Drilling system and method and application thereof

A drilling and drilling fluid technology, applied in the field of hot dry rock drilling, can solve the problems of affecting the rock-breaking effect of liquid nitrogen and poor rock-carrying effect, and achieve the effects of weakening heat transfer effect, improving wear resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

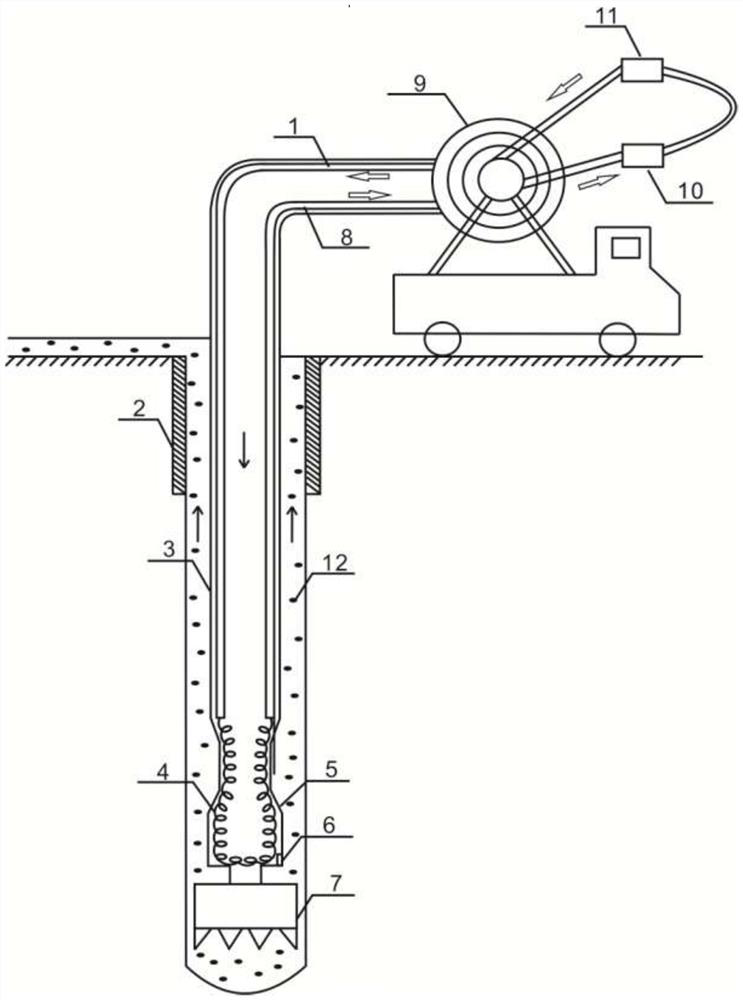

[0049] The drilling system for improving the drilling efficiency of hot dry rock described in the present invention includes parts including a high-pressure injection pump, a cold fluid circulation pipeline, a coiled tubing, a fluid temperature control chamber, and a refrigeration heat exchanger;

