner pipe is provided with an inner pipe flow passing hole communicating with the annular passage; and the slide valve assembly includes a core pipe and a slide valve which is arranged between the joint inner pipe and the core pipe in sliding and sealing manners, the slide valve divides the inner cavity of the joint inner pipe into an inner pipe upper cavity and an inner pipe lower cavity, the top of the core pipe is closed, the bottom of the core pipe is open, the upper pipe wall of the core pipe is provided with a core pipe upper flow passing hole, and the lower pipe wall of the core pipe is provided with a core pipe lower flow passing hole. When the dual-channel drill bit is used for drilling, under the action of the pressure difference of high and low temperature drilling liquid, the core pipe upper flow passing hole and the inner pipe upper cavity are periodically connected and disconnected, the core pipe lower flow passing hole and the inner pipe lower cavity are periodically connected and disconnected, the high and low temperature drilling liquid is automatically switched and alternatively used, and variable temperature drilling and efficient rock breaking are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Adjustable pulse oscillation pdc drill bit

ActiveCN110029939BExtended service lifeSimple structureDrill bitsDrilling rodsEngineeringMechanical engineering

The invention discloses an adjustable and controllable pulse oscillation PDC drill bit. The adjustable and controllable pulse oscillation PDC drill bit comprises a drill bit joint, a drill bit body, arectangular sealing ring a, a support spring, a sliding piston, a rectangular sealing ring b, a pulse oscillation nipple, a rectangular sealing ring c and a cylindrical pin. Drilling fluid enters thedrill bit from the drill bit joint, passes through the sliding piston and then flows out of a drill bit water hole, when the drill bit does not need to have a pulse oscillation function, the conventional drilling fluid pressure only needs to be kept, and the sliding piston is kept to make contact with the drill bit joint; and when the drill bit needs to have the pulse oscillation function, the drilling fluid pressure is increased, the sliding piston is pushed to move downwards and communicates with the pulse oscillation nipple, and the drilling fluid enters the pulse oscillation nipple, so that the pulse oscillation nipple generates a pulse oscillation effect, and thus efficient rock breaking of the drill bit is achieved. According to the adjustable and controllable pulse oscillation PDCdrill bit, the pulse oscillation function can be adjusted and controlled, the application range is wide, the phenomena of stick slip, bit balling and the like of the drill bit can be relieved, and theservice life of the drill bit is prolonged.

Owner:四川保瑞特钻头有限公司

Reversible sand-washing cleaning tool

The invention provides a sand washing and cleaning tool capable of reversing. The reversible sand washing tool comprises an upper connector, a barrel, a backward nozzle and a forward nozzle which are connected in sequence. The backward nozzle comprises a first hollow cavity and a second hollow cavity which are communicated with each other, a jet hole is formed in the outer wall of the backward nozzle, and the jet hole is communicated with the first hollow cavity; the reversible sand washing tool further comprises a piston rod which is movably arranged in the barrel and provided with a hollow flow channel, and a water outlet hole is formed in the end, close to the forward nozzle, of the piston rod so that fluid can flow into the backward nozzle and / or the forward nozzle from the water outlet hole. The piston rod is provided with a first position, a second position and a third position sequentially close to the forward nozzle. And the rotation generating impeller is arranged in the forward nozzle and is connected with one end, close to the forward nozzle, of the backward nozzle, so that fluid flows through the rotation generating impeller to form rotational flow and then is sprayed out from an outlet of the forward nozzle. The problems that in the prior art, the shaft cleaning effect is poor, and efficiency is low are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

