Self-advancing cuttings abrasive direct-rotation mixed-jet drill bit

A self-advancing, cuttings technology, used in drill bits, drilling with liquid/gas jet drilling, drilling equipment, etc., can solve the problems of irregular wellbore, easy failure, difficulty in removing cuttings from annulus, and save drilling costs. , Improve the effect of rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will be further described in conjunction with the accompanying drawings:

[0024] figure 1 It is a three-dimensional schematic diagram of the self-advancing cuttings abrasive direct-rotation mixed-jet drill bit patented by the present invention. The drill bit is designed in one piece, and multiple processes are completed. figure 1 It can be seen from the figure that there is no cooperation of parts inside the drill bit, which enhances the reliability of the drill bit.

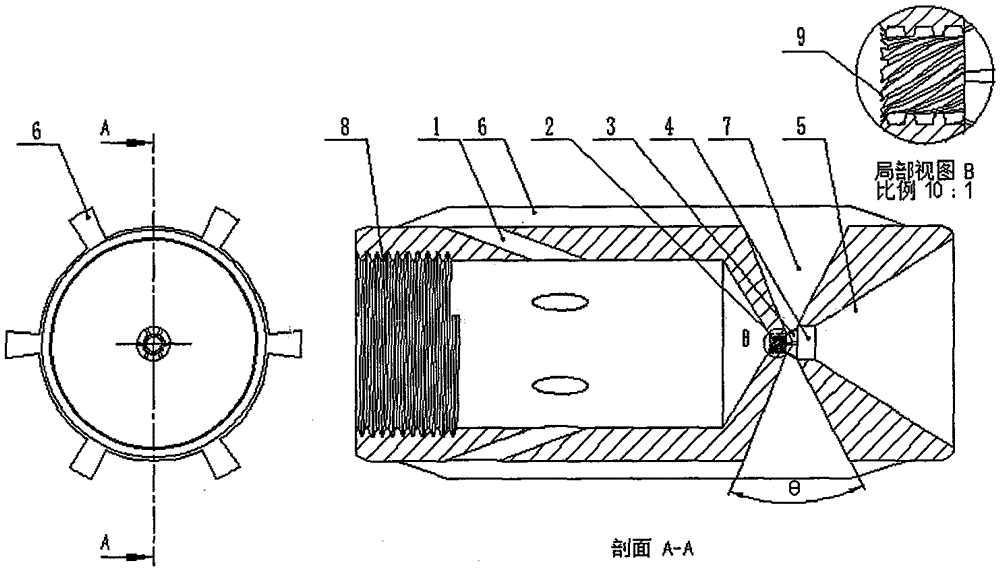

[0025] figure 2 The left view, A-A sectional view and partial view of the self-propelled circulating self-mixing abrasive jet drill bit patented by the present invention are in figure 2 Among them, the drill bit of the present invention is provided with an internal thread 8 for connecting the coiled tubing, and the rear end of the drill bit is evenly distributed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com