Underground cavity peeping device and method based on three-dimensional scanning and 3D printing

A 3D printing and underground cavity technology, applied in measuring devices, cross-section drawing, instruments, etc., can solve the problem of not being able to obtain cavity information in all directions, and achieve the effect of simple structure, convenient operation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

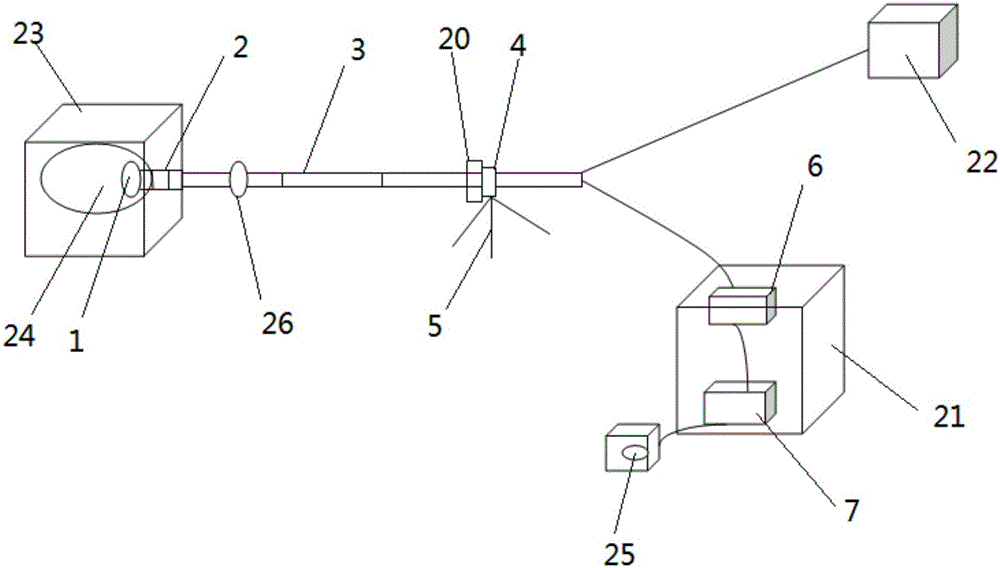

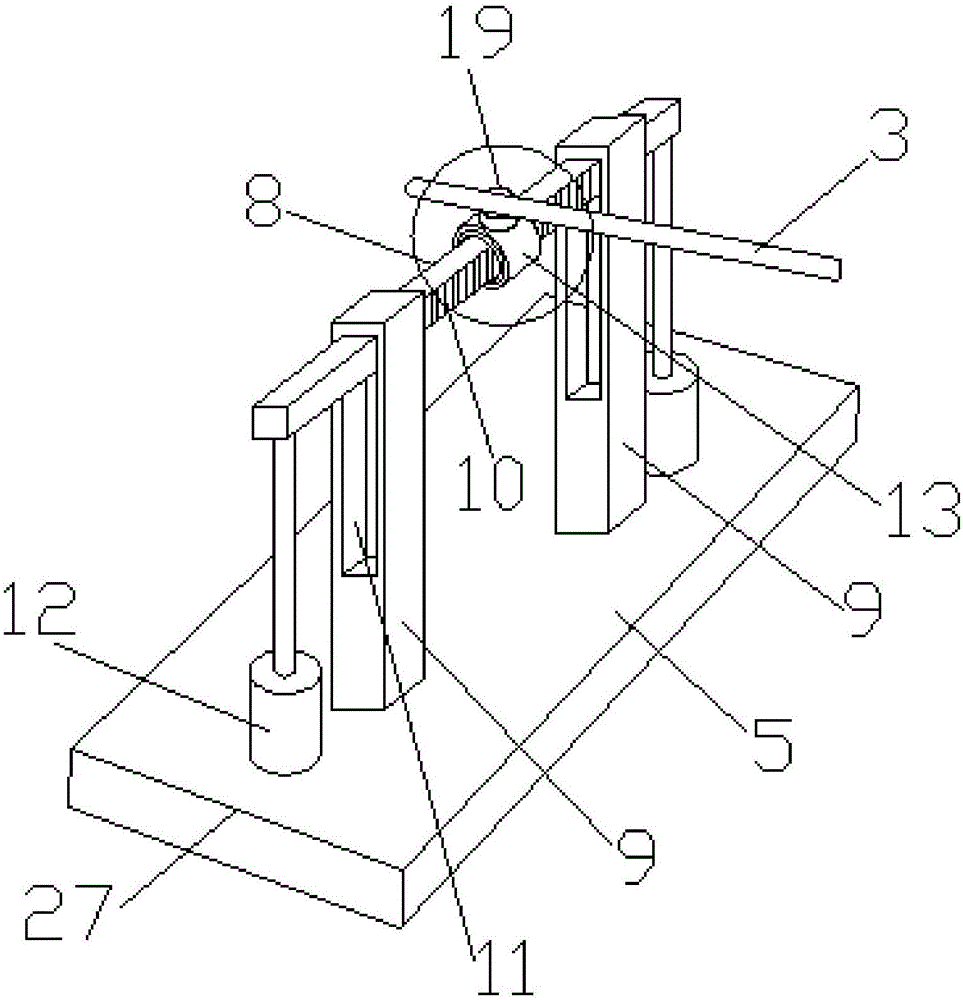

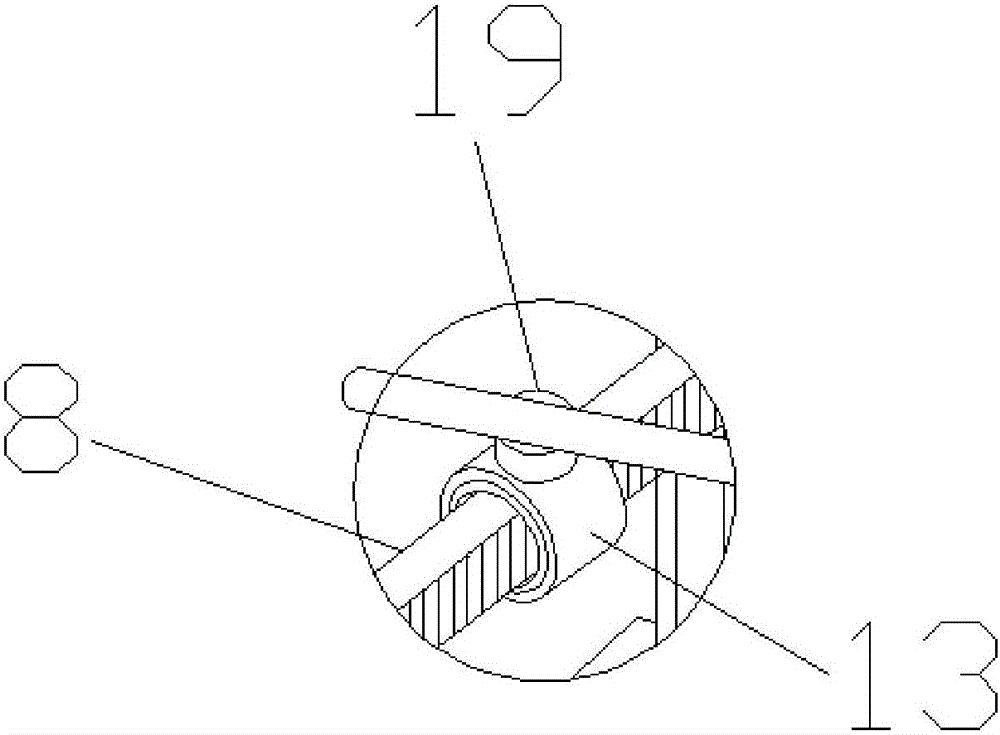

[0028] Such as Figure 1 to Figure 5 As shown, an underground cavity peeping device based on 3D scanning and 3D printing includes a 3D probe 1. The 3D probe 1 adopts white light surface scanning technology, and the scanning accuracy is within 0.1 mm. Compared with the laser 3D scanner, the accuracy is higher, and the details The features are more complete, and the scanning speed is 3-4 times that of similar products. It is simple and fast. It can flexibly switch between turntable scanning and free scanning modes, adapting to 3D scanning of different sizes. Through data splicing, large-scale 3D scanning can be realized. White light scanning phase Compared with laser scanning, it is safer and will not cause accidental damage to human eyes. It is lightweight and portable. After scanning, it can directly output STL data for 3D printing and seamless connection; the three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com