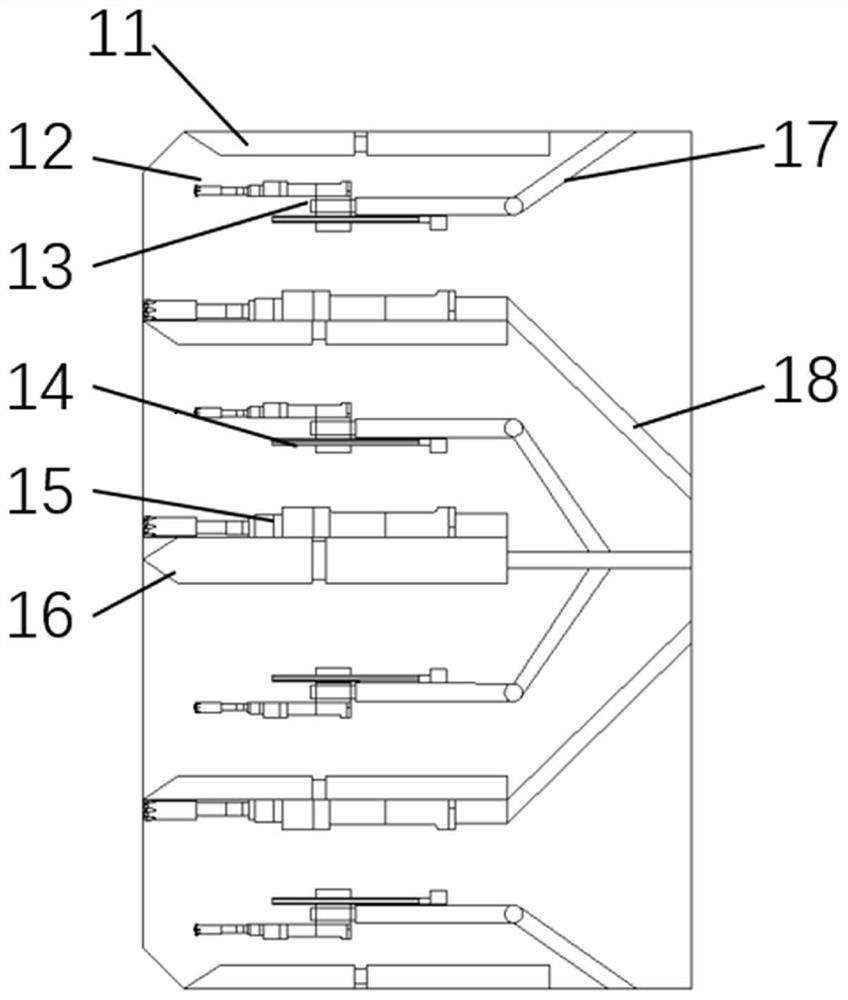

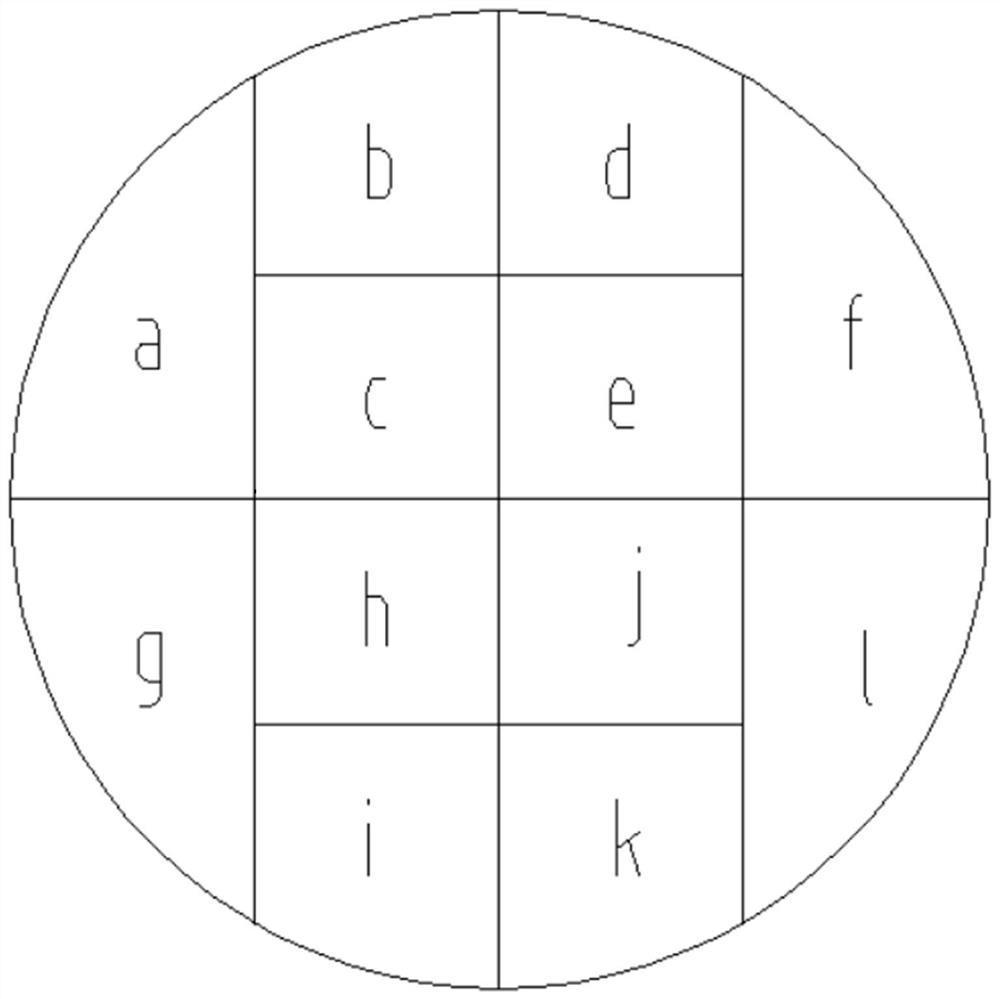

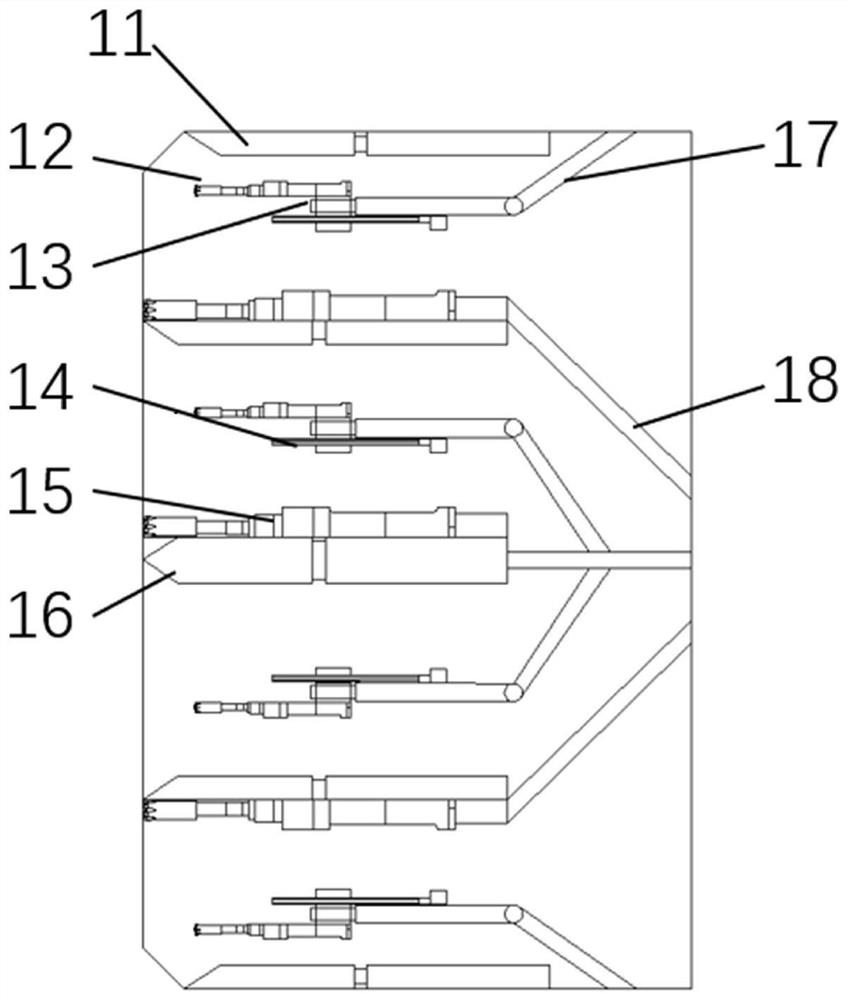

A cutter head, a full-face hard rock tunneling machine based on drilling and blasting construction, and a rock breaking method

