Patents

Literature

33results about How to "Flexible production organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

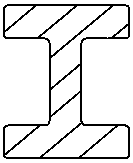

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

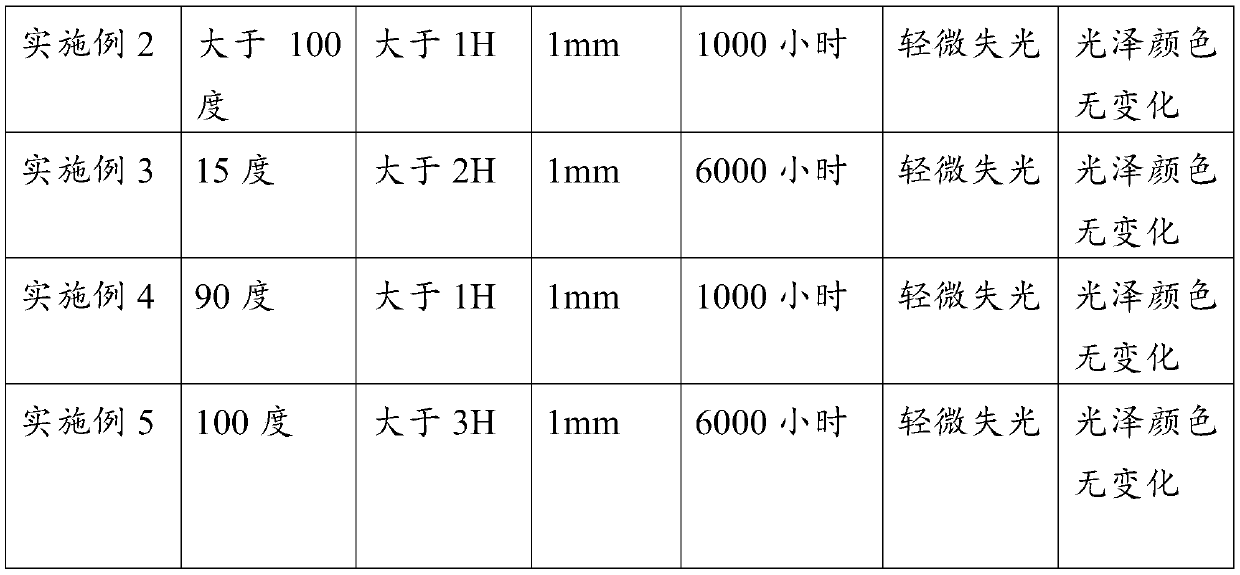

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

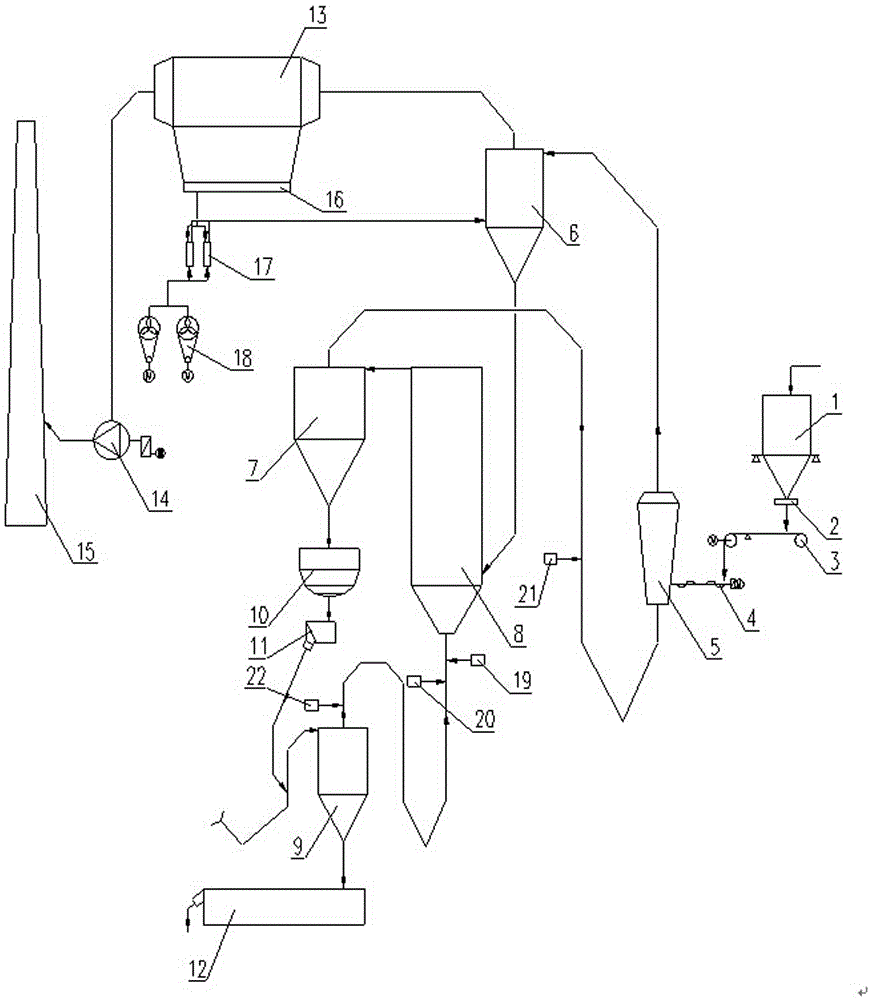

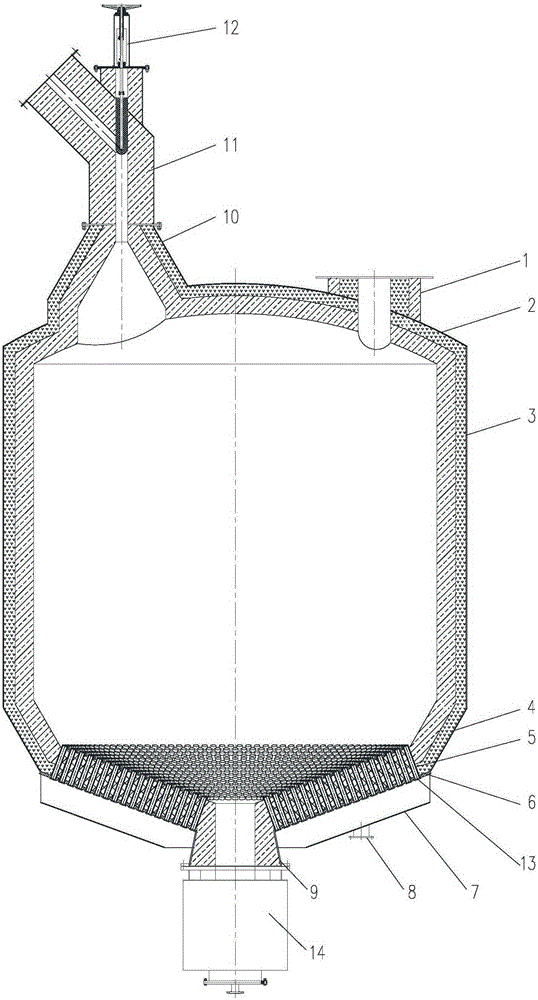

Suspension roasting device and technology for producing multiform aluminum oxide

InactiveCN104692435AReduce production linksSave construction investmentAluminium oxide/hydroxide preparationAluminium hydroxideEngineering

The invention belongs to the technical field of metallurgy, and particularly relates to a suspension roasting device and technology for producing multiform aluminum oxide. The device is composed of a feeding system, a roasting system, a crystal separation system and a cyclone dust removal system, wherein the feeding system comprises a quantitative feeder, a spiral feeder and a drier, the roasting system comprises a cyclone preheater, a roasting furnace and a burning station, the crystal separation system comprises a cyclone separator, a crystallizer, a controllable material level valve, a cyclone cooler and a drying cooler, and the cyclone dust removal system comprises a dust remover, an induced draught fan and a chimney. During working, an aluminum hydroxide filter cake serves as the raw material, the roasting temperature of the roasting furnace and the time for materials staying in the crystallizer are adjusted according to different requirements of multiform aluminum oxide products, and finally obtained different aluminum oxide products are discharged out of the drying cooler. According to the device and technology, metallurgical aluminum oxide and high-temperature aluminum oxide are produced at the same time with one set of device and the same kind of material by adjusting operating parameters.

