Transparent and insulating graphene composite heat-conducting film and preparation method thereof

A graphene composite and graphene film technology, applied in chemical instruments and methods, heat exchange materials, coatings, etc., can solve problems such as difficult to meet, high energy consumption, environmental pollution, etc., to avoid the use of organic solvents, Excellent thermal expansion coefficient and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

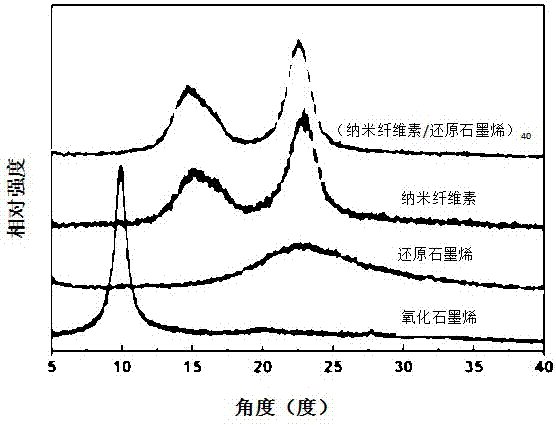

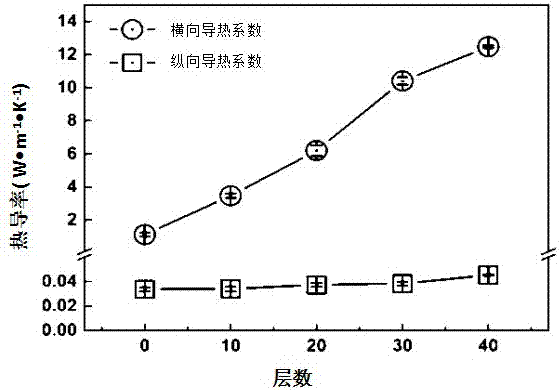

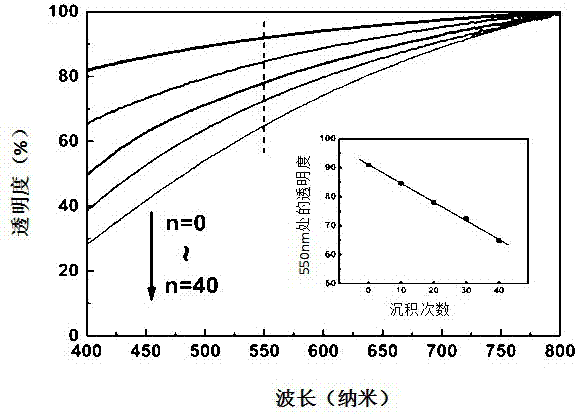

[0030] A method for preparing a transparent and insulating high-performance graphene composite heat-conducting film, the specific steps are as follows:

[0031] (1). The nanocellulose film is obtained by vacuum filtration and drying of the nanocellulose dispersion;

[0032] (2). The nanocellulose film obtained in step (1) is fully washed with ethanol and deionized water;

[0033] (3). The film obtained in step (2) was first immersed in a graphene oxide solution (0.1 mg / mL) for 5 minutes, then immersed in deionized water for 2 minutes, and dried in a hot air flow in an infrared rapid drying oven;

[0034] (4). Immerse the film obtained in step (3) in the nanocellulose dispersion (0.1mg / mL) for 5 min, then repeat step (3), and go through the same rinsing and drying process;

[0035] (5). Repeat step (3) and step (4) 40 times to obtain nanocellulose-graphene oxide composite film;

[0036] (6). Put the composite film obtained in step (5) into a reducing solution, raise the tempe...

Embodiment 2

[0041] A method for preparing a transparent and insulating high-performance graphene composite heat-conducting film, the specific steps are as follows:

[0042] (1). The nanocellulose film is obtained by vacuum filtration and drying of the nanocellulose dispersion;

[0043] (2). The nanocellulose film obtained in step (1) is fully washed with ethanol and deionized water;

[0044] (3). The film obtained in step (2) was first immersed in graphene oxide solution (3 mg / mL) for 10 minutes, then immersed in deionized water for 5 minutes, and dried in a hot air flow in an infrared rapid drying oven;

[0045] (4). Immerse the film obtained in step (3) in the nanocellulose dispersion (3 mg / mL) for 10 min, then repeat step (3) and go through the same rinsing and drying process;

[0046] (5). Repeat step (3) and step (4) 40 times to obtain nanocellulose-graphene oxide composite film;

[0047] (6). Put the composite film obtained in step (5) into a reducing solution, raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com