Laser-mechanical drill bit for laser-mechanical combined efficient rock breaking

A laser and mechanical technology, applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of short life of drill bits, high mining costs, obstruction of deep oil and gas resources, etc., and achieve the effect of reducing the cost of rock breaking and improving the efficiency of rock breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and this embodiment.

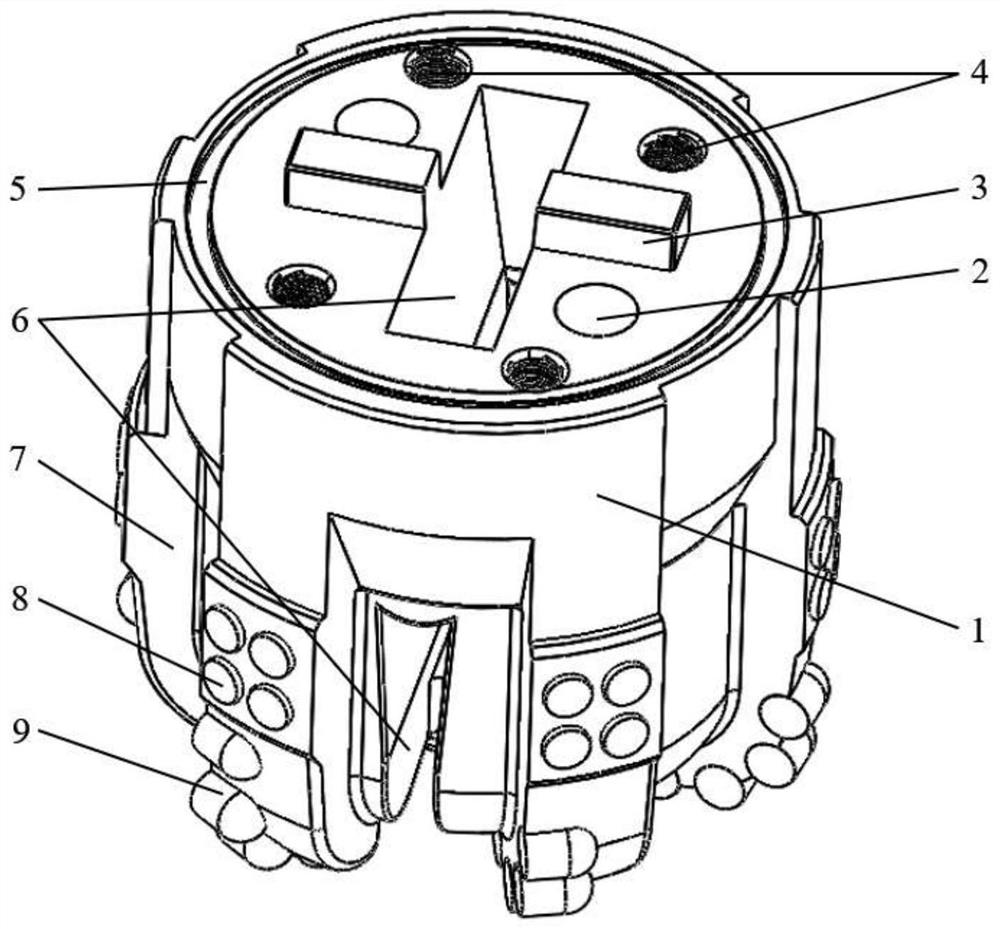

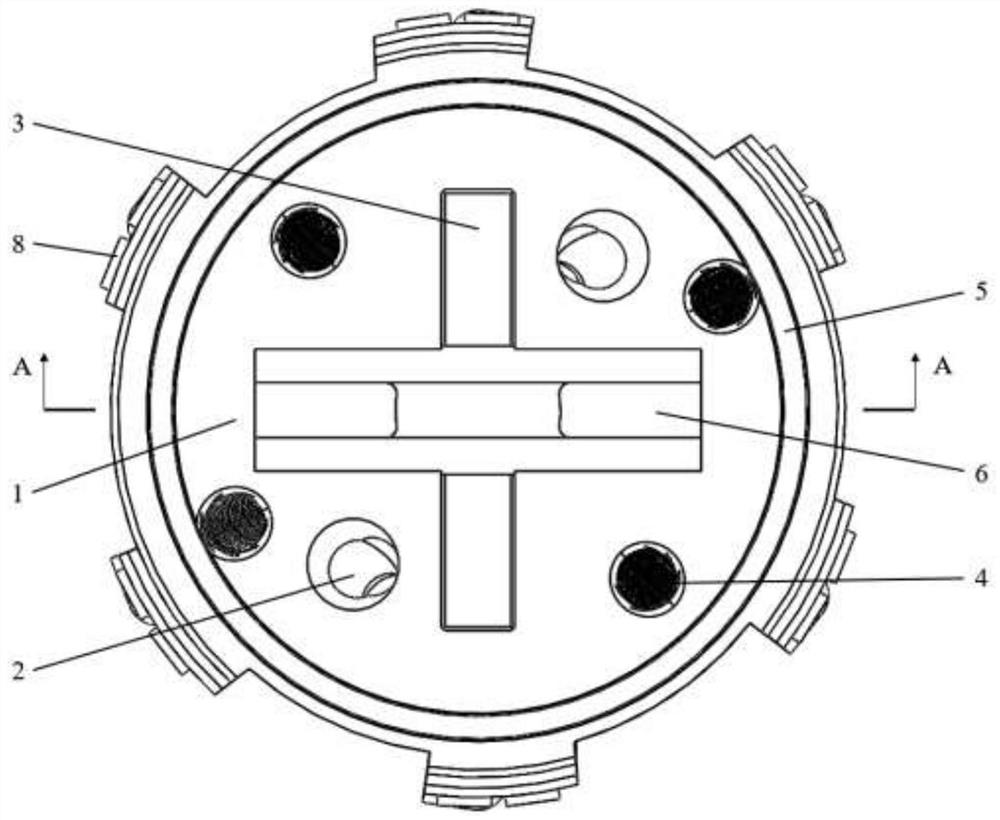

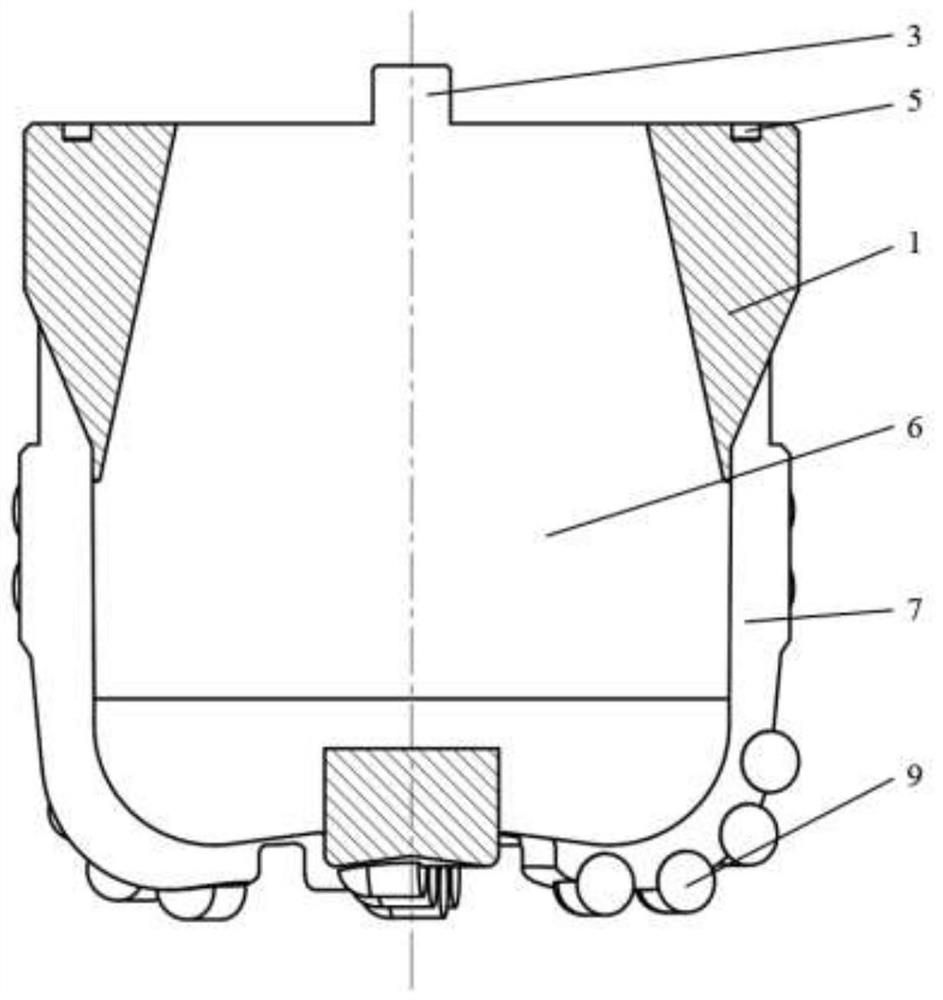

[0021] Such as figure 1 As shown, the present invention is a laser-mechanical drill bit for laser-mechanical combined high-efficiency rock breaking. Composed of wings 7, gauge teeth 8 and cutting teeth 9; the gauge teeth 8 and cutting teeth 9 are welded on the blade 7; the blade 7 extends from the drill body 1 and is integrally machined with the drill body 1 Forming, a chip removal groove is formed between adjacent blades 7; the number of blades 7 on the drill bit body 1 is greater than or equal to three;

[0022] The inside of the drill bit body 1 is provided with a through dovetail groove-shaped laser channel 6, and the shaped linear laser beam is irradiated at a designated position on the rock surface through the laser channel 6, and rotates with the drill bit; there are 6 laser channels on the drill bit body 1 The number is greater than or equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com