Green anode skeletal material monosystem manufacturing technique

A single-system, raw anode technology, applied in the new process field of single-system preparation of raw anode aggregates, can solve the problems of PLC control system with many control points, complicated environmental protection projects, complex production processes, etc. Environmental protection and pollution control, the effect of reducing pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

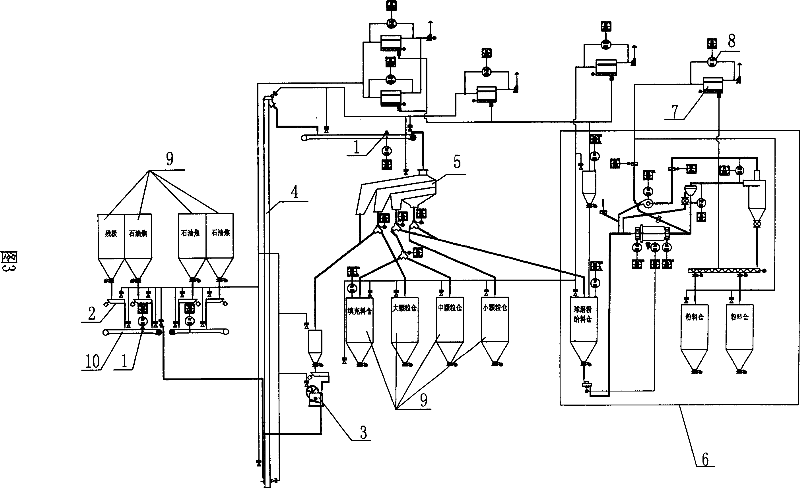

[0047] Petroleum coke and residual poles are weighed with a belt electronic scale according to the weight percentage of 75:25, and then input into the impact crusher. After being crushed by the crusher, they are fed into the three-layer vibrating screen with a bucket elevator for screening. . After sieving, they are respectively put into storage bins with particle sizes of 4-8mm, 2-4mm, 2-1mm and <1mm for later use.

[0048] The material on the top vibrating screen is sent back to the crusher for crushing, and the unbalanced material under the bottom vibrating screen is sent to the mill for grinding through the chute.

[0049] During the next step of kneading process, press

[0050] Particle size (mm) Proportion (wt%)

[0051] 8-4 14

[0052] 4-2 23

[0053] 2-1 21

[0054] <1 42

[0055] Just do the ingredients.

Embodiment 2

[0057] Petroleum coke and residual poles are weighed with a belt electronic scale according to the weight percentage of 85:15, and sent to the impact crusher. After being crushed by the crusher, they are fed into the three-layer vibrating screen by the bucket elevator for screening. point. After sieving, they are respectively put into storage bins with particle sizes of 8-4mm, 4-2mm, 2-1mm and <1mm for later use.

[0058] The material on the top vibrating screen is returned to the crusher for crushing through the chute, and the unbalanced material under the bottom vibrating sieve is sent to the mill for grinding through the chute.

[0059] When carrying out the next step of kneading process, according to the following ratio:

[0060] Particle size (mm) Proportion (wt%)

[0061] 8-4 16

[0062] 4-2 25

[0063] 2-1 19

[0064] <1 32

[0065] Just do the ingredients.

Embodiment 3

[0067] Petroleum coke and residual poles are weighed with a belt electronic scale according to the weight percentage of 80:20, and sent to the impact crusher. After crushing, they are fed into a three-layer vibrating screen with a bucket elevator for screening. After being separated, they are put into storage bins with particle sizes of 8-4mm, 4-2mm, 2-1mm and <1mm respectively for later use.

[0068] Same as in Examples 1 and 2, the material on the top vibrating screen is returned to the crusher through the chute for crushing, and the unbalanced material under the sieve at the bottom of the vibrating sieve is sent to the mill for grinding through the chute.

[0069] When carrying out the next step of kneading process, according to the following ratio

[0070] Particle size (mm) Proportion (wt%)

[0071] 8-4 15

[0072] 4-2 25

[0073] 2-1 20

[0074] <1 40

[0075] Just do the ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com