The invention discloses a cutter head, a full-face hard rock tunneling machine based on drilling and blasting construction and a rock breaking method. The cutter head is divided into N areas, and a first inserting knife is arranged between two adjacent areas, and each The other boundary position of the area is provided with a second inserting knife, the impactor and the first arm frame connected with the impactor are arranged in the cutter head, and the first inserting knife or the second inserting knife of each area is provided with a gap for the impactor Extending and retracting, the boundary of each area is provided with a guide rail to form a circular guide rail for the impactor to move. A second arm frame is arranged inside the cutter head, and a slewing device is installed on the second arm frame. One side of the slewing device is provided with a Drill, the other side of which is provided with a filling device, and each area is provided with a drill for extending and retracting, and a rotary device for rotating after the drill is retracted so that the filling device is located at the side of the drill. Retracted position for extending and retracting through holes. It can combine the safety of the shield method and the high efficiency of the drill and blast method at the same time. Increase efficiency and increase safety.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Dual-channel drill bit with drilling fluid switching function

ActiveCN110644927BDrilling achievedRealize variable temperature drillingDrill bitsFlushingSpool valveWell drilling

The invention discloses a dual-channel drill bit with drilling fluid switching function, which comprises a connected drill body and a dual-channel joint. The dual-channel joint includes a joint outer pipe, a joint inner pipe, a slide valve assembly located in the inner cavity of the joint inner pipe, and an inner joint There is an annular passage between the pipe and the outer pipe of the joint, and the inner pipe of the joint is provided with an inner pipe flow hole that communicates with the annular passage; the slide valve assembly includes a core pipe and a slide valve that is slidingly sealed between the joint inner pipe and the core pipe. The slide valve divides the inner tube cavity of the joint into the upper cavity of the inner tube and the lower cavity of the inner tube. The top of the core tube is closed and the bottom is open. The upper tube wall of the core tube is equipped with the upper part of the core tube. Flow holes; when drilling with the dual-channel drill bit of the present invention, under the action of the high and low temperature drilling hydraulic pressure difference, between the flow holes at the upper part of the core pipe and the upper chamber of the inner pipe, and between the flow holes at the lower part of the core pipe and the lower chamber of the inner pipe Periodically turn on or off, automatically switch between high and low temperature drilling fluids alternately, realizing variable temperature drilling and efficient rock breaking.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anti-skid drilling tool for stick-slip reduction with multi-start screw

ActiveCN106050160BIncreased versatilityRealize reciprocating motionDrilling rodsDrilling casingsSmall amplitudeDrive shaft

Owner:沛县东宝机电设备有限公司

Hydraulic oscillator with energy-gathering shock-absorbing function

ActiveCN106014317BReduce torsional vibrationReduce frictionDrilling rodsVibration devicesEnergy absorptionDamping function

The invention relates to a novel hydraulic oscillator with energy gathering and damping functions. The novel hydraulic oscillator is fixedly mounted in the position close to a drill bit and comprises a damping assembly, a transmission assembly and an oscillating assembly. The oscillating assembly is mounted at the front end of the transmission assembly. The damping assembly is mounted at the rear end of the transmission assembly. Vibration generated on an upper tool by the oscillator during operating is absorbed through multiple stages of vibration absorption rings; bit pressure and torque are transmitted through a disk spring and splines, and the disk spring and the splines are connected in series. When flowing through a flow guide pipe, drilling fluid flows into a pressure chamber through flow guide holes in the circumference of the flow guide pipe and then flows back to a central flow channel, pressure pulsation of the drilling fluid fluctuates, and the oscillating assembly generates an oscillating effect. The novel hydraulic oscillator with the energy gathering and damping functions can generate the oscillating frequency of a certain range to reduce friction drag borne by a drilling tool in the rock breaking process of the drill bit, automatically absorb vibration and reduce the influence of the oscillating assembly on the upper drilling tool during operating, so that the well drilling efficiency is improved.

