Self-propelled rotary jet multi-hole nozzle

A multi-hole nozzle, self-propelled technology, applied in the direction of drilling with liquid/gas jets, etc., can solve the problems of large forward jet recoil, irregular shape, fast jet decay, etc., to reduce self-propelled resistance and simple structure. , to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

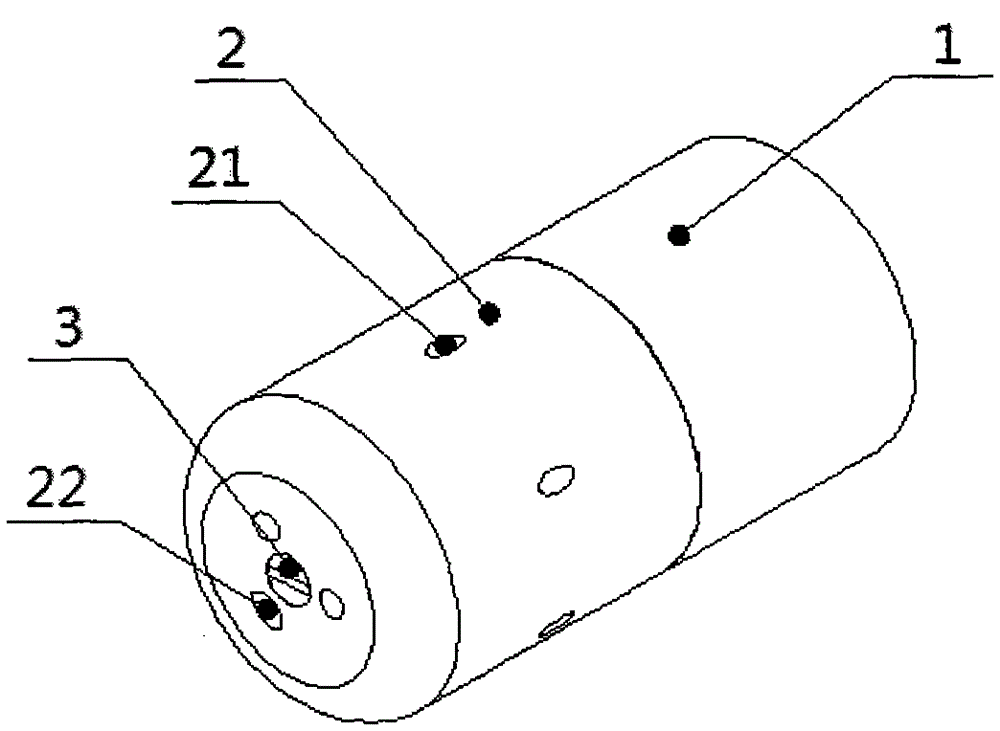

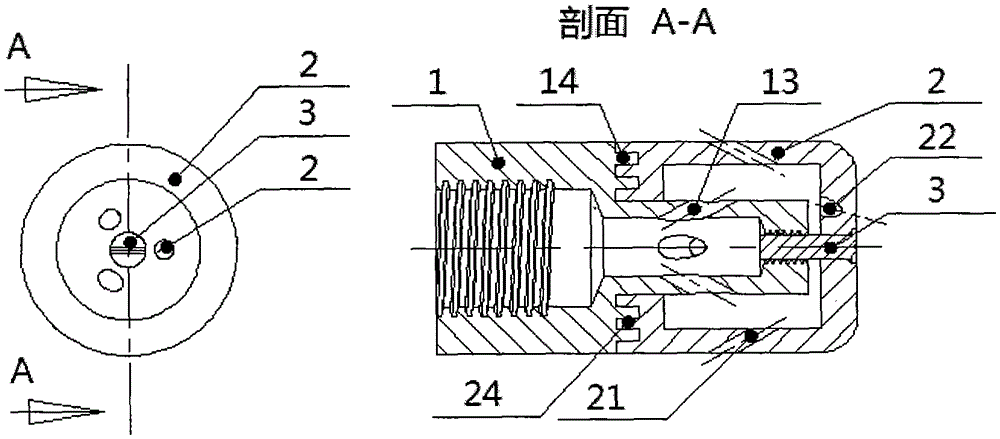

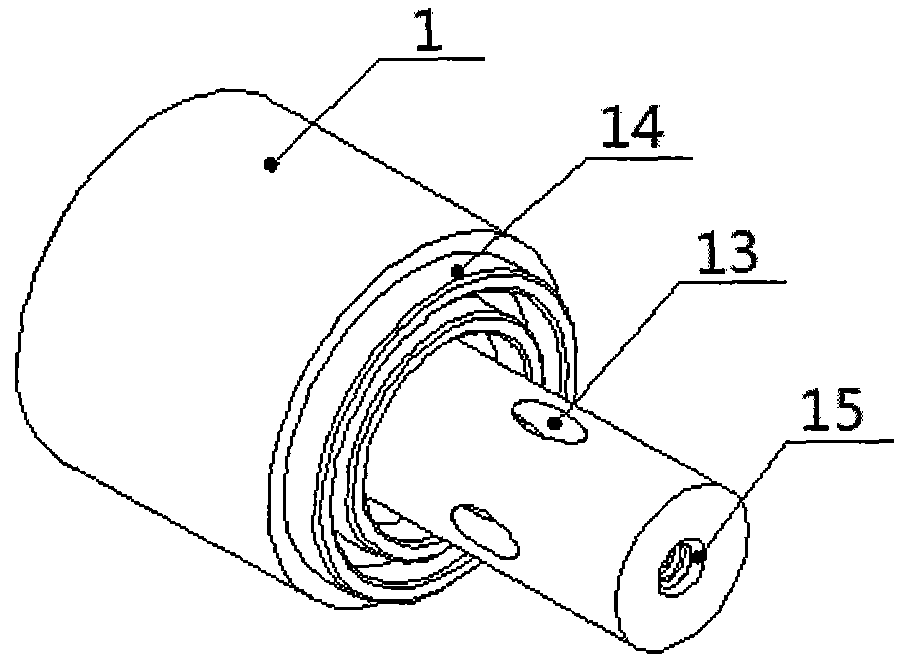

[0029] The self-propelled rotary jet multi-hole nozzle of the present invention mainly includes: a nozzle cap, a rear end shaft, screws and the like. It is characterized in that the front end of the nozzle cap is evenly distributed with a plurality of forward holes on a circle with a certain distance from the center, and the jet formed by the high-pressure fluid through the forward holes has a high tangential velocity, which is beneficial to rock breaking; The momentum causes the nozzle cap to rotate itself, and the orbital scanning of each hole is combined to break rocks, which is conducive to the formation of large-diameter regular holes and the self-advancement of the nozzle; there are multiple backward holes evenly distributed in the same width area on the outside of the nozzle cap. The nozzle provides self-progressive force and torque; the rear shaft is a variable-diameter hollow cylinder, the large-diameter part at the rear is used to connect the fluid pipeline, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com