Suspension roasting device and technology for producing multiform aluminum oxide

A technology of suspension roasting and alumina, which is applied in the field of metallurgy, can solve problems such as unstable product quality, high energy consumption for operation, and small production capacity of a single machine, and achieve the effects of convenient and flexible production organization, saving construction investment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

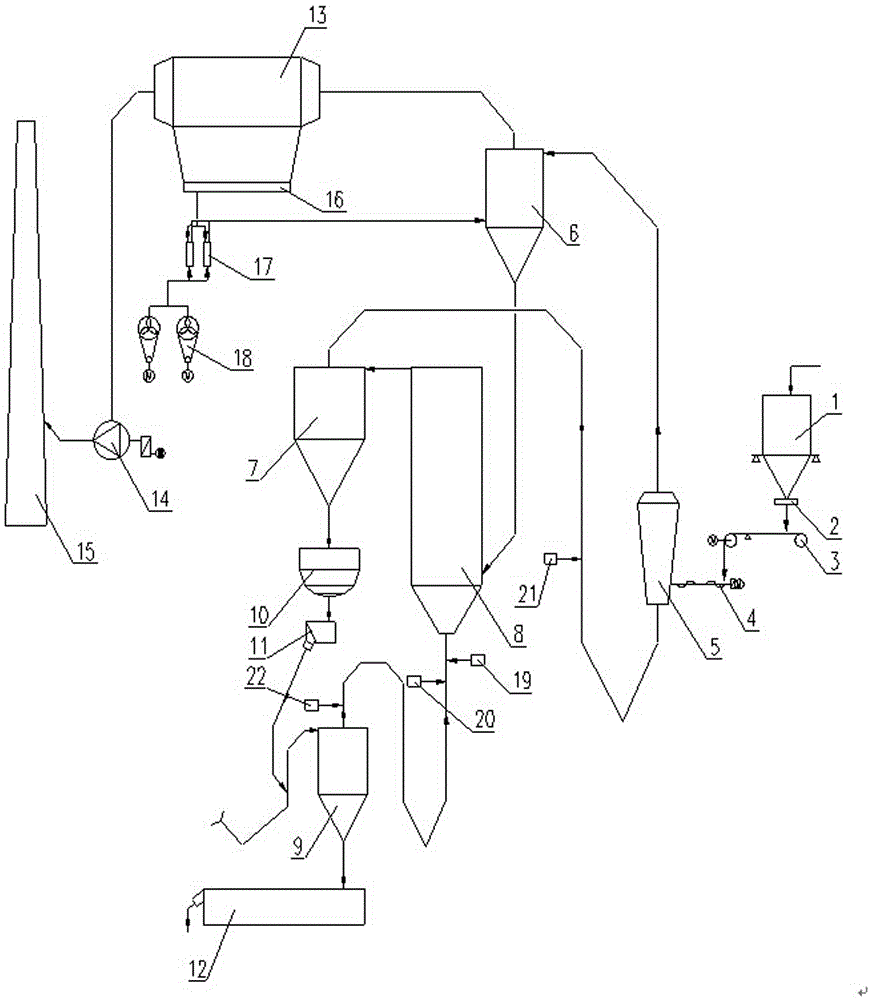

[0043] The structure of the suspension roasting device for producing multi-variety alumina in the embodiment of the present invention is as follows: figure 1 shown;

[0044] It consists of a feeding system, a roasting system, a crystallization separation system and a cyclone dust removal system; wherein the feeding system includes a quantitative feeder 3, a screw feeder 4 and a dryer 5; the roasting system includes a cyclone preheating Device 6, roasting furnace 8 and combustion station 19 ~ 22; Described crystallization separation system comprises cyclone separator 7, crystallizer 10, controllable material level valve 11, cyclone cooler 9 and dry cooler 12; Described cyclone Dust removal system comprises dust remover 13, induced draft fan 14 and chimney 15;

[0045] The quantitative feeder 3 feeds the screw feeder 4, the discharge port of the screw feeder 4 is connected with the drier 5, the discharge port of the drier 5 is connected with the feed end of the cyclone preheate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com