Manufacturing method for Ni50Mn34In12Co4 alloy film of high smoothness

A technology of alloy thin film and flatness, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of large roughness, composition deviation from target, etc., achieve strong anisotropy and simple preparation process , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

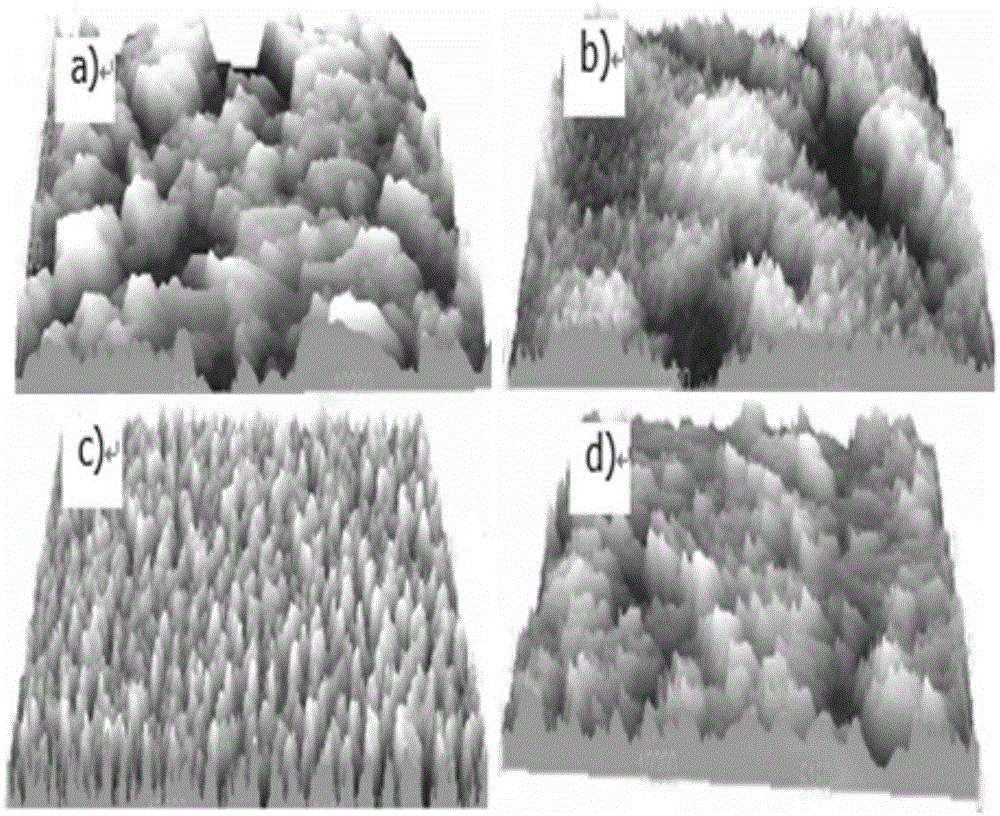

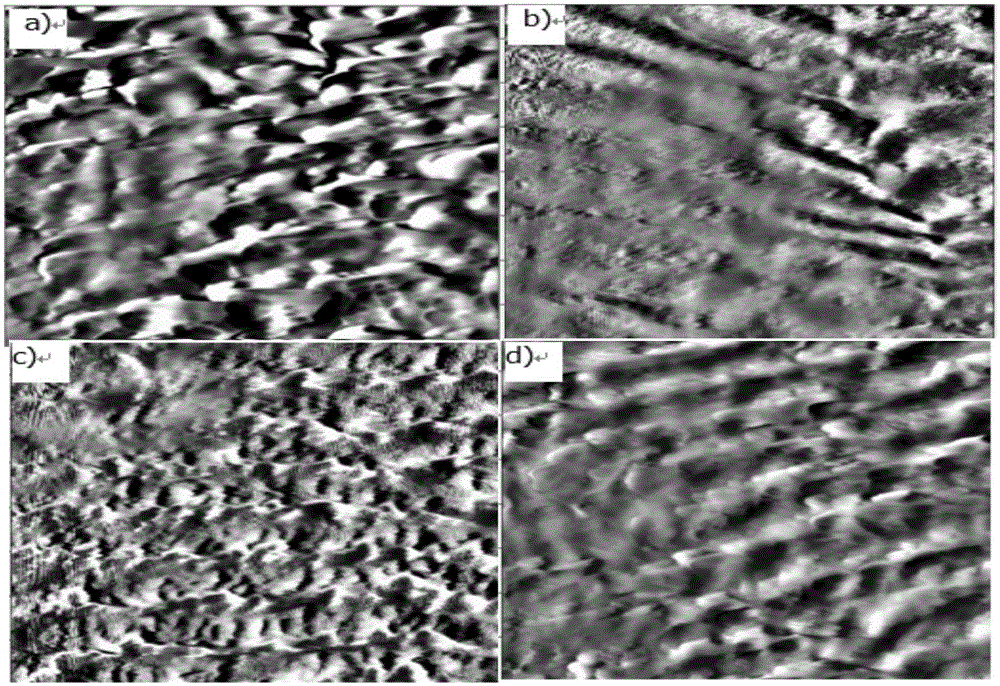

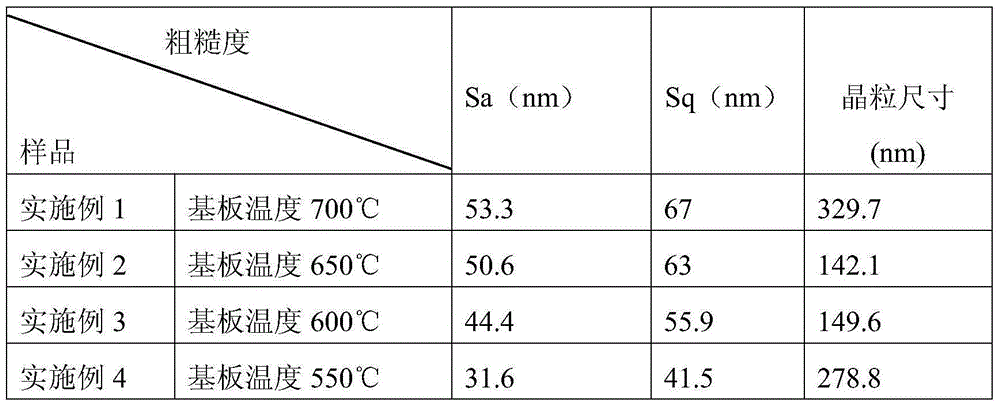

Embodiment 1

[0022] The test alloy targets were selected from four metal elements with a purity of 99.99at.%-Ni, 99.95at.%-Mn, 99.99at.%-In, and 99.95at.%-Co. According to the molar ratio, 50 parts of Ni, 34 parts of Mn, 12 parts of In and 4 parts of Co are placed in a vacuum non-consumable electrode electric arc furnace. Before melting, the furnace cavity is evacuated to a degree of 5×10 -3 Pa, filled with Ar protective gas. In order to make the composition of the material uniform, the material is turned over by a manipulator before each smelting, and the smelting is turned over at least 4 times, and magnetic stirring is added during the smelting process. After smelting, an ingot with a diameter of 50 mm was obtained. After being ground on the grinding wheel, the ingot was placed on a wire electric discharge machine and cut into a circular target with a diameter of 3mm×2mm. Quartz glass with a specification of 30mm×30mm×3mm is selected as the substrate of the thin film. Pretreatment of...

Embodiment 2

[0024] The test alloy targets were selected from four metal elements with a purity of 99.99at.%-Ni, 99.95at.%-Mn, 99.99at.%-In, and 99.95at.