Owner:江苏弘业检测技术有限公司

Self-propelled rotary jet multi-hole nozzle

ActiveCN103806836BGuaranteed reliabilitySimple structureLiquid/gas jet drillingJet flowFeeding force

The invention relates to a self-feeding rotary jet flow multi-hole spray nozzle, which comprises a spray nozzle cap, a back end shaft, a screw and the like. The self-feeding rotary jet flow multi-hole spray nozzle has the basic work principle that a plurality of forward holes are uniformly formed in a certain circle, leaving away from the center for a certain distance, of the front end surface of the spray nozzle, a plurality of center axes of the holes are in the located plane of a certain tangent line of the circle and are distributed in a way of forming different angles with an axial line of the spray nozzle cap, and the projection of the axial lines of the holes in the front end surface is a tangent line of the same circle, so the jet flow has high tangential speed, and the efficient rock breaking is favorably realized; the jet flow dispersion is realized, the acting range is wide, and large-aperture holes are favorably formed; the spray nozzle cap realizes autorotation through the jet flow reaction, each hole is scanned along the self rail for completing the rock breaking, and the formed holes are more regular; the spray nozzle cap realizes the autorotation, and the self feeding of the spray nozzle is favorably realized. The backward spray nozzle provides the self-feeding force, and meanwhile, the autorotation of the spray nozzle cap can be controlled. The self-feeding rotary jet flow multi-hole spray nozzle has the advantages that the structure is simple, the efficient rock breaking can be realized, and large-diameter regular holes are formed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

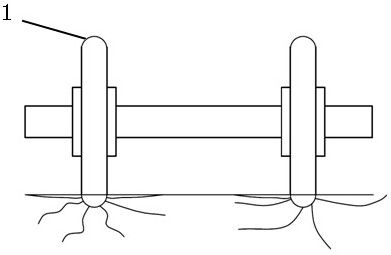

Area resonance drilling device and drilling method thereof

ActiveCN109854175BReduce wearEfficient rock breakingDrill bitsVibration devicesWell drillingClassical mechanics

The invention relates to a regional resonant well drilling device and a well drilling method thereof. The regional resonant well drilling device comprises a rotating disc, a drill pipe, a resonant generating chamber, a main drill bit and four resonant drill bits, the lower end of the drill pipe is connected with the resonant generating chamber, the lower end of the resonant generating chamber is connected with the main drill bit, a water outlet pipe is arranged in the center of the main drill bit, and the four resonant drill bits are distributed around the water outlet pipe and exposed at thebottom end of the main drill bit; two supporting rods are installed on a bottom plate of the resonant generating chamber, a first vibration excitation platform and a second vibration excitation platform are installed at the upper ends of the supporting rods correspondingly, a power supply device and a resonant frequency control center are connected with the first vibration excitation platform andthe second vibration excitation platform correspondingly, the resonant drill bits are all connected to the bottom end of the resonant generating chamber through transmission rods, and the main drill bit and the drill pipe are connected through the water outlet pipe. According to the regional resonant well drilling device, the four resonant drill bits and the main drill bit work alternately for a certain period of time, by cooperating with drilling, rock breaking can be effectively achieved on a hard formation, and the well drilling speed is increased.

Owner:NORTHEAST GASOLINEEUM UNIV

Rotary PDC drill bit

The invention relates to a rotary PDC drill bit. The rotary PDC drill bit is mainly composed of a drill bit base body, blades, blade supporting seats, blade rolling shafts, PDC cutting teeth, nozzles and flow channels, wherein the blades are fixed to the drill bit base body through the blade rolling shafts and the blade supporting seats, each blade is provided with the PDC cutting teeth, the blades are disc type blades with through holes in the centers, and the disc type blades can freely rotate around the blade rolling shafts. The blades keep rotating while cutting the stratum, the rotating blades can evenly disperse abrasion of the cutting teeth on the blades, meanwhile, the cutting teeth are effectively cooled and kept sharp, and therefore the effects of efficient drilling and prolonging of the service life of the drill bit are achieved; the free rotation disc type blade structure has the advantages of being high in drilling speed and long in service life, and compared with a drilling method adopting a full-imported drill bit, the drilling cost can be saved; and when the drill bit is used for drilling in stratums with high abrasiveness and poor drillability, the aim of efficiently breaking rocks can also be achieved by adopting conventional drilling parameters.

