A kind of long cycle life lithium ion battery carbon negative electrode material and preparation method thereof

A lithium-ion battery and anode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low cycle life and rate performance of natural graphite, difficulty in overcoming structural degradation, degradation of battery cycle performance, etc., and achieve excellent chemical stability High stability, excellent structural stability, and less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

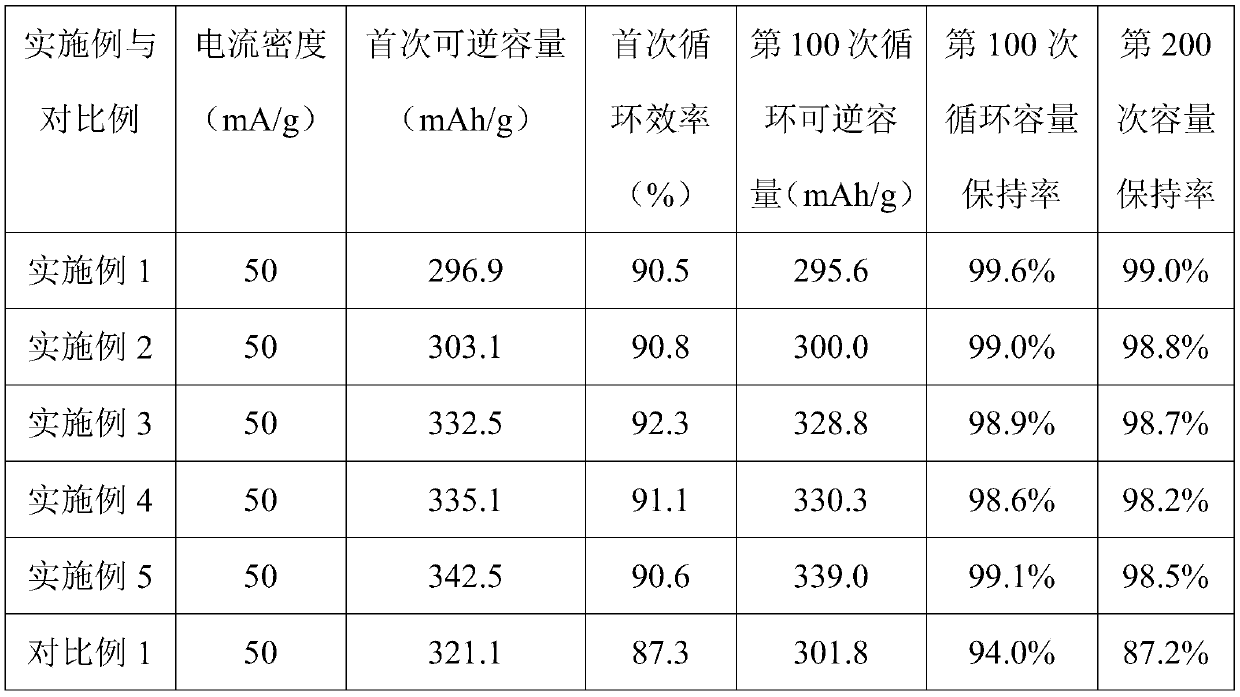

[0017] Preheat the chemical vapor phase reaction furnace to 1200°C in an argon atmosphere, use ethylene as a raw material, and control the concentration of the raw material to 0.1mg / cm 3 , the reaction time is 5 hours, and the carbon microsphere precursor is prepared. First, the carbon microsphere precursor was heat-treated at 1400°C for 10 hours, the heating rate was 1°C / min, and the heat treatment atmosphere was a hydrogen-argon mixture containing 10% hydrogen. The carbon microsphere precursor that has undergone low-temperature heat treatment is heat-treated at 3000°C for 1 hour, the heating rate is 5°C / min, and the heat treatment atmosphere is argon, so that a multi-shell and carbon sheet with an average particle size of 800 nm can be obtained. The layer is a carbon microsphere material with a structure similar to concentric spheres. According to the test method of lithium-ion battery negative electrode materials in button batteries (active material powder, conductive agen...

Embodiment 2

[0021] Preheat the chemical vapor phase reaction furnace to 1300°C in an argon atmosphere, use coal tar as a raw material, and control the concentration of the raw material to 20mg / cm 3 , the reaction time is 2 hours, and the carbon microsphere precursor is prepared. First, the carbon microsphere precursor was heat-treated at 1200°C for 8 hours, the heating rate was 2°C / min, and the heat treatment atmosphere was argon. The carbon microsphere precursor that has undergone low-temperature heat treatment is heat-treated at 2600 ° C for 2 hours, the heating rate is 1 ° C / min, and the heat treatment atmosphere is argon, and the multi-shelled and carbon microspheres with an average particle size of 1 micron can be obtained. The sheet layer is a carbon microsphere material with a structure similar to that of concentric spheres. According to the test method of the lithium-ion half-battery in Example 1, the material of Example 2 has a reversible capacity of 300.0mAh / g after 100 times...