Owner:SHENYANG XINBO IND TECH

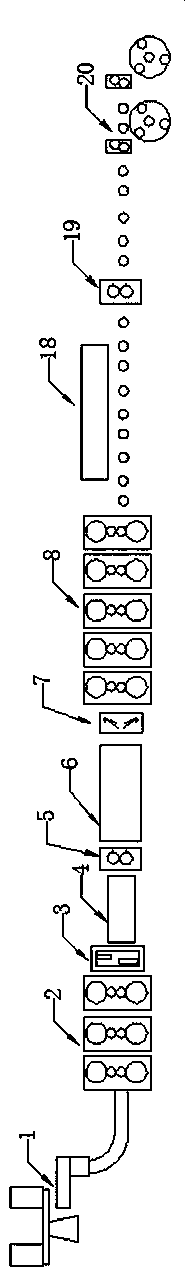

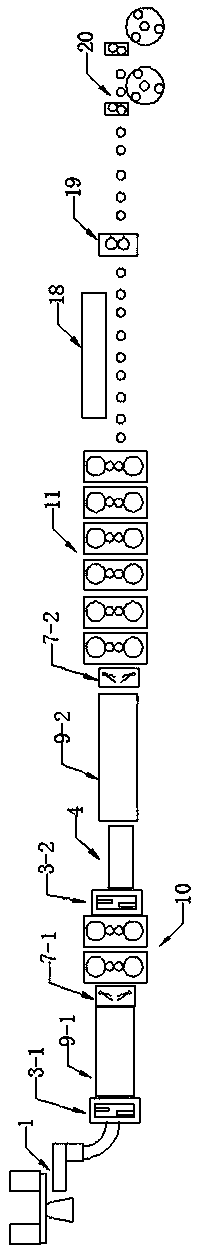

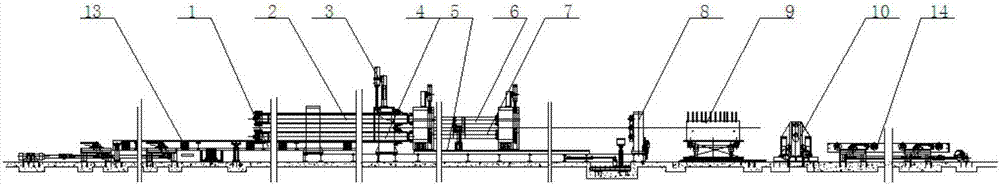

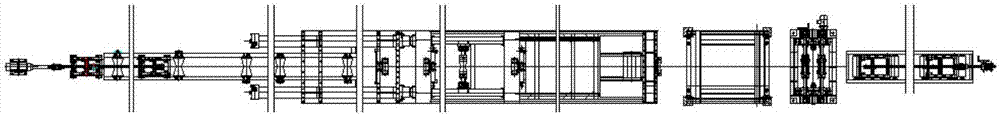

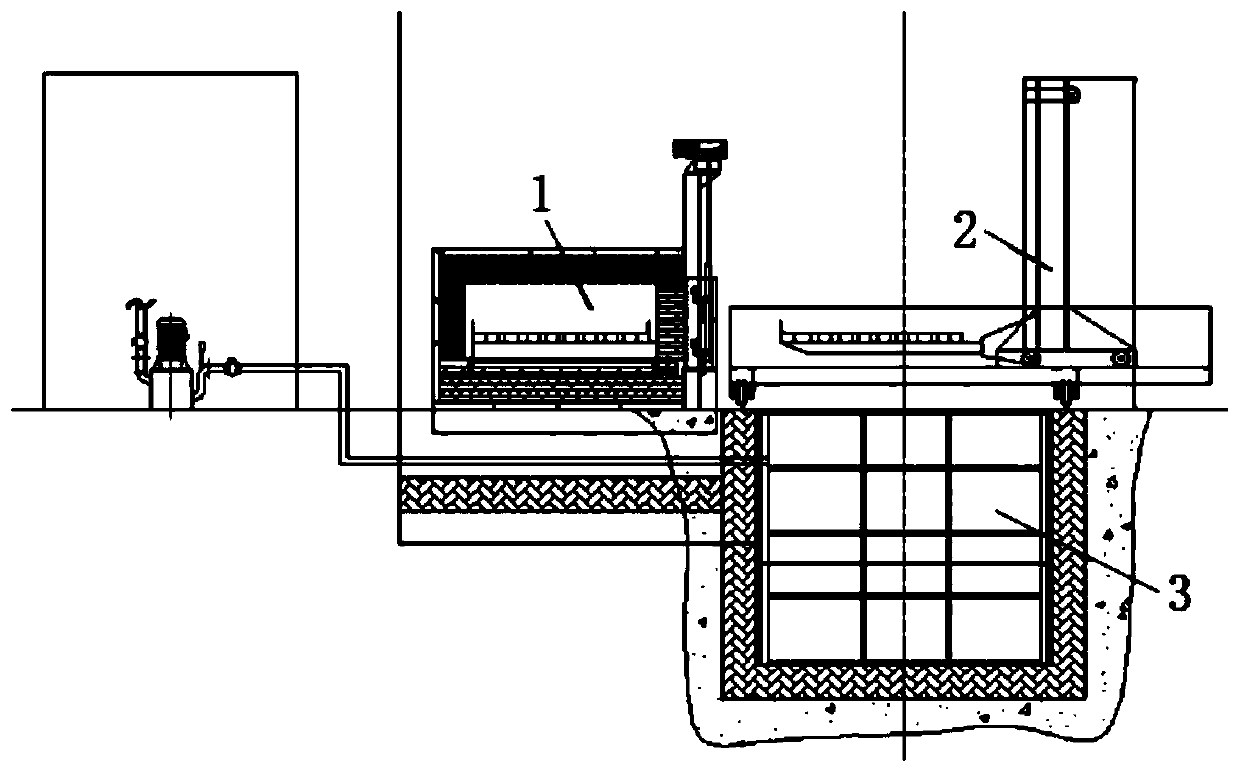

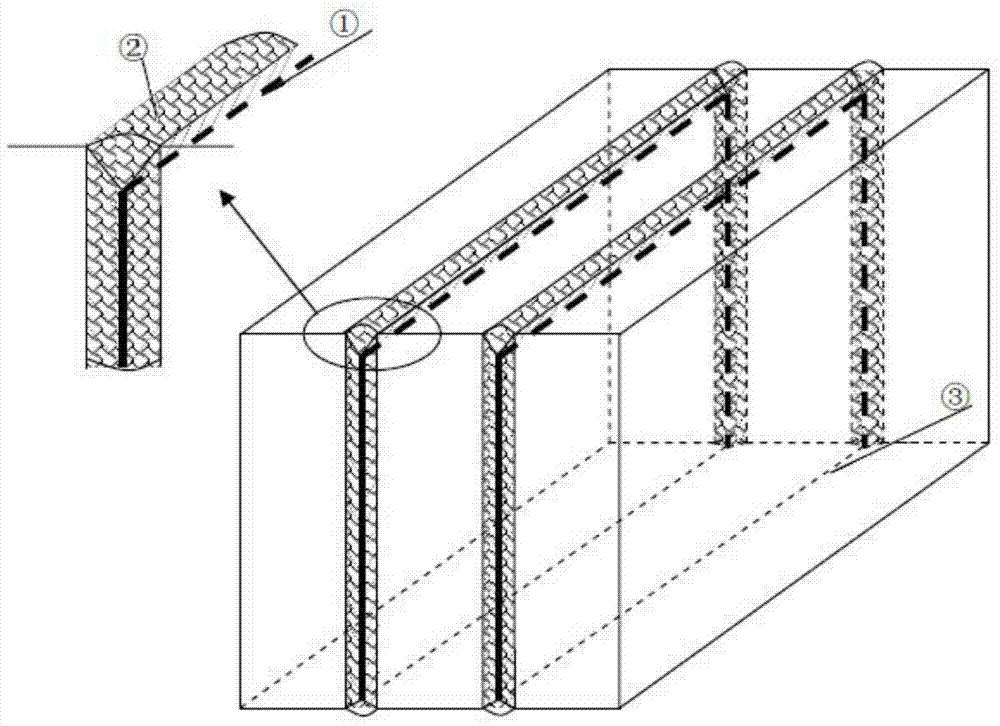

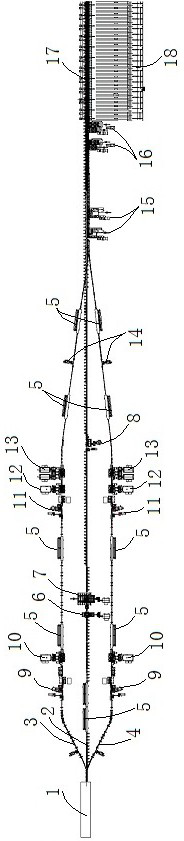

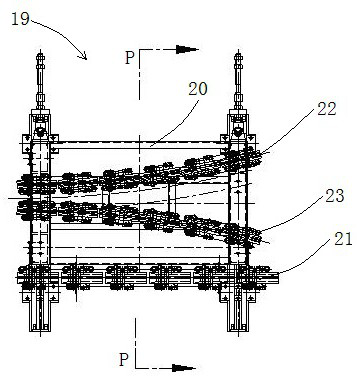

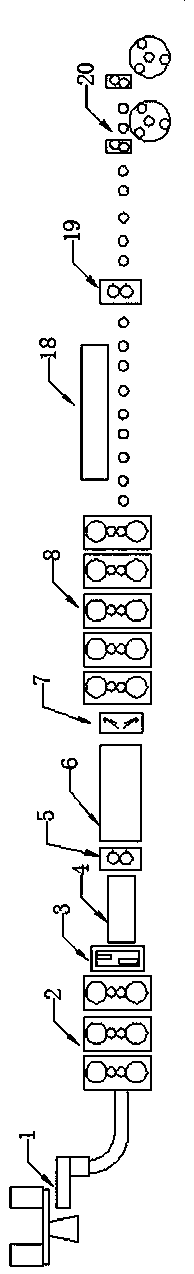

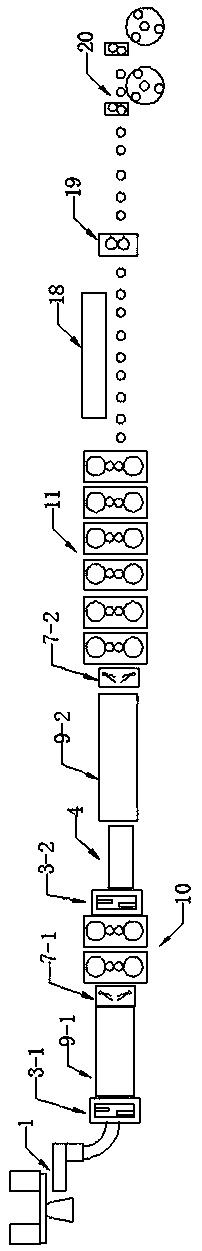

Sheet billet continuous casting and rolling production line and production process thereof

ActiveCN109013701AAvoid major production accidentsPromote warmingMetal rolling arrangementsProduction lineLaminar cooling

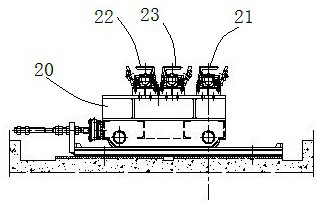

The invention relates to a sheet billet continuous casting and rolling production line and a production process thereof, and belongs to the technical field of sheet billet continuous casting and rolling. According to the technical scheme, the sheet billet continuous casting and rolling production line comprises a continuous casting machine (1), a 1#pendulum shear (3-1), a 1#tunnel type heating furnace (9-1), a 1#descaler (7-1), a roughing mill group (10), a 2#pendulum shear (3-2), a billet picking device (4), a 2#tunnel type heating furnace (9-2), a 2#descaler (7-2), a finishing mill group (11), a laminar cooling (18), a flying shear (19) and a reeling-up machine set (20) which are arranged in sequence according to a rolling sequence. When the continuous casting speed of the continuous casting machine (1) is less than 5m / min, single block rolling or semi-endless rolling is adopted; and when the continuous casting speed of the continuous casting machine (1) is greater than or equal to 5m / min, endless rolling is adopted. The sheet billet continuous casting and rolling production line and the production process thereof have the beneficial effects that the temperature uniformity and the surface quality of a casting blank can be ensured, and different rolling modes can be adopted according to the continuous casting speed of the continuous casting machine.

Owner:唐山全丰薄板有限公司

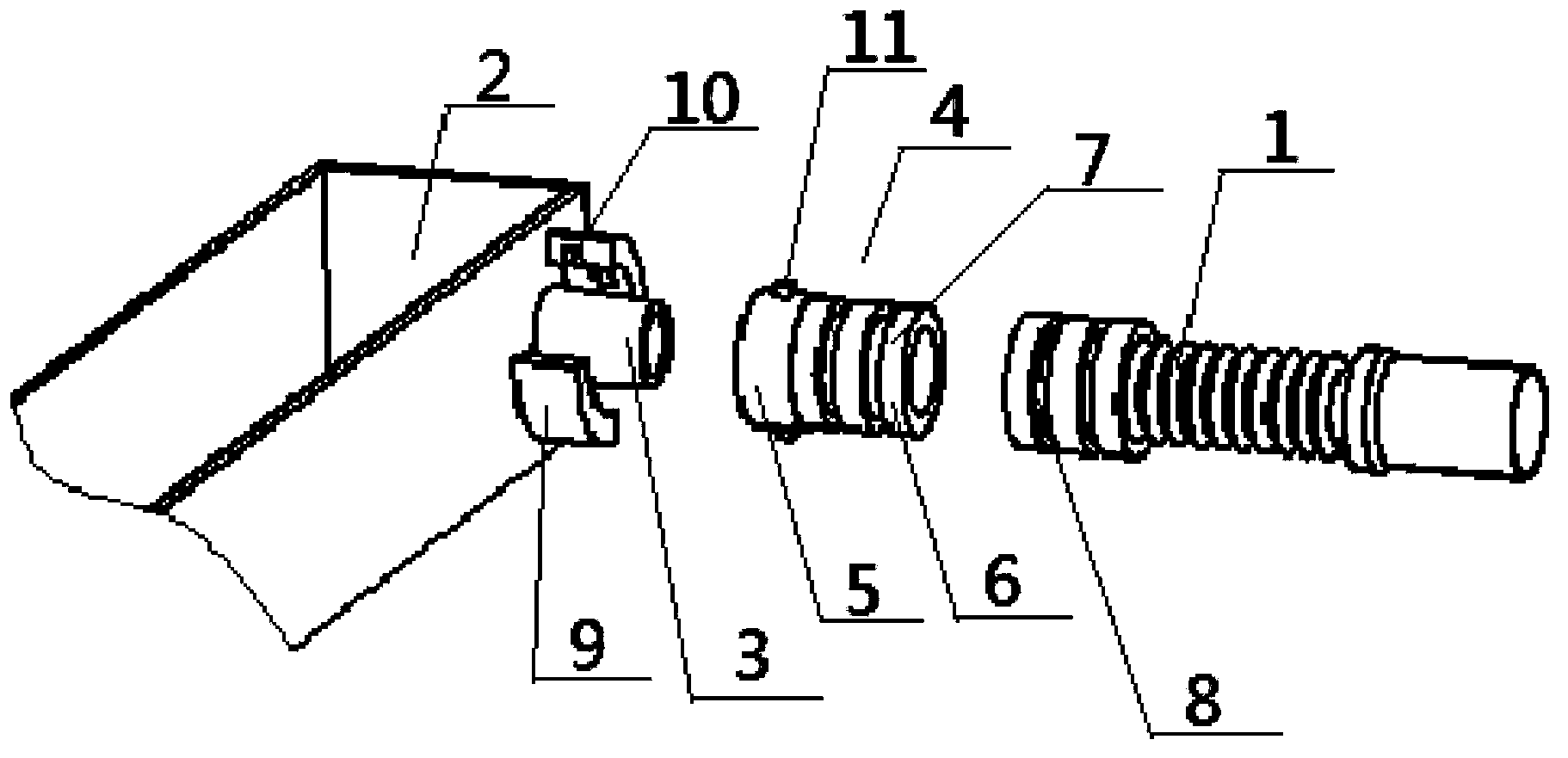

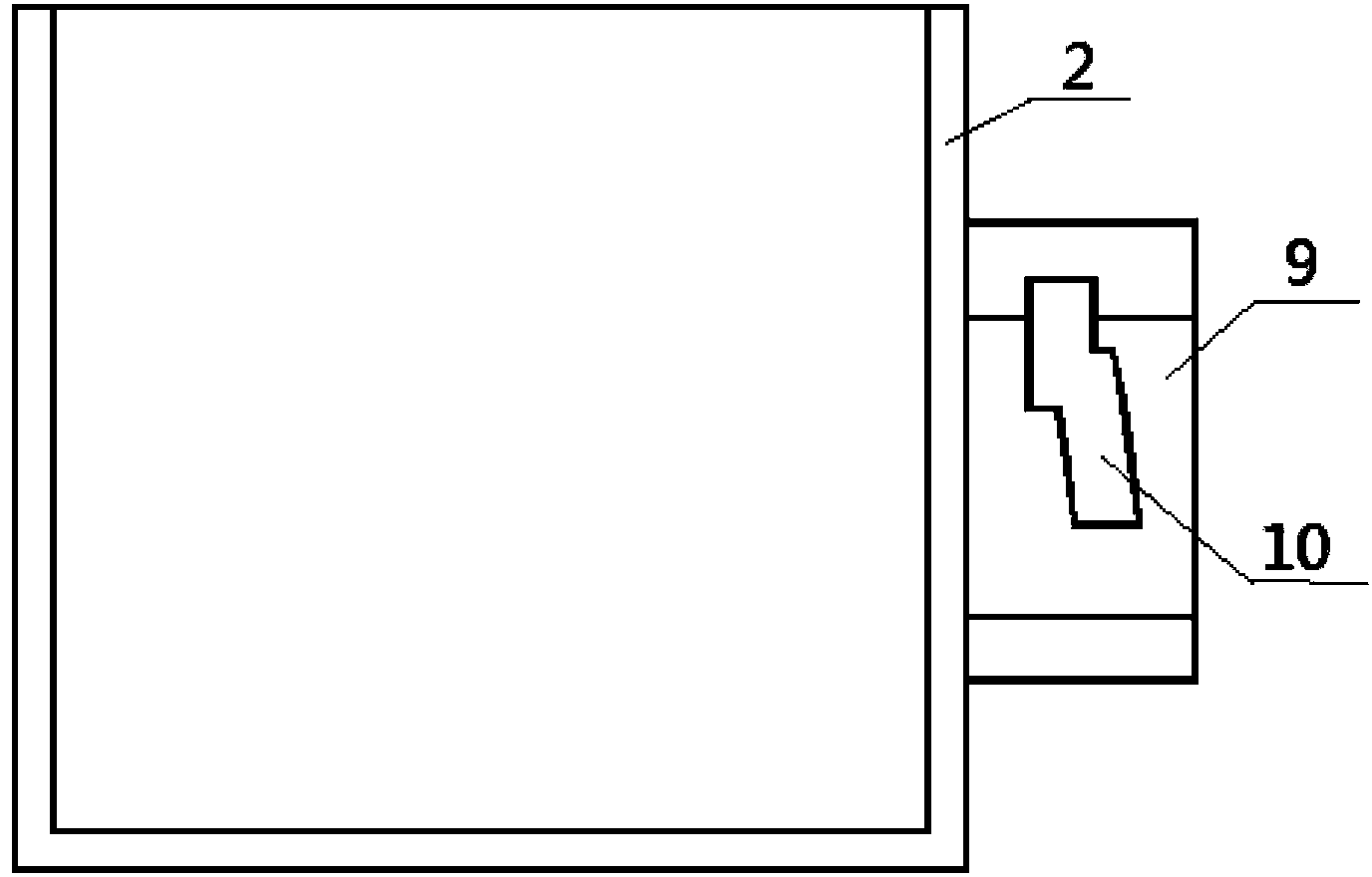

Air-conditioning indoor unit and drain pipe connecting structure thereof

ActiveCN104110817ASimple structureSimplified installation stepsCondensate preventionAir conditioningDrain tube

The invention relates to an air-conditioning indoor unit and a drain pipe connecting structure thereof. The drain pipe connecting structure comprises a water pan and a drain pipe. A water outlet is formed in the water pan. An end of the drain pipe is connected with a water outlet through a pipe connector. The pipe connector comprises a clamping portion and a connecting portion. The clamping portion is fixedly clamped to a water outlet of the water pan. The connecting portion is connected with the drain pipe in a sealing manner. The drain pipe connecting structure is simple, and two ends of the pipe connector are fixedly connected with a mounting seat and the drain pipe respectively so as to mount the drain pipe. In this way, mounting steps are simplified, production efficiency is improved, and production organization is convenient and flexible.

Owner:GUANGDONG KELON AIR CONDITIONER

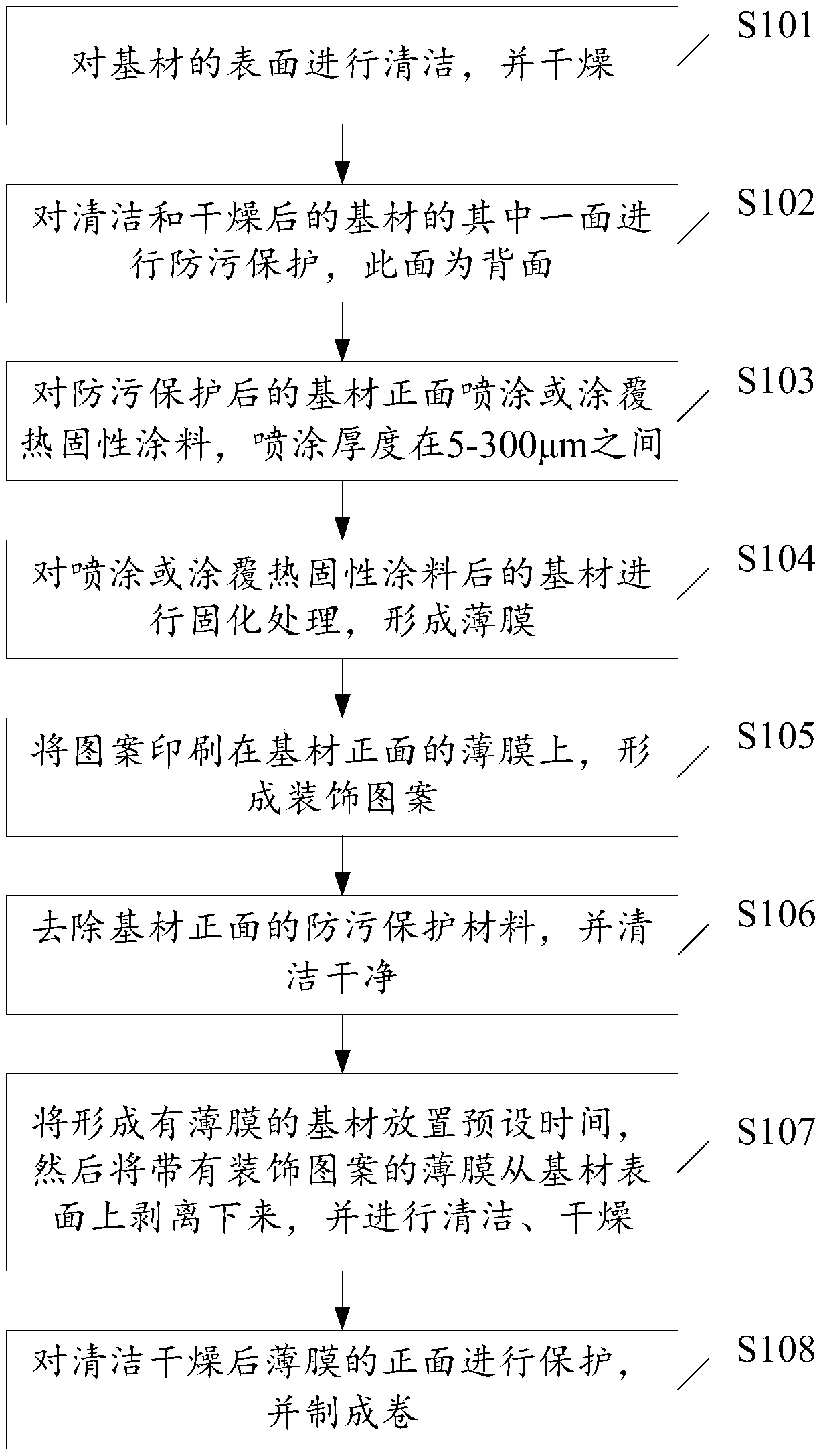

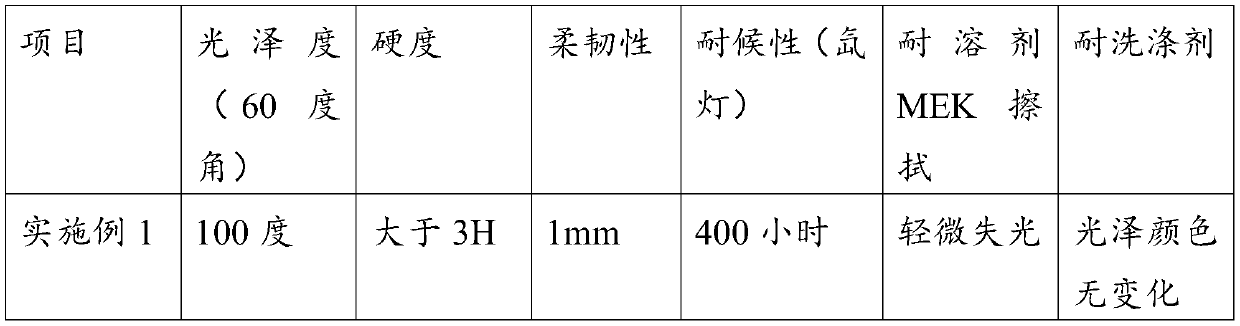

Polymer composite film preparation method

ActiveCN110408250AFlexible thickness adjustmentAdjustable thicknessAntifouling/underwater paintsPaints with biocidesComposite filmOrganic solvent

