Preparation method of broadband gradient LED (Light-emitting Diode) fluorescent film

A gradient, broadband technology applied in the field of LED solid-state lighting systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Example 1 Preparation of YAG series broadband gradient phosphor powder

[0113] 1. Raw materials and reagents:

[0114] Yttrium oxide (Y 2 o 3 ≥99.99%) or yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O≥99.99%); cerium nitrate (Ce(NO) 3 ·6H 2 O, analytically pure); aluminum nitrate (Al(NO 3 ) 3 9H 2 O, analytically pure); gallium nitrate (Ga(NO 3 ) 3 9H 2 O, analytically pure), gadolinium nitrate (Gd(NO 3 ) 3 ·6H 2 O, analytically pure), concentrated nitric acid HNO 3 , analytically pure; absolute ethanol, C 2 h 5 OH, analytically pure; distilled water H 2 O; ammonium bicarbonate (NH 4 HCO 3 , analytically pure); ammonia water (NH 3 ·H 2 O, analytically pure); polyethylene glycol (PEG1000)

[0115] 2. Experimental equipment

[0116] Conventional glass apparatus; dryer; pure water system; fully automatic electronic analytical balance; constant temperature magnetic stirrer; electric heating constant temperature water tank; pH acidity meter; Drying box; agate ...

Embodiment 2

[0163] BSS–A, BSS-B series broadband gradient phosphor preparation process such as Figure 7 and Figure 8 Shown:

[0164] 1 Raw materials and reagents:

[0165] Barium oxide (BaO≥99.99%) or barium nitrate (Ba(NO 3 ) 2 ≥99.99%); strontium oxide (SrO≥99.99%) or strontium nitrate (Sr(NO 3 ) 2 ≥99.99%); europium nitrate (Eu(NO 3 ) 3 6H2O, analytically pure); ethyl orthosilicate (Si(OC 2 h 5 ) 4 , analytically pure); concentrated nitric acid HNO 3 , analytically pure; absolute ethanol, C 2 h 5 OH, analytically pure; distilled water H 2 O; ammonium bicarbonate (NH 4 HCO 3 , analytically pure); ammonia water (NH 3 ·H 2 O, analytically pure); polyethylene glycol (PEG1000)

[0166] 2 experimental equipment

[0167] Conventional glass apparatus; dryer; pure water system; fully automatic electronic analytical balance; constant temperature magnetic stirrer; electric heating constant temperature water tank; pH acidity meter; Drying box; agate mortar; high-temperature g...

