Designing method for advanced small pipe-steel arch-foot locking anchor rod integrated mechanical model and advanced small pipe-steel arch-foot locking anchor rod integrated mechanical model

An advanced technology of small conduits and locking foot bolts, applied in computer-aided design, calculation, special data processing applications, etc., can solve the problems of waste of resources and funds, and the inability to fully utilize the bearing capacity of each component, and achieve high guiding significance , The design result is safe and reasonable, and the effect of ensuring economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

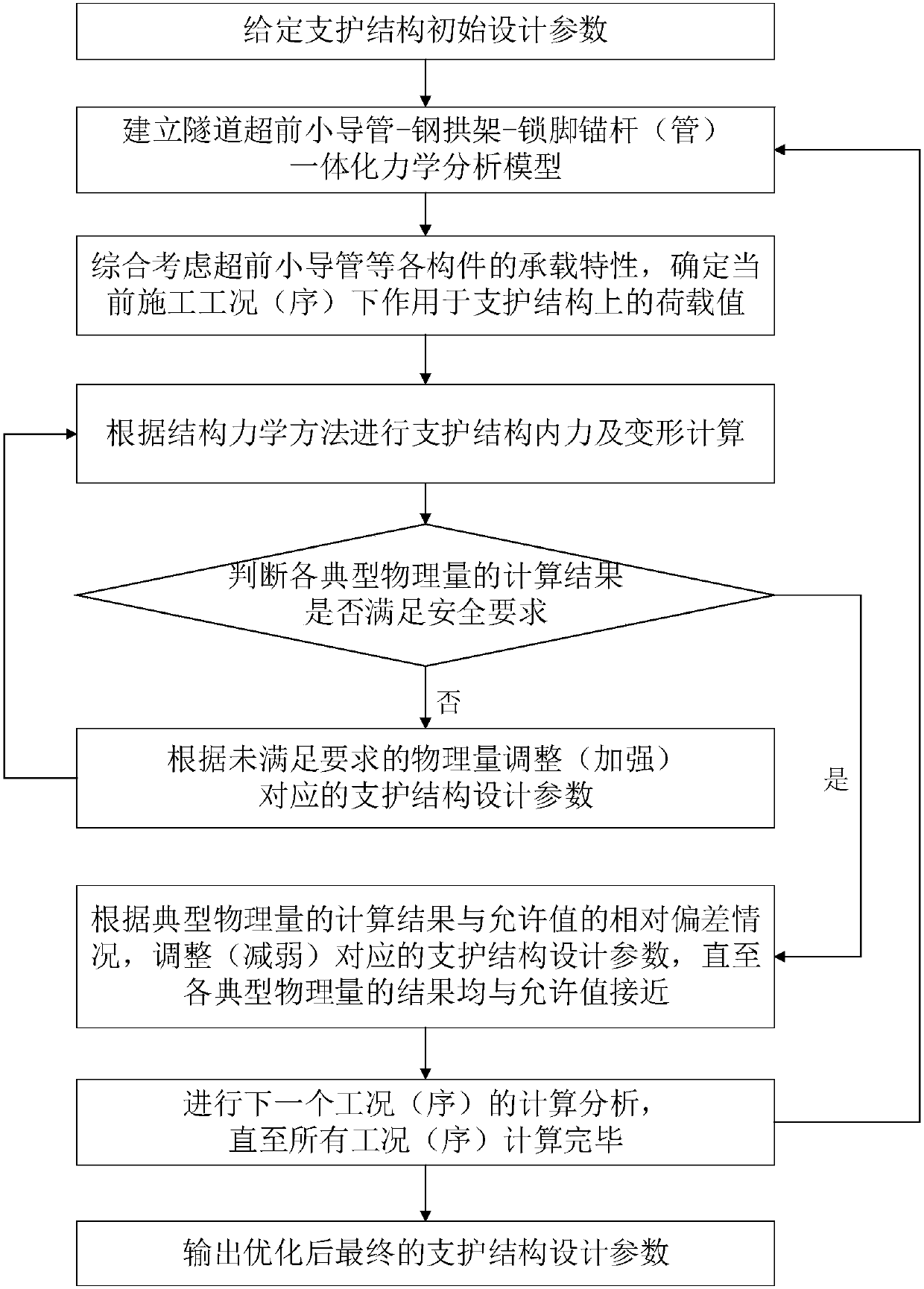

[0041] like figure 1 , the inventive method flow process is as follows:

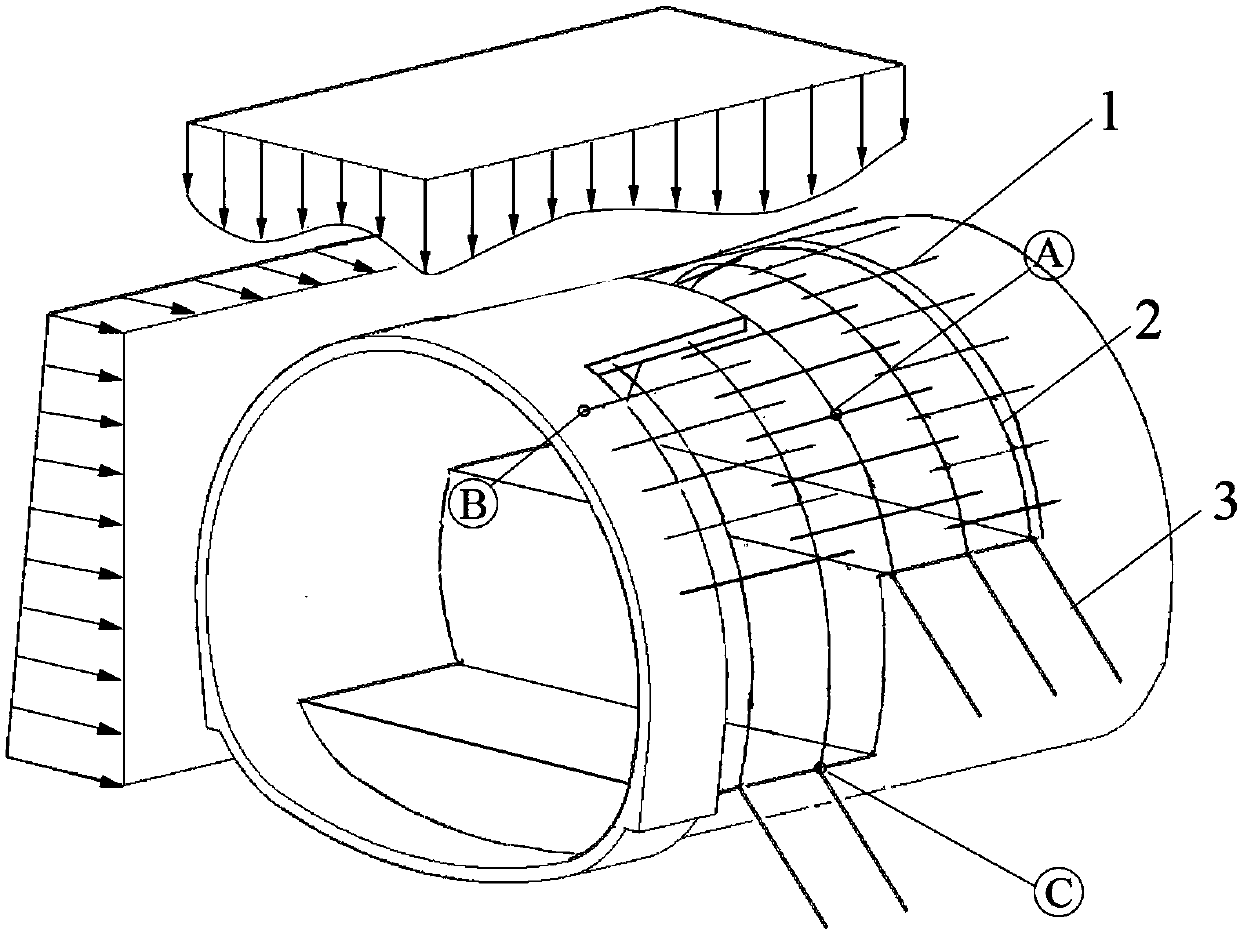

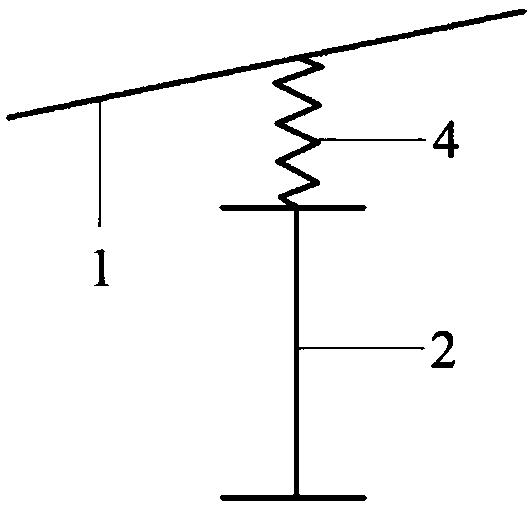

[0042] (1) According to the actual construction conditions (sequence), assuming the initial design parameters of the support structure, an integrated mechanical analysis model of the tunnel’s advanced small conduit-steel arch frame-lock foot anchor (pipe) is established;

[0043] (2) Determine the applied load value according to the current construction status and the agreed calculation method, and calculate the internal force and deformation of the structure;

[0044] (3) Judging whether each typical physical quantity exceeds the allowable value, if it exceeds, strengthen the corresponding support structure design parameters according to the physical quantity that does not meet the requirements, return to the second step for recalculation, if not, gradually weaken the corresponding support structure design parameter and return to the second step to recalculate until the typical physical quantities obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com