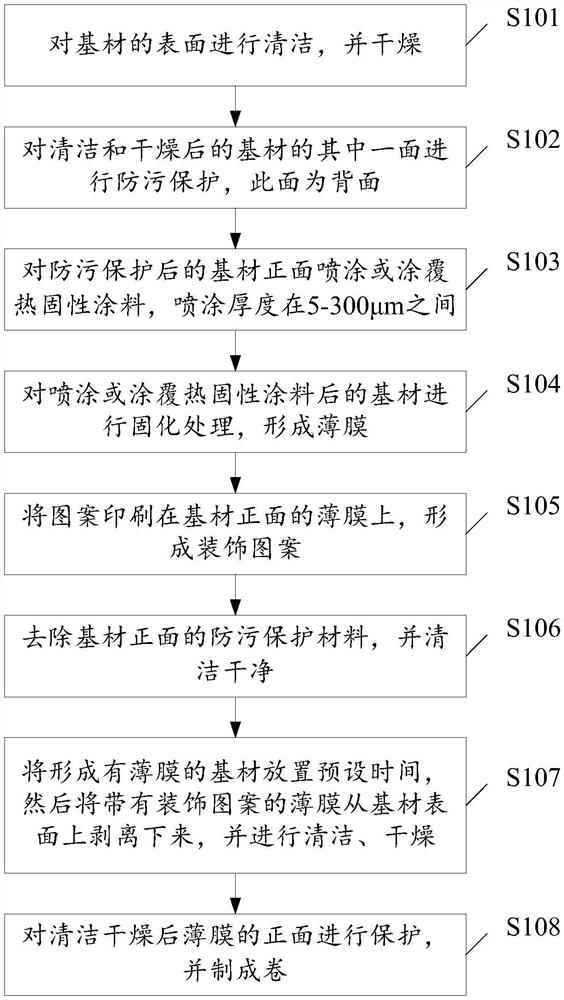

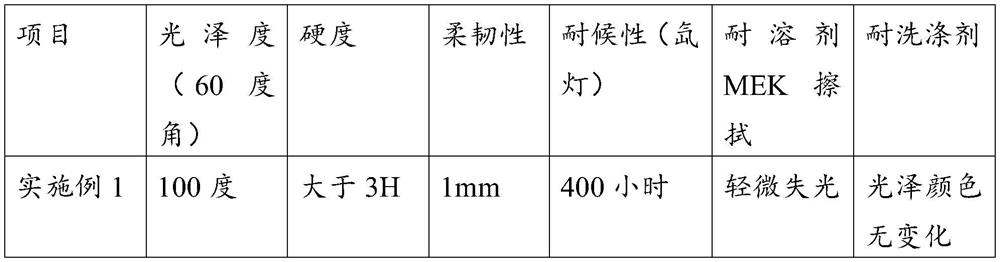

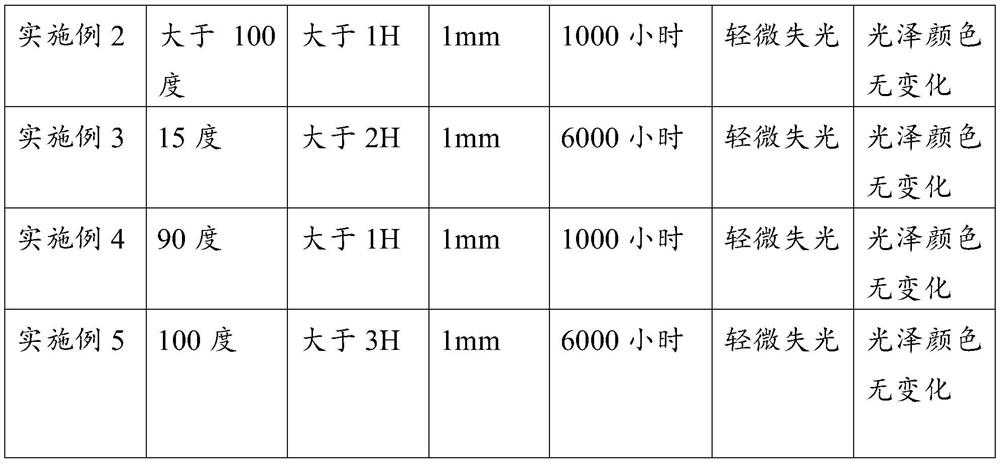

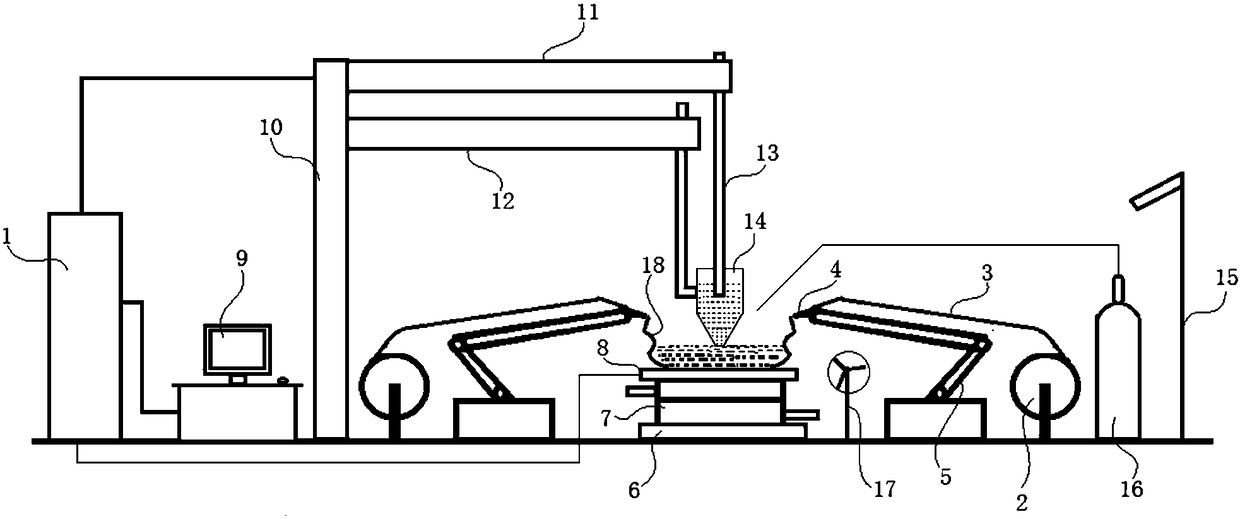

The invention discloses a polymer composite film preparation method, which comprises: (1) cleaning the surface of a base material, and drying; (2) carrying out antifouling protection on one surface ofthe base material; (3) spraying or coating the front surface of the base material with a thermosetting coating material; (4) curing the base material to form a film; (5) printing a pattern on the film on the front surface of the base material to form a decorative pattern; (6) removing the antifouling protection material, and completely cleaning; (7) placing a preset time, and peeling off the filmwith the decorative pattern from the surface of the base material; and (8) protecting the front surface of the base material, and preparing a roll. According to the present invention, the single-layer or multi-layer composite film is prepared by using the coating material peelable film forming technology, such that the method is simple, the preparation cost of the composite film is greatly reduced, the peeling process is simple, and does not use demolding agents, organic solvents and acid-alkali solutions, and the surface can achieve the highlight effect of the mirror surface.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

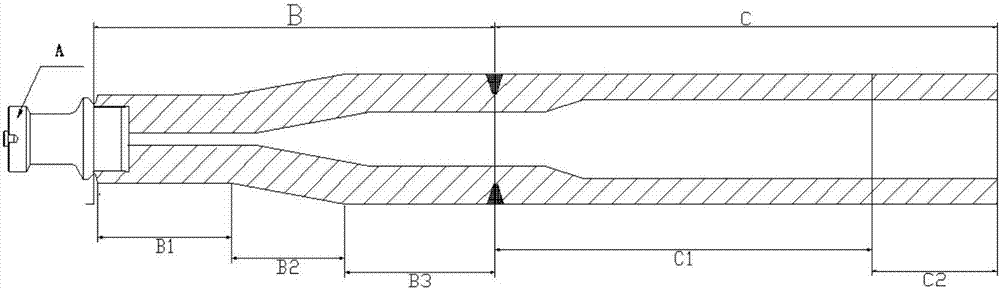

Two-step push type external expander of large-caliber seamless steel pipe and thermal expanding process for two-step push type external expander

InactiveCN106914554AFast and even controllable heatingUniform and controllable heatingShaping toolsMetal-working feeding devicesHydraulic cylinderMedium frequency

The invention discloses a two-step push type external expander of a large-caliber seamless steel pipe. The two-step push type external expander comprises a base and a drawbar, wherein a to-be-pushed steel tube sleeves outside one end of the drawbar; the other end of the drawbar is equipped with a pushing core rod; a feeding roller path for conveying the steel tube is arranged on the base; a hydraulic lifting gate plate capable of vertically lifting is arranged on the feeding roller path; and the hydraulic lifting gate plate can descend, jack and push the steel tube to horizontally convey to a medium-frequency induction heating coil. According to the two-step push type external expander disclosed by the invention, length of a hydraulic cylinder can be reduced nearly a half through two-step push, so that equipment manufacturing cost is reduced, length limitation of oil cylinder processing is solved from the process, raw materials are be quickly and uniformly heated in a controllable mode by the medium-frequency heating equipment, the raw materials can be pushed and deformed at constant speed, and performance uniformity of the tube body can be guaranteed. According to the thermal expander and the process thereof, the investment is less, the equipment is simple, the construction period is short, the product quality is good, the geometric accuracy is high, the yield is high, the energy consumption is low, and pollution is avoided.

