Optimization design method of solenoid type solenoid valve

An optimized design and solenoid valve technology, applied in computer-aided design, calculation, electrical digital data processing, etc., can solve the problems of less output parameters, low consistency of solenoid valve measured results, and low service life, and achieve the goal of simplifying the cumbersome process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present application will be further described below in connection with the embodiments. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

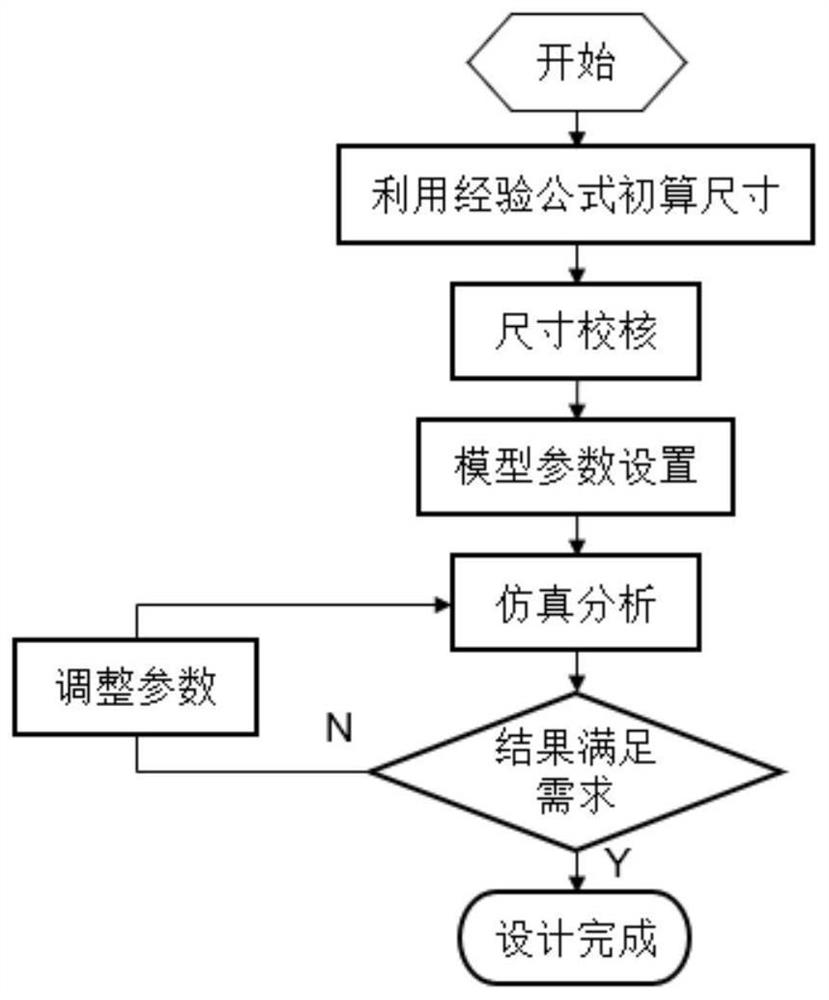

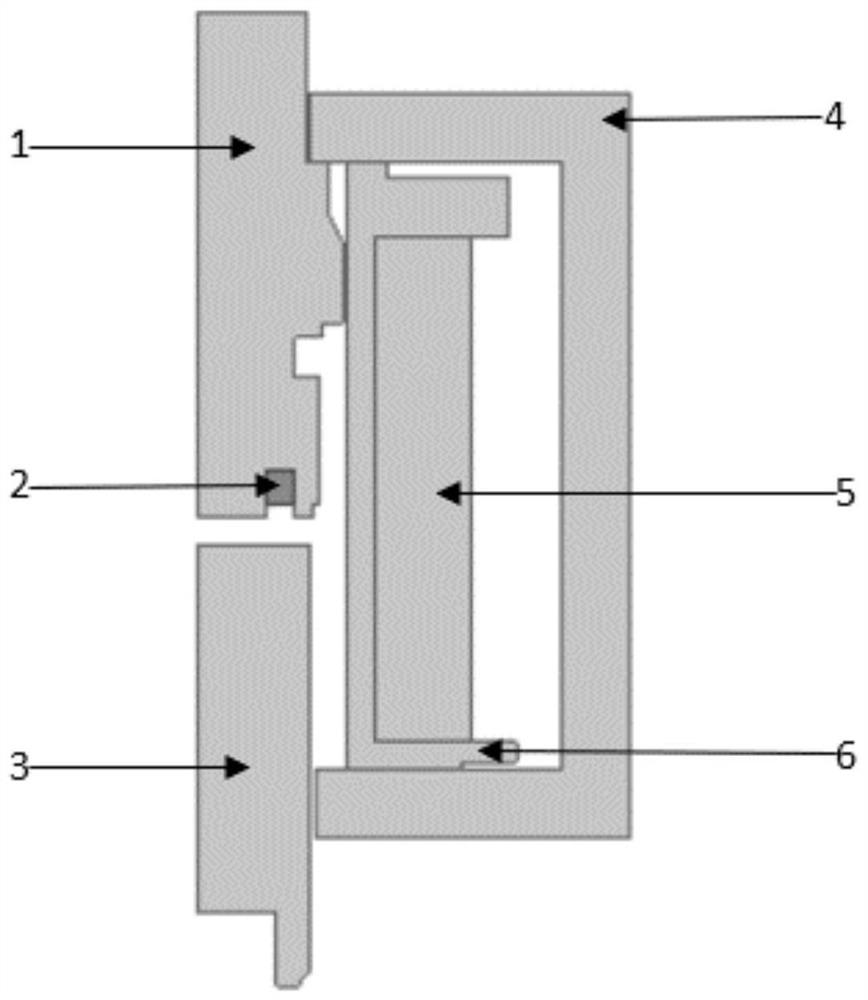

