A thin slab continuous casting and rolling production line and its production process

A thin slab continuous casting and production process technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems affecting the surface quality of strip steel, achieve good heating and temperature control capabilities, and ensure furnace temperature and temperature uniformity, flexible production organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

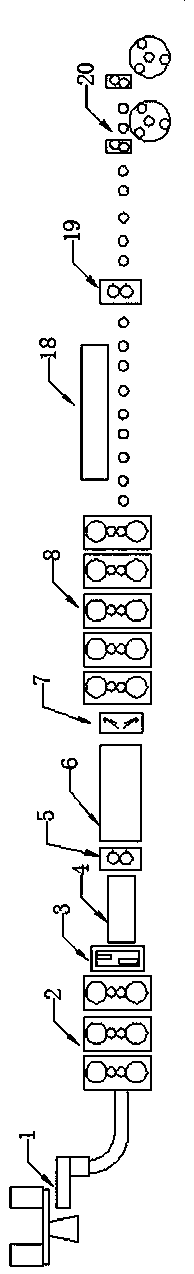

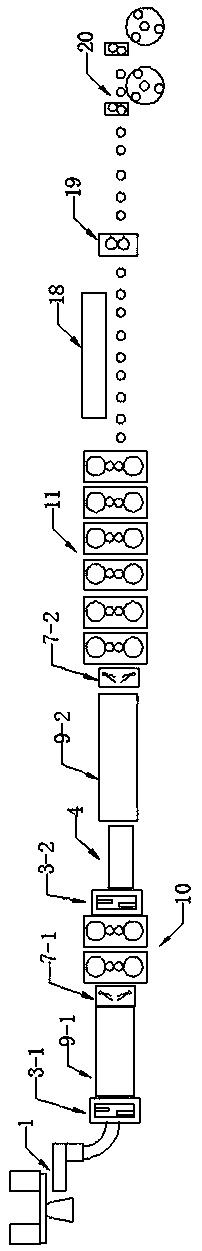

[0032] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0033] Refer to attached image 3 , 4, a thin slab continuous casting and rolling production line, including continuous casting machine 1, 1# pendulum shear 3-1, 1# tunnel heating furnace 9-1, 1# descaling machine 7-1, rough rolling unit 10, 2 # pendulum shear 3-2, billet removal device 4, 2# tunnel heating furnace 9-2, 2# descaler 7-2, finishing rolling unit 11, laminar cooling 18, flying shear 19 and coiling unit 20, The continuous casting machine 1, 1# pendulum shear 3-1, 1# tunnel heating furnace 9-1, 1# descaler 7-1, rough rolling unit 10, 2# pendulum shear 3-2, billet removal device 4. 2# tunnel heating furnace 9-2, 2# descaling machine 7-2, finishing rolling unit 11, laminar flow cooling 18, flying shear 19 and coiling unit 20 are arranged in sequence according to the rolling sequence.

[0034] In this embodiment, the rough rolling unit 10 is two cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com