Owner:浙江卓业能源装备有限公司

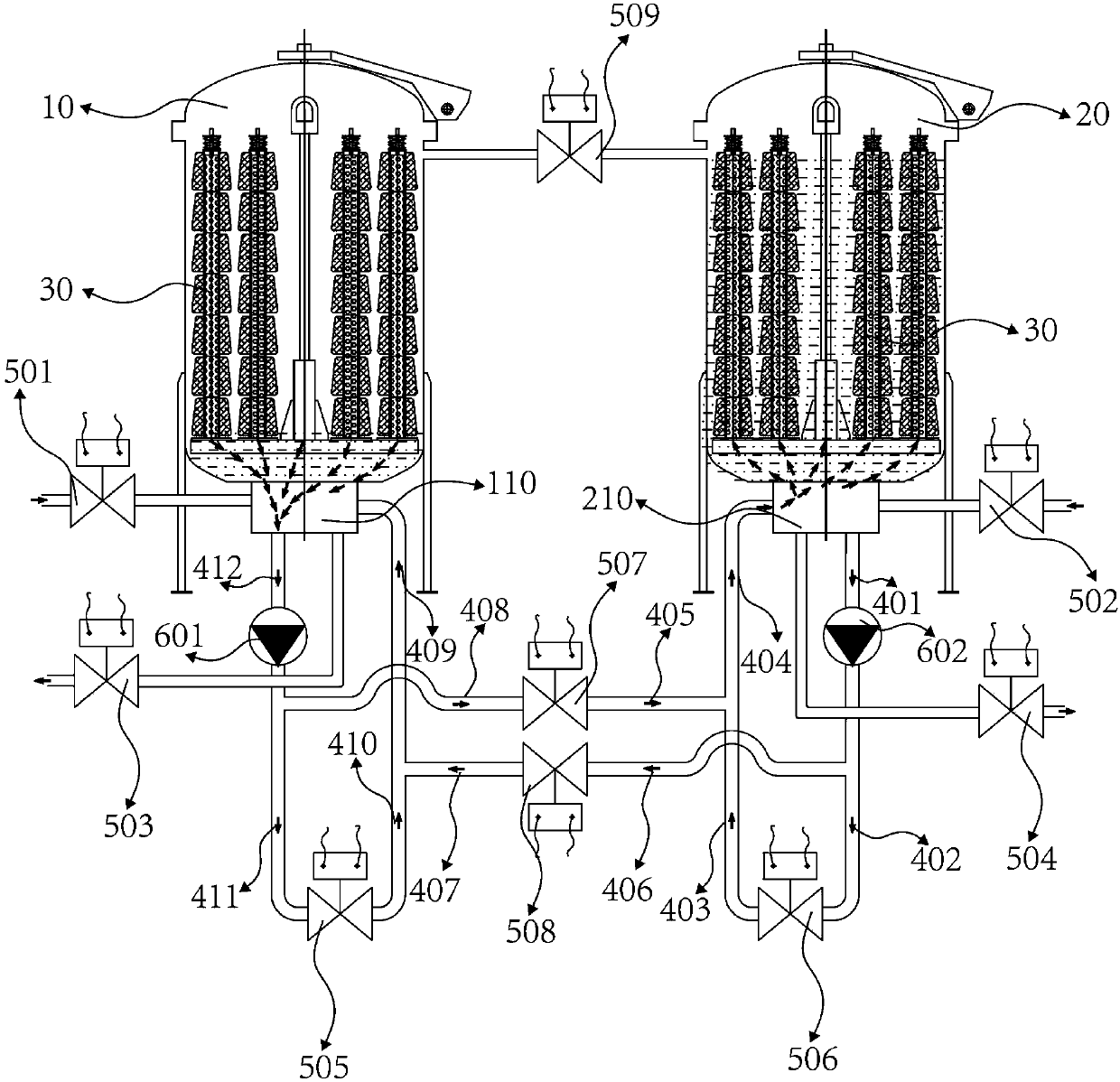

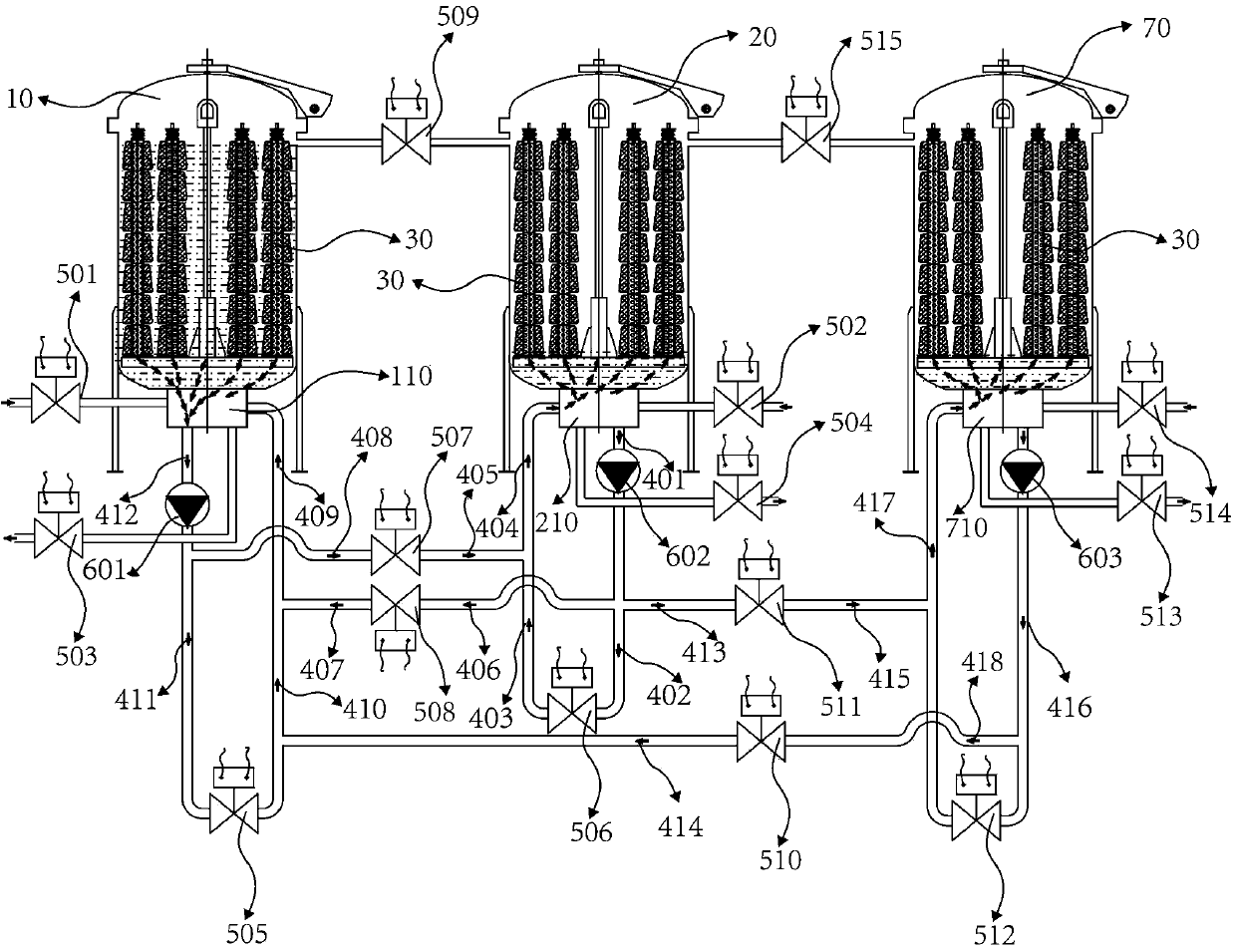

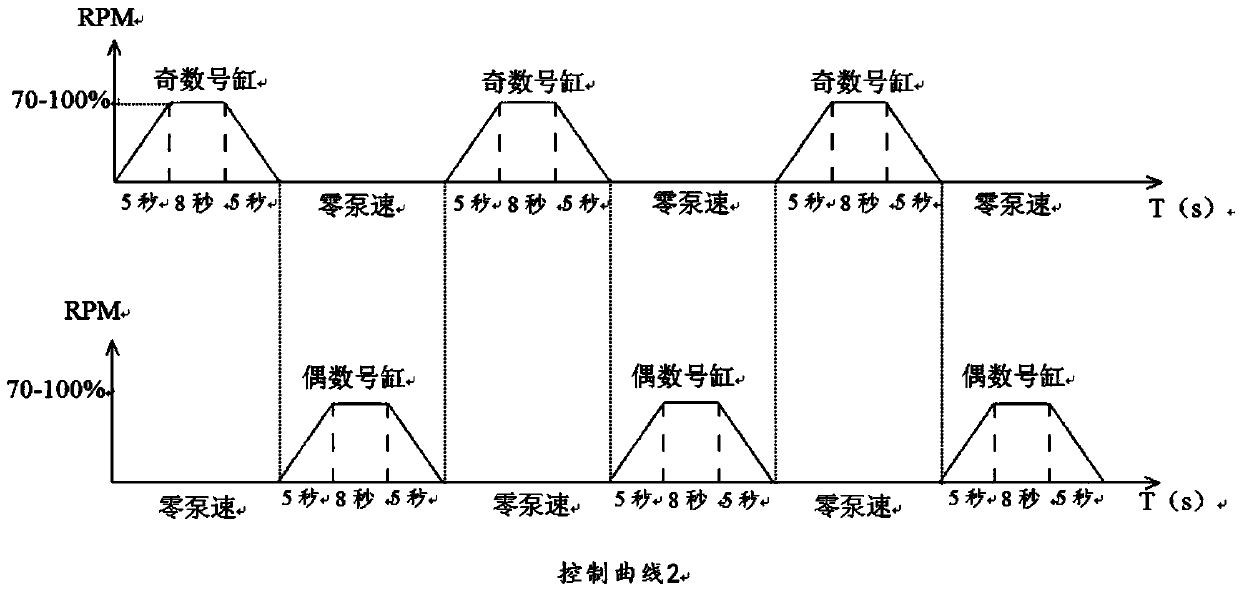

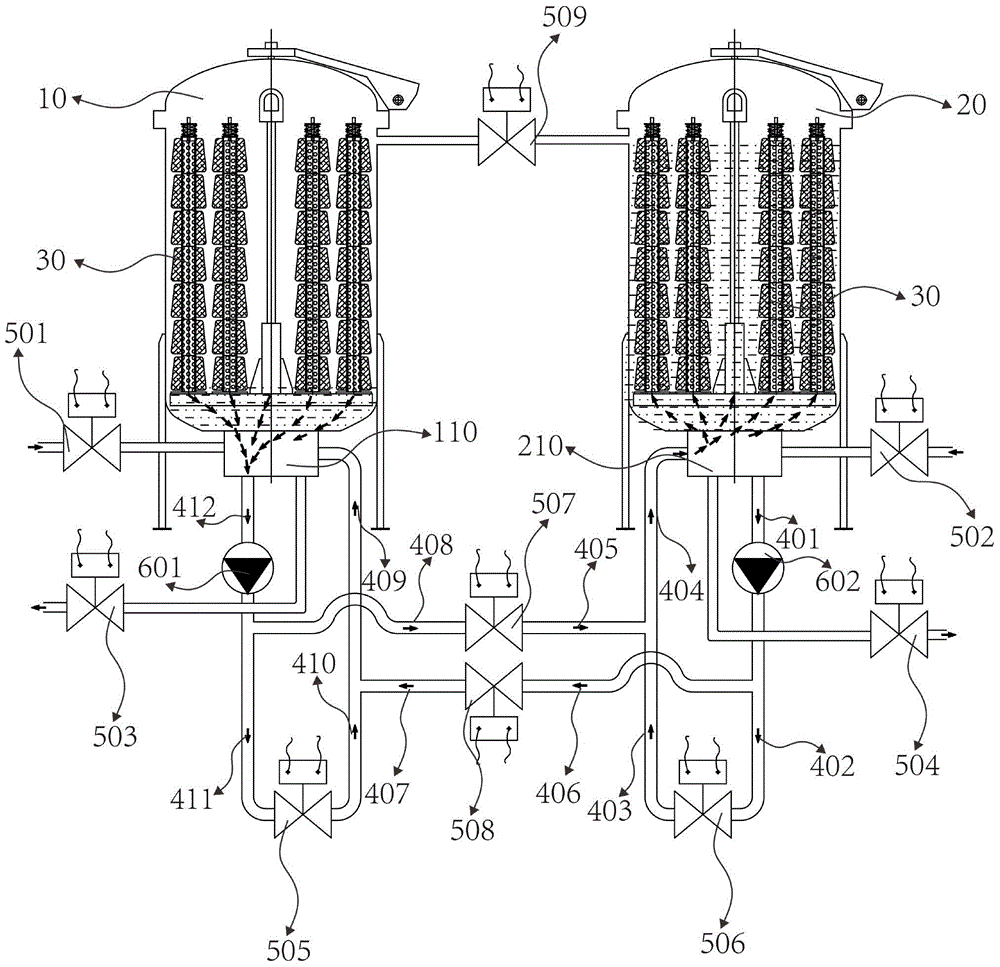

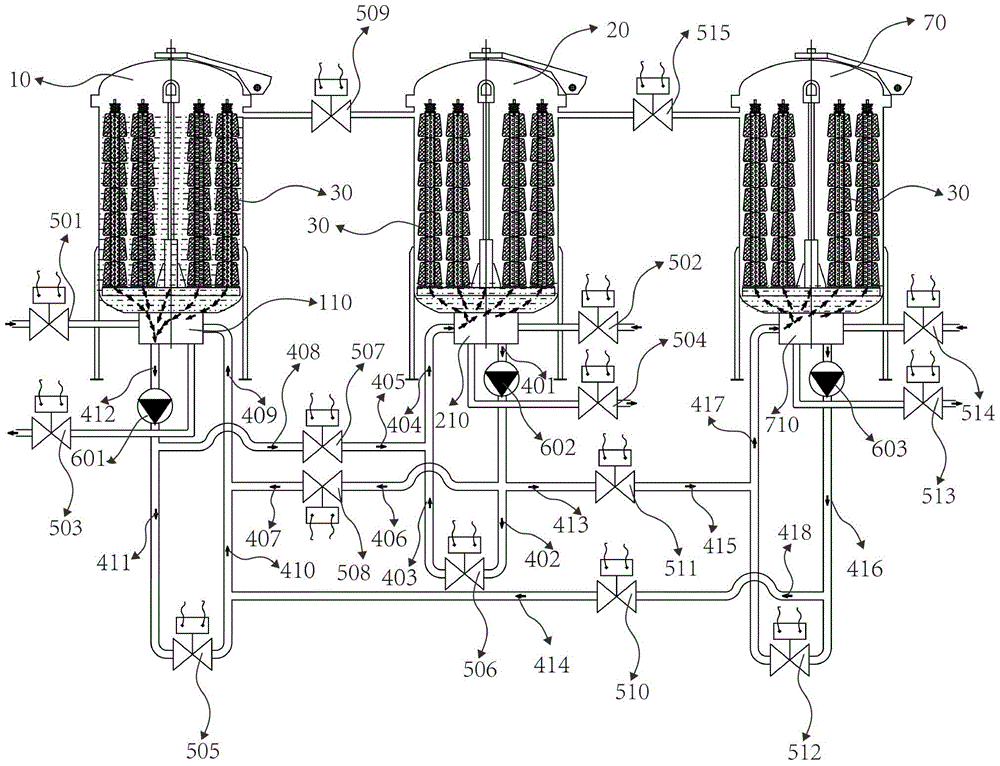

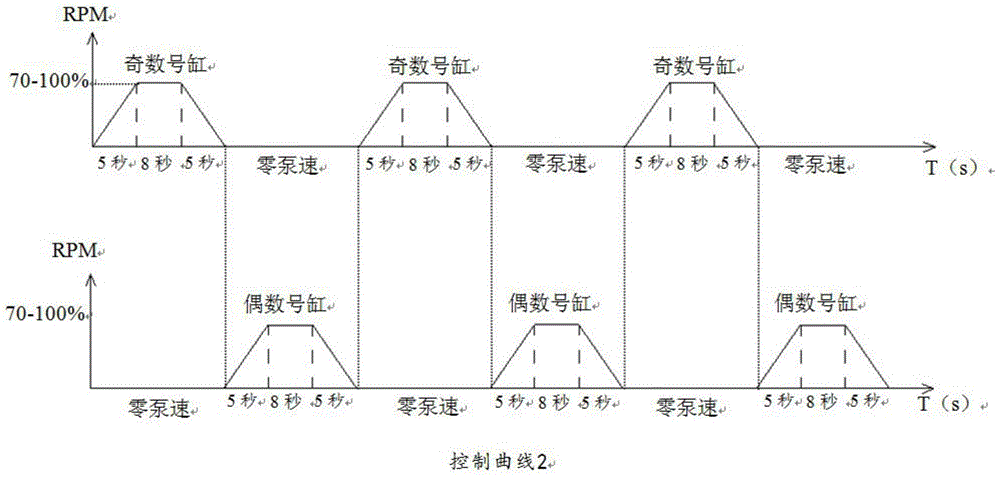

United-cylinder dyeing method and dyeing device adopting same

ActiveCN104178954AReduce dosageReduce the problem of cylinder difference phenomenonTextile treatment containersLiquid/gas/vapor yarns/filaments treatmentEngineeringControl valves

The invention discloses a united-cylinder dyeing method and a dyeing device adopting the same. The united-cylinder dyeing method comprises the following steps: a cylinder cloth is arranged respectively in a first cylinder body and a second cylinder body, and all outlets of the first cylinder body and all outlets of the second cylinder body are closed; dyeing fluid is pumped into the first cylinder body for dyeing, and after dyeing, the dyeing fluid in the first cylinder body is pumped into the second cylinder body for dyeing; after dyeing, the dyeing fluid in the second cylinder body is pumped into the first cylinder body for dyeing the cylinder cloth in the first cylinder body, and the cycle continues. A united-cylinder dyeing device comprises the first cylinder body and the second cylinder body, and a control valve is connected in series between the top of the first cylinder body and the top of the second cylinder body; the first cylinder body and the second cylinder body are provided with water inlets and water outlets, and a control valve and a dyeing fluid main pump are connected in series between the first cylinder body and the second cylinder body. The united-cylinder dyeing device is capable of ensuring the dyeing quality of products, improving production efficiency and reducing investment.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1189256CIncrease the compression ratioReduce pull speedMetal rolling arrangementsThin slabHeating furnace

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

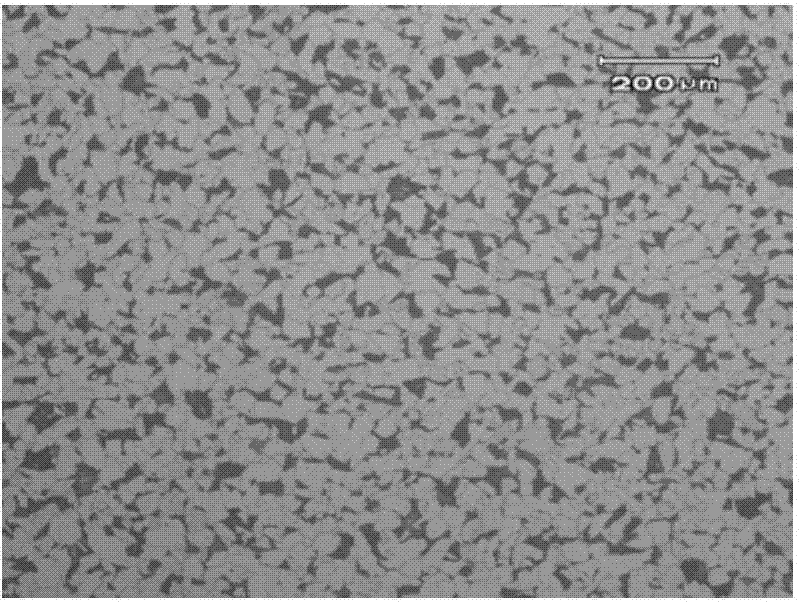

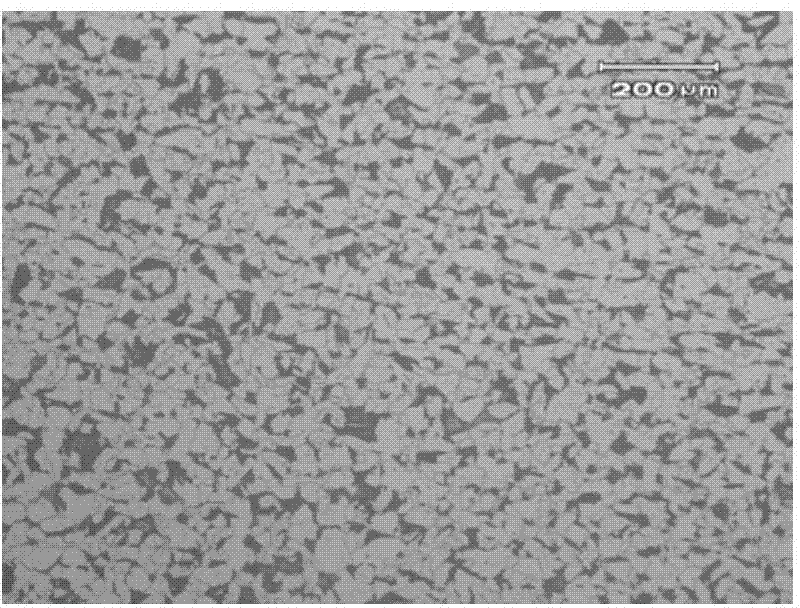

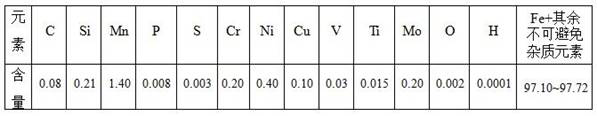

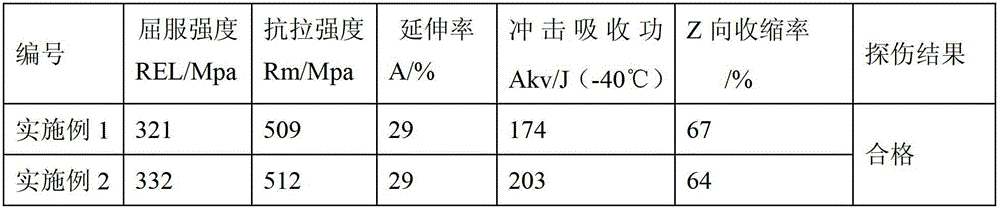

Manufacturing method for low-alloy super-thick steel plates with excellent low-temperature toughness

InactiveCN112322992AImprove low temperature toughnessAchieve Uniformity ControlElectron beam welding apparatusThick plateAlloy

The invention relates to a manufacturing method for low-alloy super-thick steel plates with excellent low-temperature toughness. The method comprises the steps of raw material blank preparation, blankcutting, milling and cleaning, vacuum girth welding compounding, blank heating and rolling, super-thick steel plate heat treatment and the like. The thickness of one obtained extra-thick steel plateranges from 100 millimeters to 260 millimeters, the obtained super-thick steel plate has the yield strength ReH of 325MPa or above, the tensile strength Rm of 450MPa or above, the elongation of 21% orabove, the minus 20 DEG C side knock absorbed energy KV2 of 120J or above, the minus 40 DEG C side knock absorbed energy of 100J or above, and the minus 60 DEG C side knock absorbed energy of 60J orabove. The manufacturing method for the low-alloy super-thick steel plates with excellent low-temperature toughness has the advantages of being stable in raw material source, flexible in production organization, high in efficiency, high in yield, low in energy consumption, environmentally friendly and the like, and compared with a continuous casting billet direct rolling super-thick plate process,the investment cost of an expensive large-section continuous casting machine can be saved.