[0039] like figure 1 As shown, an optimized design method of a screw-type solenoid valve according to the present application, includes the following steps:

[0040] The first step: the preliminary design calculation of the basic structural dimensional parameters of the solenoid valve using the empirical formula. Among them, the dimensional parameters mainly include the armature diameter, the armature length, the inner diameter of the coil, and the outer diameter of the coil.

[0041] In the example, the size of the initial calculation is 8.3 mm, the armature length is 16.3 mm, the inner diameter of the coil is 13 mm, and the outer diameter of the coil is 21 mm.

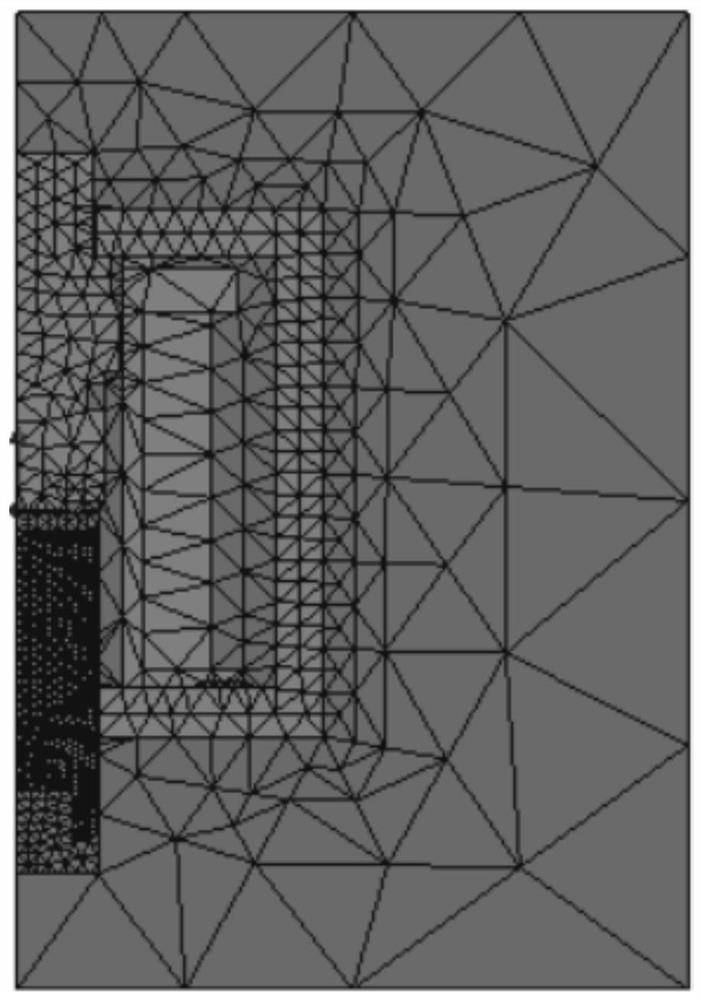

[0042] In the second step, a finite element simulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com