A gear contact fatigue reliability analysis method

A contact fatigue and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as nonlinearity, large dispersion of uncertain parameters, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

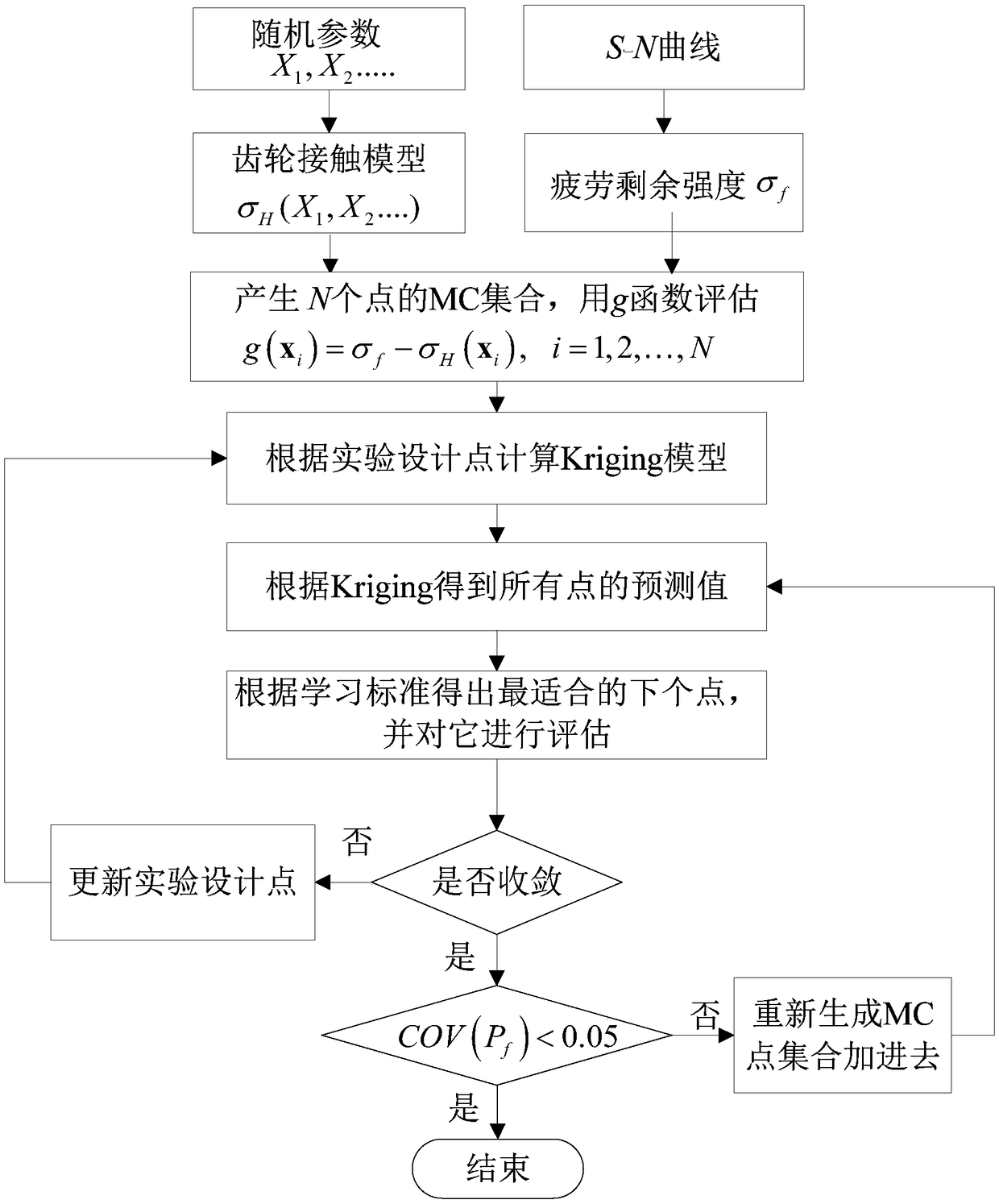

Method used

Image

Examples

Embodiment Construction

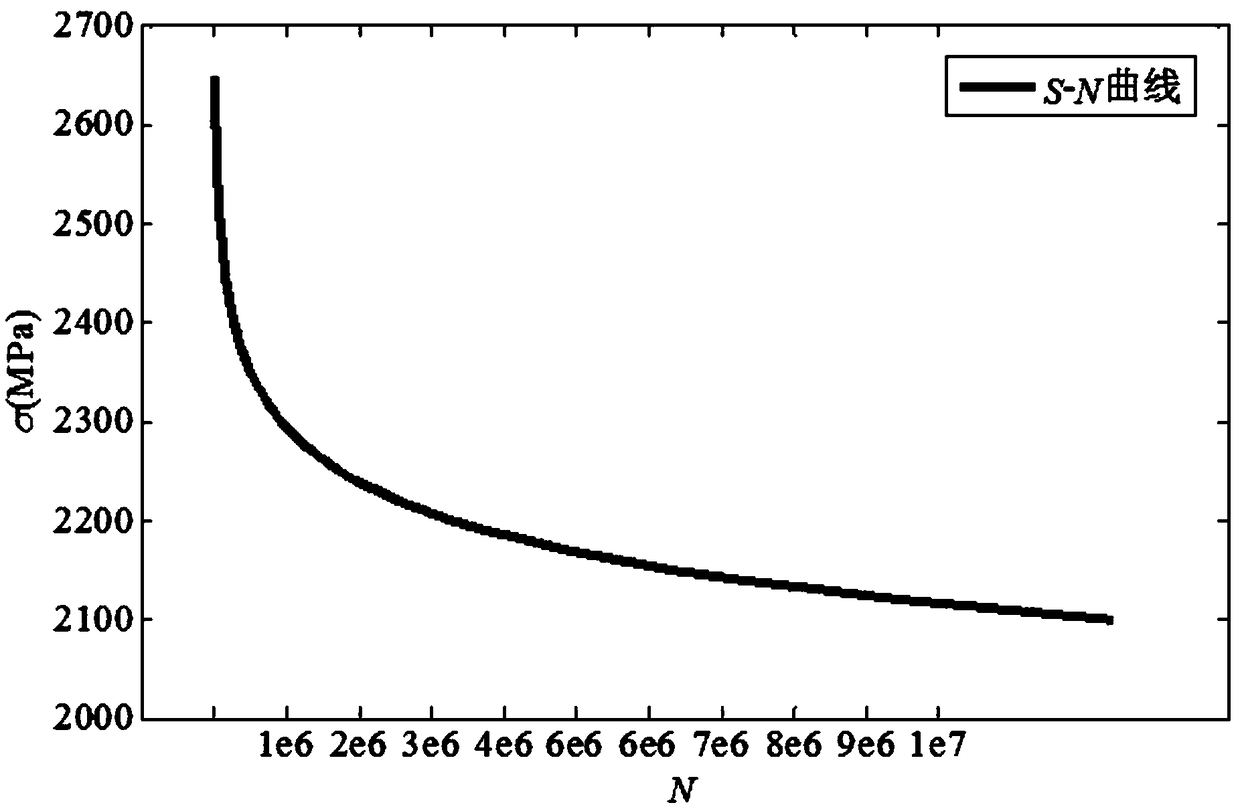

[0010] Due to the cyclic action of the contact force on the tooth surface, the gear structure will be damaged by contact fatigue. Due to the influence of manufacturing errors and environmental factors, the gear structure has parameter uncertainties in terms of geometric characteristics, material properties and loads. The invention patent can consider