Preparation method of anisotropic lanthanum calcium manganese oxygen-based ceramic target

A lanthanum calcium manganese oxide and anisotropic technology, which is applied in the field of preparation of anisotropic lanthanum calcium manganese oxide ceramic targets, can solve the problems of low doping ratio, inability to enter effectively, loss of doping amount, etc., and achieve improved Effect of doping, elimination of defect structure, effect of strengthening anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

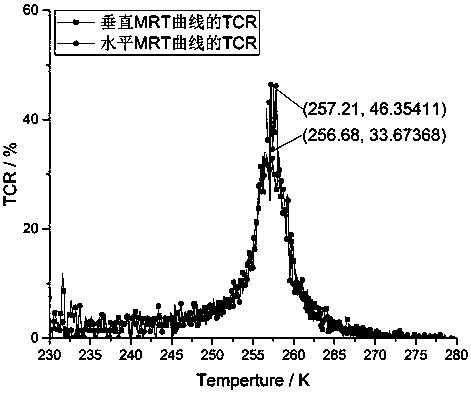

Embodiment 1

[0035] A strong anisotropy (La 0.7 Ca 0.3 MnO 3 )·Ag 0.2 The preparation process of the ceramic target specifically comprises the following steps:

[0036] (1) Sol process: pour lanthanum nitrate, calcium nitrate, manganese nitrate and citric acid into the mixing container according to the mass ratio of 6:1:6:19, use methanol as the mixed solvent carrier, use ethylene glycol as the dispersant, mix to obtain transition I.

[0037] (2) Gel process: place the transition material I obtained in step (1) in an environment of 80°C for drying to obtain the transition material II.

[0038] (3) Dry glue process: Place the transition material II obtained in step (2) in an environment of 120°C for dehydration and foaming to obtain the transition material III.

[0039] (4) Primary crushing process: the transition material III obtained in step (3) is pulverized by a ball mill to obtain transition material IV (particle size less than 0.1 mm).

[0040] (5) Primary calcination process: T...

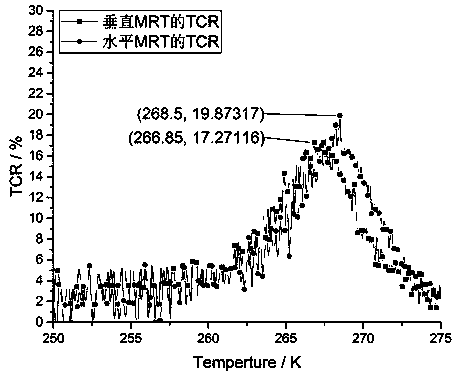

Embodiment 2

[0050] A strong anisotropy (La 0.7 Ca 0.3 MnO 3 )·Ag 0.2 The preparation process of the ceramic target specifically comprises the following steps:

[0051] (1) Sol process: pour lanthanum nitrate, calcium nitrate, manganese nitrate and citric acid into the mixing container according to the mass ratio of 6:1:6:19, use methanol as the mixed solvent carrier, use ethylene glycol as the dispersant, mix to obtain transition I.

[0052] (2) Gel process: The transition material I obtained in step (1) was placed in a 75°C environment for drying to obtain the transition material II.

[0053] (3) Dry glue process: Place the transition material II obtained in step (2) in an environment of 110°C for dehydration and foaming to obtain the transition material III.

[0054] (4) Primary crushing process: the transition material III obtained in step (3) is pulverized by a ball mill to obtain transition material IV (particle size less than 0.1 mm).

[0055] (5) Primary calcination process: ...

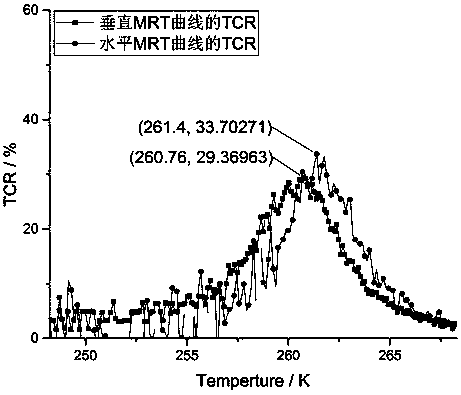

Embodiment 3

[0065] A strong anisotropy (La 0.7 Ca 0.3 MnO 3 )·Ag 0.2 The preparation process of the ceramic target specifically comprises the following steps:

[0066] (1) Sol process: pour lanthanum nitrate, calcium nitrate, manganese nitrate and citric acid into the mixing container according to the mass ratio of 6:1:6:19, use methanol as the mixed solvent carrier, use ethylene glycol as the dispersant, mix to obtain transition I.

[0067] (2) Gel process: The transition material I obtained in step (1) was placed in an environment of 90°C for drying to obtain the transition material II.

[0068] (3) Dry glue process: Place the transition material II obtained in step (2) in an environment of 130°C for dehydration and foaming to obtain the transition material III.

[0069] (4) Primary crushing process: the transition material III obtained in step (3) is pulverized by a ball mill to obtain transition material IV (particle size less than 0.1 mm).

[0070] (5) Primary calcination proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com