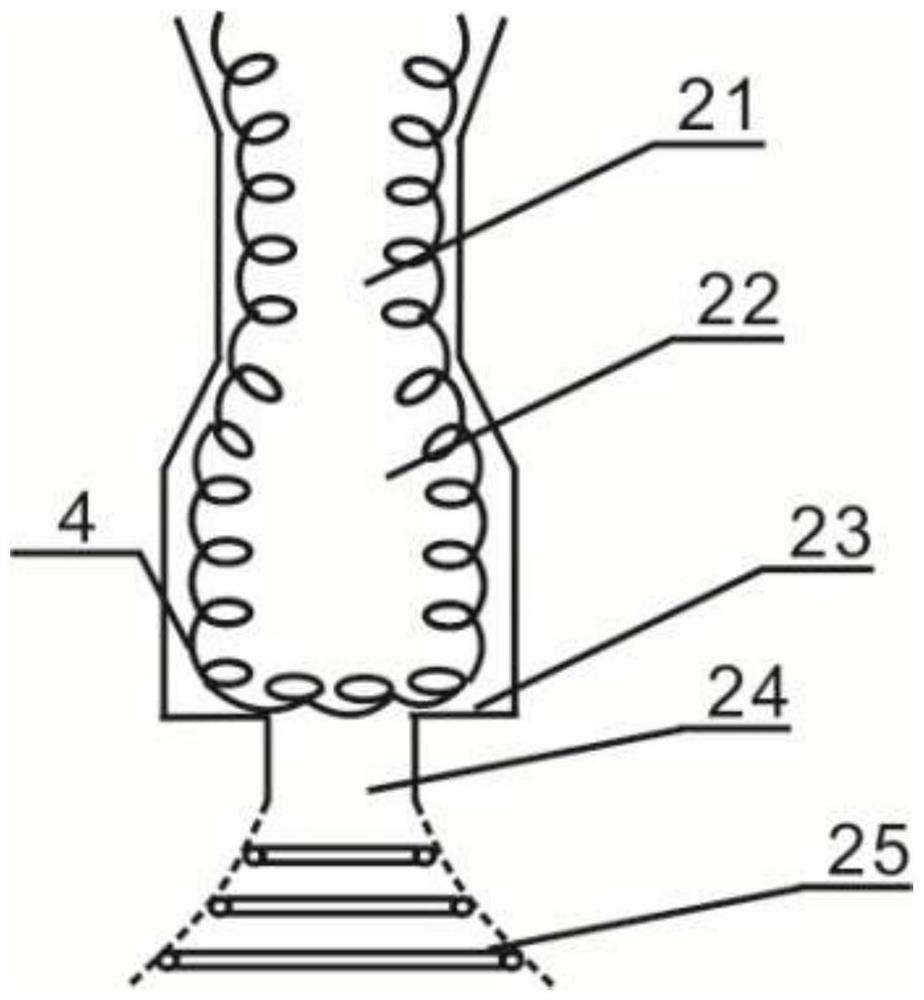

[0050] The cold fluid circulation pipe includes a spiral heat exchange pipe and an external cold fluid circulation pipeline;

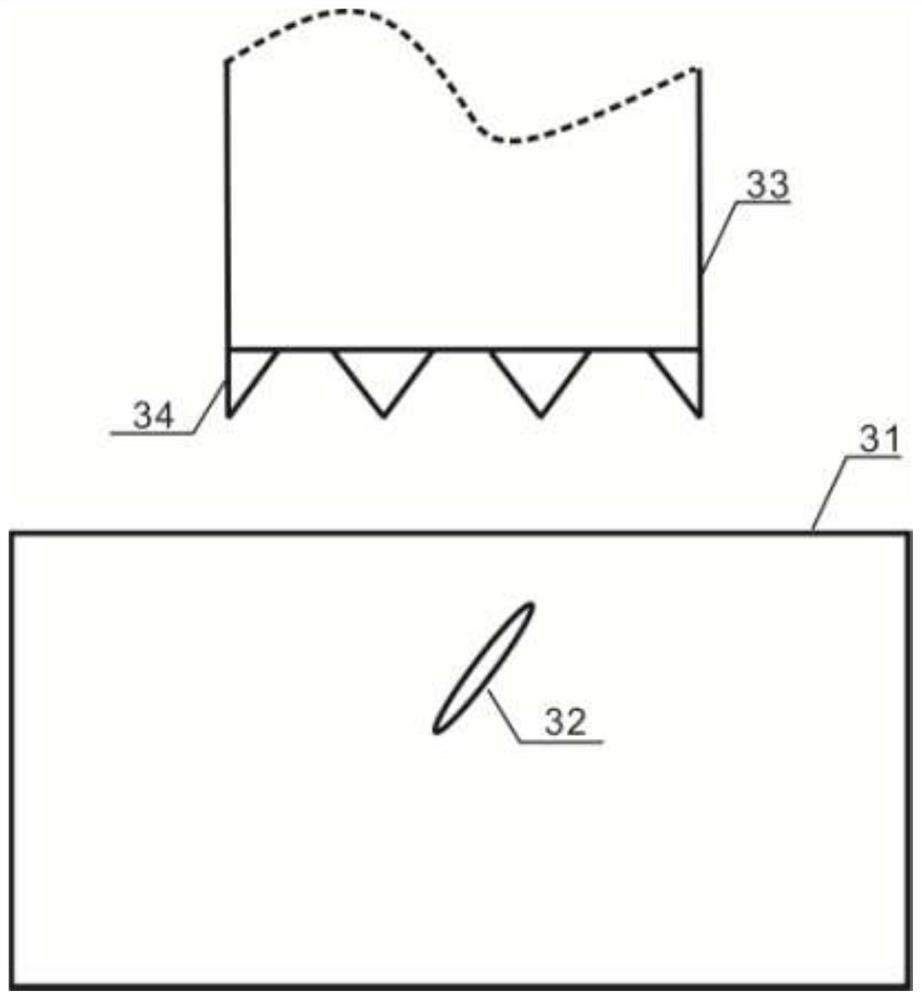

[0051] The surface 41 of the spiral heat exchange tube is coated with a multi-layer composite coating. The multi-layer composite coating consists of a polymer-nanoparticle composite coating 42 , a carbon-carbon coating 43 and a silicon carbide whisker coating 44 from the base pipe outward along the vertical pipe wall. Polymer-nanoparticle composite coating 42, that is, nanoparticles uniformly dispersed in a polymer resin matrix. Wherein the nanoparticle thermal conductivity is at least 1500W / m·K. The interfacial thermal resistance between the polymer resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com