Owner:中石化石油工程技术服务有限公司 +2

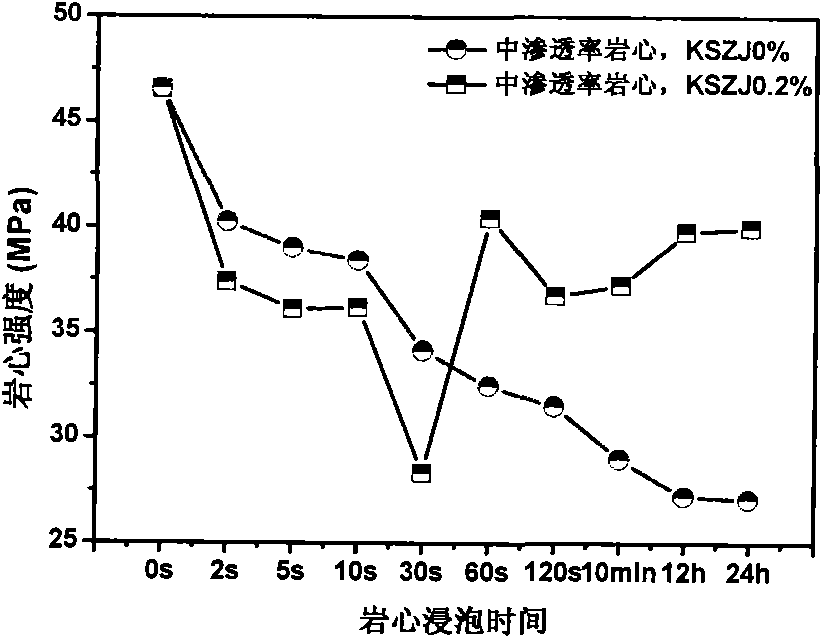

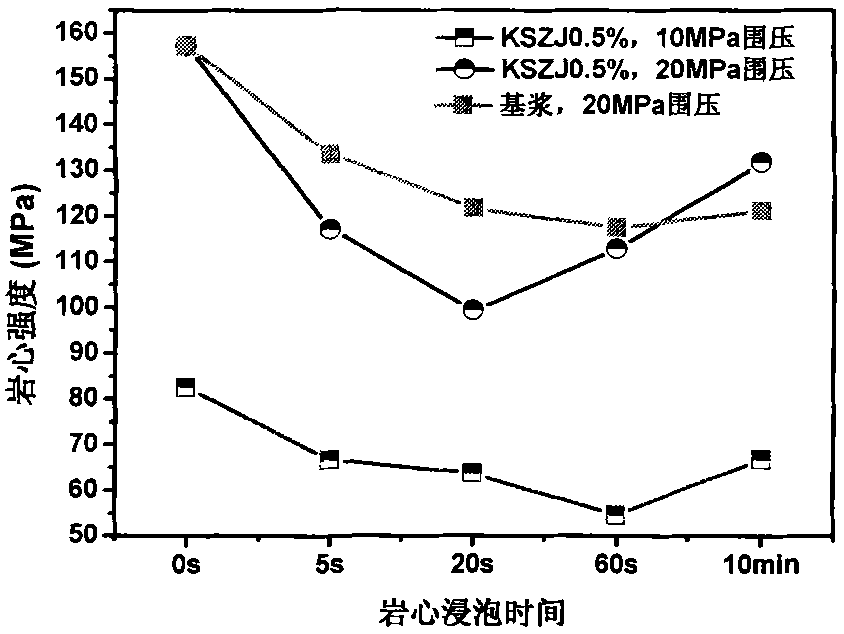

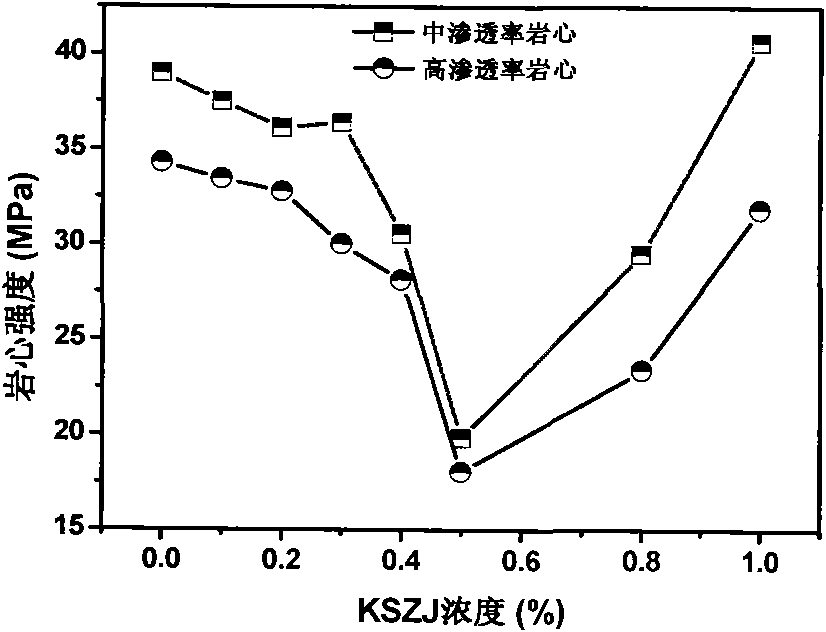

Rock breaking agent for stabilizing well walls and preparation method thereof

ActiveCN102399549AIncrease penetration rateLarge osmotic volumeDrilling compositionPolyolUltimate tensile strength

The invention relates to a rock breaking agent for stabilizing well walls and a preparation method thereof. The rock breaking agent consists of the following components in part by mass: 80 to 100 parts of plant protein, 180 to 200 parts of water, 50 to 65 parts of 20 mass percent n-hexane solution of phosphorus oxychloride, 20 to 40 parts of sulphydryl polyether polyol, 30 to 40 parts of sulfonated dioctyl succinate, 16 to 24 parts of sulfonating agent and pH regulator. The efficient rock breaking agent for stabilizing the well walls can instantaneously and effectively reduce the strength of stratum rock, is favorable for stabilizing the well walls, and improves the drilling speed so as to reduce the exploratory development cost, protect the oil-gas layer and improve the recovery rate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Self-advancing cuttings abrasive direct-rotation mixed-jet drill bit

InactiveCN103835653BGuaranteed reliabilitySimple structureDrill bitsLiquid/gas jet drillingWell drillingStructural engineering

The invention relates to a self-propelled rock debris grinding material straight-spinning jet mixing flow drill bit. The drill bit comprises a backward nozzle, a straight-spinning jet flow nozzle, a rock debris grinding material funnel, a forward nozzle, stabilizing supports and the like. According to the basic working principle of the drill bit, when jet flow passes through the drill bit, one part of the jet flow is jetted through the forward nozzle to provide self-propelled force for the drill bit and to broaden holes, the other part of the jet flow is jetted at high speed through the straight-spinning jet flow nozzle of the drill bit, the jet flow pumping effect is generated in an interval section, rock debris grinding materials sucked into the rock debris grinding material funnel enter the forward nozzle, eventually straight-spinning jet mixing flow of the rock debris grinding materials is formed to jet and break rock, and therefore rock breaking efficiency is improved, broken rock debris is discharged through an annulus along with drilling fluid, part of the rock debris enters the rock debris grinding material funnel due to the gravity effect and the jet flow pumping effect and supplies grinding materials to grinding material jet flow rock breaking. According to the drill bit, rock breaking efficiency of a radial horizontal well with the ultra-short radius can be effectively improved, and a well track can be effectively controlled.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Tunneling device with drilling angle being adjustable and tunneling machine