the influence of these uncertain parameters, and carry out efficient fatigue reliability analysis on the gear structure.

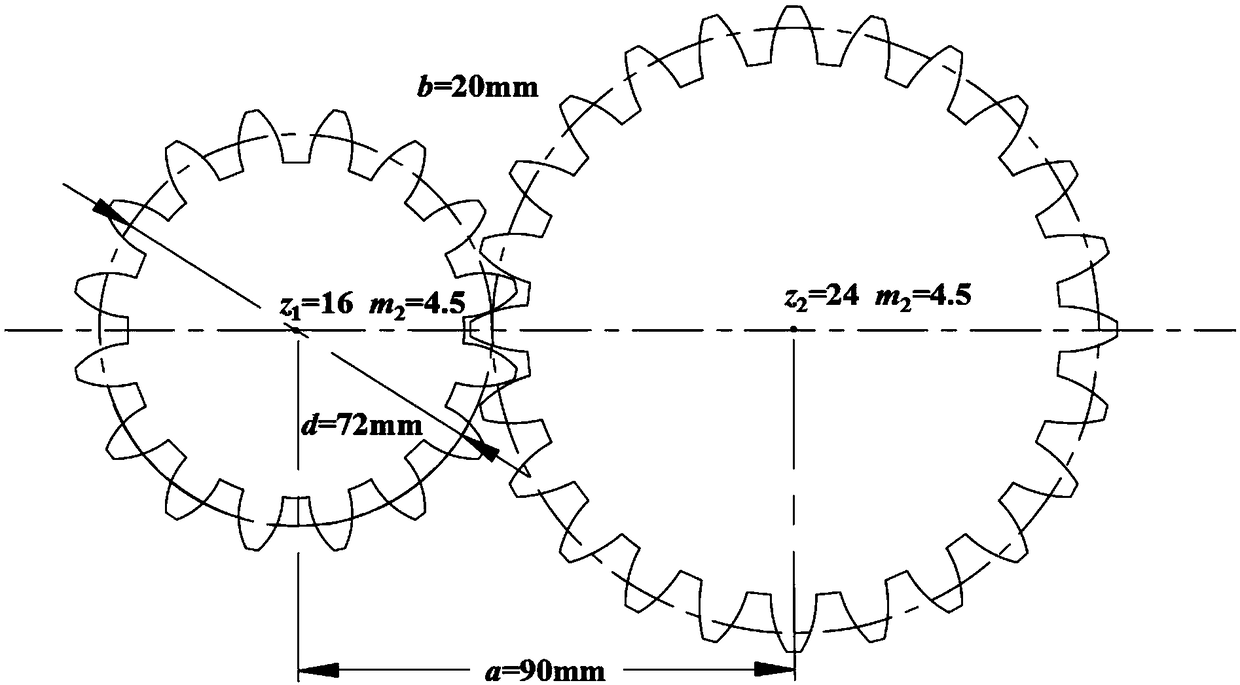

[0011] In actual engineering, there are many factors that affect the contact stress of the tooth surface. For different working conditions, system effects, gear precision, etc., the contact stress of the tooth surface often varies greatly. For the sake of convenience, the present invention is described by taking an involute spur gear as an example. According to the American ANSI / AGMA2001-D04 standard, the tooth surface contact stress σ H It can be calculated as follows:

[0012]

[0013] In the formula: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com