Steel ladle sliding nozzle oil cylinder and steel ladle nozzle control device

A sliding nozzle and control device technology, applied in fluid pressure actuation devices, manufacturing tools, fluid pressure actuation system safety, etc., can solve the problem of burns to site workers, burning of continuous casting equipment, ladle nozzles that cannot be opened or closed Housing and other issues to ensure safety and eliminate hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

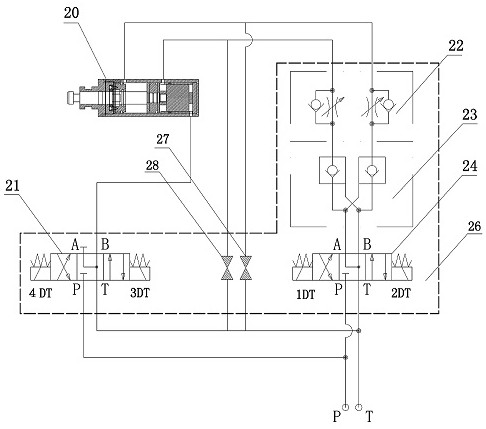

[0021] The invention provides a ladle sliding nozzle oil cylinder and a ladle nozzle control device, which can reliably close the ladle sliding nozzle when the ladle sliding nozzle oil cylinder leaks, prevent burning of continuous casting equipment and on-site staff, and improve the stability of continuous casting equipment in steelmaking plants performance, reliability, and security.

[0022] see figure 1 with figure 2 , the ladle sliding nozzle control device of the present invention includes a ladle sliding nozzle cylinder 20, an emergency reversing valve 21, a one-way throttle valve 22, a hydraulic control one-way valve 23, a main reversing valve 24, an integrated block 26, a first high-pressure ball valve 27 and the second high pressure ball valve 28.

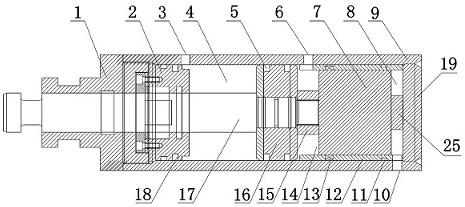

[0023] Ladle sliding nozzle oil cylinder 20 mainly includes front end cover 1, piston rod guide sleeve 2, front cavity oil port 3, front cavity 4, piston seal 5, middle cavity oil port 6, plunger 7, rear cavity 8, cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com