Method for forming polycrystalline structure welding spot by prefabricating IMC bonding pad

A technology of polycrystalline structure and pads, which is applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of reducing the service life and failure of electronic products, and achieve the reduction of unfavorable grain orientation, controllable solder joint size, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

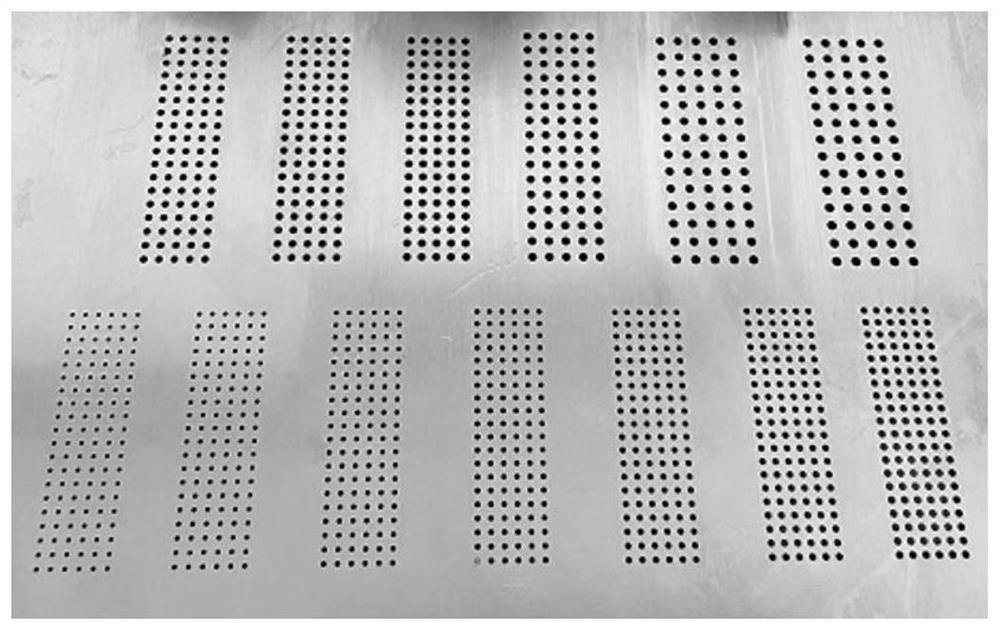

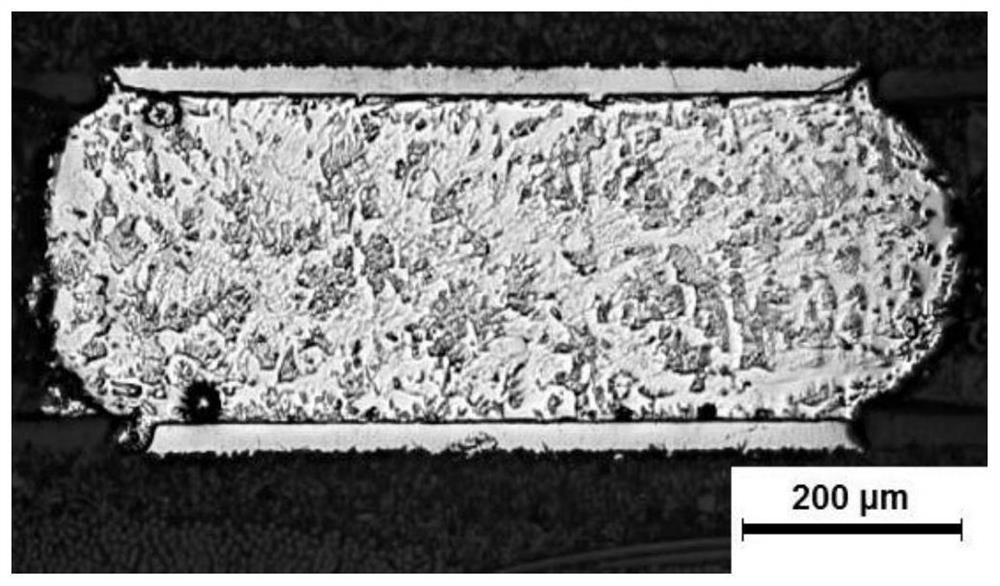

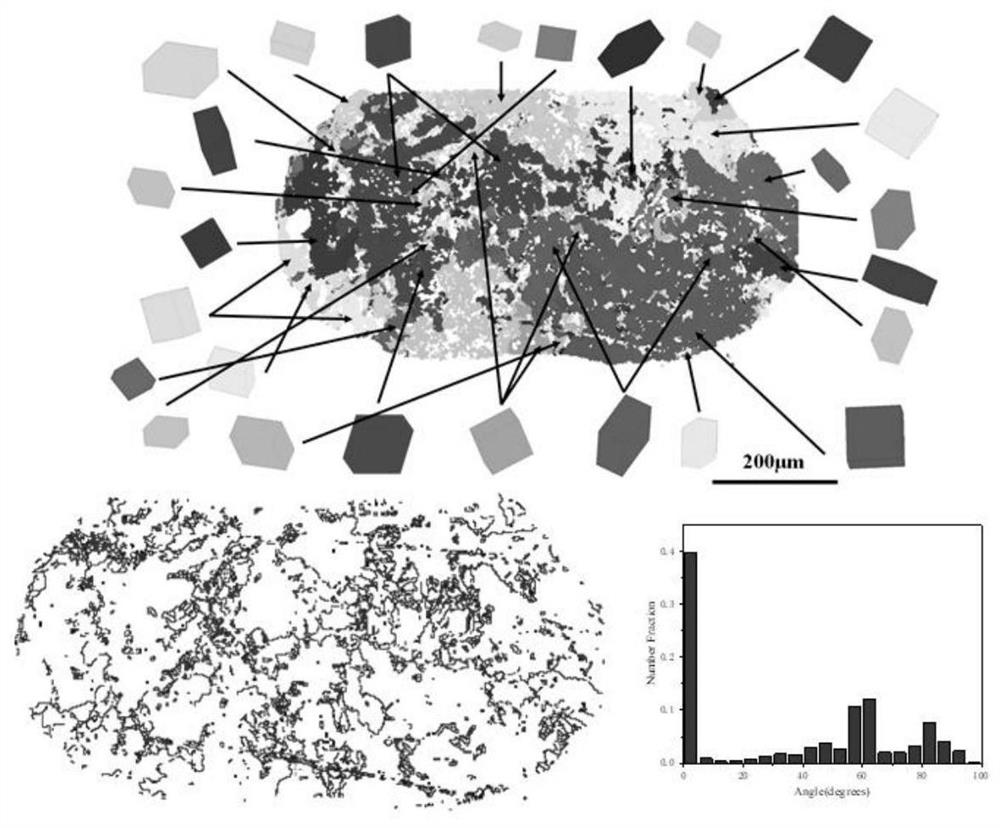

[0039] The preparation of the IMC / SABI / Cu welding spot of the polycrystalline structure of embodiment 1 different crystal orientations

[0040] (1) The Sn-Ag-Bi-In solder is printed on the glass plate through the screen, and the size of the screen is 700 μm;

[0041] (2) Heat the missed-printed solder to form a Sn-Ag-Bi-In solder ball with a size of 700 μm by hot air soldering equipment (US PACE ST325, the same below). The remelting temperature is 245°C and the remelting time is 30s , cooling with the furnace for 30s;

[0042] (3) Use acetone and ethanol successively to clean the Sn-Ag-Bi-In solder balls in an ultrasonic cleaner;

[0043] (4) Under a stereo microscope, select Sn-Ag-Bi-In solder balls that are consistent with the pad size (700 μm) for use;

[0044] (5) Clean the surface of the PCB board with ethanol in an ultrasonic cleaner;

[0045] (6) Coat a layer of flux (ALPHA POP707, the same below) on the PCB;

[0046](7) Put the prefabricated Sn-Ag-Bi-In solder ball...

Embodiment 2

[0056] (1) The Sn-Ag-Bi-In solder is printed on the glass plate through the screen, and the size of the screen is 700 μm;

[0057] (2) Heat the missing solder by hot air soldering equipment to form Sn-Ag-Bi-In solder balls with a size of 700 μm. The remelting temperature is 245°C, the remelting time is 30s, and the furnace is cooled for 30s;