Owner:SD STEEL RIZHAO CO LTD

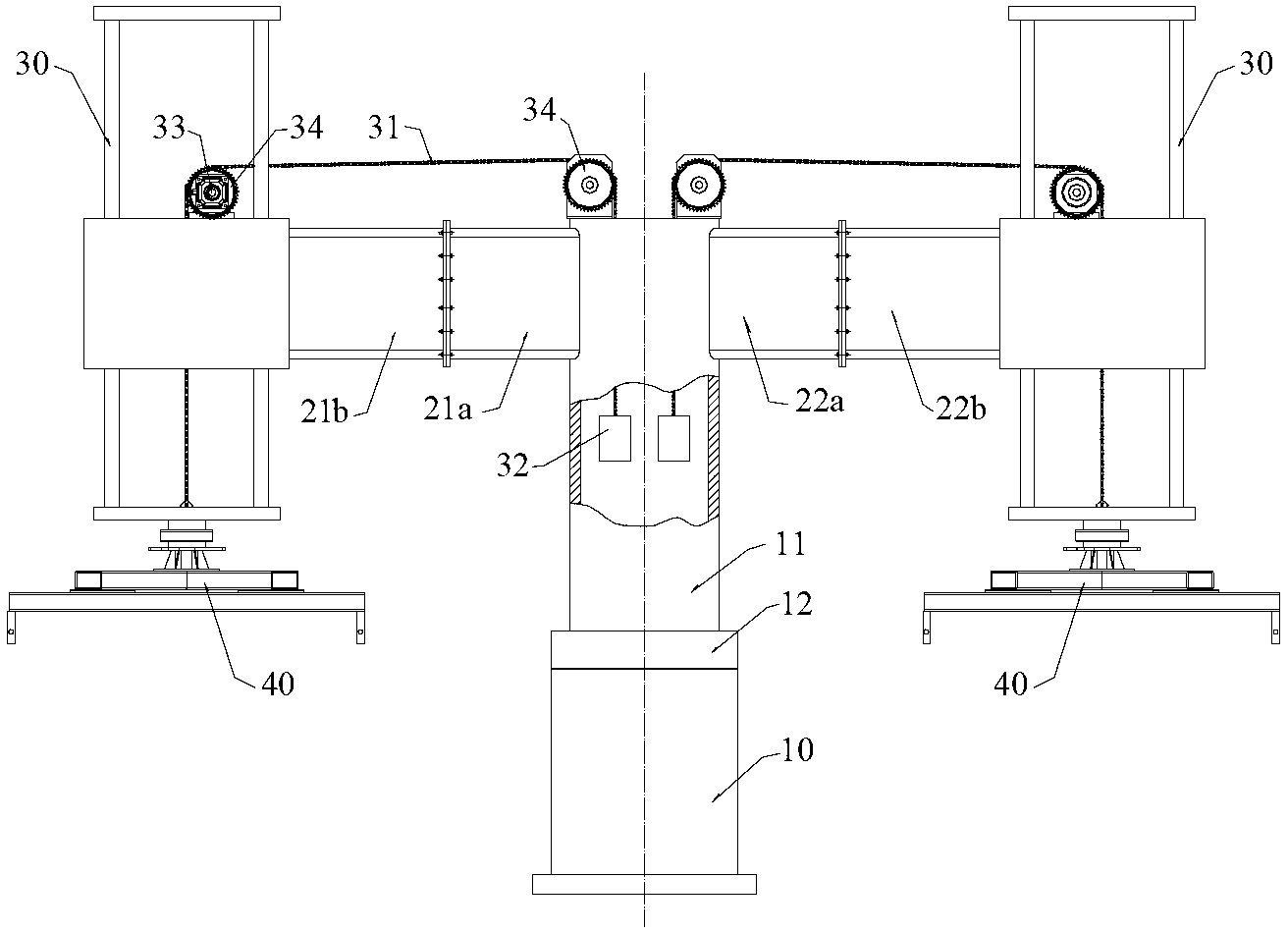

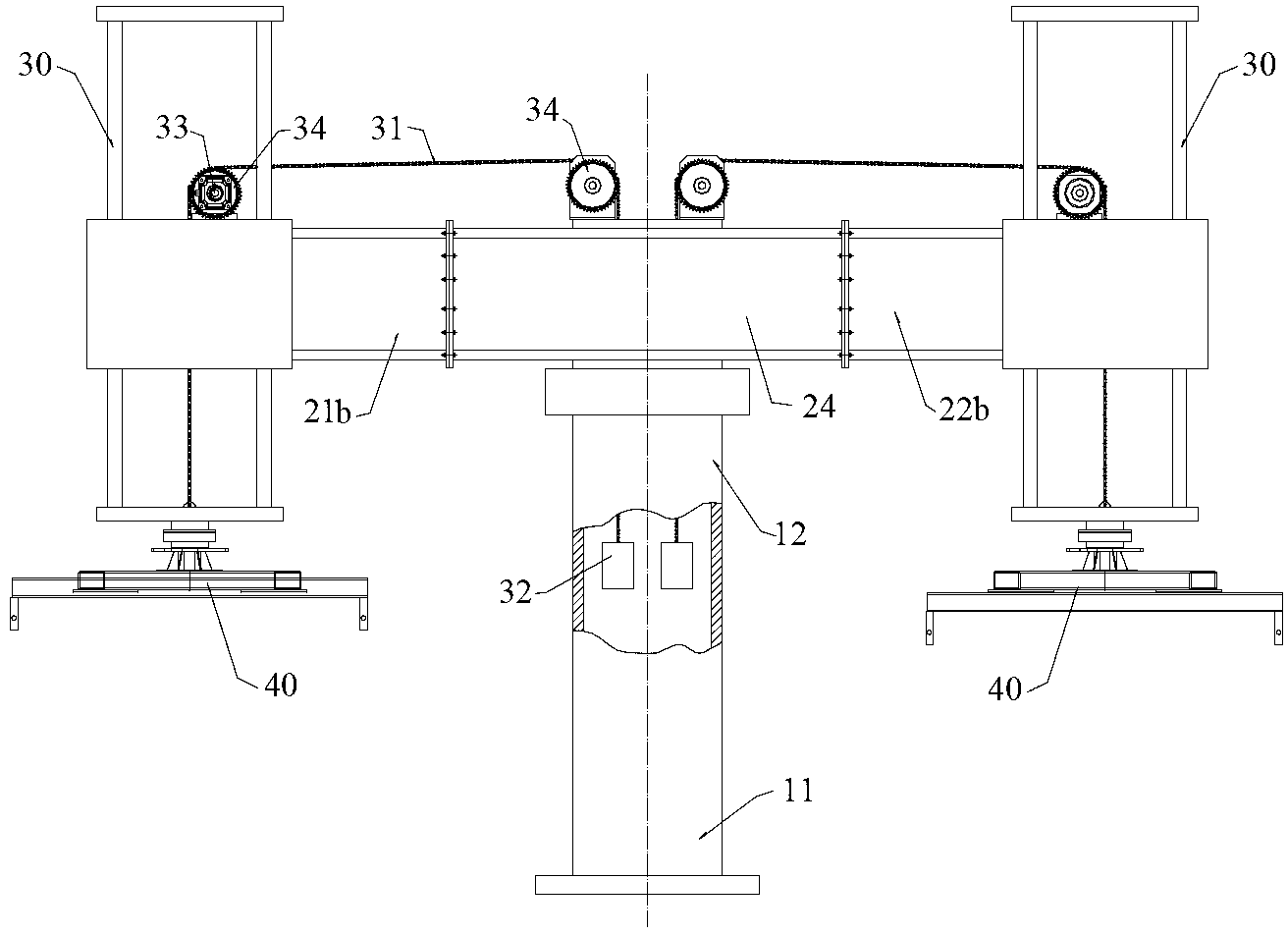

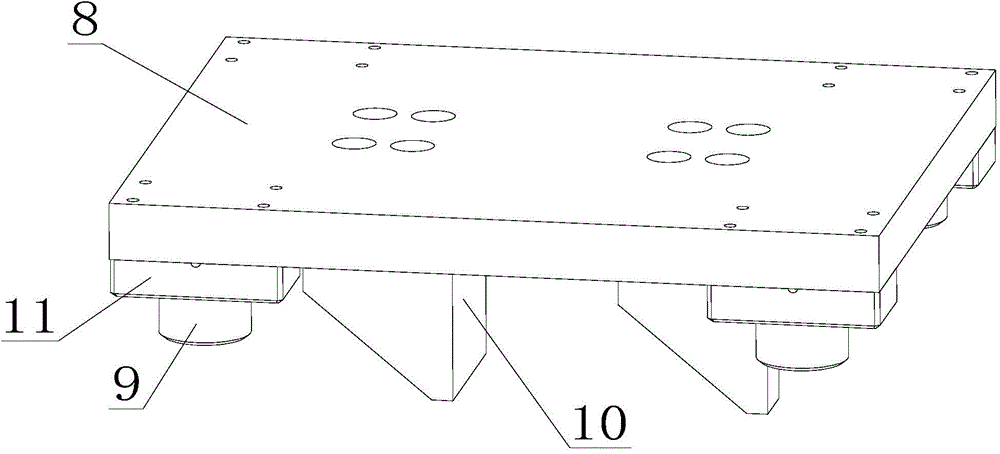

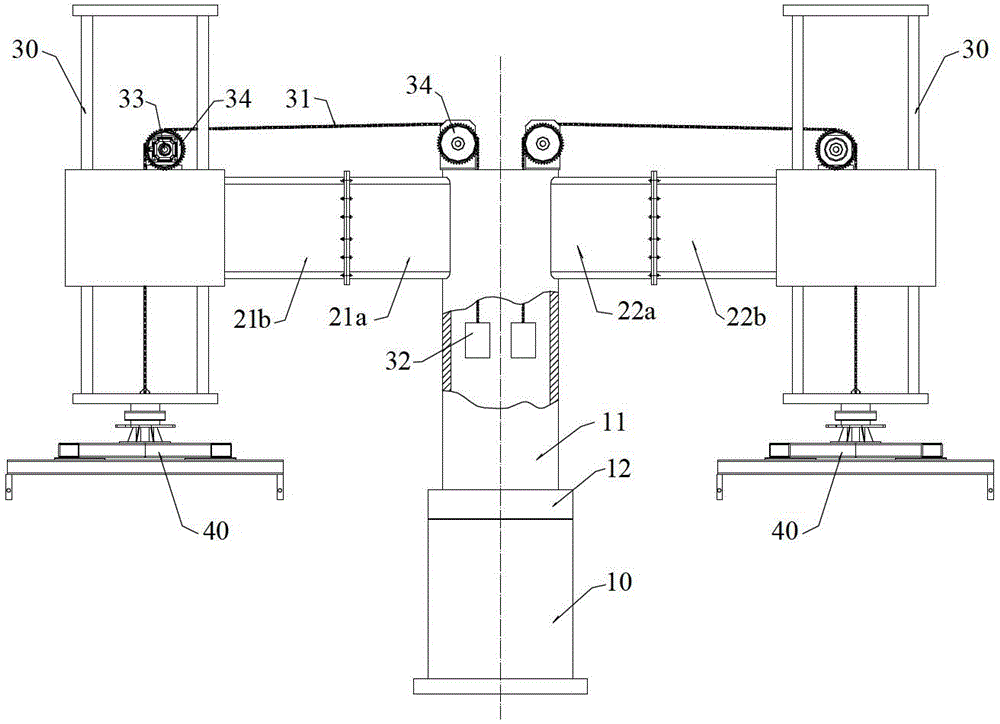

Tower rotating multi-arm full-automatic setting machine

ActiveCN103241556AFast transferSimple structureStacking articlesDe-stacking articlesEngineeringTower

The invention discloses a tower rotating multi-arm full-automatic setting machine to greatly improve setting efficiency, simplify structure and decrease occupied floor area. The tower rotating multi-arm full-automatic setting machine comprises a rotatable vertical column device, at least one rotating arm device, corresponding lifting devices and chuck systems, the rotating arm devices are fixedly connected to the top end of the rotatable vertical column device and are circumferentially symmetric, the lifting devices are arranged at two ends of each rotating arm device, and the chuck systems are fixedly mounted on the lifting devices.

Owner:ZIYANG JINGGONG MECHANICS

A fluidized residence conversion device and conversion method for producing α-alumina

ActiveCN104692432BControl dwell timeGuaranteed uniformityAluminium oxides/hydroxidesResidencePulp and paper industry

Te invention belongs to the technical field of metallurgy, and particularly relates to a fluidization type stay reforming device and method for producing alpha-aluminum oxide. The device comprises a cylinder, wherein a top cover is arranged on the top of the cylinder, the lower portion of the cylinder is a cone body, the top cover is communicated with a feed inlet and an exhaust pipe, an inner port of the exhaust pipe is communicated with a valve element of a pressure regulating valve, the inner wall of the lower cone body of the cylinder and an air distributing plate are welded into a whole, a discharge outlet is formed in the middle of the air distributing plate, the discharge outlet is communicated with a feed inlet of a material level valve, an air distributor is installed on the air distributing plate, the upper portion of the air distributor penetrates through the cone body to enter the cylinder, the lower portion of the air distributor is communicated with an air chamber, and the bottom of the air chamber is communicated with an air inlet pipe. When the device works, 1300-1500 DEG C metallurgical aluminum oxide is fed into the cylinder via the top cover through the feed inlet, fluidizing air enters the air chamber through the air inlet pipe, and then alpha-aluminum oxide is discharged through a discharge outlet of the material level valve after crystal transfer is completed. Production processes are simplified, energy is saved by 60-80% compared with a rotary kiln, the fluidization technology is adopted to process powder materials, and product quality is good.

Owner:SHENYANG XINBO IND TECH

Technology for producing alloy aluminum inside aluminum cell

The invention discloses a technology for producing alloy aluminum inside an aluminum cell. In the aluminum electrolysis production process, a simple substance or a midbody or an alloy body of an alloying element A is added into molten aluminum in the aluminum cell in the mode of penetrating a dielectric layer, and meanwhile an oxide of an alloying element B is added into the molten aluminum in the mode of penetrating the dielectric layer, a simple substance of the alloying element is obtained from the oxide of the alloying element B under the reducing action of aluminum, the simple substance of the alloying element B and the simple substance or the midbody or the alloy body of the alloying element A are evenly dispersed into the molten aluminum at high temperature under the external magnetic stirring action, the molten aluminum is taken out for cooling to obtain alloy aluminum. According to the technology, the technical difficulties and technical defects in the prior art are overcome, melting in the large modern prebaking cell and melting in a self-baking cell can be achieved, stability and easy controllability of working of the cell are not affected, and high-quality alloy aluminum of various trademarks, varieties and batches can be organized and produced flexibly.

