Designing and manufacturing method of flexible wheel of harmonic reducer

A technology of harmonic reducer and manufacturing method, applied in the direction of mechanical equipment, components with teeth, belt/chain/gear, etc., can solve the problem of low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] After analyzing the sensitivity of flexspline structure parameters to fatigue life, Table 1 can be obtained

[0019] Table 1 Sensitivity value of flexspline fatigue life to each parameter

[0020]

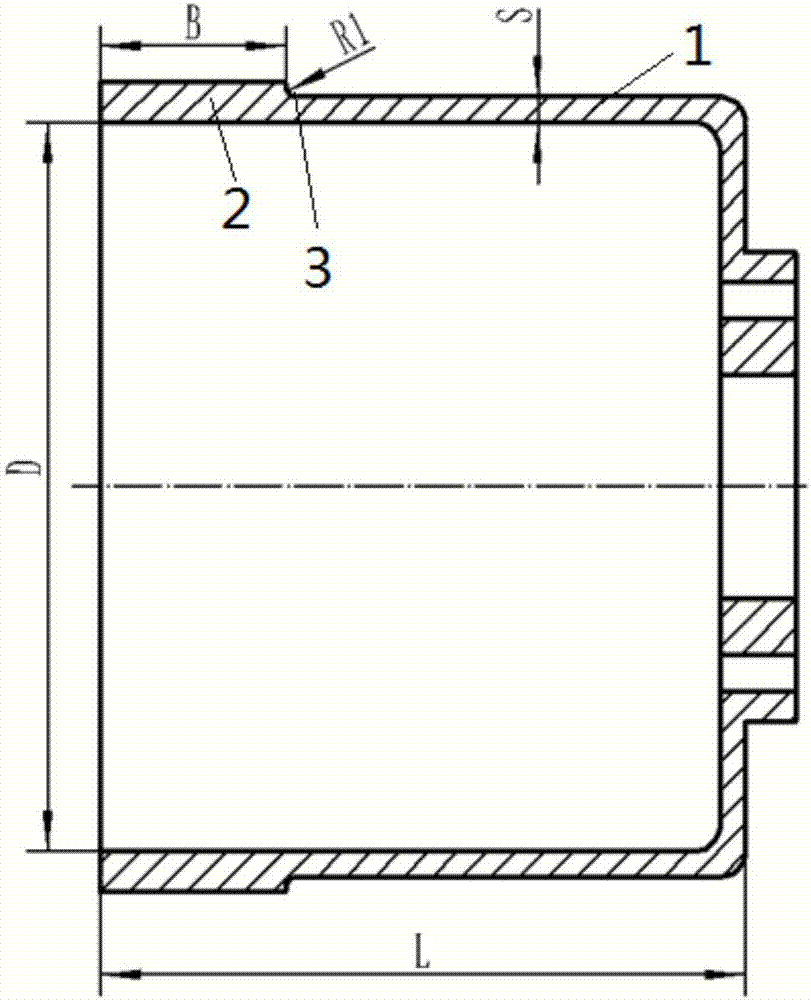

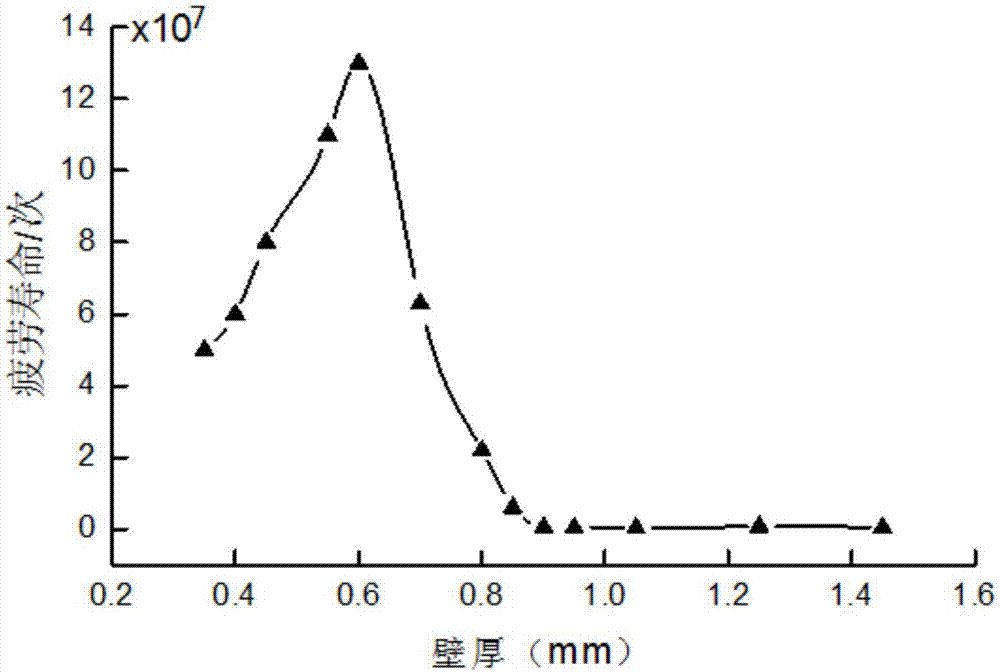

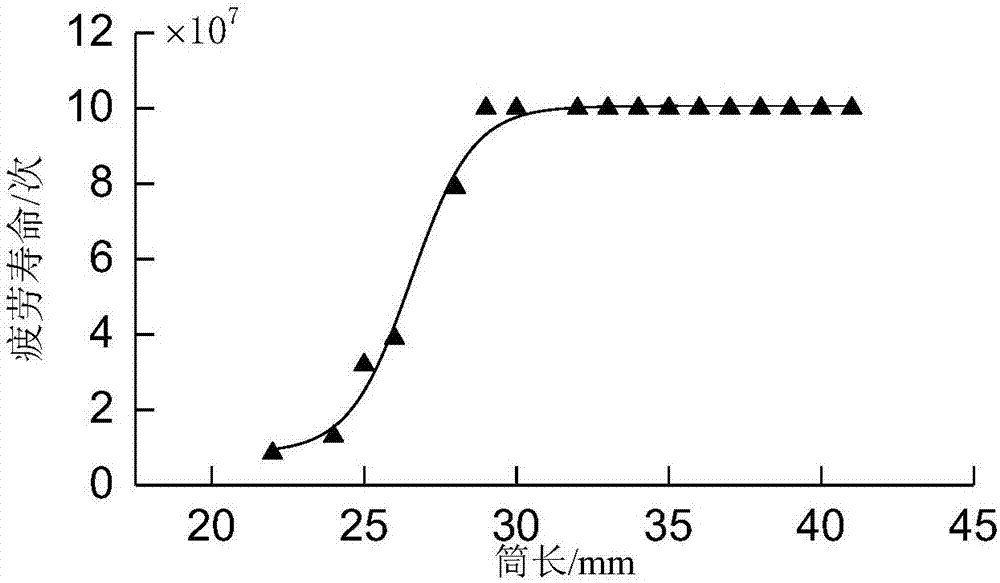

[0021] Among them, L is the length of the flexspline tube, R is the excessive fillet of the rear end surface of the tooth and the tube wall, D is the diameter of the inner circle of the tube wall, B is the tooth width of the external tooth, S is the thickness of the tube wall, T is the load torque, and E is the material The modulus of elasticity, μ is the Poisson's ratio of the material. It can be seen from Table 1 that the sensitivity of the fatigue life of the harmonic gear flexspline to the change of each parameter in descending order is: S, B, L, R, E, D, T, μ. It can be clearly found that the structural parameters of the flexspline have a great influence on its fatigue life, especially the influence of S, B, L and R fatigue life is particularly obvious, and should b...

Embodiment 2

[0028] A method for making a harmonic reducer, the method for making a flexwheel comprises the steps of: adding materials to a ball mill for grinding in proportion, the materials include 94.3 parts by weight of iron (phosphorus content is less than 0.01%), 5 parts by weight of graphene , the silicon of 2 parts