[0058] (3) Use acetone and ethanol successively to clean the Sn-Ag-Bi-In solder balls in an ultrasonic cleaner;

[0059] (4) Under a stereo microscope, select Sn-Ag-Bi-In solder balls that are consistent with the pad size (700 μm) for use;

[0060] (5) Clean the surface of the PCB board with ethanol in an ultrasonic cleaner;

[0061] (6) Coating a layer of flux on the PCB;

[0062] (7) Put the prefabricated Sn-Ag-Bi-In solder ball on the copper sheet on the surface of the PCB and heat it with hot air welding equipment to remelt the solder ball and combine it with the copper sheet on the PCB board. The remelting temperature is 200°C , ...

Embodiment 3

[0072] (1) The Sn-Ag-Bi-In solder is printed on the glass plate through the screen, and the size of the screen is 700 μm;

[0073] (2) Heat the missed-printed solder to form a Sn-Ag-Bi-In solder ball with a size of 700 μm by hot air soldering equipment (US PACE ST325, the same below). The remelting temperature is 245°C and the remelting time is 30s , cooling with the furnace for 30s;

[0074] (3) Use acetone and ethanol successively to clean the Sn-Ag-Bi-In solder balls in an ultrasonic cleaner;

[0075] (4) Under a stereo microscope, select Sn-Ag-Bi-In solder balls that are consistent with the pad size (700 μm) for use;

[0076] (5) Clean the surface of the PCB board with ethanol in an ultrasonic cleaner;

[0077] (6) Coating a layer of flux on the PCB;

[0078] (7) Put the prefabricated Sn-Ag-Bi-In solder ball on the copper sheet on the surface of the PCB and heat it with hot air welding equipment to remelt the solder ball and combine it with the copper sheet on the PCB b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com