Owner:周俊和 +1

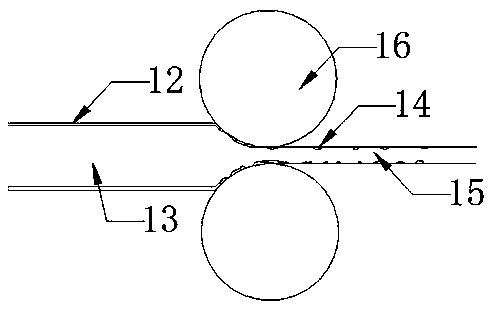

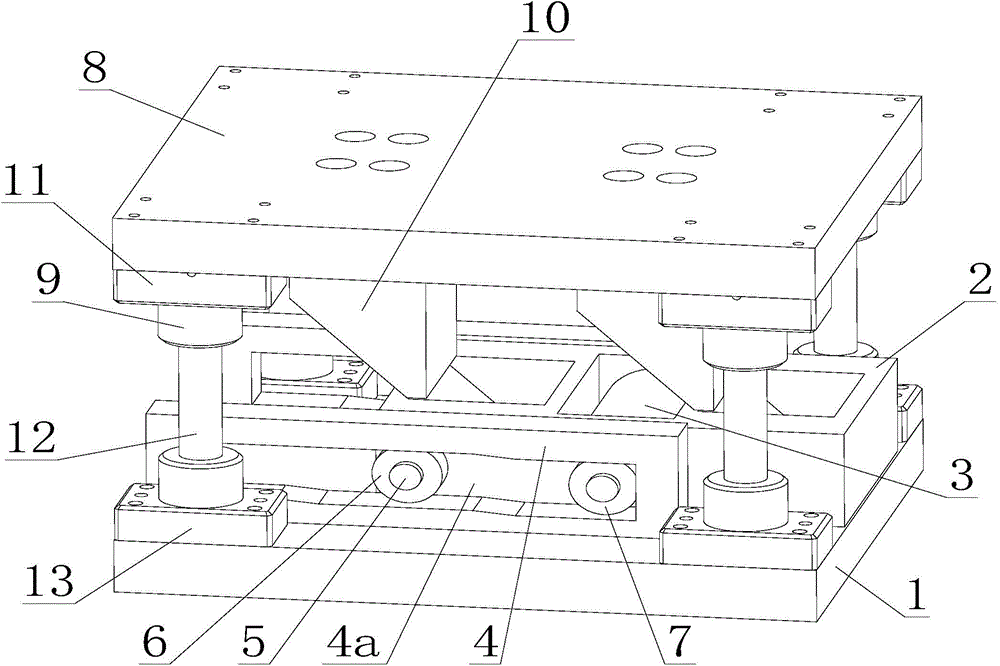

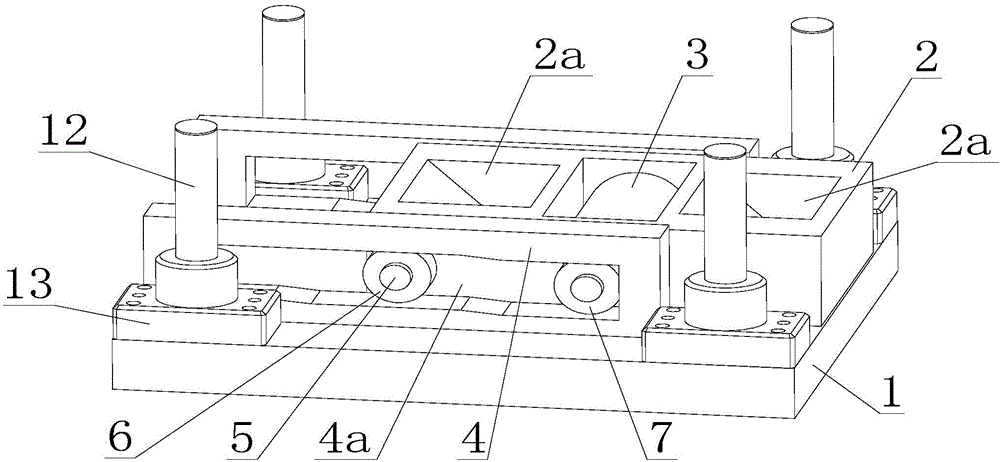

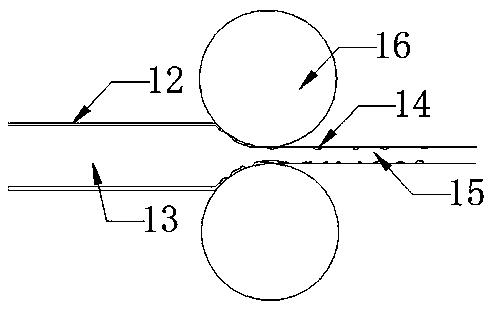

Rolling device of continuous differential thick plate

InactiveCN104889158ARealize profilingSimple structureMetal rolling stand detailsRoll mill control devicesThick plateEngineering

The invention discloses a rolling device of a continuous differential thick plate. The rolling device comprises a base, a rolling mechanism and a driving mechanism; the rolling mechanism is arranged on the base in a sliding mode; the driving mechanism is used for driving the rolling mechanism to move; the rolling mechanism comprises a sliding block, a roller and a guide plate; the roller is arranged in the sliding block in a rotatable mode; the guide plate is located on the outer side of the sliding block; the guide plate is detachably arranged on the base; a guide sliding groove is formed at the inner edge of the guide plate along the horizontal direction; the sliding block and the roller are connected with the guide sliding groove in a sliding mode. According to the rolling device of a continuous differential thick plate, the structure is simple, the profiling machining can be implemented, the versatility is high, the continuous differential thick plate with the transition contour which is a complex curve and the transition area which is a curved surface can be produced out according to the machining requirements, the adaptability is wide, the production organization is flexible, and the investment cost is low.

Owner:CHONGQING JIAOTONG UNIVERSITY

Solid solution treatment device of stainless steel plate

PendingCN111172376ALow investment costLess investmentFurnace typesHeat treatment furnacesSolution treatmentThick plate

The invention provides a solid solution treatment device of a stainless steel plate. The solid solution treatment device comprises a feeding mechanism, a hot rolling heating furnace, a discharging mechanism and a cooling water pool, the feeding mechanism can install the stainless steel plate into the hot rolling heating furnace, the hot rolling heating furnace can heat the stainless steel plate tothe solid solution temperature, and the discharging mechanism can take the stainless steel plate from the hot rolling heating furnace and transports the stainless steel plate to the cooling water pool for cooling to realize solid solution treatment of the stainless steel plate. According to the treatment device, the stainless steel plate is heated by a slab heating furnace in a hot rolling plant,through solid solution treatment technology that the heated stainless steel plate is cooled rapidly by the cooling pool, the stainless steel plate can be subjected to the solid solution treatment ina heating furnace area of a hot rolling workshop, the solid solution treatment device is especially suitable for the solution treatment of a thick plate of austenite stainless steel, the production process is simplified, and the production efficiency is improved.

Owner:广西北港新材料有限公司

A kind of large-thickness slab manufacturing process method

InactiveCN102764936BImprove welding efficiencyFully automatedWorkpiece edge portionsWelding apparatusEngineeringElectron bombardment

Owner:JIGANG GRP

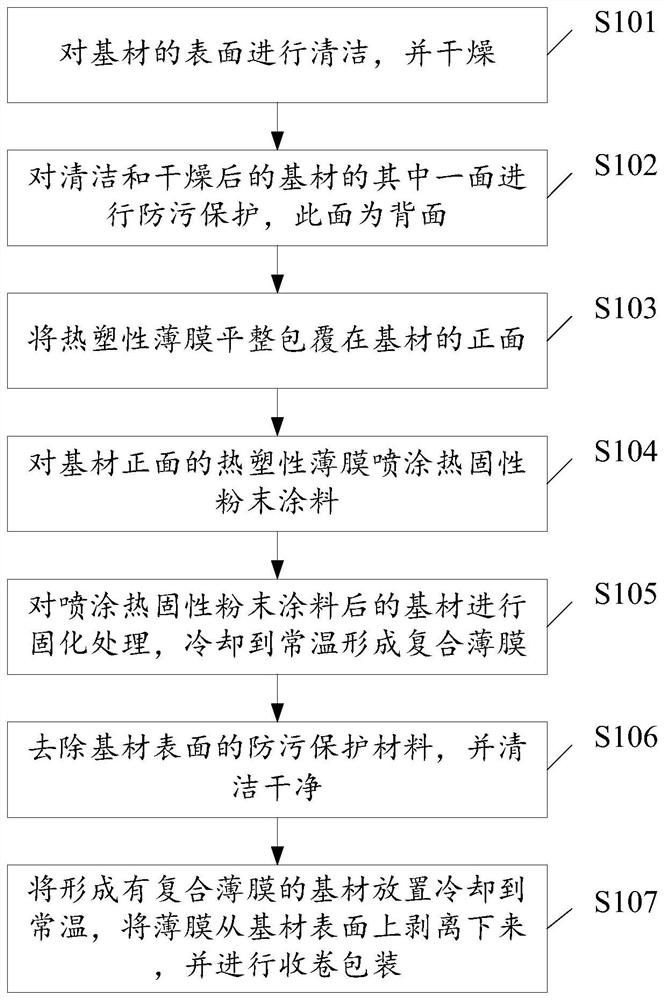

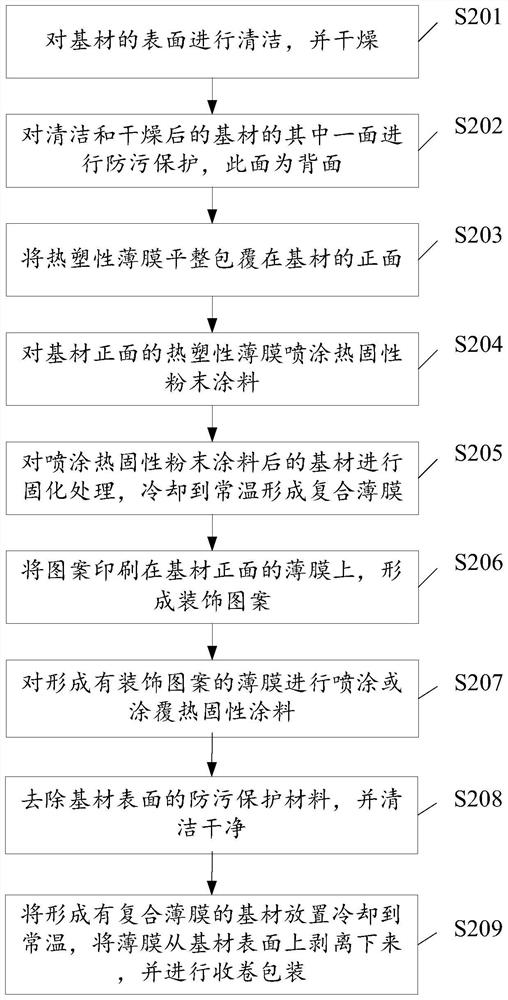

A kind of preparation method of polymer composite film

ActiveCN110408249BFlexible thickness adjustmentReduce manufacturing costAntifouling/underwater paintsPaints with biocidesPolymer scienceComposite film

The invention discloses a preparation method of a polymer composite film, comprising: (1) cleaning and drying the surface of a base material; (2) performing antifouling protection on one side of the cleaned and dried base material, the (3) wrap the thermoplastic film flatly on the front of the substrate; (4) spray the thermosetting powder coating on the thermoplastic film on the front of the substrate; (5) cure the substrate after spraying the thermosetting powder coating, Cool to normal temperature to form a composite film; (6) remove the antifouling protective material on the surface of the substrate and clean it; (7) place the substrate formed with the composite film to cool to normal temperature, peel the film off the surface of the substrate, And carry out winding packaging. The invention utilizes the paint-peelable film-making technology to prepare a single-layer or multi-layer composite film, the method is simple, the preparation cost of the composite film is greatly reduced, and the stripping process is simple, without using a release agent, an organic solvent and an acid-base solution.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

