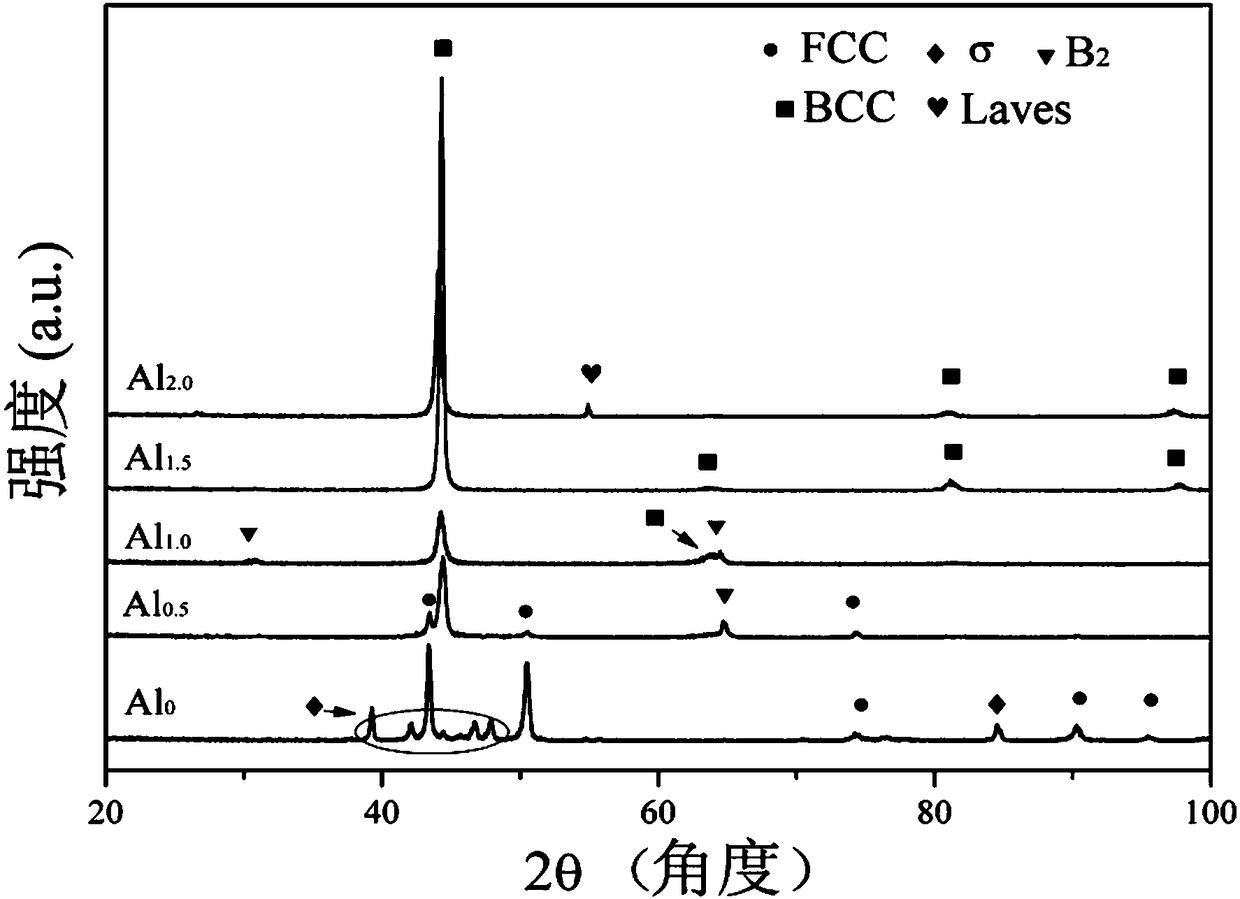

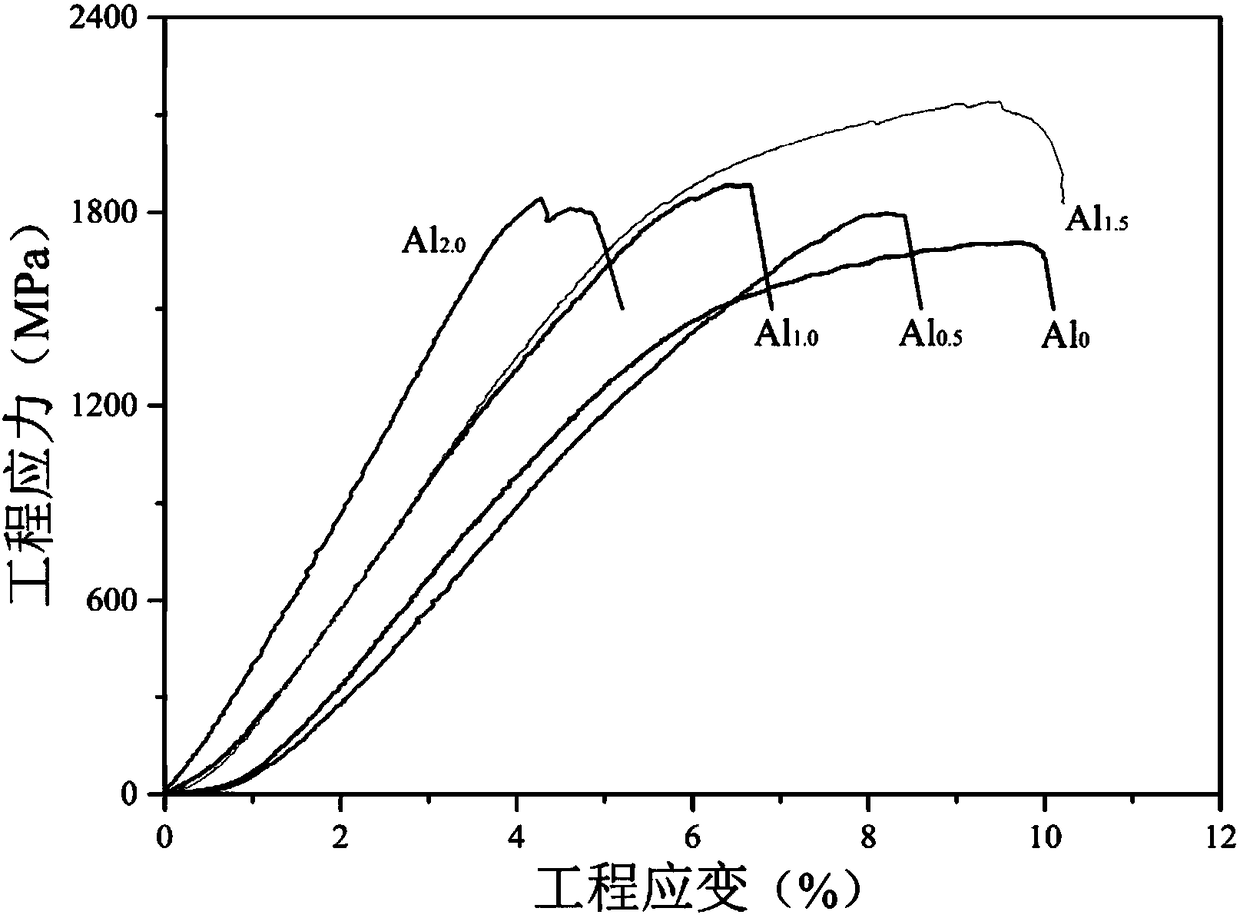

High-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and preparation method thereof

A high-entropy alloy and high-strength technology, which is applied in the field of high-entropy alloys, can solve the problems of burning loss of Al-added elements and uneven melting, and achieve the effects of easy burning loss, precise alloy composition ratio, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]A high-strength refractory five-element high-entropy alloy, the high-entropy alloy composition is CoCrFeNiV, and the purity of each component element of the alloy is ≥99.9%. The surface oxide skin of the raw material is removed by mechanical methods such as files and sandpaper, and industrial ethanol is used Clean, use the electronic balance to weigh according to the proportion shown in Table 1, and the error is controlled at 3 / 10,000.

[0033] Table 1: Raw material ratio of each component of the alloy

[0034]

[0035] In the embodiment of the present invention, a WK type non-consumable vacuum arc melting furnace is used, equipped with a water-cooled copper crucible, and an intermediate alloying method is used to prepare the target alloy.

[0036] The specific operation steps are as follows:

[0037] (1) Put Co, Ni and Fe with lower melting points into the water-cooled copper crucible in the non-consumable vacuum electric arc furnace in order of melting point from l...

Embodiment 2

[0041] A high-strength refractory five-element high-entropy alloy, the high-entropy alloy composition is CoCrFeNiVAl 0.5 , the purity of each component element of the alloy is ≥99.9%. Use mechanical methods such as files and sandpaper to remove the surface oxide skin of the raw material, and use industrial ethanol to clean it. Use an electronic balance to weigh according to the ratio shown in Table 2, and the error is controlled within 10,000. the third.