%-Co. According to the molar ratio, 50 parts of Ni, 34 parts of Mn, 12 parts of In and 4 parts of Co are placed in a vacuum non-consumable electrode electric arc furnace. Before melting, the furnace cavity is evacuated to a degree of 5×10 -3Pa, filled with Ar protective gas. In order to make the composition of the material uniform, the material is turned over by a manipulator before each smelting, and the smelting is turned over at least 4 times, and magnetic stirring is added during the smelting process. After smelting, an ingot with a diameter of 50 mm was obtained. After being ground on the grinding wheel, the ingot was placed on a wire electric discharge machine and cut into a circular target with a diameter of 3mm×2mm. Quartz glass with a specification of 30mm×30mm×3mm is selected as the substrate of the thin film. Pretreatment of ...

Embodiment 3

[0026] The test alloy targets were selected from four metal elements with a purity of 99.99at.%-Ni, 99.95at.%-Mn, 99.99at.%-In, and 99.95at.%-Co. According to the molar ratio, 50 parts of Ni, 34 parts of Mn, 12 parts of In and 4 parts of Co are placed in a vacuum non-consumable electrode electric arc furnace. Before melting, the furnace cavity is evacuated to a degree of 5×10 -3 Pa, filled with Ar protective gas. In order to make the composition of the material uniform, the material is turned over by a manipulator before each smelting, and the smelting is turned over at least 4 times, and magnetic stirring is added during the smelting process. After smelting, an ingot with a diameter of 50 mm was obtained. After being ground on the grinding wheel, the ingot was placed on a wire electric discharge machine and cut into a circular target with a diameter of 3mm×2mm. Quartz glass with a specification of 30mm×30mm×3mm is selected as the substrate of the thin film. Pretreatment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com