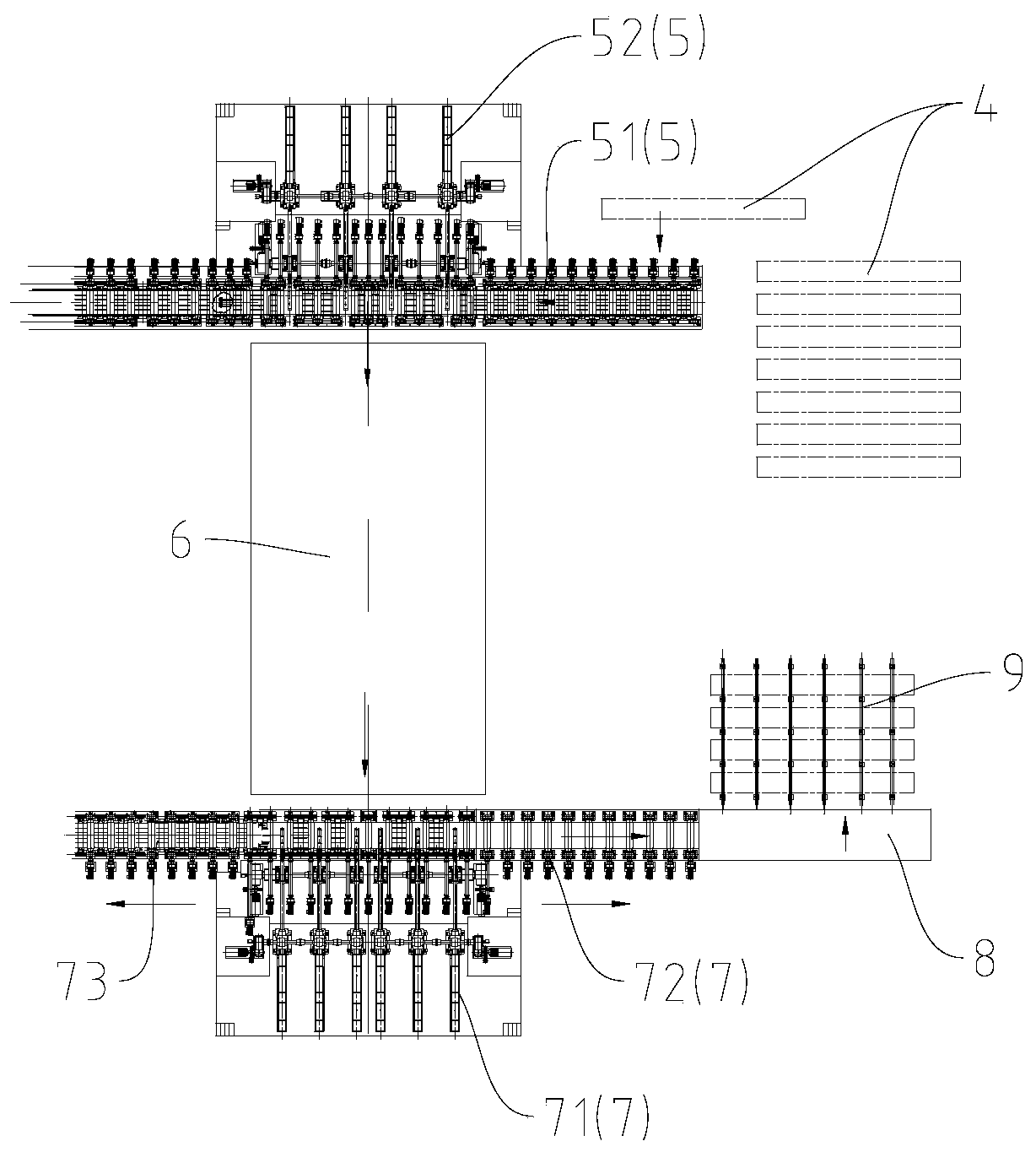

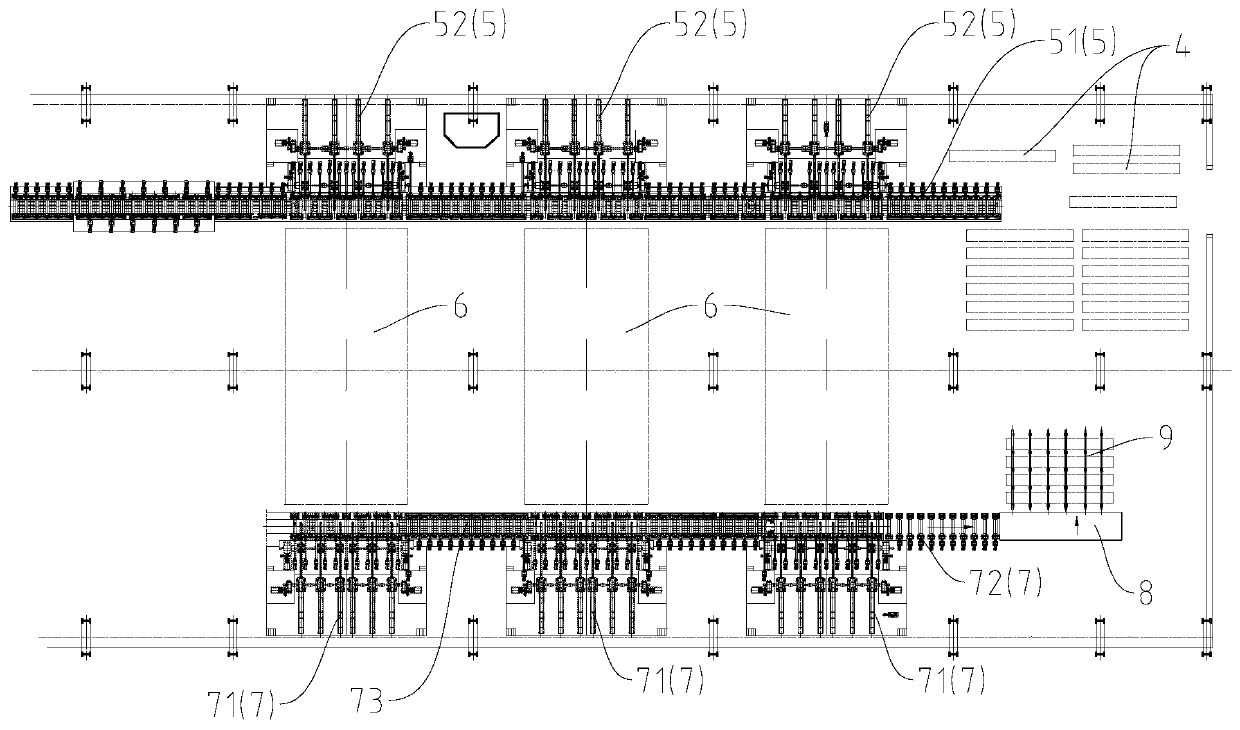

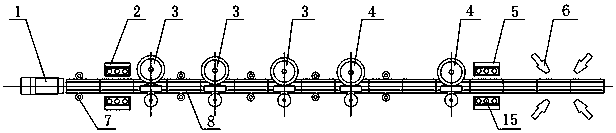

High-yield bar production system

PendingCN114260311AComprehensive investment is lowFlexible production organizationGuiding/positioning/aligning arrangementsWork treatment devicesBrakeProcess engineering

The invention belongs to the technical field of hot-rolled bars, and particularly relates to a high-yield bar production system which comprises a rough finish rolling area, an intermediate finish rolling area, a pre-finish rolling area and a high-speed area. The high-speed area comprises an A-line production channel, a B-line production channel and a C-line production channel; the A-line production channel comprises a water cooling unit, a first rolling mill set, a second rolling mill set and a double-length flying shear which are arranged in sequence; the B-line production channel and the C-line production channel each comprise a first flying shear, a third rolling mill set, a water cooling unit, a second flying shear, a fourth rolling mill set, a fifth rolling mill set, a pinch roll, a multiple-length shearing device, a pinch brake device and a rotating hub steel feeding device which are sequentially arranged. Production of all product specifications can be achieved on one production line, compared with a common bar production line, the functions of multiple production lines can be achieved only by adding a small amount of equipment in a high-speed area, and comprehensive investment is saved; and the production organization mode is more flexible, and the annual output can reach 2 million tons.

Owner:WISDRI ENG & RES INC LTD

Open type filter screen of continuous casting secondary cooling water zero section

PendingCN110755905AAvoid enteringAvoid cloggingStationary filtering element filtersThermodynamicsFiltration

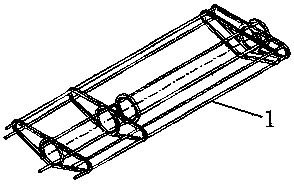

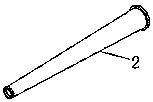

The invention relates to an open type filter screen of a continuous casting secondary cooling water zero section, and belongs to the technical field of continuous casting secondary cooling water zerosection filtering equipment in the metallurgical industry. According to the technical scheme, one end of a secondary cooling water zero section cooling pipeline (5) is connected with a water inlet pipe (6), the other end of the secondary cooling water zero section cooling pipeline (5) is provided with an end cover (7), and the secondary cooling water zero section cooling pipeline (5) is provided with multiple water outlet pipes (8) connected with water spray nozzles; a filter screen framework (1) is fixed in the zero section cooling pipeline (5); and a filter residue basket (3) and a leakage-proof fence (4) are fixed on the filter screen framework (1), one end of a water inlet filter screen pipe (2) is connected to the water inlet pipe (6) of the secondary cooling water zero section cooling pipeline (5), and the other end of the water inlet filter screen pipe (2) is connected with a connecting pipe (31) on the filter residue basket (3). The open type filter screen has the beneficial effects that supplied water filtration of the secondary cooling water zero section can be realized only by the water supply pressure, normal operation time of the secondary cooling water zero section isprolonged, and the workload of maintenance is reduced.

Owner:HANDAN IRON & STEEL GROUP +1

A kind of preparation method of polymer composite film

ActiveCN110408250BFlexible thickness adjustmentAdjustable thicknessAntifouling/underwater paintsPaints with biocidesPolymer scienceComposite film

The invention discloses a preparation method of a polymer composite film, comprising: (1) cleaning and drying the surface of a base material; (2) performing antifouling protection on one side of the base material; (3) cleaning the base material Spraying or coating thermosetting paint on the front; (4) curing the substrate to form a film; (5) printing the pattern on the film on the front of the substrate to form a decorative pattern; (6) removing the antifouling protective material and cleaning (7) leave the film for a preset time, and then peel off the film with the decorative pattern from the surface of the substrate; (8) protect the front side of the film and make it into a roll. In the present invention, single-layer or multi-layer composite films are prepared by using the paint strippable film-making technology. The method is simple, and the preparation cost of the composite film is greatly reduced. Moreover, the stripping process is simple, and no release agent, organic solvent and acid-base solution are used. The surface can achieve a specular highlight effect.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

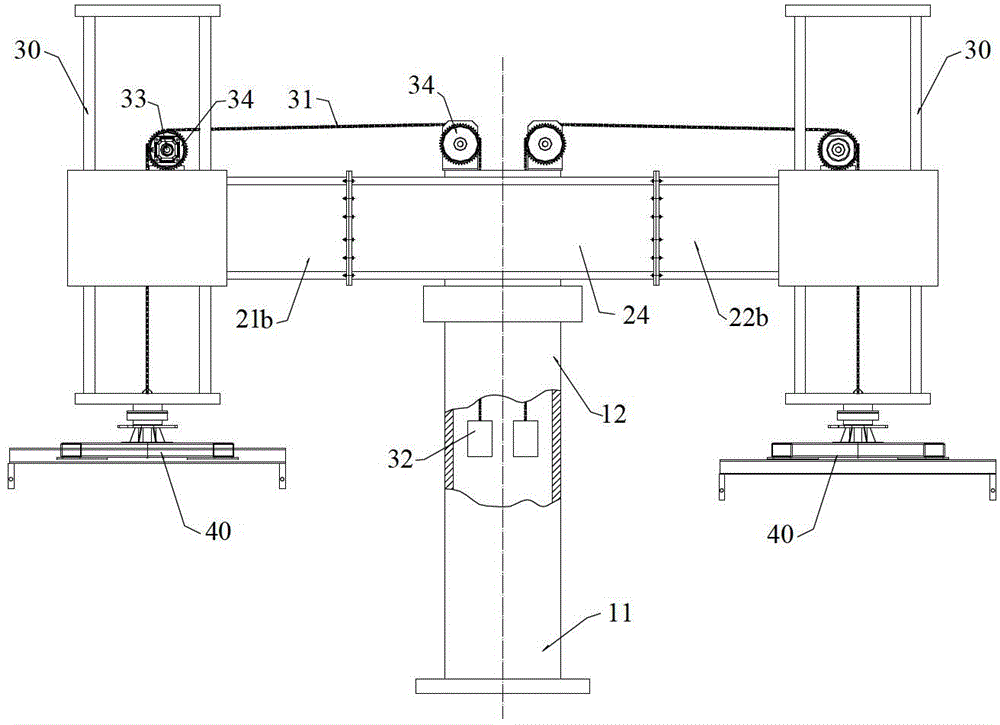

A rapid prototyping device for metal components

ActiveCN107267768BThe new manufacturing process has a short cycle timeDense tissueAdditive manufacturing apparatusElectricitySlag

The invention discloses a rapid metal component forming device, belonging to the technical field of metallurgy. The rapid metal component forming device comprises a power supply, a consumable electrode, a refiner and an additive manufacturing mechanism connected with a computer, wherein the additive manufacturing mechanism is used for 3D printing out the shell of a metal component on a bearing plate; the lower end of the refiner faces to the inner part of the shell of the metal component, and the refiner is filled with refining slag; the consumable electrode is positioned above the refiner, and the lower end of the consumable electrode extends into the refining slag in the refiner; one end of the power supply is connected with the consumable electrode, and the other end of the power supply is connected with the bearing plate. The rapid metal component forming device aims to overcome the defects of low efficiency and low quality of the current rapid forming technology during forming large-size structural components, combines the advantages of the rapid forming process and a special metallurgical technology, and can significantly improve the production efficiency and product quality of rapid forming of large-size metal components.

Owner:MAANSHAN SHANGYUAN METALLURGICAL TECH CO LTD

Method of using aod to desulfurize molten iron

ActiveCN106011380BWith the function of desulfurization outside the furnaceFlexible production organizationProcess efficiency improvementAlkalinitySulfur

The invention discloses a method for conducting molten iron desulphurization through AOD. The method technology includes the steps that oxygen blowing desulphurization is carried out through an AOD furnace in the manners of top blowing and side blowing at the same time, and the oxygen blowing quantity is calculated according to the terminal temperature ranging from 1380 DEG C to 1430 DEG C; lime is added while oxygen blowing is started, the adding quantity is calculated according to the alkalinity ranging from 1.7 to 1.9, and then fluorite and / or bauxite accounting for 20%-30% of the quantity of the lime are / is added; Si remaining after oxygen blowing is controlled to be larger than or equal to 0.1 weight percent; and oxygen supplying is stopped after the oxygen blowing quantity reaches a preset value, and meanwhile side blowing gas is changed into nitrogen for stirring and turning down. A metallurgy function of the AOD furnace is utilized in the method, thermodynamics and kinetics conditions of molten iron pre-desulfurization are met to the maximum degree, the sulfur element (not larger than 1000 ppm) in the molten iron can be reduced to be smaller than 20 ppm, and the desulphurization efficiency is 97% or higher and reaches or exceeds the level of a KR method.

Owner:XINGTAI IRON & STEEL

Tower rotary dobby automatic stacking machine

ActiveCN103241556BFast transferSimple structureStacking articlesDe-stacking articlesEngineeringTower

The invention discloses a tower rotating multi-arm full-automatic setting machine to greatly improve setting efficiency, simplify structure and decrease occupied floor area. The tower rotating multi-arm full-automatic setting machine comprises a rotatable vertical column device, at least one rotating arm device, corresponding lifting devices and chuck systems, the rotating arm devices are fixedly connected to the top end of the rotatable vertical column device and are circumferentially symmetric, the lifting devices are arranged at two ends of each rotating arm device, and the chuck systems are fixedly mounted on the lifting devices.