Embodiment 3

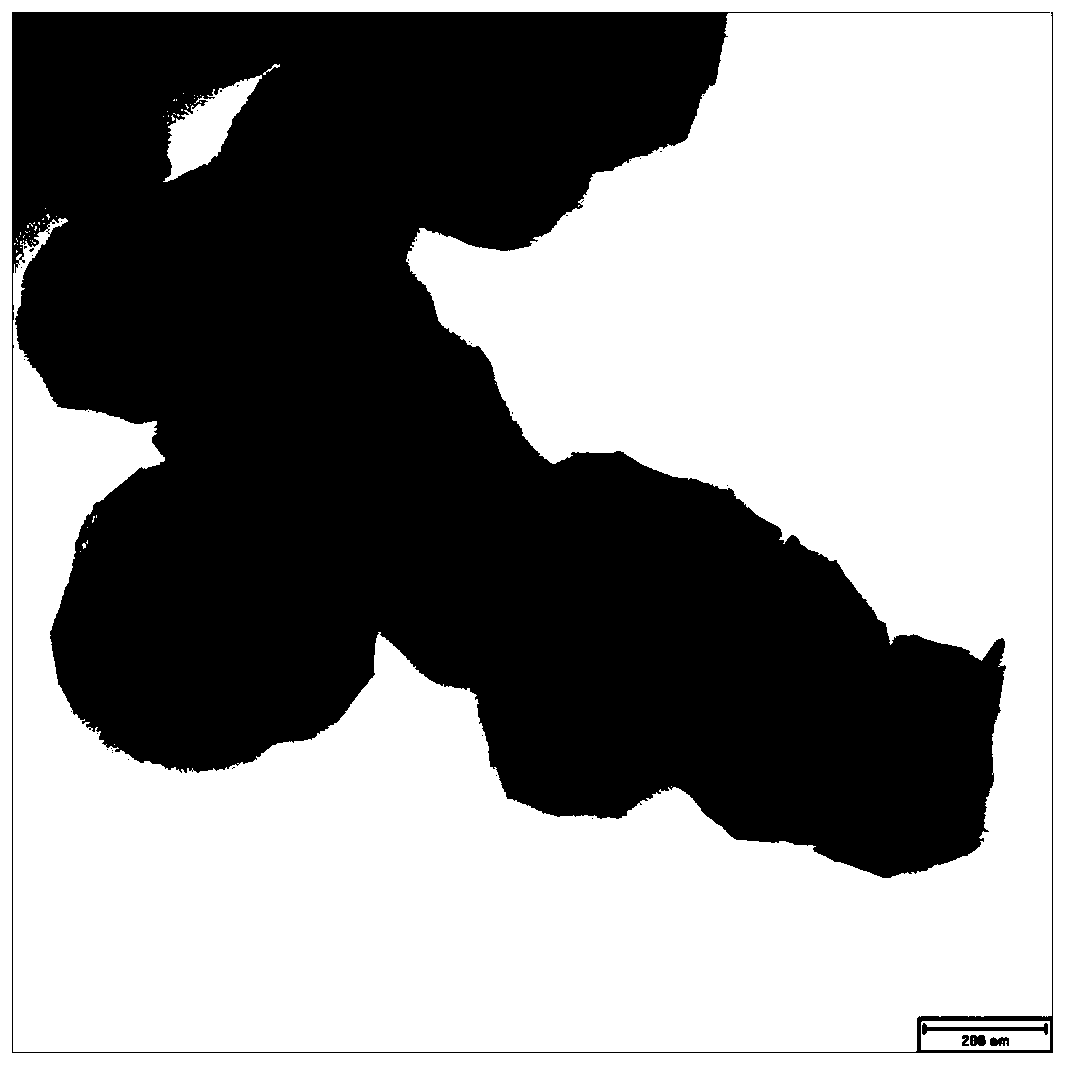

[0023] Preheat the chemical vapor phase reaction furnace to 900°C in an argon atmosphere, use pyridine as a raw material, and control the concentration of the raw material to 1.55mg / cm 3 , the reaction time is 3 hours, and the carbon microsphere precursor is prepared. First, the carbon microsphere precursor was heat-treated at 1200 °C for 5 hours, the heating rate was 1 °C / min, and the heat treatment atmosphere was nitrogen. The low-temperature heat-treated carbon microsphere precursor is heat-treated at 2800°C for 1 hour, the heating rate is 2°C / min, and the heat-treatment atmosphere is argon to obtain multi-shell and carbon microspheres with an average particle size of 2 microns. The carbon microsphere material whose sheets are arranged in a structure similar to concentric spheres, and its transmission microscope photos are as follows: figure 1 shown. According to the test method of the lithium-ion half-battery in Example 1, the material of Example 3 has a reversible capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com