The invention discloses a tunneling device with the drilling angle being adjustable and a tunneling machine. The tunneling device comprises a cutterhead, multiple heads, drilling mechanisms and a fixing mechanism, and the heads are vertically arranged on the cutterhead. The drilling mechanisms are rotationally arranged on the cutterhead and comprise drill rods capable of stretching and retractingin the axial direction on the cutterhead. The fixing mechanism is used for fixing the drilling mechanisms rotating on the cutterhead onto the cutterhead so as to adjust the positions of the drill rodson the cutterhead. According to the tunneling device, prefabricated cracks with a certain inclination angle are formed in to-be-excavated rock mass through the drilling mechanisms, then tunneling iscarried out through the heads on the cutterhead, and therefore the mechanical performance of the heads is better played, and then the aim of efficient tunneling of the to-be-excavated rock mass is achieved; and the tunneling device is especially suitable for tunneling of the tunneling machine in hard rock engineering.

Owner:TSINGHUA UNIV +1

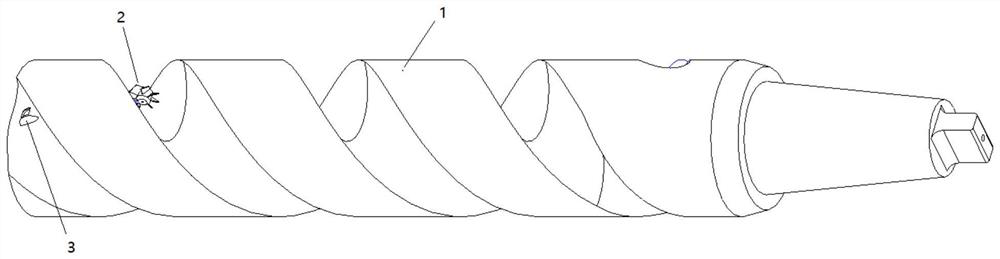

Self-sweeping laser twist bit

InactiveCN112252990APromote fragmentationEasy dischargeEarth drilling toolsDrill bitsGeology of the MoonWell drilling

The invention provides a self-sweeping laser twist bit, and relates to the technical field of lunar resource exploration drilling tools. The twist bit solves the technical problems that the cutting efficiency of a drill bit is general and rock debris is difficult to discharge. The self-sweeping laser twist bit comprises a twist bit body, a self-sweeping device, a mixing device, a laser assembly and a light transmitting assembly; the laser assembly is arranged in the mixing device; the mixing device is arranged in the twist bit body and is used for grouping and guiding laser beams emitted by the laser assembly; the light transmitting assembly is arranged on a light transmitting hole of the twist bit body and is used for transmitting laser; the self-sweeping device is connected with the light transmitting assembly for sweeping the light transmitting assembly; and the self-sweeping device is a self-sweeping device without external power input. The twist bit is used for lunar geological drilling, has the characteristics of high rock breaking speed, high rock debris discharging speed, long equipment service life and high drilling efficiency, and is suitable for the air-free and water-free moon.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Cutter head, full-section hard rock heading machine based on drilling and blasting construction and rock breaking method

The invention discloses a cutter head, a full-section hard rock heading machine based on drilling and blasting construction and a rock breaking method. The cutter head is divided into N areas, a first slotting tool is arranged between every two adjacent areas, and second slotting tools are arranged at other boundary positions of each area; an impactor and a first arm frame connected with the impactor are arranged in the cutter head, a notch is formed in the first slotting tool or the second slotting tool of each area for the impactor to stretch out and retract, and a guide rail is arranged on the boundary of each area to form an annular guide rail for the impactor to move; a second arm frame is arranged in the cutter head, a rotating device is arranged on the second arm frame, a drilling device is arranged on one side of the rotating device, and a chemical filling device is arranged on the other side of the rotating device; and each area is provided with a through hole for the drilling device to stretch in and retract and for the rotating device to rotate after the drilling device retracts so that the chemical filling device can stretch in and retract at the retracting position of the drilling device. The safety of a shield method and the high efficiency of a drilling and blasting method can be achieved at the same time. The efficiency is improved, and the safety is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com