Owner:ZIYANG JINGGONG MECHANICS

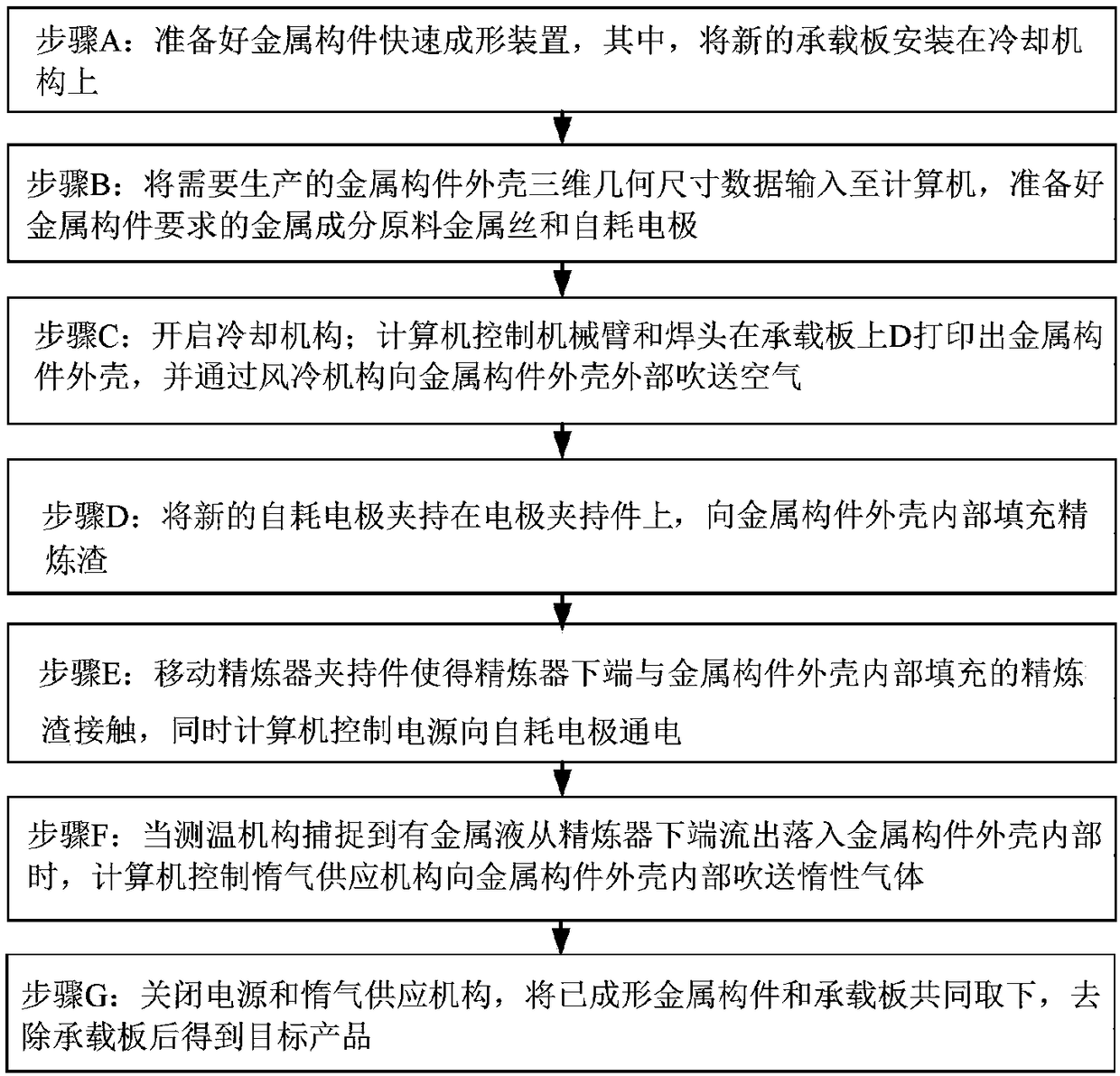

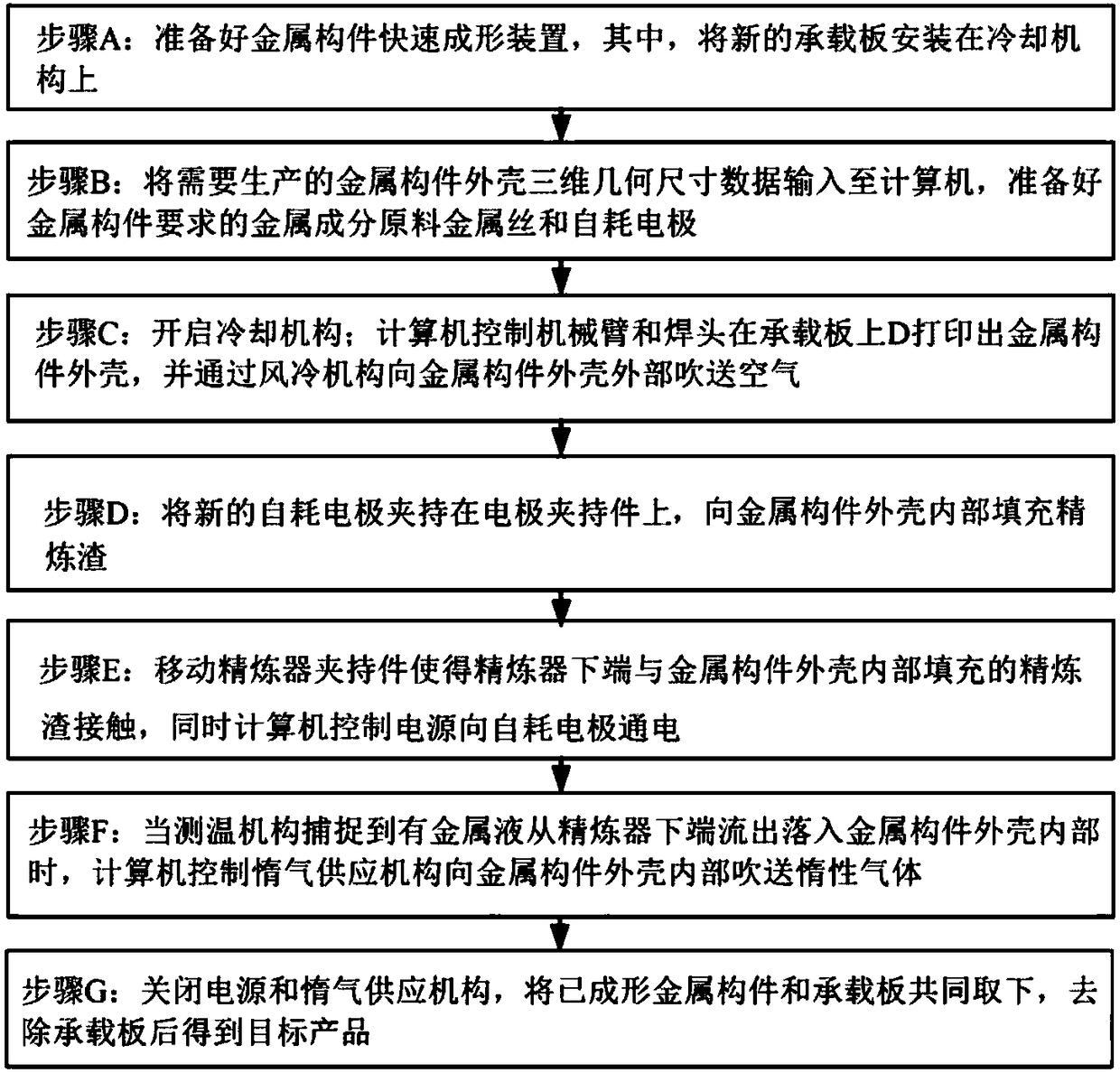

A method for rapid prototyping of metal components

ActiveCN107460335BThe new manufacturing process has a short cycle timeDense tissueAdditive manufacturing apparatusSlagRapid prototyping

The invention discloses a metal component quick forming method, and belongs to the technical field of metallurgy. The metal component quick forming method comprises the following steps: (A) a metal component quick forming device is prepared; (B) three-dimensional geometric size data of a metal component shell is input in a computer; (C) a mechanical arm and a welding head are used for 3D printing of the metal component shell on a bearing plate; (D) a new consumable electrode is clamped on an electrode clamping piece; and refining slag is filled in the metal component shell; (E) the consumable electrode is electrified; (F) inert gas is blown; and (G) a power supply and an inertia gas supply mechanism are closed. In order to overcome the defects of lower efficiency and lower quality in formation of large-size structural parts by a traditional quick forming technology, the invention provides the metal component quick forming method; and the advantages of the quick forming process and the special metallurgy process are combined to prominently improve the production efficiency of quick forming of large-size metal components and the product quality.

Owner:MAANSHAN SHANGYUAN METALLURGICAL TECH CO LTD

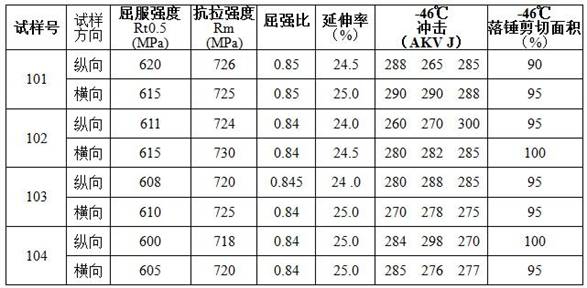

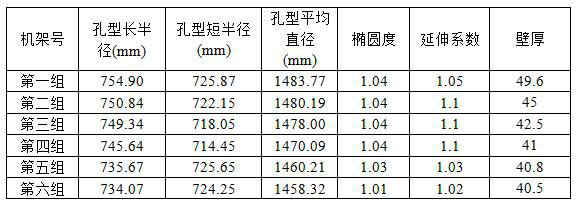

Production method of X80 large-diameter seamless steel pipe with diameter of 1422mm for oil and gas pipeline engineering

ActiveCN114558890ARapid coolingBig investmentRoll mill control devicesMetal rolling arrangementsPipeContinuous rolling

The invention discloses a production method of an X80 large-diameter seamless steel pipe with the diameter of 1422mm for oil and gas pipeline engineering, and relates to the technical field of seamless steel pipe manufacturing in the metallurgical industry, X80 steel is continuously cast to obtain a solid round pipe blank, the solid round pipe blank is punched after being heated to obtain a tubular billet, then the tubular billet is subjected to skew rolling expanding to obtain a pierced billet, and then the pierced billet is subjected to flattening continuous rolling, sizing, on-line controlled cooling, straightening, nondestructive inspection and fixed-length saw cutting; the diameter of the solid round tube blank is 1000 mm to 1200 mm; carrying out on-line thermal centering on the solid round tube blank between heating and perforating; the outer diameter of a hollow billet obtained after perforation is 1195 mm; the outer diameter of a pierced billet obtained after oblique rolling and expanding is 1526 mm; the outer diameter of the steel pipe obtained after flattening continuous rolling forming is 1484 mm; the outer diameter of the steel pipe after sizing is 1430 mm; and carrying out on-line controlled cooling on the sized steel pipe, and cooling to obtain the seamless steel pipe with the outer diameter of 1422mm and the wall thickness of 40.5 mm. The requirements for long distance, high pressure, large conveying capacity, low temperature resistance and safety of oil and gas pipelines are met.

Owner:YANGZHOU CHENGDE STEEL PIPE

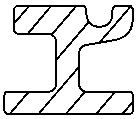

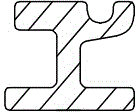

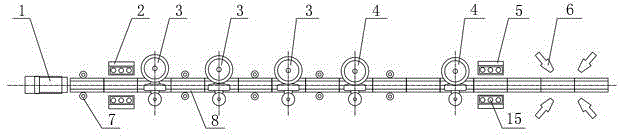

A kind of equipment and method of push-roll forming track

InactiveCN106270321BRealize the function of transmissionSimple structureMetal rolling arrangementsLight railEngineering

The invention discloses equipment and a method for pushing and rolling molding of a rail. The equipment comprises a thrust device 1, a heating device 2, roller devices 3, reshaping and straightening devices 4, a reheating device 5 and an atomizing and spraying device 6 which are arranged sequentially; and a guide component 7 is arranged on the equipment to guide movement of a steel blank 8. The metal pushing and rolling technology is as follows: at the state that metal reaches the rolling temperature through induction heating, the steel blank is pushed by the thrust device, is rolled, is subjected to reeling and is straightened by longitudinal columns of molds and is heated and subjected to spraying treatment to reach the light rail parameter requirements, the manner combines metal extrusion, rolling and online heat treatment, the investment is lower than that of a traditional manner, the production organization is flexible, the cost is relatively low, the technology is applicable to medium and small-sized enterprises, and other kinds of like profile steel can be produced with the rolling method and changed combination manners and structures of hole patterns.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Combined cylinder dyeing method and dyeing device

ActiveCN104178954BReduce dosageReduce the problem of cylinder difference phenomenonTextile treatment containersLiquid/gas/vapor yarns/filaments treatmentControl valvesVat dye

The invention discloses a cylinder dyeing method and a dyeing device thereof. The cylinder dyeing method comprises the following steps: placing cloth in a first cylinder and a second cylinder respectively, closing all outlets of the first cylinder, All the outlets of the second cylinder; pump dyeing solution into the first cylinder for dyeing, after dyeing, pump the dyeing solution in the first cylinder into the second cylinder for dyeing; after dyeing, put the dye in the second cylinder The dyeing solution is pumped into the first cylinder, and the cloth in the first cylinder is dyed, and the circulation is like this. The cylinder dyeing device comprises a first cylinder body and a second cylinder body, and a control valve is connected in series between the top of the first cylinder body and the top of the second cylinder body; the first cylinder body and the second cylinder body have A water inlet, a water outlet, and a control valve and a dyeing solution main pump are connected in series between the first cylinder and the second cylinder. The cylinder-connected dyeing device of the invention can not only ensure the dyeing quality of the product, but also improve the production efficiency and reduce the input cost at the same time.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

A thin slab continuous casting and rolling production line and its production process

ActiveCN109013701BAvoid major production accidentsAvoid pressing into the matrixMetal rolling arrangementsProduction lineLaminar cooling

The invention relates to a sheet billet continuous casting and rolling production line and a production process thereof, and belongs to the technical field of sheet billet continuous casting and rolling. According to the technical scheme, the sheet billet continuous casting and rolling production line comprises a continuous casting machine (1), a 1#pendulum shear (3-1), a 1#tunnel type heating furnace (9-1), a 1#descaler (7-1), a roughing mill group (10), a 2#pendulum shear (3-2), a billet picking device (4), a 2#tunnel type heating furnace (9-2), a 2#descaler (7-2), a finishing mill group (11), a laminar cooling (18), a flying shear (19) and a reeling-up machine set (20) which are arranged in sequence according to a rolling sequence. When the continuous casting speed of the continuous casting machine (1) is less than 5m / min, single block rolling or semi-endless rolling is adopted; and when the continuous casting speed of the continuous casting machine (1) is greater than or equal to 5m / min, endless rolling is adopted. The sheet billet continuous casting and rolling production line and the production process thereof have the beneficial effects that the temperature uniformity and the surface quality of a casting blank can be ensured, and different rolling modes can be adopted according to the continuous casting speed of the continuous casting machine.

Owner:唐山全丰薄板有限公司

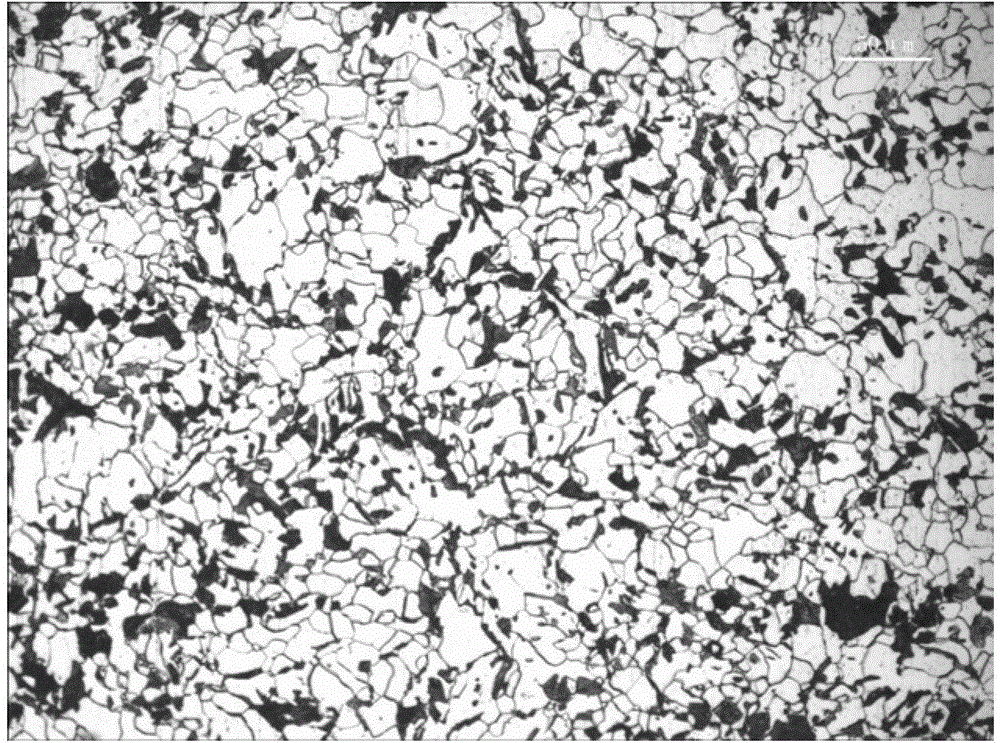

Manufacturing technique of 150-300mm thick low-alloy high-strength steel plate

InactiveCN102764959BImprove welding efficiencyFully automatedWorkpiece edge portionsWelding apparatusAbsorbed energyElectron bombardment

The invention discloses a manufacturing technique of a 150-300mm thick low-alloy high-strength steel plate. The chemical components of the used continuous casting slabs are as follows: 0.14-0.20% of C, 0.20-0.50% of Si, 1.10-1.60% of Mn, equal to or less than 0.010% of S and equal to or less than 0.20% of micro-alloyed elements; and at least two continuous casting slabs are provided with grooves, overlapped and welded into a big-thickness continuous casting blank by using a combined welding technique of gas shielded welding, submerged-arc welding and electron-bombardment welding, and then, the blank is arranged in a bogie-type furnace or a soaking pit furnace for heating, rolled by a thick plate rolling machine after being discharged from the furnace, cooled under control and subjected to heat treatment so as to obtain the steel plate. The produced low-alloy high-strength steel plate has the following characteristics that the comprehensive mechanical properties are excellent, the inspection qualified rate is higher than 98%, the Q345E level steel plate low-temperature (-40) DEG C impact absorbing energy is more than 160J averagely, the Z-direction tensile section shrinkage factor is more than 60%, and the blank yield is higher than 88%.

Owner:JIGANG GRP

Equipment and method for pushing and rolling molding of rail

The invention discloses equipment and a method for pushing and rolling molding of a rail. The equipment comprises a thrust device 1, a heating device 2, roller devices 3, reshaping and straightening devices 4, a reheating device 5 and an atomizing and spraying device 6 which are arranged sequentially; and a guide component 7 is arranged on the equipment to guide movement of a steel blank 8. The metal pushing and rolling technology is as follows: at the state that metal reaches the rolling temperature through induction heating, the steel blank is pushed by the thrust device, is rolled, is subjected to reeling and is straightened by longitudinal columns of molds and is heated and subjected to spraying treatment to reach the light rail parameter requirements, the manner combines metal extrusion, rolling and online heat treatment, the investment is lower than that of a traditional manner, the production organization is flexible, the cost is relatively low, the technology is applicable to medium and small-sized enterprises, and other kinds of like profile steel can be produced with the rolling method and changed combination manners and structures of hole patterns.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Method for conducting molten iron desulphurization through AOD

ActiveCN106011380AWith the function of desulfurization outside the furnaceFlexible production organizationProcess efficiency improvementAlkalinitySulfur

The invention discloses a method for conducting molten iron desulphurization through AOD. The method technology includes the steps that oxygen blowing desulphurization is carried out through an AOD furnace in the manners of top blowing and side blowing at the same time, and the oxygen blowing quantity is calculated according to the terminal temperature ranging from 1380 DEG C to 1430 DEG C; lime is added while oxygen blowing is started, the adding quantity is calculated according to the alkalinity ranging from 1.7 to 1.9, and then fluorite and / or bauxite accounting for 20%-30% of the quantity of the lime are / is added; Si remaining after oxygen blowing is controlled to be larger than or equal to 0.1 weight percent; and oxygen supplying is stopped after the oxygen blowing quantity reaches a preset value, and meanwhile side blowing gas is changed into nitrogen for stirring and turning down. A metallurgy function of the AOD furnace is utilized in the method, thermodynamics and kinetics conditions of molten iron pre-desulfurization are met to the maximum degree, the sulfur element (not larger than 1000 ppm) in the molten iron can be reduced to be smaller than 20 ppm, and the desulphurization efficiency is 97% or higher and reaches or exceeds the level of a KR method.

Owner:XINGTAI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com