Combined rock breaking test device based on high-pressure water jet and cutter sequential operation and application

A technology of high-pressure water jet and test equipment, applied in the direction of measuring equipment, testing machinability, instruments, etc., can solve the problem of shallow cutting depth, etc., and achieve the effect of low energy consumption rock breaking, high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

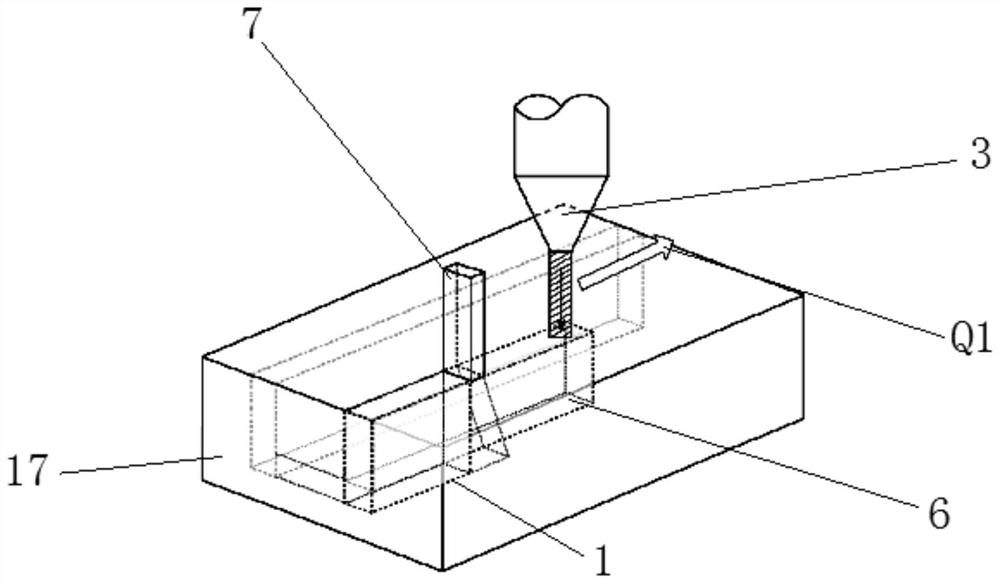

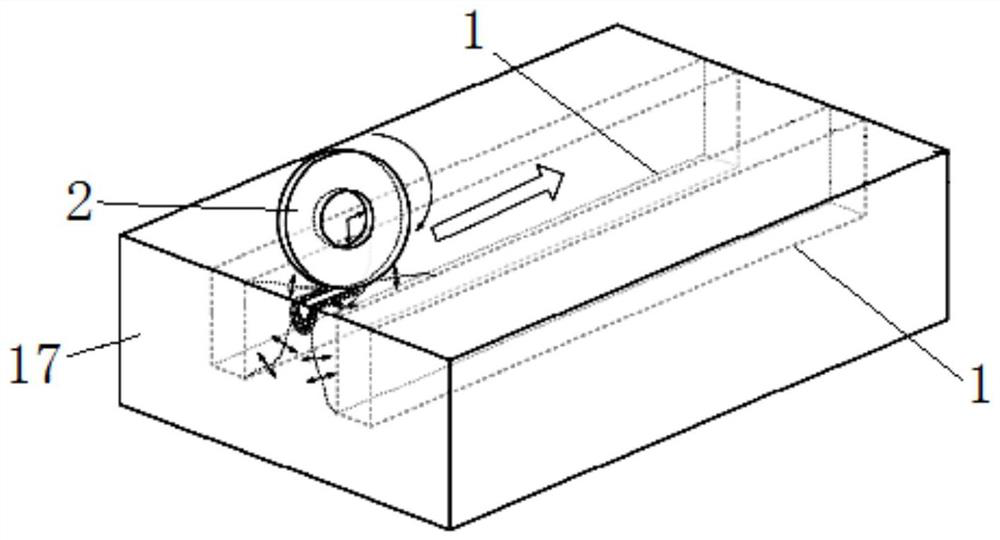

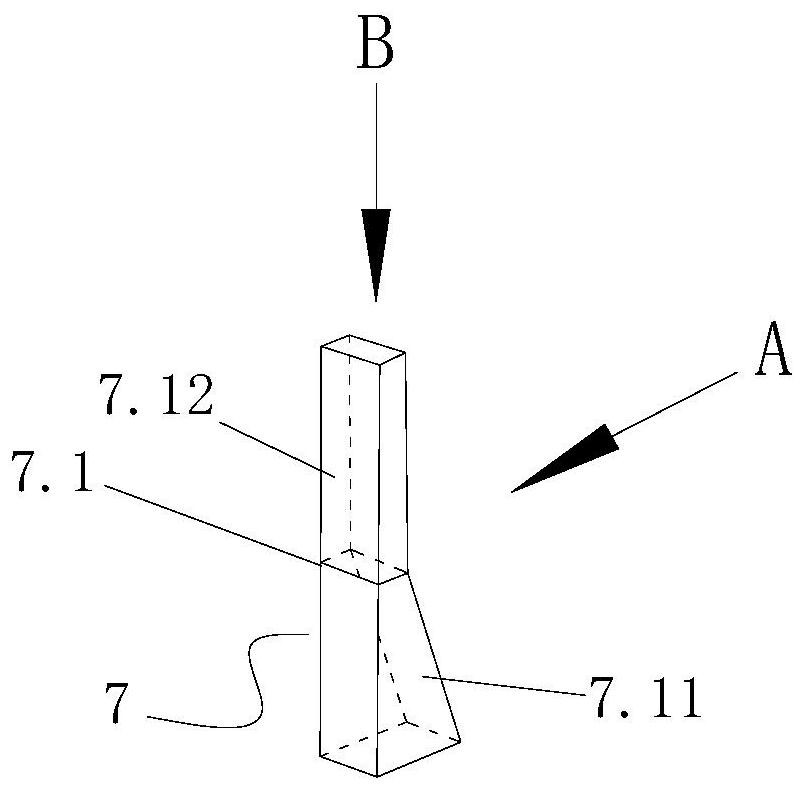

[0076] Referring to the accompanying drawings, it can be seen that the combined rock-breaking test device based on high-pressure water jet + cutter sequential operation includes a cutter head 4, a mechanical hob structure 2, a high-pressure water jet structure 3, and a scraper structure 7; the mechanical hob structure 2, high-pressure Both the water jet structure 3 and the scraper structure 7 are installed on the cutter head 4; the mechanical hob structure 2, the high-pressure water jet structure 3, and the scraper structure 7 are arranged in partitions on the cutter head 4;

[0077] In the direction of travel of the cutter head 4, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com