Production method of X80 large-diameter seamless steel pipe with diameter of 1422mm for oil and gas pipeline engineering

A technology of oil and gas pipelines and seamless steel pipes, which is applied in the field of seamless steel pipe manufacturing, can solve problems such as high efficiency, low consumption, and high-quality production requirements, and achieves avoiding side effects of heating pre-oxidation, avoiding sharp surface of knife holes, and uniform longitudinal deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

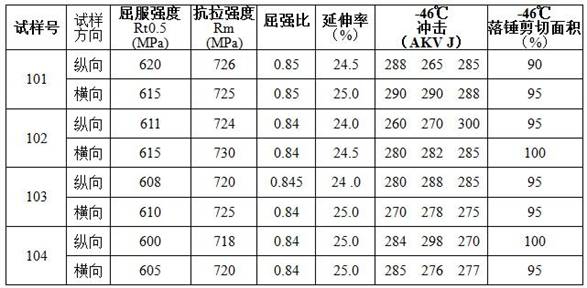

Examples

Embodiment 1

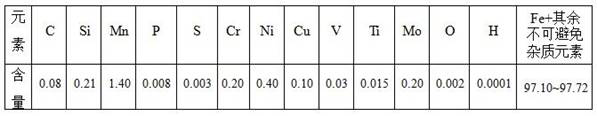

[0032] 1. Composition of X80 steel

[0033] The molten steel after refining is analyzed for composition, and the content of each element is shown in Table 1.

[0034] Table 1 Chemical composition table (unit: wt%)

[0035]

[0036] 2. Production process of continuous casting round tube billet with an outer diameter of 1100mm:

[0037] The refined molten steel was continuously cast into a solid continuous casting round tube billet with an outer diameter of 1100 mm.

[0038] The continuous casting process goes through tundish electromagnetic stirring, secondary electromagnetic stirring and terminal electromagnetic stirring in sequence.

[0039] The pulling speed is 0.10 m / min.

[0040] The length of the central crack is less than or equal to 120mm.

[0041] The depth of surface cracks, pits and flat areas is less than or equal to 20mm.

[0042] The bending degree of the tube blank per meter is ≤10mm, and the total bending degree is not more than 0.6% of the total length....

Embodiment 2

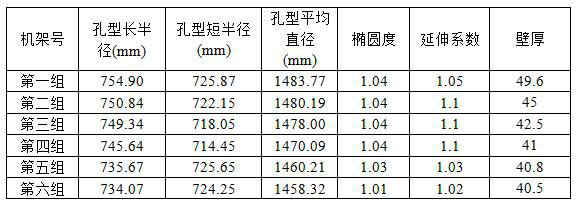

[0066] Six groups of stand rolls are used in uniform continuous rolling. The rolling parameters and die dimensions of the six groups of stand rolls are shown in the table below:

[0067]

[0068] The rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com