Downhole tool for achieving efficient rock breaking through spin vibration

A technology for downhole tools and rock breaking, applied in drilling, natural gas exploitation, and petroleum fields, can solve problems such as difficulty in meeting site requirements, matching of power drilling tools, and complex tool structure, so as to improve rock breaking efficiency, increase oscillating force, and output torque. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

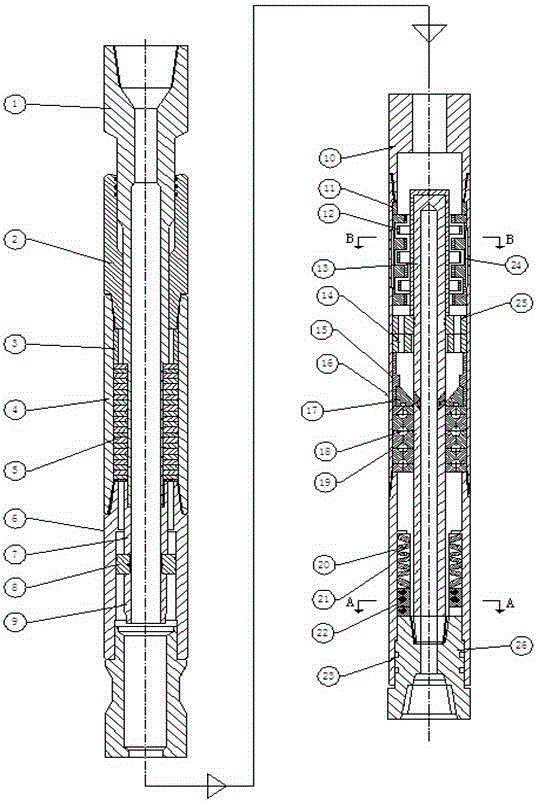

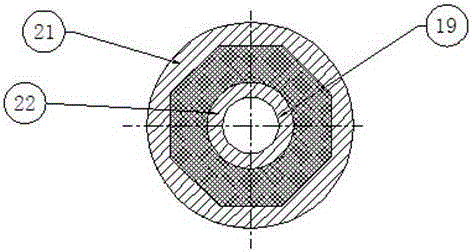

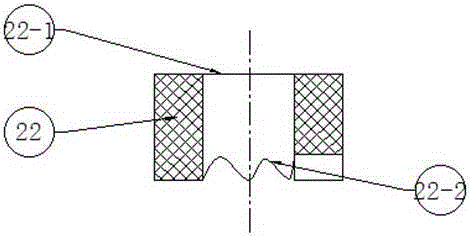

[0023] Such as figure 1 As shown, the downhole tool mentioned in the present invention realizes high-efficiency rock breaking by means of rotary percussion oscillation pressurization, including a mandrel (1), an upper joint (2), a spacer (3), an outer tube (4), and a disc spring group (5), middle joint (6), mandrel middle joint (7), Ster seal piston (8), mandrel lower joint (9), lower joint (10), adjustment ring (11), turbine rotor (12 ), turbine stator (13), lower disc valve (14), adjustment sleeve (15), sleeve I (16), shunt sleeve (17), thrust bearing (18), transmission shaft (19), power storage spring ( 20), sleeve II (21), toothed surface impact hammer (22), cyclone seal (23), upper plate valve (25), passive impact joint (26).

[0024] The sleeve I (16) is connected to the turbine stator (13) through a flat key; the lower end of the turbine stator (13) is installed with a disc valve group; the lower end of the shunt sleeve (17) is installed with a thrust bearing (18); the...

Embodiment 2

[0029] The downhole tool mentioned in the present invention utilizes rotary percussion oscillation pressurization to realize high-efficiency rock breaking, and its use process is as follows:

[0030] In the downhole tool of the present invention, which realizes high-efficiency rock breaking by means of rotary punching oscillation pressurization, the drilling fluid drives the rotary impeller to rotate at high speed, so that the upper disc valve (25) of the disc valve group rotates, the lower disc valve (14) is fixed, and the upper disc valve group The liquid inlet hole of the disc valve (25) and the reset hole of the lower disc valve (14) are periodically communicated and closed, and the flow area between the two will change, thus forming a periodic pulse pressure wave with a certain amplitude. When the pressure rises , the drilling fluid acts on the Step seal piston, and the disc spring group is compressed to push the mandrel to move to the left. When the pressure decreases, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com