O-shaped loop and metal ring two-way combined sealed oil storage single-cone bit

A combined sealing and metal ring technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of cone loss, low sealing life, restricting the excellent technical characteristics of single cone drill bits, etc., to improve stability, Optimize the effect of cloth teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

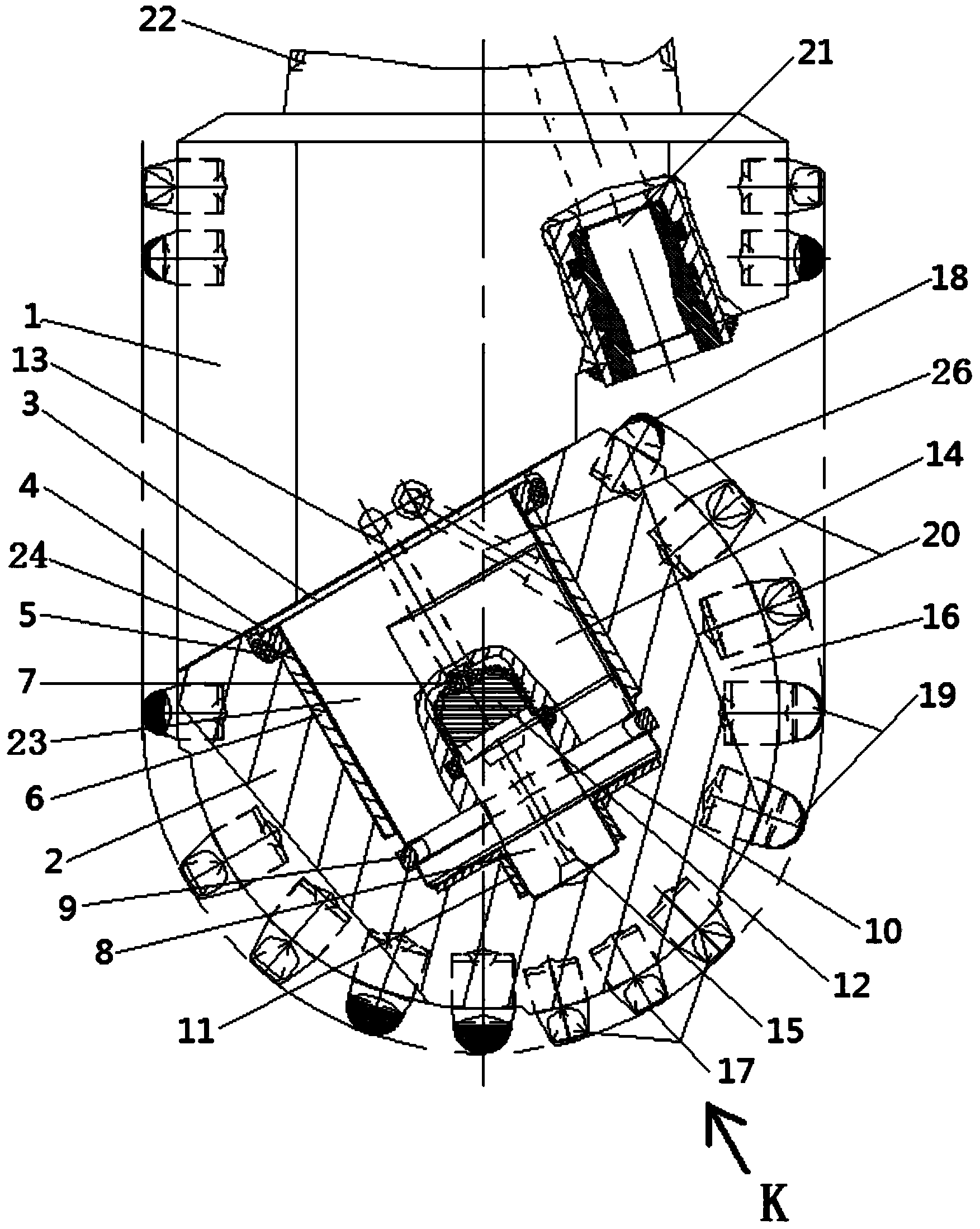

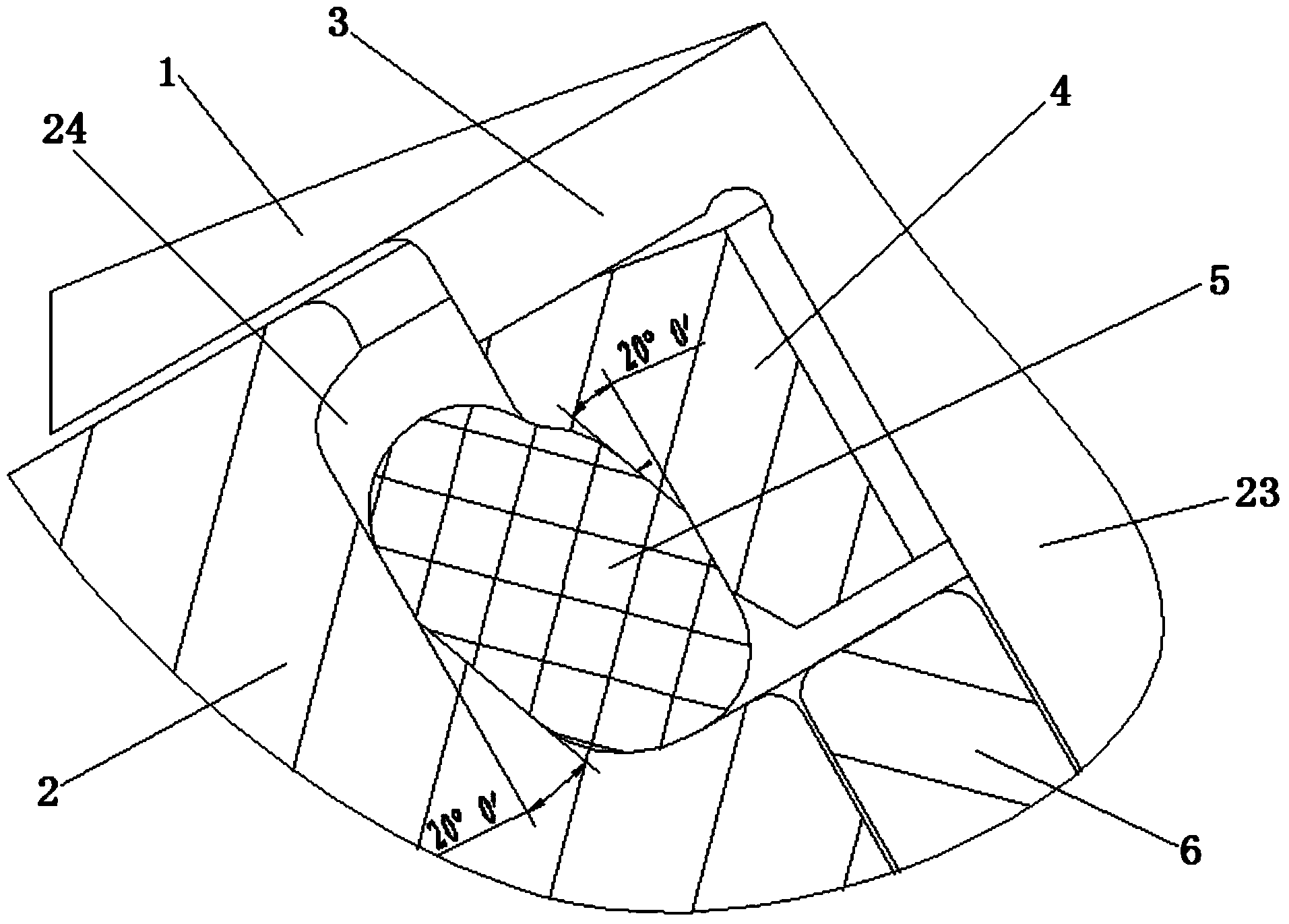

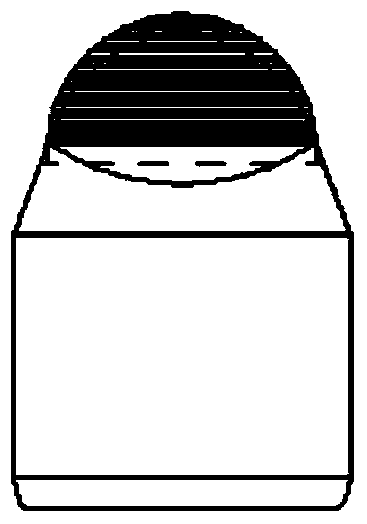

[0027] refer to figure 1 , is an oil-storage single-cone bit with an O-ring metal ring bidirectional combination seal of the present invention, which includes a wheel metal ring (4), a wheel O-ring (5), a small shaft (8), and an oil storage bag ( 7), the small shaft sleeve (11), the main body (1) with connecting thread (22) on the upper part, the large journal (23) protruding obliquely from the bottom of the main body (1), and the sleeve on the large journal (23) The toothed wheel (2), the tooth post arranged on the toothed wheel (2), is set on the large shaft sleeve (6) on the outer wall of the large journal (23); the toothed wheel (2) is provided with a stepped blind hole for installation, and the steps There is an inner wall annular groove near the step in the large hole of the blind hole, and the outer wall annular groove corresponding to the inner wall annular groove is arranged on the top surface of the large journal (23), and the outer wall annular groove and the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Tooth height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com