Composite rock breaking method, cutterhead and heading machine

A rock-breaking and cutter head technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of high installation rate, large thrust and large torque of composite rock-breaking roadheaders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

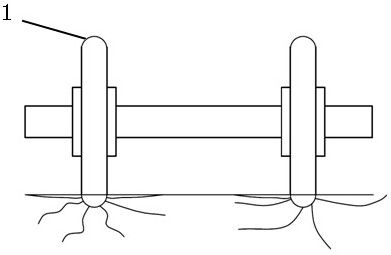

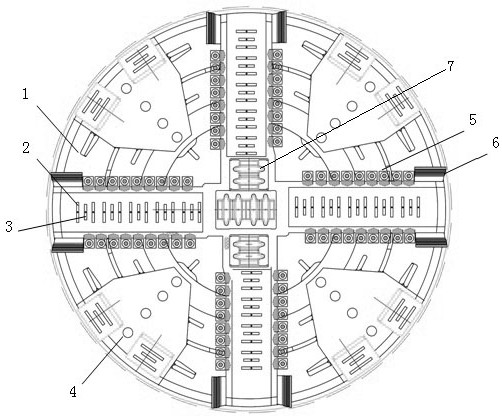

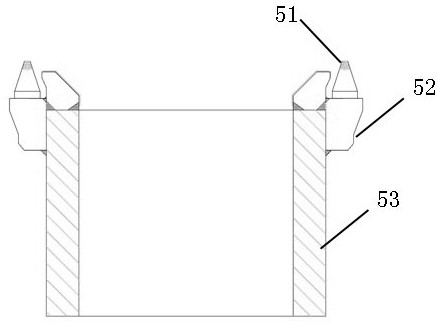

[0030] Embodiment 1, a kind of composite rock breaking method, such as Figure 4 As shown, the high-speed water jet ejected from the high-speed water jet nozzle 2 causes cracks in the rock mass; as Figure 5 As shown in , the supercritical carbon dioxide injected from the supercritical carbon dioxide nozzle is injected into the fracture; Figure 6 As shown, the microwave generating system heats the supercritical carbon dioxide in the fracture through the microwave radiating arm 4 to cause a rapid phase transition, and uses a cutter system to break the supercritical carbon dioxide in the fracture after the phase transition. First, high-speed water jets are used to create cross-cracks at a certain angle in the rock mass, and then supercritical carbon dioxide is quickly injected into the cross-cracks, and a microwave generation system is used to heat the supercritical carbon dioxide injected into the prefabricated cracks to heat up rapidly. The critical carbon dioxide rapidly un...

Embodiment 2

[0031] Embodiment 2, a composite rock-breaking method, the high-speed water jet, supercritical carbon dioxide injection into cracks, heating by microwave generation system, and rock-breaking by tool system are performed sequentially and cyclically. By maximizing the expansion of supercritical carbon dioxide in fractures created by high-velocity water jets, the cutter system can more easily break rock efficiently.

[0032] Other methods of this embodiment are the same as in Embodiment 1.

Embodiment 3

[0033] Embodiment 3, a composite rock-breaking method, the high-speed water jet, supercritical carbon dioxide injected into cracks, microwave generation system heating, and cutter system rock-breaking are carried out simultaneously, so that the cracks produced by high-speed water jet rock-breaking can be combined with supercritical carbon dioxide The blasting gas and the tool system are superimposed on rock breaking at the same time, layer by layer, to achieve the effect of efficient rock breaking.

[0034] Other methods of this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com