by weight, the manganese of 0.3 parts by weight, the nickel of 0.065 parts by weight; The sulfur of 0.05 parts by weight, the chromium of 1.6 parts by weight, the copper of 0.17 parts by weight, the aluminum of 0.07 parts by weight; Add the material after grinding In a furnace filled with inert gas, heat and melt to form an alloy solution. When heating, mix and alternately heat up by 6°C per minute and 4°C per minute until fully melted, then pour the alloy solution into the flexible spline mold to cool and form That is to say, the flexible tire is prepared, and the flexible tire is heated to 600°C for 3 hours under the protection of nitrogen, then cooled to 260°C for 0.5 ...

Embodiment 3

[0030] On the basis of embodiment 2, the preparation method of flexible spline comprises the steps: according to proportion, material is added ball mill and grinds, and described material comprises the iron of 96 weight parts (phosphorus content is less than 0.01%), the graphene of 1 weight part, The silicon of 1.5 parts by weight, the manganese of 0.2 parts by weight, the nickel of 0.044 parts by weight; The sulfur of 0.03 parts by weight, the chromium of 1.2 parts by weight, the copper of 0.1 parts by weight, the aluminum of 0.02 parts by weight; In an inert gas furnace, heat and melt to form an alloy solution. When heating, mix and alternately heat up by 6°C per minute and 4°C per minute until fully melted. To obtain a soft wheel, heat the soft wheel to 630°C for 3 hours under the protection of nitrogen, then cool to 280°C and keep it for 1 hour, then keep it in an alkaline solution with a temperature of 90°C and a pH of 9 for 1 hour, wash and dry dry; and then carry out ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com