A method for testing and evaluating the mechanical properties of engineering materials against temperature changes

A technology of temperature change and engineering materials, which is applied in the analysis of materials, strength characteristics, scientific instruments, etc., can solve the problems of not considering the influence of material damage accumulation, and can not reflect the performance of materials against temperature stress, so as to achieve simple structure and test accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

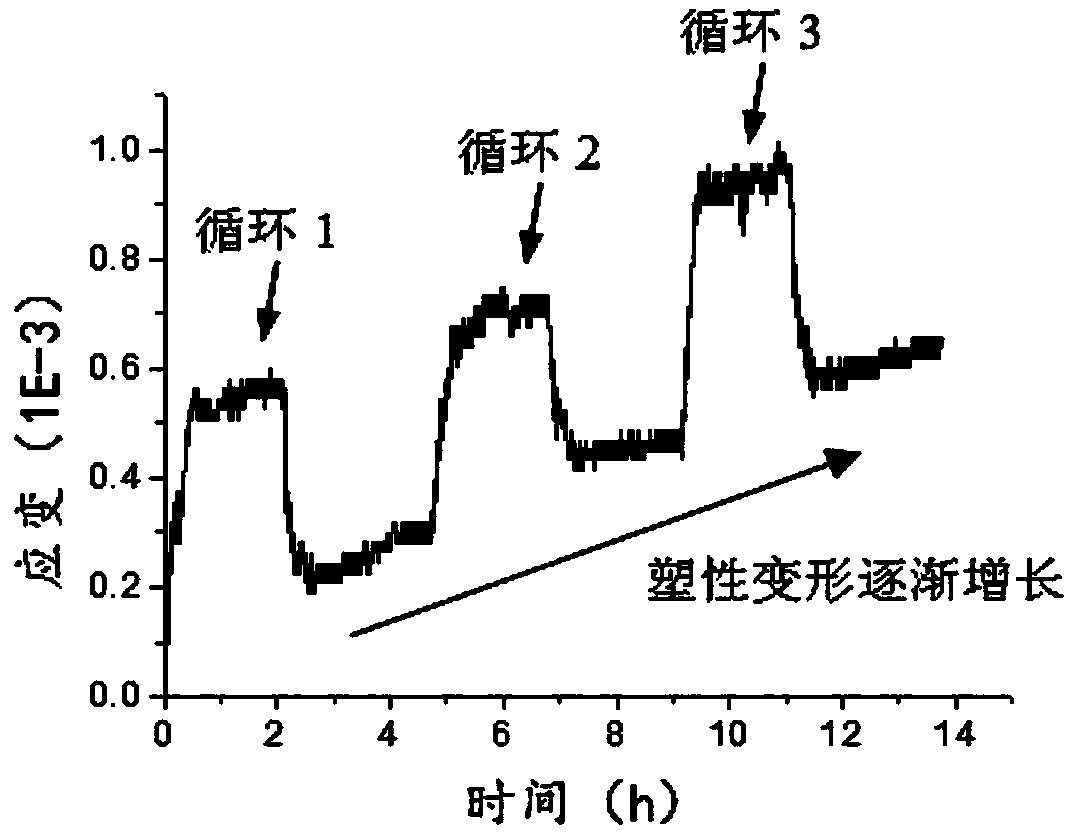

[0045] see Figure 1 to Figure 5 A method for testing and evaluating mechanical properties of engineering materials against temperature changes, comprising the following steps:

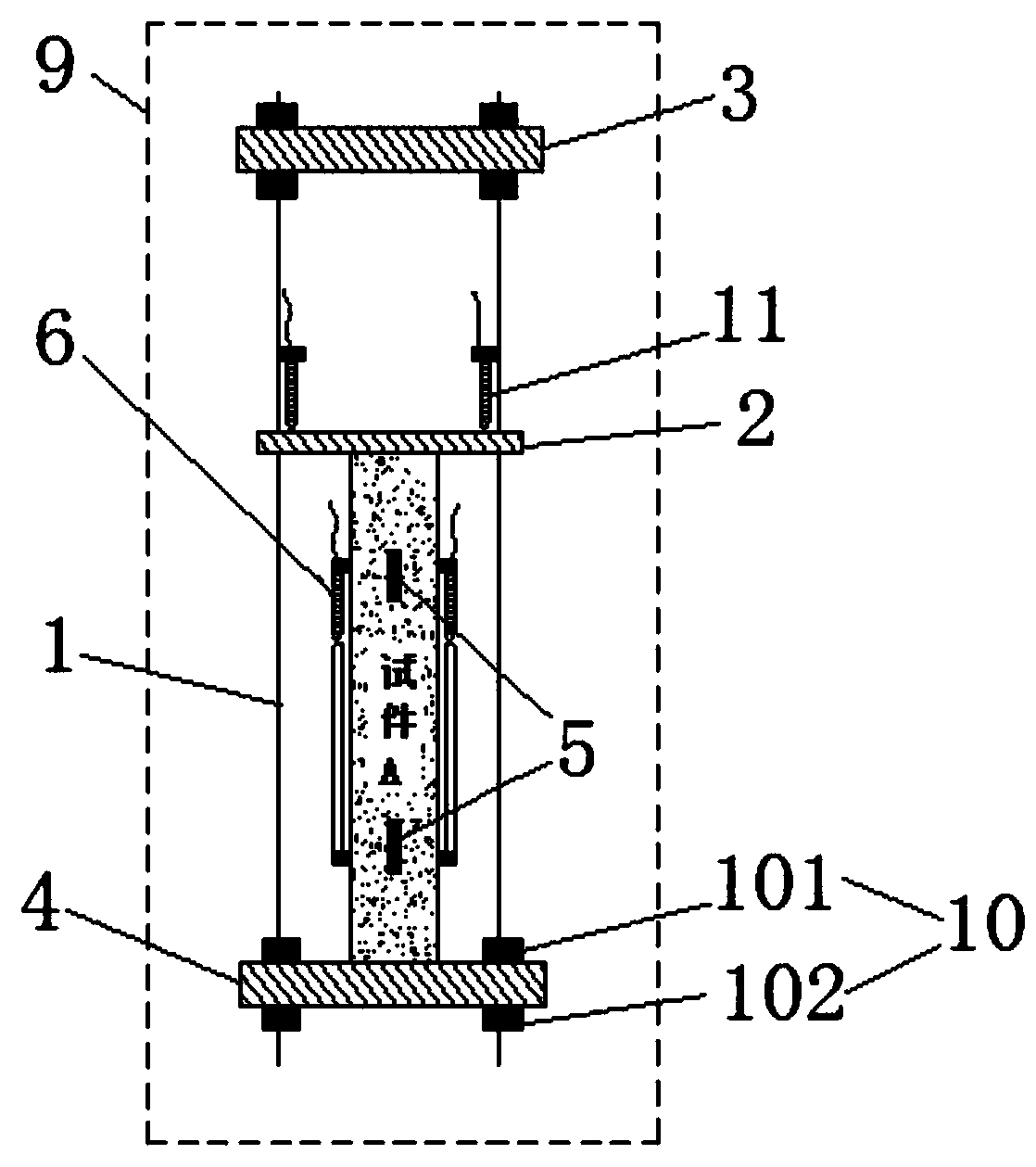

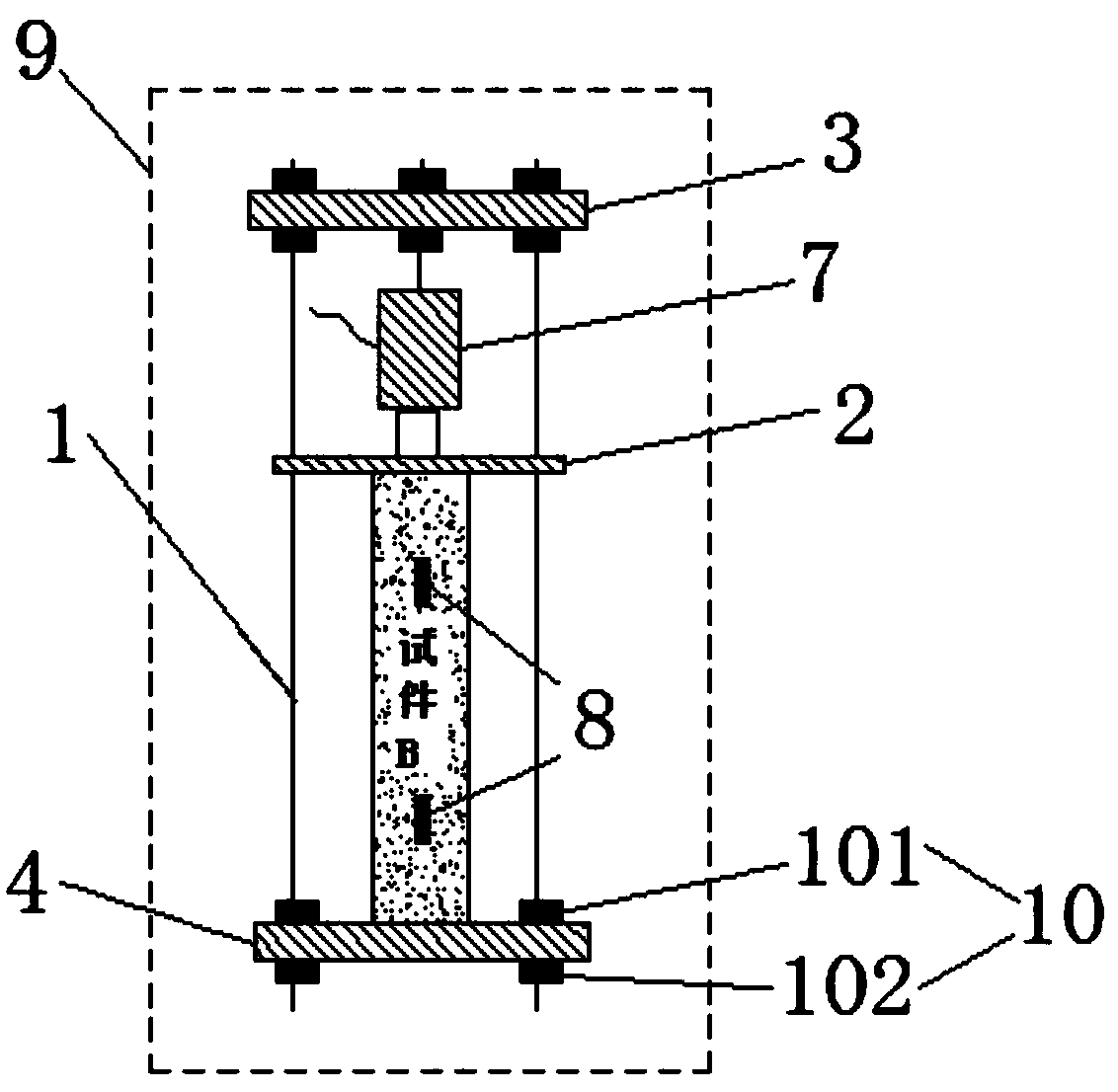

[0046] 1) Make the basic test device: the basic test device includes a guide rod 1, a middle plate 2, an upper fixed plate 3 and a lower fixed plate 4, and the upper fixed plate and the lower fixed plate are respectively fixed on the upper and lower ends of the guide rod. The middle plate is arranged between the fixed plate and the lower fixed plate, and the middle plate is provided with a guide hole for the guide rod to pass through, and the middle plate can slide back and forth along the length direction of the guide rod; in this embodiment, the guide rod adopts four wires The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com