Experiment device for testing rock breakage and method for calibrating impact speed and loss energy

An experimental device and rock technology, which is applied in the field of rock crushing research and testing, can solve the problems that the rock crushing process cannot be well done anyway, and the effect of rock crushing without considering the impact speed of the equipment, etc. It achieves simple structure, high simulation authenticity, and repeatability. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

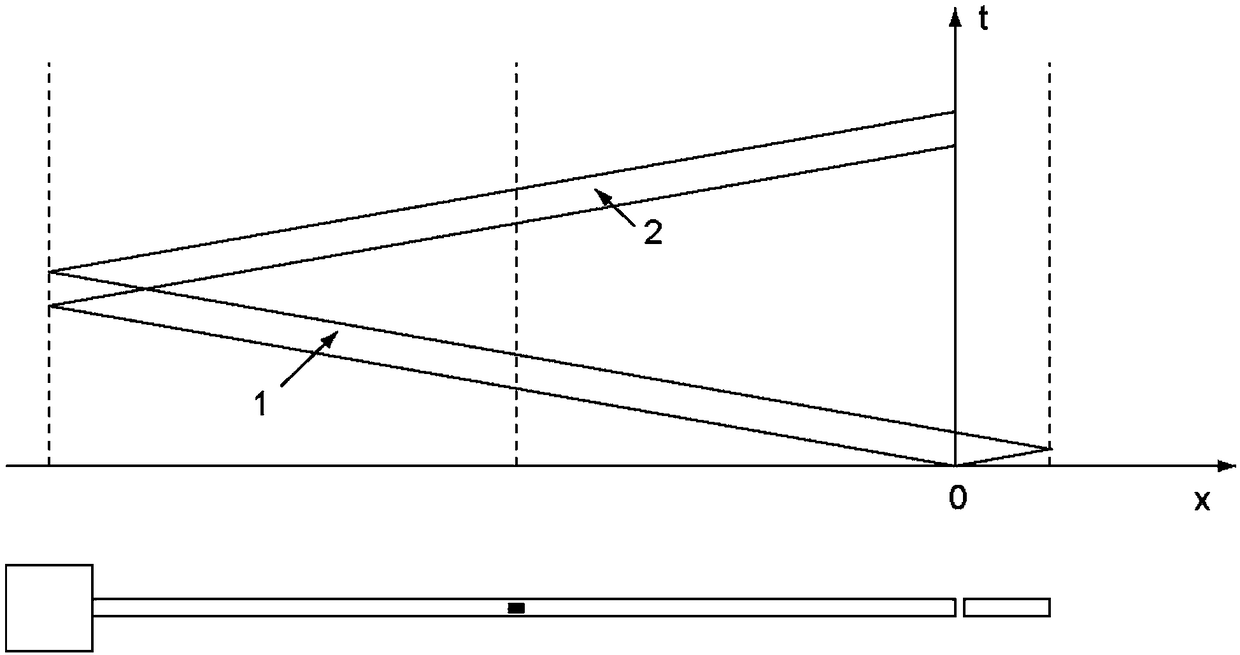

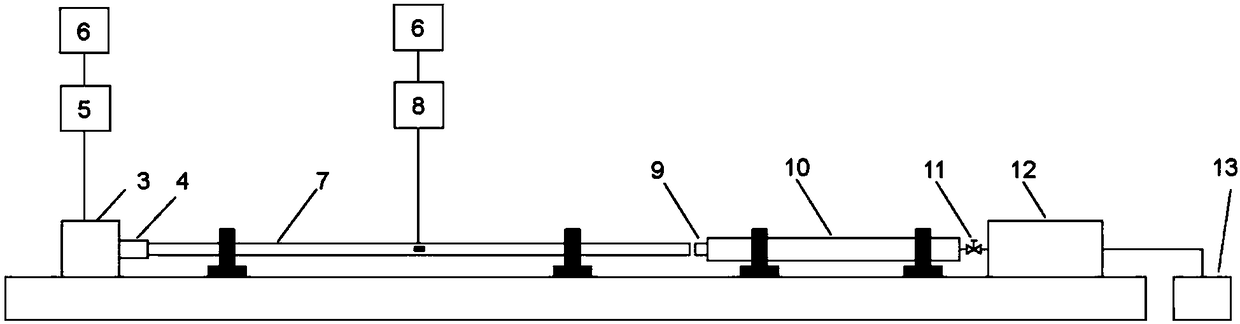

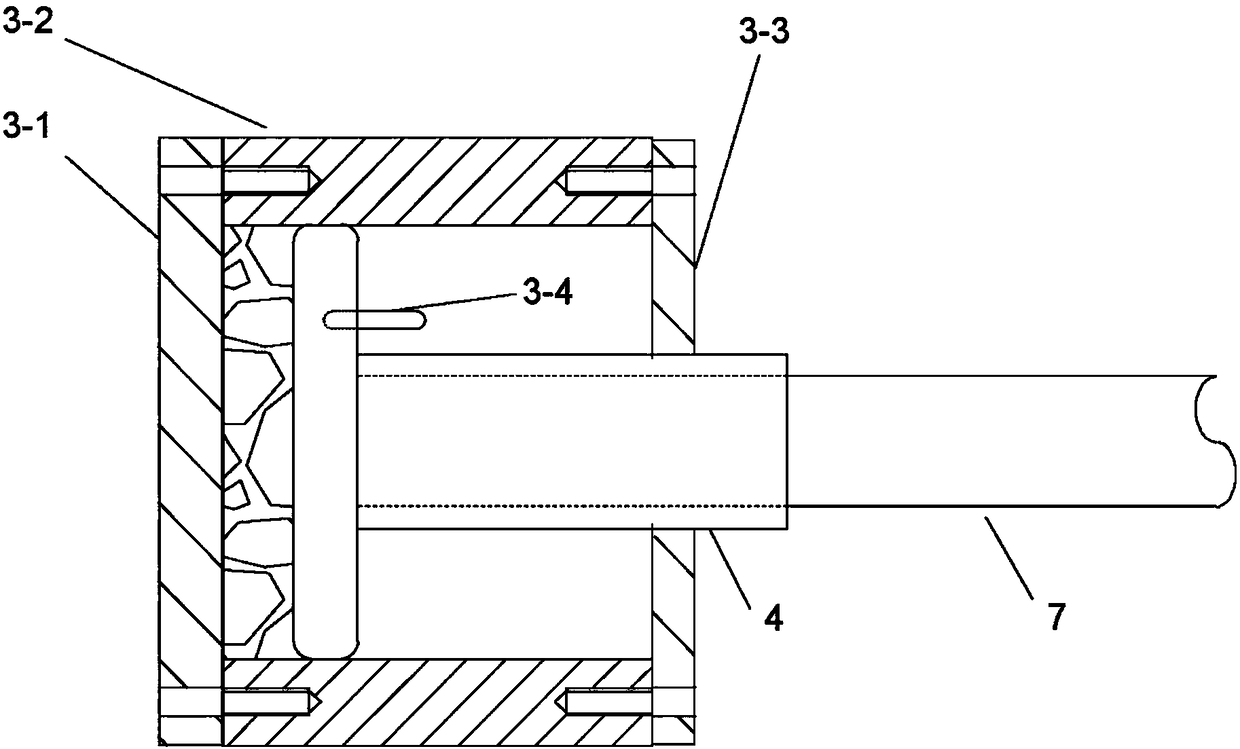

[0043] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings: figure 2 , 3 Shown is a rock crushing simulation test device. The simulation test device includes a horizontal test platform. One end of the test platform is provided with a test chamber 3 containing a rock test piece inside. The sliding piston 4 is used to place, load and recover the rock specimen. The test chamber 3 and piston 4 simulate the hardened metal surface in actual engineering. A test rod 7 is set on the outer side of the piston circular plane and on the central axis of the piston, which is airtightly fitted with the piston 4. A compression strain gauge is pasted at 1 / 2 of the length of the test rod 7, and the compression strain gauge is connected to the dynamic strain gauge 8. The dynamic strain gauge 8 is connected to the oscilloscope 6; at the other end of the test rod, at a distance of 10cm~15cm from the end of the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com