Embodiment 3

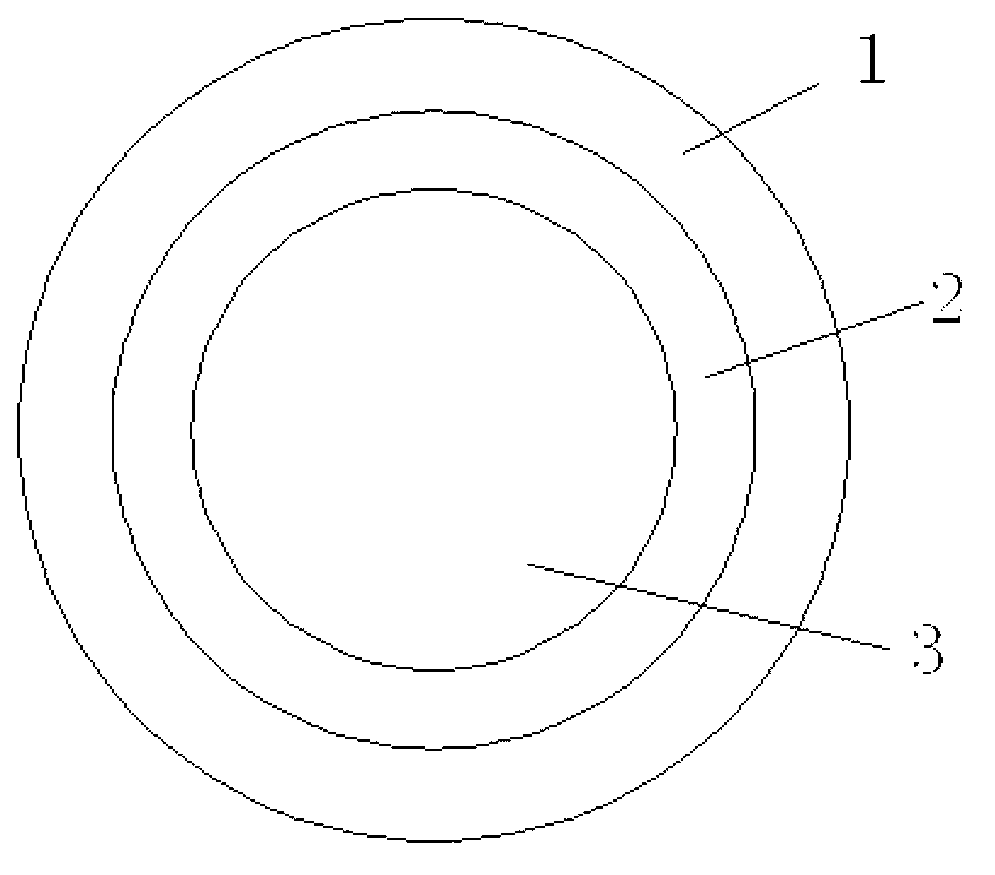

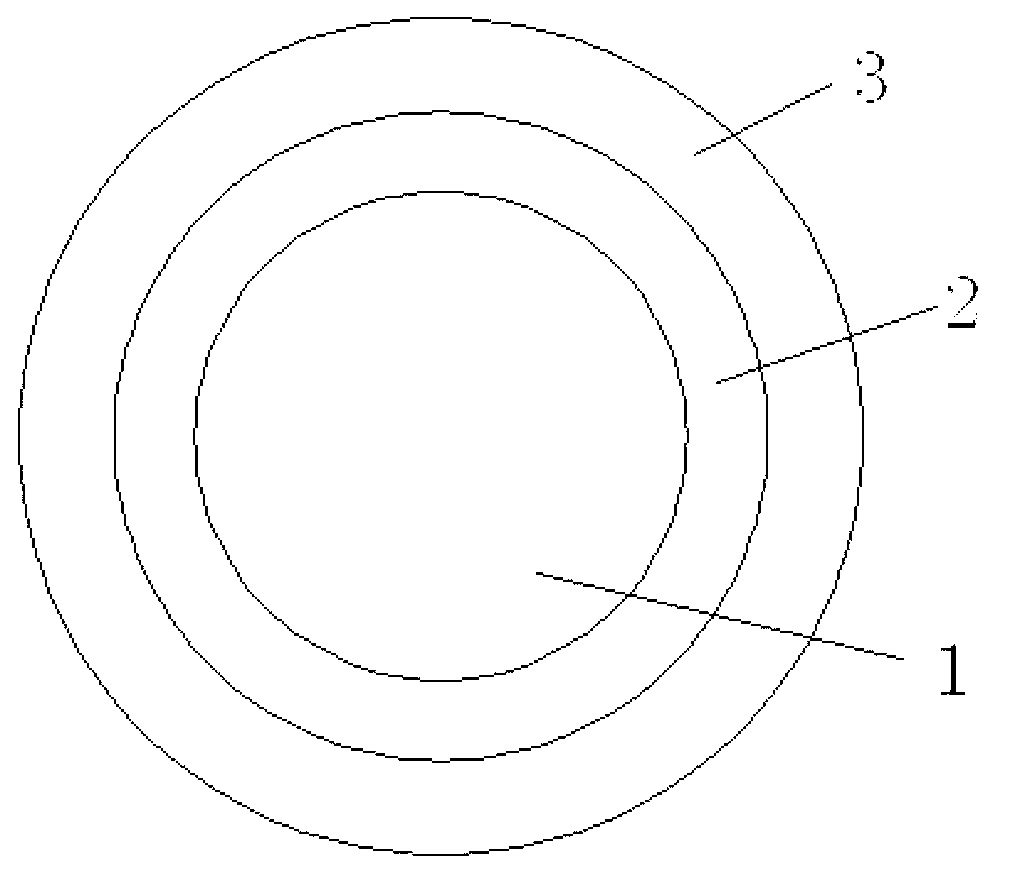

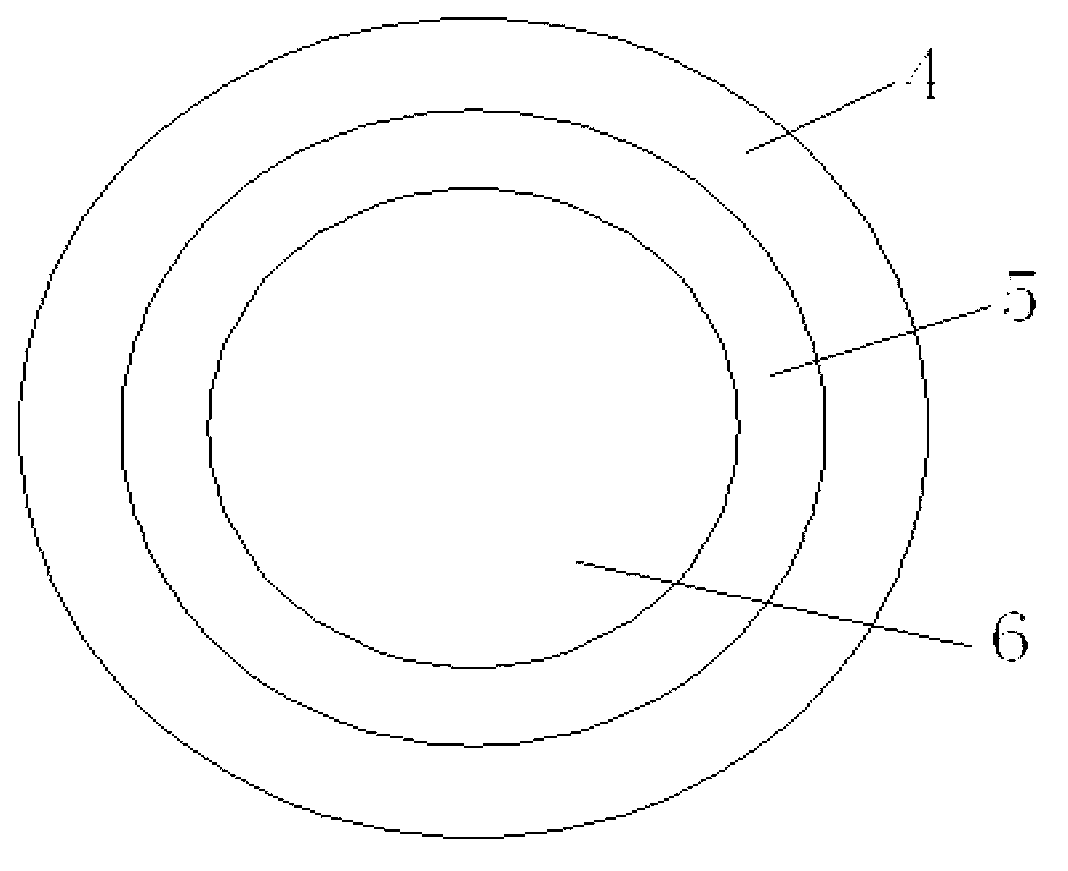

[0186] Embodiment 3: the preparation method of LED broadband fluorescent film, such as Figure 18 As shown, the film can be directly coated on the LED chip; Figure 19 As shown, it can also be directly coated on the LED lampshade.

[0187] 1. The technical process of preparing YAG series fluorescent thin films by suspension method is as follows: Figure 20 As shown, the specific steps are as follows:

[0188] 1.1 Pour any YAG series phosphor powder prepared in Example 1 into methanol (METHANOL) or xylene (XYLENE) or 2-ethylhexanoic acid (2-ETHLHEXANOIC ACID) or their mixture to form Suspension with a mass concentration of about 5%;

[0189] 1.2 Preparation of YAG:Ce from the suspension 3+ Fluorescent film; directly deposit YAG:Ce on the LED chip or on the LED lampshade by the suspension coating method 3+ fluorescent film;

[0190] 1.3 Dry the prepared film, and heat-treat it in a hydrogen atmosphere at 380°C-420°C for 1-10 minutes to form a dense film of 5-30μm. This th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com