A kind of preparation method of polymer composite film

A composite film and polymer technology, used in biocide-containing paints, powder coatings, coatings, etc., can solve problems such as damage to paint adhesion, poor thermal stability, poor chemical resistance, etc., and achieve rich film types and functions. , Widen the selection range of raw materials, and the effect of good dimensional stability of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

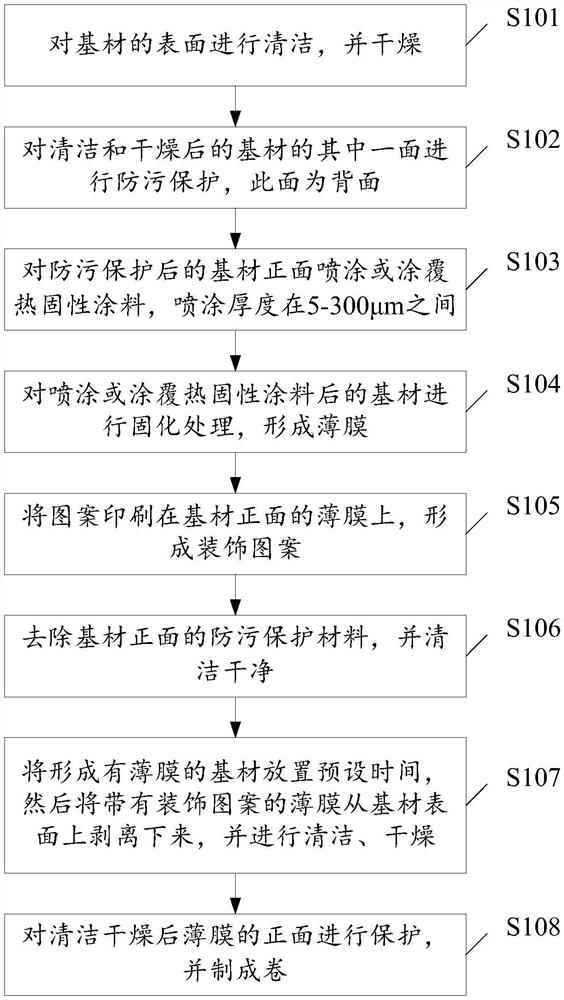

[0059] Traditional film production uses thermoplastics through blow molding, calendering, casting, multi-layer co-extrusion and other methods, but the present invention uses thermosetting coating materials and construction principles to make single-layer or multi-layer high-quality films with different functions. The molecular composite film is then peeled off from the substrate, with small equipment investment, flexible production organization, rich film types and functions, and personalized customization. The number of composite layers is not limited by the equipment, and the thickness can be adjusted flexibly; due to the wide variety of coatings, coating various functional coatings can realize more functions of the composite film. Specifically, such as figure 1 Shown, the preparation method of polymer composite film of the present invention comprises:

[0060] S101. Clean and dry the surface of the substrate.

[0061] The material of the substrate is glass, ceramics, meta...

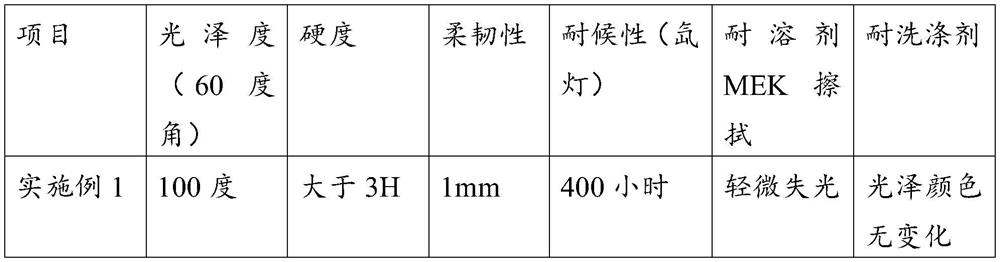

Embodiment 1

[0138] Example 1: Three-layer composite decorative film with high gloss and high hardness mirror surface

[0139] 1) Selection of base material: choose a piece of ordinary white glass of 400*600*5mm, first wash the surface with clean water and dry it at 120°C for 5 minutes;

[0140] 2) Antifouling protection is carried out on one side of the cleaned and dried substrate, which is the back side;

[0141] 3) The UV radiation-cured transparent coating is applied by roller coating, such as EBECRY1600 of Allnex Company, to the front of the substrate with a paint film thickness of 8 μm, and then cured by UV radiation to form a UV radiation-cured coating;

[0142] 4) Using electrostatic powder spraying equipment, two-component polyester powder coatings, such as SJ-4G and SJ-4H produced by Anhui Shenjian Company, are made with TGIC as the curing agent (the amount of curing agent added is 1-20%) The powder coating is sprayed on the ultraviolet radiation cured coating that completed ste...

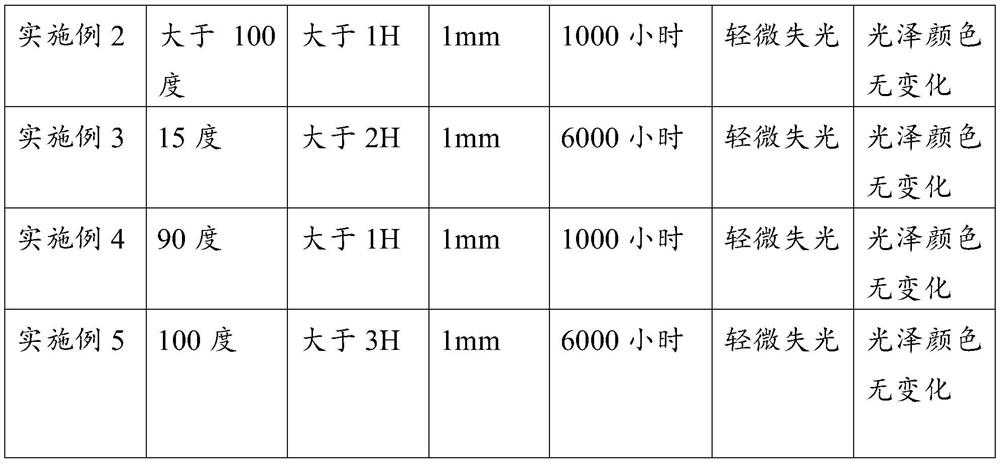

Embodiment 2

[0151] Example 2: High-gloss mirror surface double-layer composite metal effect decorative film

[0152] 1) Selection of base material: choose a piece of ordinary white glass of 400*600*5mm, first wash the surface with clean water and dry it at 120°C for 5 minutes;

[0153] 2) Antifouling protection is carried out on one side of the cleaned and dried substrate, which is the back side;

[0154] 3) Using electrostatic powder spraying equipment, two-component polyester powder coatings, such as SJ-4G and SJ-4H produced by Anhui Shenjian Company, supplemented with TGIC as a curing agent (the amount of curing agent added is 1-20%), And mix 1-10% aluminum powder and 1-10% pearl powder to make powder coating, spray on the front of the glass, and bake in an oven at 160 ° C for 15 minutes to form a layer of metal with a thickness of 40 μm Silver effect coating;

[0155] 4) the workpiece that completes step 4) is cooled to room temperature;

[0156] 5) Using electrostatic powder spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com