[0042] Table 2: Raw material ratio of each component of the alloy

[0043]

[0044] In the embodiment of the present invention, a WK type non-consumable vacuum arc melting furnace is used, equipped with a water-cooled copper crucible, and an intermediate alloying method is used to prepare the target alloy.

[0045] The specific operation steps are as follows:

[0046] (1) Put Co, Ni, Al and Fe with lower melting points into the water-cooled copper crucible in the non-consumable vacuum electric arc furnace in order of me...

Embodiment 3

[0050] A high-strength refractory five-element high-entropy alloy, the high-entropy alloy composition is CoCrFeNiVAl 1.0 , the purity of each component element of the alloy is ≥99.9%. Use mechanical methods such as files and sandpaper to remove the oxide skin on the surface of the raw material, and use industrial ethanol to clean it. Use an electronic balance to weigh according to the ratio shown in Table 3. The error is controlled within ten thousand the third.

[0051] Table 3: Raw material ratio of each component of the alloy

[0052]

[0053] In the embodiment of the present invention, a WK type non-consumable vacuum arc melting furnace is used, equipped with a water-cooled copper crucible, and an intermediate alloying method is used to prepare the target alloy.

[0054] The specific operation steps are as follows:

[0055] (1) Put Co, Ni, Al and Fe with lower melting points into the water-cooled copper crucible in the non-consumable vacuum electric arc furnace in ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com