New well drilling method for efficient rock breaking by means of heating power jet flow

A new method and thermal technology, applied in the direction of drilling with liquid/gas jet, can solve the problems of low rock breaking efficiency and insufficient bottom hole energy, and achieve the effects of good site adaptability, low drilling cost and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

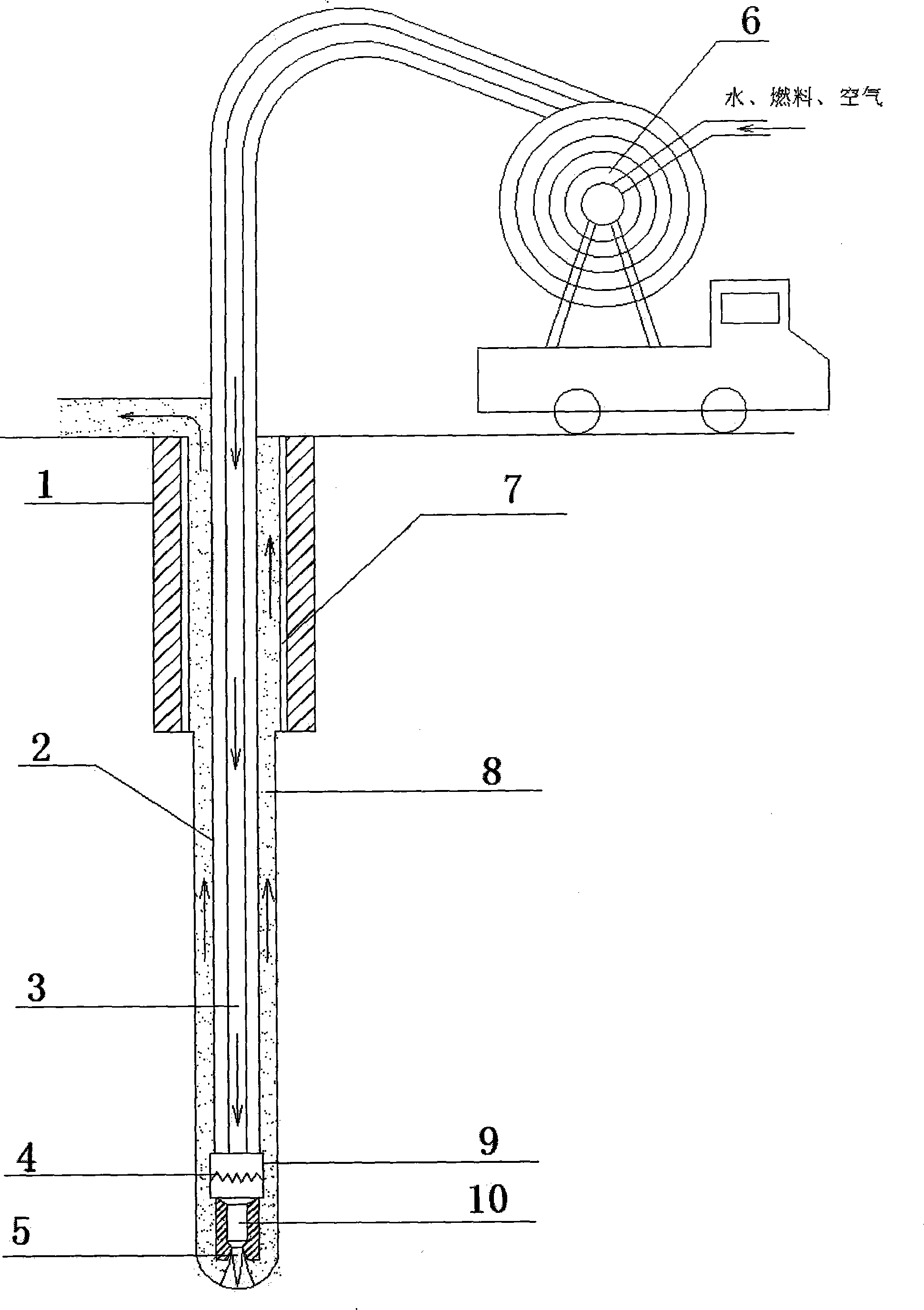

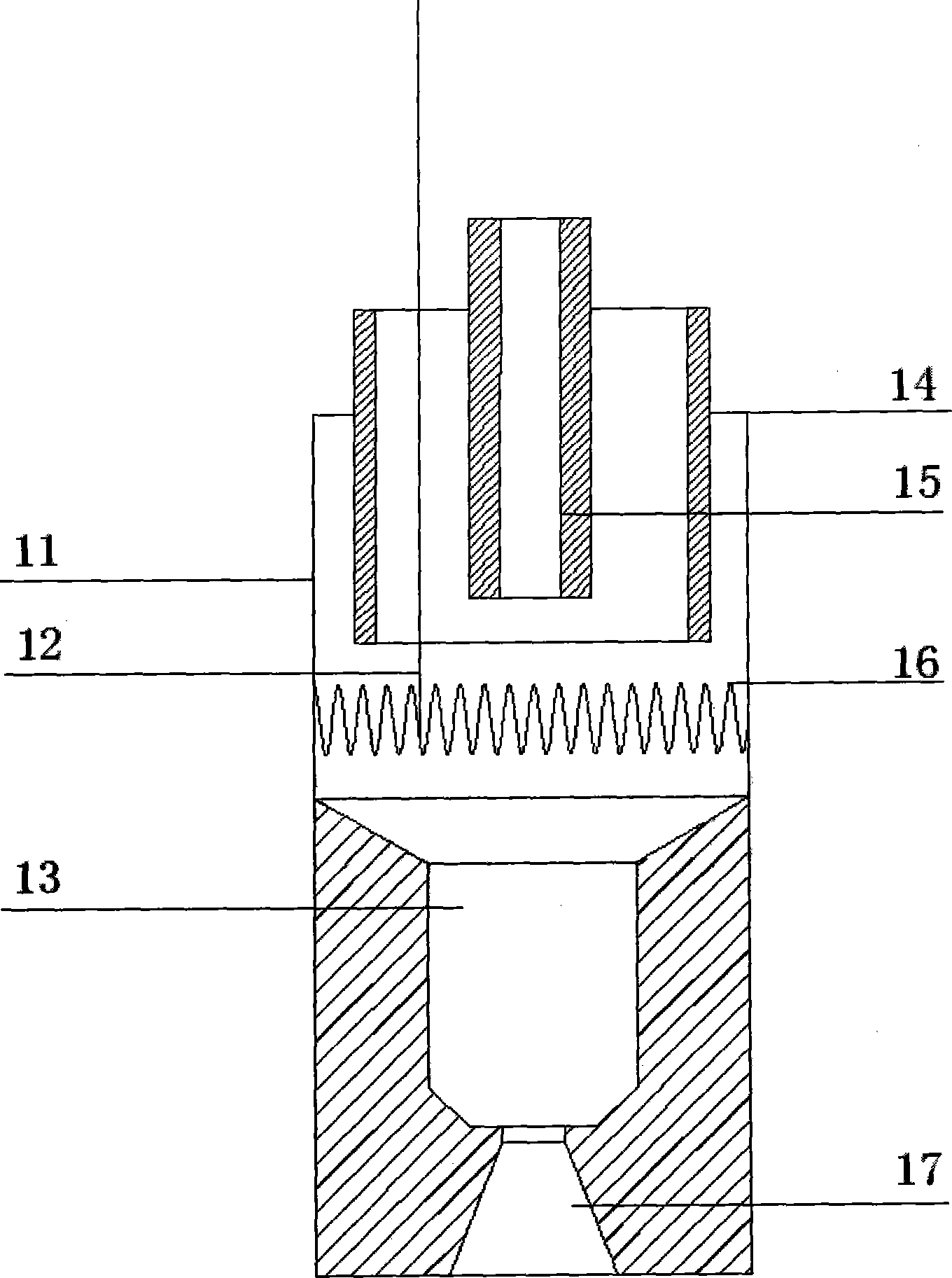

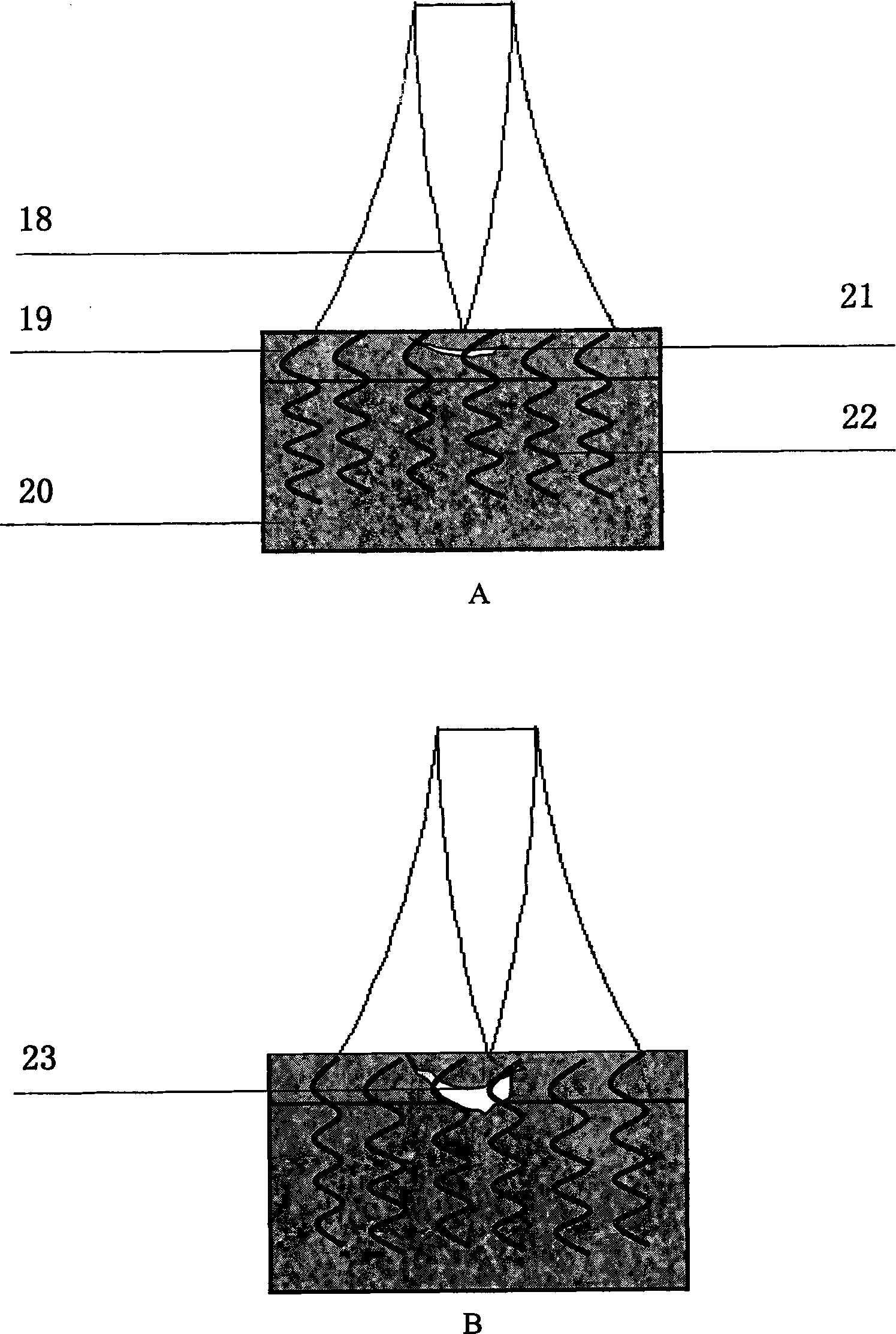

[0033] The invention creatively proposes to apply thermal jet and rock pyrolysis technology to deep well hard formation drilling, and forms a complete set of construction scheme. It solves the key problems such as low rock-breaking efficiency in deep hard formations and insufficient energy at the bottom of the well. With the use of coiled tubing drilling technology, there is no need to replace the drill bit, which greatly saves the tripping time and reduces the wear of the pipe string. At the same time, the energy utilization rate of thermal jet rock breaking is high, and the non-contact rock breaking in deep hard formations can greatly increase the drilling speed and greatly shorten the drilling time. Thermal jet drilling can also increase the porosity and permeability of the near-wellbore zone, which is conducive to more efficient and effective mining in the later stage.

[0034] The system composition of thermal jet rock breaking drilling mainly includes: coiled tubing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com